DOI:10.19476/j.ysxb.1004.0609.2018.02.07

Ti-35Nb合金中原子占位对β→ω相变的影响

孙锦辉1,陈 冷1,孟 利2,王玉会3

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 钢铁研究总院 华东分院北京研发中心,北京 100081;

3. 北京航空材料研究院,北京 100095)

摘 要:

利用第一性原理计算了Ti-35Nb(质量分数,%)合金的广义层错能,并讨论了合金中Nb原子占位对β→ω相变的影响。结果表明:在β相中沿{112}<111>滑移系开动会引起β→ω相变,形成ω相和孪晶相间隔的“三明治”结构,包含最近邻Nb原子链的{112}<111>滑移系的临界剪切应力约是2126.46 MPa,应力诱发的ω相最小尺寸约是长2.6444 nm,厚1.1297 nm;而包含次近邻Nb原子链的{112}<111>滑移系的临界剪切应力约是180.21 MPa,ω相最小尺寸约是长1.304 nm,厚0.3766 nm,较容易开动。

关键词:

文章编号:1004-0609(2018)-02-0267-08 中图分类号:TG146.23 文献标志码:A

Ti-35Nb(质量分数,%)合金具有高强度、高塑性和低弹性模量的特点,被称为口香糖合金[1-4],主要用作生物材料[5]、形状记忆材料[5-6]和航空材料[7]等。Ti-35Nb(质量分数,%)中的β相,是一种亚稳定BCC结构,在应力作用下容易诱发β→ω相变[8]。ω相的大小、形状和分布对合金的力学性能有很大影响[9-10]。

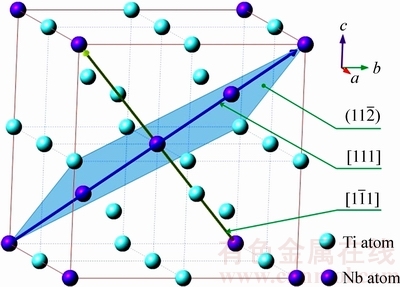

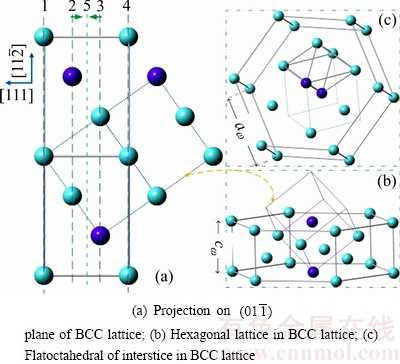

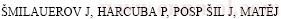

Ti-35Nb合金中相晶体结构可看作是由2×2×2 个基本BCC结构组成的超晶胞,每个超晶胞共含有16个原子,其中有4个Nb原子[11]。LAZAR等[11]根据第一性原理,用声子谐振分析了β相结构稳定性,在保持晶胞形状和空间群对称性条件下,经过足够能量松弛计算后,发现只有3种组合具有稳定的BCC结构,分别是G1、D03和L60。G1结构中最近邻Nb原子链沿一条体对角线(<111>)方向分布,D03结构中最近邻Nb原子链分布在超晶胞的面对角线(<110>)方向,L60结构中最近邻Nb原子链分布在<100>方向。在这三种结构中,G1结构能量最小,结构最稳定,结构模型如图1所示。在应力作用下,G1结构容易诱发β→ω相变,L60结构容易诱发β→α″相变,D03结构不发生相变。

Ti-Nb基合金中还包括ω和α″等相[3, 7, 12],其中ω相可以提高屈服强度和弹性模量,但是同时会增加合金的脆性[5, 12-13]。ω相是IVB元素及其合金中的亚稳定相[14],LIU等[15]认为Ti合金β→ω相变可分为等温(约300~500 ℃时效保温后水淬)、绝热(800~1100℃退火保温后水淬或低温-100 ℃变形)和应力诱发β→ω相变三类。YANG等[16]发现变形Ti-23Nb-0.7Ta-2.0Zr- 1.2O(摩尔分数,%)合金中的应力诱发片状ω相,并且ω相和β相的{112}<111>、{332}<113>孪晶有关。LAI等[8]在Ti-36Nb-1.4Ta-2.8Zr-0.3O(质量分数,%;e/a=4.23)变形合金中β相的{112}孪晶界处观测到了片状ω相。PANIGRAHI等[17]发现严重塑性变形+极高静水压力条件下会发生β→ω相变。DUBINSKIY等[18]发现Ti-21.8Nb-6.0Zr(质量分数,%) (TNZ)合金在无应变加热条件下会发生ω→β和α″→β相变。许艳飞等[19]发现对Ti-25Nb-10Ta-1Zr-0.2Fe进行双级时效后,发生β→β+ω→β+α″→β+α。

图1 G1结构中的 和

和 滑移系

滑移系

Fig. 1 Slip systems of  and

and  in G1 crystalline structure

in G1 crystalline structure

现阶段,解释Ti-Nb合金中的β→ω相变机制主要是“坍塌模型”[8, 11]。吴松全等[20-21]用点阵模型分析了ω相形成和终止机制,论述了β→ω相变的几何尺寸因素。由于ω相与β相在特殊条件下存在如下尺寸关系[8, 11]:aω= aβ和cω=(

aβ和cω=( /2)aβ。LI等[7]发现Ti-6Cr-5Mo-5V-4Al(质量分数,%)(Ti-6554)中等温型β→ω相变是纳米级调幅分解,还发现ω相的形核尺寸和分布与溶质元素的分布有关。YAMAMOTO等[22]发现单晶Ti-Nb基合金在加热时,ω相会在β相中均匀分布形成,但在Nb原子周围却被抑制,而ω相中的Nb原子周围{111}面“坍塌”程度更高。Ti合金中ω相一般尺寸范围是10~100 nm[22],测量比较困难[8]。

/2)aβ。LI等[7]发现Ti-6Cr-5Mo-5V-4Al(质量分数,%)(Ti-6554)中等温型β→ω相变是纳米级调幅分解,还发现ω相的形核尺寸和分布与溶质元素的分布有关。YAMAMOTO等[22]发现单晶Ti-Nb基合金在加热时,ω相会在β相中均匀分布形成,但在Nb原子周围却被抑制,而ω相中的Nb原子周围{111}面“坍塌”程度更高。Ti合金中ω相一般尺寸范围是10~100 nm[22],测量比较困难[8]。 等[23]报道,固溶处理后的ω相(0001)ω方向尺寸约是2 nm,时效后的ω相椭圆方向直径约是6 nm。LAI等[2]发现ω相的尺寸是1.9 nm、2.8 nm的椭球体。

等[23]报道,固溶处理后的ω相(0001)ω方向尺寸约是2 nm,时效后的ω相椭圆方向直径约是6 nm。LAI等[2]发现ω相的尺寸是1.9 nm、2.8 nm的椭球体。

广义层错能(Generalized-stacking-fault energy,GSFE)由 [24]在1968年首先提出,在指定滑移系统发生剪切变形时,用Peierls位错模型[25]来描述衡量相邻原子层间所需克服能量障碍的物理参量,可反映层错缺陷形成的难易程度以及晶体中位错在指定滑移面(γ面)滑动的能力[26]。广义层错能影响材料的显微组织和力学性能等[27]。MORENO等[4]用第一性原理计算了Nb原子含量对β、α″和ω相稳定性的影响,表明Nb含量大于18.75%时,β相比其他相稳定。OJHA等[28]用第一性原理计算了Ti-6.25Nb合金中BCC→ HCP(β→α/α′)相变中{110}

[24]在1968年首先提出,在指定滑移系统发生剪切变形时,用Peierls位错模型[25]来描述衡量相邻原子层间所需克服能量障碍的物理参量,可反映层错缺陷形成的难易程度以及晶体中位错在指定滑移面(γ面)滑动的能力[26]。广义层错能影响材料的显微组织和力学性能等[27]。MORENO等[4]用第一性原理计算了Nb原子含量对β、α″和ω相稳定性的影响,表明Nb含量大于18.75%时,β相比其他相稳定。OJHA等[28]用第一性原理计算了Ti-6.25Nb合金中BCC→ HCP(β→α/α′)相变中{110} 广义层错能曲线。HUANG等[1]计算了不同Nb含量的Ti-Nb合金在{110

广义层错能曲线。HUANG等[1]计算了不同Nb含量的Ti-Nb合金在{110 和{112}

和{112} 滑移系上的广义层错能曲线,发现当价电子e/a=4.25时,{110}<111>滑移系的不稳定层错能比{112}<111>大,即{110}<111>滑移系的能量势垒要比{112}<111>大,从而说明相同条件下{112}<111>滑移系更易于开动。而Ti-35Nb基合金的价电子浓度接近于4.25,于是可以推断β相中最易开启的滑移系是{112}<111>。上述文献中的计算多采用D03结构。NAGASAKO等[29]用G1结构计算了Nb原子占位对{112}<111>能量-应变曲线的影响,重点阐述了加载方向对β相应力临界剪切应力的影响。

滑移系上的广义层错能曲线,发现当价电子e/a=4.25时,{110}<111>滑移系的不稳定层错能比{112}<111>大,即{110}<111>滑移系的能量势垒要比{112}<111>大,从而说明相同条件下{112}<111>滑移系更易于开动。而Ti-35Nb基合金的价电子浓度接近于4.25,于是可以推断β相中最易开启的滑移系是{112}<111>。上述文献中的计算多采用D03结构。NAGASAKO等[29]用G1结构计算了Nb原子占位对{112}<111>能量-应变曲线的影响,重点阐述了加载方向对β相应力临界剪切应力的影响。

Nb原子在Ti-35Nb合金中的分布,影响着ω相的形成和坍塌程度,Nb原子占位对β→ω相变有较大影响,但是相关研究尚不多见。由于ω相很小,数量有很多,Ti合金在变形同时还会产生着大量α″相,所以准确测量应力诱发β→ω相变的临界剪切应力比较困难。因此,本研究根据第一性原理计算了G1结构的广义层错能,并由此计算了β→ω的临界剪切应力和ω相形核尺寸。

计算结果表明,Nb原子占位对广义层错能有很大影响,{112}<111>滑移系包含最近邻Nb原子链和次近邻Nb原子链2种,它们的广义层错能曲线,在能量大小、形状、鞍点的数量和位置上存在较大差异。依据“坍塌模型”理论[14, 30, 31]和位错与孪晶的竞争Peierls标准[32-36],可以合理解释Ti-35Nb合金容易发生β→ω相变和形成β相孪晶的原因,同时根据Peierls标准,计算出β→ω相变的临界应力和ω相最小尺寸。

1 计算方法和结果

1.1 计算方法

将β晶体模型沿{112}面分成上下两个部分,在<111>方向上滑移,滑移步长分别是<111>单位矢量的0、△、2△、…、n△(即间隔Burgers矢量(1/6)<111>的1/n),然后依据第一性原理计算[28]出不同状态下的总能量Ei,i=0, 1, 2, …, n,即可算出广义层错能 :

:

(1)

(1)

式中:Ei是发生层错体系的总自由能;E0是未发生层错的总自由能;S是超晶胞中发生层错的面积。

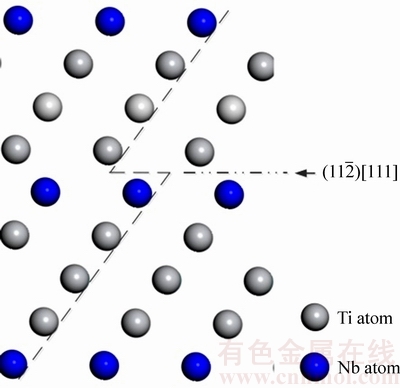

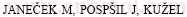

图2所示为计算用的晶体结构模型。图2中最近邻Nb原子链沿滑移方向(<111>晶向排成直线)。在G1结构中,体对角线即为<111>晶向,而<111>晶向可分为最近邻Nb原子链和次近邻原子链两类。<111>晶向共计4个,在G1结构中,只有1个<111>晶向含最近邻Nb原子链,其他3个含次近邻Nb原子链。

计算用滑移方向分别沿最近邻Nb原子链的<111>晶向和含次近邻Nb原子链的<111>晶向,滑移面分别是两个不同的{112}面。设最近邻Nb原子链的体对角线为[111],次近邻Nb原子链为 ,则两个被计算的滑移系分别是

,则两个被计算的滑移系分别是 [111]和

[111]和 ,晶体结构模型如图1所示。

,晶体结构模型如图1所示。

图2 计算用晶体结构模型示意图图中上半部分沿 面[111](箭头)方向滑移

面[111](箭头)方向滑移

Fig. 2 Schematic view of model for calculation (The up half atoms slip along [111] direction in  plane)

plane)

1.2 参数设置

本工作计算采用Material Studio软件的CASTEP工具包。计算Ei时,基于密度泛函理论[37]计算其总能量,电子与芯的相互作用采用投影缀加平面波的超软赝势(Ultrasoft Pseudopotentials),交换关联能采用广义梯度近似(GGA)中的Perdew-Burke-Ernzerhof形式,选取自洽(SCF)方法进行计算,平面波截断能量为320 eV,选用周期边界条件,k点网格取2×3×1。经计算可知,平面波截断能量低于280 eV时,能量变化较大,故选取320 eV。k点网格根据Material Studio推荐的2×3×1,经计算后得出此网格能量波动最小。

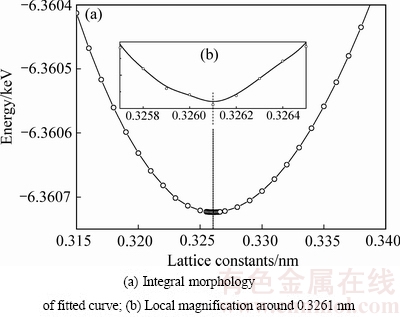

Ti-35Nb合金中晶格常数因掺杂元素的种类和数量而变化,现阶段还没有统一的数值[2-3, 6, 8, 11, 28]。β相晶格常数随Nb等元素含量的增加[6, 8, 11]而增大。HUANG等[1]认为β相的D03结构晶格常数为0.3260 nm,本工作使用广义梯度近似(GGA)对G1的晶格常数确定进行了计算,计算结果见图3,由图3可知G1结构晶格常数是0.3261 nm。

当沿{112}原子面上<111>方向上做定量滑移时,做垂直于剪切面(γ)完全弛豫计算[28, 33]。OGATA等[33-35]认为在10-3 eV/atom范围内不做弛豫计算和做弛豫计算的结果相差较小,可忽略不计。 [24]认为,原子层面被刚性切动后,原子间距发生改变,导致原子间的作用力发生了改变,因此必须作弛豫计算。DOU等[38]认为弛豫计算对层错能的影响较大。因此在垂直于剪切面方向上作完全弛豫计算,能量收敛大小为CASTEP推荐的10-5 eV/atom,大于OGATA等结 论[33-35],经计算得出,作用在所有未束缚原子上的Hellman-Feyman力小于0.03 eV/

[24]认为,原子层面被刚性切动后,原子间距发生改变,导致原子间的作用力发生了改变,因此必须作弛豫计算。DOU等[38]认为弛豫计算对层错能的影响较大。因此在垂直于剪切面方向上作完全弛豫计算,能量收敛大小为CASTEP推荐的10-5 eV/atom,大于OGATA等结 论[33-35],经计算得出,作用在所有未束缚原子上的Hellman-Feyman力小于0.03 eV/  ,可以认为体系已经完成了优化。

,可以认为体系已经完成了优化。

图3 Ti-35Nb合金晶格常数能量最小拟合曲线

Fig. 3 Fitted curve of energy minimization with respect to lattice parameters variation in Ti-35Nb

插入真空层厚度为1.5 nm,根据计算结果在真空层厚度大于1.2 nm时,原子层的碰撞较小,可忽略不计。

1.3 计算结果

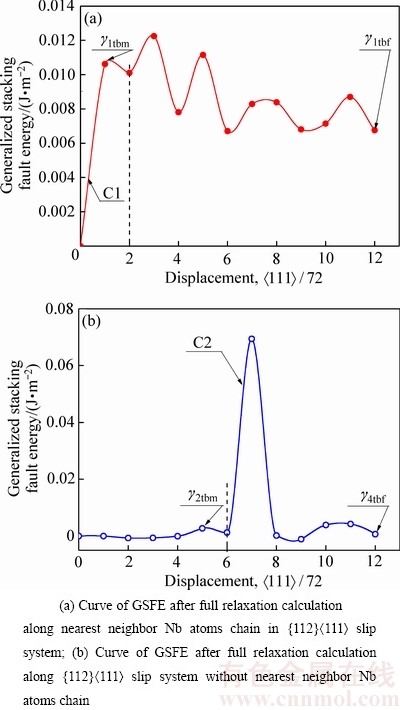

图4(a)和(b)所示为做优化计算得出的G1结构在最近邻Nb原子链和次近邻Nb原子链在<111>方向上的广义层错能曲线。其中横轴的0、1、2、…、12分别代表(0/72) [111]、(1/72) [111]、(2/72) [111]、…、(12/72) [111]错配位置。

从图4中可以看出,包含最近邻Nb原子链的滑移系具有较低的广义层错能,范围在0.001~0.012 J/m2,而包含次近邻Nb原子链的滑移系则具有稍高的广义层错能,范围在0~0.07 J/m2。同时,包含最近邻Nb原子链的滑移系中,不稳定广义层错能中最大值是0.012 J/m2,而包含次近邻Nb原子链的滑移系中,不稳定广义层错能中最大值是0.069 J/m2,计算数值与参考文献[11, 28]相符,图3(a)和OGATA等[33]计算的广义层错能曲线形貌基本相符。为论述方便,将图3(a)中的曲线标记为C1,图3(b)中的曲线标记为C2。

2 分析和讨论

从计算结果可以看出,Nb原子占位对Ti-35Nb合金的广义层错能影响很大,广义层错能又影响滑移系的开动,从而影响变形机制和变形的难易程度[11, 38]。本工作根据广义层错能分析,说明在β→ω相变过程中Nb原子占位对合金结构的影响,并且计算了β→ω相变时临界剪切应力和ω相最小尺寸。

图4 G1结构中沿不同{112}<111>滑移系的广义层错能曲线

Fig. 4 Generalized stacking fault energy curves of {112}<111> slip system

2.1 广义层错能曲线与β→ω相变的关系

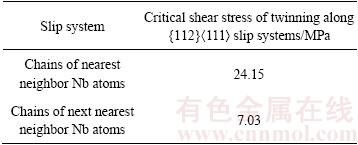

Ti-35Nb合金中,与{112}<111>滑移系相关的相变主要是ω相和孪晶[1, 3, 8, 11-12, 24, 31, 39]。Ti-35Nb合金中的ω相分为两类结构[11, 40]:理想六方结构(hexagonal),空间群是P6/mmm,标记为ω1;非正常的三角结构(trigonal),空间群是P m1,标记为ω2。BCC的结构可以看作由4层相邻{111}β晶面构成,如图5所示。根据“坍塌模型”[3, 7-8, 11, 14]解释ω形成:固定1层和4层,在一定应力作用下,2和3层原子向其中间平面5相向运动,从而形成各种ω相。

m1,标记为ω2。BCC的结构可以看作由4层相邻{111}β晶面构成,如图5所示。根据“坍塌模型”[3, 7-8, 11, 14]解释ω形成:固定1层和4层,在一定应力作用下,2和3层原子向其中间平面5相向运动,从而形成各种ω相。

图5 BCC结构用非密排六方结构表示

Fig. 5 Schematic illustration of denote BCC lattice by non-close-packed hexagonal lattice

广义层错能曲线中的“鞍点(saddle point)”提供了原子在滑移后“驻留”的可能性,即原子可能会在此位置停留下来,形成ω相等。TADMOR等[32]和OGATA等[33-35]从裂纹尖端的模型出发,分析了部分位错与孪晶(和层错)的竞争关系,并给出了形成部分位错或孪晶的Peierls标准。根据TADMOR等[32]和OGATA等[33-35]的模型,以广义层错能曲线为研究对象(见图4),讨论“鞍点”和晶体结构的关系。图4中的C1曲线中的4个鞍点表明,晶面沿Nb原子共线的{112}<111>滑移系滑动时,可能形成4种晶体结构,分别是准ω2、准ω2、ω1和准ω2;同理,根据C2曲线的2个鞍点,当晶面沿次近邻Nb原子链的{112}<111>滑移系滑动时,可能形成2种晶体结构,分别是ω1和ω2。结合“坍塌”(collapse)模型[8, 11, 20]和C1曲线的形状和“鞍点”位置,可以合理解释β相中ω形成过程[2, 8, 11, 39]。当原子面在(1/6)<111>““鞍点”位置驻留时,形成β孪晶。

2.2 相尺寸和临界剪切应力分析

TADMOR等[32]在按照Peierls标准提出了根据广义层错能判别在裂纹尖端形成孪晶或完整位错的标准。在一般条件下,可把裂纹尖端看作晶界等[32-35]。根据TADMOR等[32]的标准,假设裂纹尖端和滑移面共面,简化后得到:

(2)

(2)

式中:T是形成孪晶倾向的标准,T>1时,原滑移面停止滑移,相邻原子面滑移开启,于是形成孪晶,而T<1时,继续在原滑移面上滑移,形成完整位错; 是泊松比,这里

是泊松比,这里 ≈0.3,

≈0.3, 是剪切模量,这里用

是剪切模量,这里用 ≈21GPa[41],

≈21GPa[41], 、

、 和

和 分别是稳定层错能、不稳定层错能和不稳定孪晶能[32]。

分别是稳定层错能、不稳定层错能和不稳定孪晶能[32]。

根据式(2)分析图3(a)中的C1曲线。把<111>/6部分位错分解成更小的位错<111>/36,根据图3中的数据,可计算出左起4个峰的全部T>1,说明每滑移到(1/6)<111>/6时,这层原子面停止滑移,相邻平行原子面开启滑动,直至下一个(1/6)<111>/6个峰前停止,然后再开启相邻原子面,当各层滑移总量达到<111>/6时,出现孪晶。于是可判断出沿C1曲线在第一个峰前形成层错,并且形成相对应的准ω2相,相邻原子层滑移量是(1/6)<111>/6=<111>/36,1层孪晶包含6层{111}原子面,于是2层孪晶包含3个准ω2相,因此,根据OGATA等[33-35]微孪晶胚(microtwin)最小的层数是2层的结论,微孪晶胚至少包含12层原子{111}面。{111}原子面间距为a0/( )≈0.2887a0,C1曲线形成的在<111>方向上准ω2相最小厚度≈12×0.2887a0≈2.309a0≈ 1.1297 nm(a0是晶格常数)。沿孪晶起始端面形成直线型部分位错,按ZHU等[36]结论,可形成均匀的变形,同时形成准ω2相和孪晶互嵌式排列结构,被称作“三明治”(sandwiches)结构。

)≈0.2887a0,C1曲线形成的在<111>方向上准ω2相最小厚度≈12×0.2887a0≈2.309a0≈ 1.1297 nm(a0是晶格常数)。沿孪晶起始端面形成直线型部分位错,按ZHU等[36]结论,可形成均匀的变形,同时形成准ω2相和孪晶互嵌式排列结构,被称作“三明治”(sandwiches)结构。

同理,根据式(2)分析图3(b)中的C2曲线,可得出T>1,因此,滑移会在原滑移面上滑移(1/2)<111>/6= <111>/12后停止,形成空间群是P6/mmm的ω1相,相邻平行原子面开启,直至滑移<111>/12后停止,转为下一个平行原子面开动。这样1个ω相包含2层孪晶,那么在<111>方向上ω相最小厚度约为0.3766 nm。

OGATA等[33-35]和ACHMAD等[42]相继给出了由广义层错能(GSFE)计算产生孪晶的临界切应力τmax,同时也给出了孪晶的长度,临界切应力公式是:

(3)

(3)

式中: 是无缺陷晶体中孪晶界形成能,即产生孪晶时的最大能量壁垒,

是无缺陷晶体中孪晶界形成能,即产生孪晶时的最大能量壁垒, 是部分位错的模,分别取bp=a0<111>/36(最近邻Nb原子链)和bp=a0<111>/12(次近邻Nb原子链),a0是晶格常数。

是部分位错的模,分别取bp=a0<111>/36(最近邻Nb原子链)和bp=a0<111>/12(次近邻Nb原子链),a0是晶格常数。

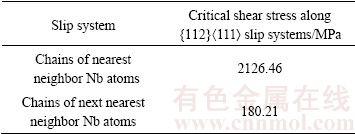

表1所列为根据公式(3)计算的孪晶临界切应力τmax。表1中的滑移系开动的最小数值略小于实验数 值[1, 2, 6, 8, 11-12, 18],但是数量级基本一致。从表1可以推测出次近邻Nb原子链的{112}<111>滑移系会较容易开动。

表1 {112}<111>滑移系的孪晶临界切应力τmax

Table 1 Critical shear stress τmax of {112}<111> slip system

实际上,由于合金本身存在大量缺陷(如位错等),所以会使实际的缺陷处孪晶临界切应力较低。如上述ω相,在位错等缺陷作用下产生孪晶的临界切应力为[33-35]:

(4)

(4)

式中:τn是在位错作用下的孪晶剪切应力; 孪晶界形成能;n是形成孪晶胚的层数,稳定孪晶胚n=2;bp是部分位错,这里bp=<111>a0/6,a0是晶格常数。

孪晶界形成能;n是形成孪晶胚的层数,稳定孪晶胚n=2;bp是部分位错,这里bp=<111>a0/6,a0是晶格常数。

表2是根据式(4)分别计算在位错等作用下的{112}<111>滑移系的孪晶临界切应力τn。

表2 {112}<111>滑移系在位错作用下的孪晶临界切应力τn

Table 2 Critical shear stress of twinning τn in condition of dislocations

表2可以看出,包含次近邻Nb原子链的{112}<111>滑移系容易开动,其临界剪切应力约为7.03 MPa,小于实验数据[2, 12]。

计算出上述条件下产生的孪晶临界剪切应力可以估算?相的尺寸。OGATA等[33-35]给出了孪晶胚最小的尺寸长度ln计算公式:

(5)

(5)

式中: 是材料的理想剪切强度,这里简化成:

是材料的理想剪切强度,这里简化成: =2τn+τmax,可用表1和表2中的数值代入即可,a0是晶格常数。

=2τn+τmax,可用表1和表2中的数值代入即可,a0是晶格常数。

分别将表1和2中数据代入式(5)中可知,包含最近邻Nb原子链的{112}<111>滑移系会发生β→ω相变,其ω相长度约为2.6444 nm,而包次近邻Nb原子链的{112}<111>滑移系也会发生β→ω相变,其ω相长度约是1.304 nm。

由上述可知,在0 K时,G1结构中{112}<111>滑移系可能产生β→孪晶(ω相),即会产生孪晶和ω相向间隔的“三明治”结构,在包含最近Nb原子链方向上的2个孪晶包含3个ω相,而次近邻Nb原子链方向上1个ω相包含2个孪晶。在部分位错等缺陷的作用下,产生孪晶的临界剪切应力约为7.03(或24.15) MPa,ω相最小尺寸约是长1.304 nm,厚0.3766 nm。在没有位错等缺陷作用下,包含次近邻Nb原子链的{112}<111>滑移的临界剪切应力约为180.21 MPa,较容易开动。本工作中的能量曲线严格按照晶体结构模型计算,发现在β→ω相变中存在“鞍点”,而其他文献并没有对此结果进行报道。本工作中“-Nb-Nb-”方向的最大临界应力基本与文献[29]一致,而“-Nb-”方向的最大临界剪切应力则相差较大,原因在于本工作将能量曲线中的(左起)第一个“峰”(第一个极大值)作为β→ω相变的能量壁垒,NAGASAKO等[29]把整个曲线中最高峰看作能量壁垒。NAGASAKO等[29]得到的不稳定层错能大约是0.05 J/m2,这与图4(b)所示结果基本一致,而与图4(a)所示结果存在一定差异,但数量级相同,数据的差异的主要来源于模型设置上的不同。LAI等[3]实验测量Ti-Nb合金的ω相尺寸是短轴1.9 nm、长轴2.8 nm的椭球体,与本文结果基本一致。

3 结论

1) Ti-35Nb合金的G1结构中,包含次近邻Nb原子链的{112}<111>滑移系的广义层错能曲线有2个鞍点,而包含最近邻Nb原子链{112}<111>滑移系广义层错能的曲线有4个鞍点。

2) Ti-35Nb合金中的G1结构,包含次近邻Nb原子链的{112}<111>滑移系具有较低的临界剪切应力,约是180.21 MPa,形成“三明治式”ω1相和孪晶,最小厚度约是0.3766 nm,长约1.304 nm;而包含最近邻Nb原子链的{112}<111>滑移系具有较高的临界剪切应力约是2126.46 MPa,形成“三明治式”ω1相和孪晶,最小厚度约1.1297nm,长约2.6444 nm。

REFERENCES

[1] HUANG J, XING H, SUN J. Structural stability and generalized stacking fault energies in β Ti-Nb alloys: Relation to dislocation properties[J]. Scripta Materialia, 2012, 66(9): 682-685.

[2] LAI M J, TASAN C C, RAABE D. Deformation mechanism of ω-enriched Ti-Nb-based gum metal: Dislocation channeling and deformation induced ω–β transformation[J]. Acta Materialia, 2015, 100: 290-300.

[3] TANE M, NAKANO T, KURAMOTO S, NIINOMI M, TAKESUE N, NAKAJIMA H. ω transformation in cold-worked Ti-Nb-Ta-Zr-O alloys with low body-centered cubic phase stability and its correlation with their elastic properties[J]. Acta Materialia, 2013, 61(1): 139-150.

[4] MORENO J J G,  M, PANAGIOTOPOULOS N T, CALIN M, PAPAGEORGIOU D G, GEBERT A, ECKERT J, EVANGELAKIS G A, LEKKA C E. Ab-initio and experimental study of phase stability of Ti-Nb alloys[J]. Journal of Alloys and Compounds, 2017, 696: 481-489.

M, PANAGIOTOPOULOS N T, CALIN M, PAPAGEORGIOU D G, GEBERT A, ECKERT J, EVANGELAKIS G A, LEKKA C E. Ab-initio and experimental study of phase stability of Ti-Nb alloys[J]. Journal of Alloys and Compounds, 2017, 696: 481-489.

[5] INAEKYAN K, BRAILOVSKI V, PROKOSHKIN S, PUSHIN V, DUBINSKIY S, SHEREMETYEV V. Comparative study of structure formation and mechanical behavior of age-hardened Ti-Nb-Zr and Ti-Nb-Ta shape memory alloys[J]. Materials Characterization, 2015, 103: 65-74.

[6] KIM H Y, IKEHARA Y, KIM J I, HOSODA H, MIYAZAKI S. Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys[J]. Acta Materialia, 2006, 54(9): 2419-2429.

[7] LI T, KENT D, SHA G, STEPHENSON L T, CEGUERRA A V, RINGER S P, DARGUSCH M S, CAIRNEY J M. New insights into the phase transformations to isothermal ω and ω-assisted α in near β-Ti alloys[J]. Acta Materialia, 2016, 106: 353-366.

[8] LAI M J, TASAN C C, ZHANG J, GRABOWSKI B, HUANG L F, RAABE D. Origin of shear induced β to ω transition in Ti-Nb-based alloys[J]. Acta Materialia, 2015, 92: 55-63.

[9] DEVARAJ A, WILLIAMS R E A, NAG S, SRINIVASAN R, FRASER H L, BANERJEE R. Three-dimensional morphology and composition of omega precipitates in a binary titanium- molybdenum alloy[J]. Scripta Materialia, 2009, 61(7): 701-704.

[10] MARKOVSKY P E, BONDARCHUK V I, MATVIYCHUK Y V, KARASEVSKA O P. Evolution of microstructure, phase composition, and tensile properties of severely cold deformed titanium metastable β alloy in rapid continuous heating[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1365-1371.

[11] LAZAR P, JAHN TEK M, HAFNER J, NAGASAKO N, ASAHI R, BLAAS-SCHENNER C, ST HR M, PODLOUCKY R. Temperature-induced martensitic phase transitions in gum-metal approximants: First-principles investigations for Ti3Nb[J]. Physical Review B, 2011, 84(5): 3337-3344.

[12] NIINOMI M, AKAHORI T, NAKAI M. In situ X-ray analysis of mechanism of nonlinear super elastic behavior of Ti-Nb-Ta-Zr system beta-type titanium alloy for biomedical applications[J]. Materials Science and Engineering C, 2008, 28(3): 406-413.

[13] DUBINSKIY S, KOROTITSKIY A, PROKOSHKIN S, BRAILOVSKI V. In situ X-ray diffraction study of athermal and isothermal omega-phase crystal lattice in Ti-Nb-based shape memory alloys[J]. Materials Letters, 2016, 168: 155-157

[14] TANG B, CUI Y W, CHANG H, KOU H, LI J, ZHOU L. A phase-field approach to athermal β→ω transformation[J]. Computational Materials Science, 2012, 53(1): 187-193.

[15] LIU H, NIINOMI M, NAKAI M, CHO K, FUJII H. Deformation-induced ω-phase transformation in a β-type titanium alloy during tensile deformation[J]. Scripta Materialia, 2017, 130: 27-31.

[16] YANG Y, WU S Q, LI G P, LI Y L, LU Y F, YANG K, GE P. Evolution of deformation mechanisms of Ti-22.4Nb-0.73Ta- 2Zr-1.34O alloy during straining[J]. Acta Materialia, 2010, 58(7): 2778-2787.

[17] PANIGRAHI A, B NISCH M, WAITZ T, SCHAFLER E, CALIN M, ECKERT J, SKROTZKI W, ZEHETBAUER M. Phase transformations and mechanical properties of biocompatible Ti-16.1Nb processed by severe plastic deformation[J]. Journal of Alloys and Compounds, 2015, 628: 434-441.

[18] DUBINSKIY S, PROKOSHKIN S, BRAILOVSKI V, INAEKYAN K, KOROTITSKIY A. In situ X-ray diffraction strain-controlled study of Ti-Nb-Zr and Ti-Nb-Ta shape memory alloys: Crystal lattice and transformation features[J]. Materials Characterization, 2014, 88:127-142.

[19] 许艳飞, 文 璟, 肖逸锋, 王 章, 阳文豪, 易丹青, 刘会群, 吴 靓, 钱锦文. 双级时效对Ti-25Nb-10Ta-1Zr-0.2Fe医用β钛合金显微组织与力学性能的影响[J]. 中国有色金属学报, 2016, 26(9): 1912-1918.

XU Yan-fei, WEN Jing, XIAO Yi-feng, WANG Zhang, YANG Wen-hao, YI Dan-qing, LIU Hui-qun, WU Liang, QIAN Jin-wen. Effects of duplex aging on microstructure and mechanical properties of Ti-25Nb-10Ta-1Zr-0.2Fe alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(9): 1912-1918.

[20] WU S Q, PING D H, YAMABE-MITARAI Y, XIAO W L, YANG Y, HU Q M, LI G P, YANG R. {112}<111> twinning during ω to body-centered cubic transition[J]. Acta Materialia, 2014, 62: 122-128.

[21] 吴松泉, 杨 义, 李阁平, 平德海, 胡青苗. {112}<111>孪生的形核和长大及终止的ω点阵机制[J]. 金属学报, 2016, 52(2): 249-256.

WU Song-quan, YANG Yi, LI Ge-ping, PING De-hai, HU Qing-miao. Lattice mechanism of {112}<111> twinning nucleation and growth and termination[J]. Acta Metallurgica Sinica, 2016, 52(2): 249-256.

[22] YAMAMOTO T, HAYASHI K, HAPPO N, HOSOKAWA S, TAJIRI H. Local atomic structure near an Nb atom in aged β-Ti alloys[J]. Acta Materialia, 2017, 131: 534-452.

[23]  Z, HOL V. Growth of ω inclusions in Ti alloys: An X-ray diffraction study[J]. Acta Materialia, 2013, 61(17): 6635-6645.

Z, HOL V. Growth of ω inclusions in Ti alloys: An X-ray diffraction study[J]. Acta Materialia, 2013, 61(17): 6635-6645.

[24]  V. Intrinsic stacking faults in body-centred cubic crystals[J]. Philosophical Magazine, 1968, 18(154): 773-786.

V. Intrinsic stacking faults in body-centred cubic crystals[J]. Philosophical Magazine, 1968, 18(154): 773-786.

[25] PEIERLS R E. The size of a dislocation[J]. Proceedings of the Physical Society, 1940, 52(1): 34-37.

[26]  V. Atomic structure of dislocations in intermetallics with close packed structures a comparative study[J]. Intermetallics, 1998, 6(7): 579-585.

V. Atomic structure of dislocations in intermetallics with close packed structures a comparative study[J]. Intermetallics, 1998, 6(7): 579-585.

[27] VELASCO L, HODGE A M. Growth twins in high stacking fault energy metals: Microstructure, texture and twinning[J]. Materials Science and Engineering A, 2017, 687: 93-98.

[28] OJHA A, SEHITOGLU H. Critical stress for the BCC-HCP martensite nucleation in Ti-6.25at.%Ta and Ti-6.25at.%Nb alloys[J]. Computational Materials Science, 2016, 111: 157-162.

[29] NAGASAKO N, ASAHI R, HAFNER J. Ideal tensile and shear strength of a gum metal approximant: Ab initiodensity functional calculations[J]. Physical Review B, 2012, 85(2): 024122-1- 024122-17.

[30] DEY G K, TEWARI R, BANERJEE S, JYOTI G, GUPTA S C, JOSHI K D, SIKKA S K. Formation of a shock deformation induced ω phase in Zr20Nb alloy[J]. Acta Materialia, 2004, 52(18): 5243-5254.

[31]  J, HARCUBA P, STRSK J, STR SK J,

J, HARCUBA P, STRSK J, STR SK J,  R, BRUN TOV T, HOL V, ILAVSK J. Ordered array of ω particles in β-Ti matrix studied by small-angle X-ray scattering[J]. Acta Materialia, 2014, 81: 71-82.

R, BRUN TOV T, HOL V, ILAVSK J. Ordered array of ω particles in β-Ti matrix studied by small-angle X-ray scattering[J]. Acta Materialia, 2014, 81: 71-82.

[32] TADMOR E B, HAI S. A Peierls criterion for the onset of deformation twinning at a crack tip[J]. Journal of the Mechanics and Physics of Solids, 2003, 51(5): 765-793.

[33] OGATA S, LI J, YIP S. Energy landscape of deformation twinning in bcc and fcc metals[J]. Physical Review B, 2005, 71(22): 224102-1-224102-11

[34] OGATA S, LI J, S Y. Ideal pure shear strength of aluminum and copper[J]. Science, 2002, 298(5594): 807-811

[35] OGATA S, LI J, YIP S. Twinning pathway in BCC molybdenum[J]. Europhysics Letters (EPL), 2004, 68(3): 405-411.

[36] ZHU T, LI J, YIP S. Atomistic study of dislocation loop emission from a crack tip[J]. Physical Review Letters, 2004, 93(2): 025503-1-025503-4.

[37] HOHENBERG P, KOHN W. Inhomogeneous electron gas[J]. Physical Review, 1964, 136(3B): B864-B871.

[38] DOU Y, ZHANG J. Effects of structural relaxation on the generalized stacking fault energies of hexagonal-close-packed system from first-principles calculations[J]. Computational Materials Science, 2015, 98: 405-409.

[39] LIN C, YIN G, ZHANG A, ZHAO Y, LI Q. Simple models to account for the formation and decomposition of athermal ω phase in titanium alloys[J]. Scripta Materialia, 2016, 117: 28-31.

[40] LEONARD K J, TEWARI R, ARYA A, MISHURDA J C, DEY G K, VASUDEVAN V K. Decomposition of the β0 phase to the P63/mcm, hP18 structure in Nb-(24-36)Ti-40Al alloys[J]. Acta Materialia, 2009, 57(15): 4440-4453.

[41] KARRE R, NIRANJAN M K, DEY S R. First principles theoretical investigations of low Young’s modulus beta Ti-Nb and Ti-Nb-Zr alloys compositions for biomedical applications[J]. Materials Science and Engineering C, 2015, 50: 52-58.

[42] ACHMAD T L, FU W, CHEN H, ZHANG C, YANG Z-G. First-principles calculations of generalized-stacking-fault-energy of Co-based alloys[J]. Computational Materials Science, 2016, 121: 86-96.

Effect of Nb atoms occupancy on β→ω phase transformation in Ti-35Nb alloys

SUN Jin-hui1, CHEN Leng1, MENG Li2, WANG Yu-hui3

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing100083, China;

2. Center of Beijing R&D, East China Branch of Central Iron and Steel Research Institute, Beijing 100081, China;

3. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The generalized stacking fault energy was calculated by the first-principles and the influence of Nb atoms occupancy on the induced β→ω phase transformations was discussed in Ti-35Nb (mass fraction, %) alloy in this work. The results show that the opening of {112}<111>systems in β phase can form ω phase alternated along twinning so called “sandwich” structure. Meanwhile the critical shear stress of {112}<111> slip systems including the nearest neighbor Nb atoms chains is 2126.46 MPa in perfect crystal, and form the minimum ω phases with 2.6444 nm in length and 1.1297 nm in width. Furthermore, the critical shear stress of {112}<111> slip systems including the next nearest neighbor Nb atoms chains is 180.21 MPa in perfect crystal, further, the minimum ω phase has 1.304 nm in length and 0.3766 nm in width.

Key words: Ti-35Nb alloy; β→ω phase transformation; Nb atoms occupancy, generalized stacking fault energy

Received date: 2016-11-29; Accepted date: 2017-06-08

Corresponding author: CHEN Leng; Tel: +86-10-62332919; E-mail: lchen@ustb.edu.cn

(编辑 何学锋)

收稿日期:2016-11-29;修订日期:2017-06-08

通信作者:陈 冷,教授,博士;电话:010-62332919;E-mail: lchen@ustb.edu.cn

摘 要:利用第一性原理计算了Ti-35Nb(质量分数,%)合金的广义层错能,并讨论了合金中Nb原子占位对β→ω相变的影响。结果表明:在β相中沿{112}<111>滑移系开动会引起β→ω相变,形成ω相和孪晶相间隔的“三明治”结构,包含最近邻Nb原子链的{112}<111>滑移系的临界剪切应力约是2126.46 MPa,应力诱发的ω相最小尺寸约是长2.6444 nm,厚1.1297 nm;而包含次近邻Nb原子链的{112}<111>滑移系的临界剪切应力约是180.21 MPa,ω相最小尺寸约是长1.304 nm,厚0.3766 nm,较容易开动。