Trans. Nonferrous Met. Soc. China 28(2018) 30-35

Enhancement of mechanical properties of duplex Mg-9Li-3Al alloy by Sn and Y addition

Li-li CHANG1, Chun-chang SHI1, Hong-wei CUI2

1. School of Materials Science and Engineering, Shandong University, Ji’nan 250061, China;

2. School of Materials Science and Engineering, Shandong University of Technology, Zibo 255000, China

Received 29 September 2016; accepted 17 March 2017

Abstract:

For enhancement of mechanical properties in Mg-9Li-3Al alloys, Mg-9Li-3Al duplex alloys were alloyed by addition of Sn and Y. Microstructure evolution and mechanical property response of as-cast Mg-9Li-3Al alloys by alloying with Sn and Y were investigated by optical microscopy, scanning electron microscopy, X-ray diffractometry and tensile tests. The results indicate that considerable blocky dendrites of primary α phase in Mg-9Li-3Al alloys become lath-like due to the addition of Sn. With addition of Y, Mg-9Li-3Al alloy consists of both block-like and lath-like α-Mg dendrites. The as-cast Mg-9Li-3Al-1Sn-1Y alloy shows a yield strength of 118 MPa, ultimate tensile strength of 148 MPa and the elongation to failure of 21%. Improvement in both strength and elongation of Mg-9Li-3Al alloys with Sn and Y addition is attributed to the combined action of MgLi2Sn and Al2Y intermetallic compounds.

Key words:

Mg-Li alloys; grain structure; tensile properties; precipitation strengthening;

1 Introduction

Magnesium alloys, with low density and high specific strength, have been widely used in automobile, aerospace and military industries [1-3]. However, conventional Mg alloys usually show poor ductility for lack of slip systems with a hexagonal-closed-packed (HCP) crystal structure. By addition of Li, the density of magnesium alloys can be reduced to 1.35-1.65 g/cm3, which is only the half that of aluminum alloys [4]. Moreover, magnesium alloys with Li addition have a good formability by transforming the crystal structure from HCP to body-centered-cubic (BCC) with more slip systems and reducing the axial ratio of the HCP Mg [5-7]. According to the Mg-Li phase diagram, when the mass fraction of Li is in the range of 5.7%-10.3%, β-Li with BCC crystal structure forms in hexagonal α-Mg, leading to a duplex structure containing both α and β phases. When the content of Li is lower than 5.7% or higher than 10.3% (mass fraction), the Mg-Li alloy is composed of either α phase or β phase. Although the Mg-Li alloys have comparative advantages over other magnesium alloys, for a wider application in engineering applications, they still have some shortcomings needed to be overcome, such as low strength, stable high temperature properties, and poor corrosion resistance.

For the enhancement of strength of materials, alloying is considered to be an effective approach to improve the strength of Mg-Li alloys by both solution hardening and precipitation hardening [8,9]. For example, Al, Sn and Zn are added into Mg-Li based alloys for improvement in strength [10-13]. Among them, Al is the most widely used alloying element in strengthening of Mg-Li alloys and WU et al [14] reported that the strength of Mg-Li alloys increased with the increase of Al content until the Al content reached 3% (mass fraction). Although solution hardening and precipitation hardening lead to the improvement of strengths of metal and alloys, simultaneous improvements in strength and ductility for most engineering materials can be achieved effectively by grain refinement [15,16]. Sn was added into Mg-9Li alloys to form MgLi2Sn for grain refinement during casting, and MgLi2Sn compounds also act as heterogeneous nucleation sites for dynamic recrystallization during the following plastic deformation process [17]. Recently, it has been reported that the addition of rare earth (RE) elements into Mg-Li alloys is quite effective to improve mechanical properties of magnesium alloys [18-21]. According to ZHU et al [22], by adding Y into Mg-Li alloys, mechanical strength of Mg-Li alloys can be increased due to the formation of Al2Y. PENG et al [23] reported that Al and Y addition into Mg-8Li alloy ensured good mechanical properties after a homogenization treatment at 300 °C for 12 h.

In the present work, a series of duplex Mg-9Li-3Al alloys with Sn and Y addition were fabricated using vacuum melting and microstructure evolutions with different alloying elements were explored. Simultaneously, the corresponding tensile properties were examined and the strengthening mechanisms were discussed in detail.

2 Experimental

Commercial pure (CP) magnesium ingot, CP aluminum, and Mg-Li-Al and Mg-Y master alloys were melted in a steel crucible in vacuum induce furnace at the temperature of 720 °C and poured into a cylinder steel mold with a diameter of 55 mm and height of 100 mm preheated to 200 °C. After solidification, samples were homogenized at 300 °C for 12 h to be prepared for the tensile tests.

Optical microscope (OM), scanning electron microscope (SEM), energy dispersive spectrometer (EDS) and X-ray diffractometer (XRD) were used to characterize the microstructure and phase compositions of alloys. Samples for OM/SEM observation and XRD characterization were ground, polished and then etched with 4% (volume fraction) nital solution. Tensile tests were conducted on a WDW-200E testing machine on flat samples 1 mm thick and 3 mm wide with a gauge length of 15 mm at a constant strain of 1×10-3 s-1 and the loading direction was parallel to the axial direction of the cylindrical ingot.

3 Results and discussion

3.1 Microstructure analysis of Mg-9Li-3Al alloys with Sn and Y addition

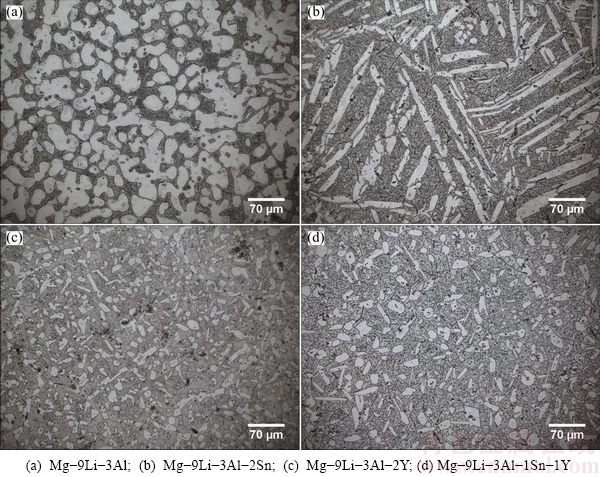

Figure 1 shows the optical microstructures of as-cast Mg-9Li-3Al based alloys. It is found that Mg-9Li-3Al alloys have two-phase structure, which is identical to the Mg-Li phase diagram. On optical microscope, the two phases are presented to be different colors, i.e. α phase shows to be white while β phase is dark. Meanwhile, abundant black points are observed inside β phase. Further investigation of Fig. 1 indicates that shapes and sizes of α and β phases are directly dependent on the addition of alloying elements. As seen in Fig. 1(a), blocky α phase distributes evenly inside β-Li matrix and second phases (black points) scatter inside β phases in the Mg-9Li-3Al alloy. With the addition of Sn, α phase becomes lath-like and the amount of α phase is reduced, simultaneously. Most of lath-like α-Mg phases are parallel to each other and black points with a high density are observed inside β phase. The microstructure of as-cast Mg-9Li-3Al-2Y is remarkably distinct from that of Mg-9Li-3Al alloys with Sn addition. When Y was added into the Mg-9Li-3Al alloy, spherical and lath-like α phases are observed. With both addition of Sn and Y into Mg-9Li-3Al alloy, the shapes of α phase remained spherical and lath-like, but the average size of α phase became larger while the volume fraction decreased, as shown in Fig. 1(d). The average sizes of α phase for Mg-9Li-3Al, Mg-9Li-3Al-2Sn, Mg-9Li-3Al-2Y and Mg-Li-Al-1Sn-1Y were determined to be 31.1, 21.9, 11.4 and 14.2 μm by Image-Pro plus, respectively.

Fig. 1 Optical microstructures of Mg-9Li-3Al based alloys

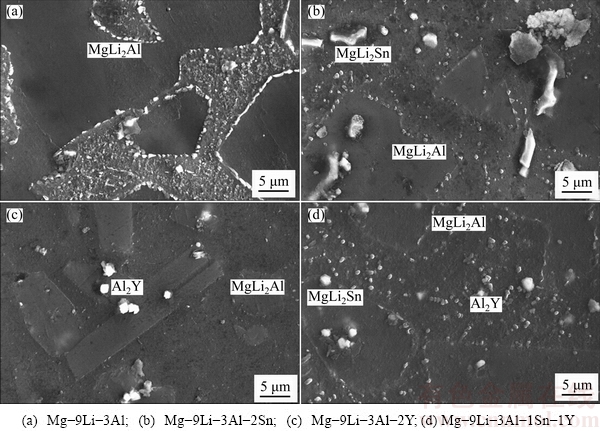

In order to identify those compounds (black points in OM images), the as-cast alloys were characterized by SEM-EDS and the SEM images of Mg-9Li-3Al based alloys are shown in Fig. 2. The corresponding elemental composition of compounds in those alloys was determined by EDS and marked on SEM images. The Mg-9Li-3Al alloys are composed of α-Mg, β-Li and MgLi2Al particles distributing mainly along the interface of two phases and inside β-Li matrix. As seen in Fig. 2(a), MgLi2Al compounds along the phase boundary between α-Mg and β-Li are shown to be large blocks (about 3 μm) in a large size, while those compounds inside β-Li matrix are much finer (about 1 μm) and they finely spread the whole β-Li region. When Sn is added into the melt, besides MgLi2Al, MgLi2Sn, MgLi2Al in a smaller size distributes mainly on boundaries and inside β-Li matrix, while large lumpy MgLi2Sn compounds form inside both α and β phases. With addition of Y in Mg-9Li-3Al, Al2Y with an average size of ~2 μm is observed inside α phase. Due to the formation of Al2Y particles, the amount of MgLi2Al in Mg-9Li-3Al-2Y is reduced significantly and the average size of MgLi2Al becomes much finer. When Sn and Y are added into Mg-9Li-3Al alloys, MgLi2Al, MgLi2Sn and Al2Y compounds are detected. It should be noted that MgLi2Sn in Mg-9Li-3Al-1Sn-1Y shows to be finer than that in Mg-9Li-3Al-2Sn. Simultaneously, compared with Al2Y in Mg-9Li- 3Al-2Y alloys, Al2Y in Mg-9Li-3Al- 1Sn-1Y presents in a smaller size. In summary, MgLi2Sn is induced into Mg-9Li-3Al alloys by Sn addition, while the amount and the particle size of MgLi2Al are reduced significantly by Y addition. For Mg-9Li-3Al alloys with Sn and Y addition, fine MgLi2Al particles distribute uniformly inside β phase while spherical MgLi2Sn and Al2Y particles distribute mainly inside α phase.

Fig. 2 SEM morphologies of Mg-9Li-3Al based alloys

According to previous studies, the grain refinement of metallic materials can be attributed to two reasons: one is the segregation power of solute elements, which is related to the growth restriction factor (GRF), and the other is the heterogeneous nucleation effect. Due to the low mass fraction of Sn and Y, the calculated GRF value of Sn and Y in Mg is very low (0.029 and 0.034, respectively). Therefore, the segregation power of solute elements is not the main cause of grain refinement of Mg-9Li-3Al based alloys. Generally, the particle which has a proper size and the lowest mismatch with the metal matrix is most likely to serve as nucleation sites for the metal matrix during dynamic recrystallization or solidification process. The intermetallic compound acting as grain refiner or not has been predicted by the edge-to-edge matching model (E2EM) which was proposed by ZHANG et al [24,25], and they found that when the crystallographic mismatch of the close- or near-close-packed planes between the compound and the metal matrix is less than 10%, the intermetallic compound could be seemed as grain refiner [24-26]. According to JIANG et al [17], the mismatch value between Mg and MgLi2Sn is lower than 10%, indicating that MgLi2Sn can also refine grains of Mg-9Li-3Al alloys. QIU et al calculated the crystallographic orientation relationships (ORs) and determined that the interplanar spacing mismatches (fd) between the matching plane pairs of  ,

,  and {044}|{0002} was 0.1%, 3.5% and 6.5%, respectively, indicating that Al2Y can act as heterogeneous nucleation sites for α-Mg phase during solidification process [13]. Hence, MgLi2Sn and Al2Y are both considered as potential grain refiners for Mg-Li based alloys and lead to refinement of α phase, and strength of Mg-9Li-3Al alloys is improved as a result of refining.

and {044}|{0002} was 0.1%, 3.5% and 6.5%, respectively, indicating that Al2Y can act as heterogeneous nucleation sites for α-Mg phase during solidification process [13]. Hence, MgLi2Sn and Al2Y are both considered as potential grain refiners for Mg-Li based alloys and lead to refinement of α phase, and strength of Mg-9Li-3Al alloys is improved as a result of refining.

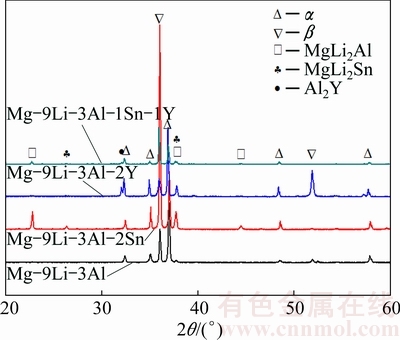

XRD patterns of as-cast alloys are shown in Fig. 3. Phase composition analysis indicates that besides α-Mg and β-Li, MgLi2Al appears in all as-cast Mg-9Li-3Al based alloys. Moreover, MgLi2Sn is detected in Mg-9Li-3Al-2Sn alloy. For Mg-9Li-3Al-2Y alloy, Al2Y metallic compound is confirmed, while MgLi2Sn and Al2Y are both detected by XRD in Mg-9Li-3Al- 1Sn-1Y. The phase composition results form XRD patterns are identical to the compositions of particles in as-cast Mg-9Li-3Al alloys determined by using SEM-EDS.

Fig. 3 XRD patterns of Mg-9Li-3Al based alloys

3.2 Mechanical properties of Mg-9Li-3Al alloys with Sn and Y addition

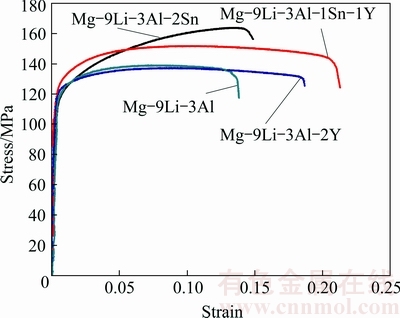

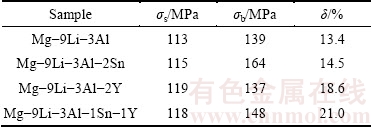

Figure 4 shows tensile engineering strain-stress curves of Mg-9Li-3Al alloys with addition of Sn and Y and specific mechanical property values from the strain-stress curves are summarized in Table 1. Without alloying, the Mg-9Li-3Al alloy shows low yield stress (YS) and ultimate tensile strength (UTS), and poor elongation (13.4%). After addition of 2% Sn, the YS and elongation at room temperature both decrease slightly, while UTS of Mg-9Li-3Al is improved significantly. With addition of 2% Y, compared with those of Mg-9Li-3Al alloy, the YS and elongation of Mg-9Li-3Al-2Y are improved. After alloying with 1% Sn and 1% Y, the values of YS and UTS are both improved apparently, and the elongation at room temperature is improved to be 21.0%.

Fig. 4 Tensile stress-strain curves of Mg-9Li-Al based alloys

Table 1 Tensile properties of Mg-9Li-Al based alloys

The strengthening effects originating from the grain-size strengthening can be estimated from the Hall-Petch law: σy=σ0+kd-1/2, where σy is the yield strength of the alloys, σ0 is the yield strength of pure Mg, k is a parameter determined by the polycrystalline material and d is the average grain size. It is believed that k is proportional to M2 (M is Taylor factor). And the value of M in magnesium alloy is large due to the lack of slip systems, so the impact on the strength of grain refining is remarkable. When Y is added into Mg-Li-Al alloy, blocky Al2Y compounds form in both α and β phases [3]. Meanwhile, α phase is refined and becomes spherical, and the formation of α phase in double phase Mg-Li alloys is restrained, which leads to the improvement of elongation.

With large solid solubility in magnesium, elements like Al can improve the strength of Mg-Li alloys based on the solid-solution strengthening effects. As a result, in recent decades, Al was one of the most widely used elements in alloying process of duplex phase Mg-Li alloys. However, the over-aging phenomenon occurs with metastable MgLi2Al transformed to AlLi even at room temperature. AlLi phase is known to segregate to grain boundaries, inducing the cleaving effects of lamellar-type discontinuous precipitate on matrix and resulting in a loss of tensile ductility. The addition of Sn can result in the formation of spherical or needle-shape MgLi2Sn intermetallic compound. MgLi2Sn has high melting point of 770 °C, implying that it is thermally stable in the temperature range of solidification of magnesium alloys. MgLi2Sn particles provide effective barriers to gliding dislocations during deformation and play an important role in the improvement of strength. Besides, MgLi2Sn phase has less than 10% mismatches with both α-Mg and β-Li matrix calculated by E2EM [15]. Therefore, this compound can act as heterogeneous nucleation site for α-Mg and β-Li grains, and serve as a grain refiner for alloys during further plastic deformation of Mg-9Li-3Al alloys with Sn addition. When Y is added into the Mg-9Li-3Al alloy, due to high melting temperature (1485 °C), the intermetallic Al2Y forms directly from the melt first. In the following solidification process, Al2Y particles serve as nucleus of α-Mg and result in grain refinement of α-Mg. Therefore, the significant improvement of YS and UTS is the result of refinement of α-Mg and precipitate strengthening from Al2Y particles. As discussed before, MgLi2Sn and Al2Y particles in Mg-9Li-3Al-1Sn-1Y are in a smaller size and distribute more uniformly inside α-Mg and β-Li, which results in a higher elongation of Mg-9Li-3Al-1Sn-1Y alloys.

4 Conclusions

1) The considerable primary α phase equiaxed dendrites of Mg-9Li-3Al alloys become lath-like due to the addition of Sn and α plates embedded in β-Li matrix with a random orientation. Mg-9Li-3Al alloys with addition of Y consist of both equiaxed and lath-like α-Mg.

2) With the addition of Sn, fine MgLi2Al particles and blocky MgLi2Sn form and distribute inside α-Mg and β-Li matrix. Finer MgLi2Al particles spread evenly inside β-Li matrix and Al2Y with an average size of 2 μm is detected in Mg-9Li-3Al alloy with Y addition. With the addition of Sn and Y, MgLi2Al finely distributes inside β-Li matrix, while MgLi2Sn and Al2Y distribute uniformly inside both α-Mg and β-Li phases.

3) The yield and tensile strengths of Mg-9Li-3Al alloys are improved by addition of Sn, while the addition of Y improves the elongation. With the addition of Sn and Y, the YS, UTS and elongation of Mg-9Li-3Al- 1Sn-1Y are improved as a result of grain refining and dispersion strengthening.

References

[1] YUE H, FU P, PENG L, LI Z, PAN J, DING W. Damage morphology study of high cycle fatigued as-cast Mg-3.0Nd-0.2Zn-Zr (wt.%) alloy [J]. Materials Characterization, 2016, 111: 93-105.

[2] LI R G, XIN R L, LIU Q, LIU J A, FU G Y, ZONG L, YU Y M, GUO S G. Effect of Ag addition on microstructure and mechanical properties of Mg-14Gd-0.5Zr alloy [J]. Materials Characterization, 2015, 109: 43-49.

[3] ZHENG J X, LI Z, TAN L D, XU X S, LUO R C, CHEN B. Precipitation in Mg-Gd-Y-Zr alloy: Atomic-scale insights into structures and transformations [J]. Materials Characterization, 2016, 117: 76-83.

[4] WU R, YAN Y, WANG G, MURR L E, HAN W, ZHANG Z, ZHANG M. Recent progress in magnesium–lithium alloys [J]. International Materials Reviews, 2015, 60: 65-100.

[5] ZHOU Y, BIAN L, CHEN G, WANG L, LIANG W. Influence of Ca addition on microstructural evolution and mechanical properties of near-eutectic Mg-Li alloys by copper-mold suction casting [J]. Journal of Alloys and Compounds, 2016, 664: 85-91.

[6] BAO L, LE Q, ZHANG Z, CUI J, LI Q. Effect of homogenization treatment on microstructure evolution and the distributions of RE and Zr elements in various Mg-Li-RE-Zr alloys [J]. Journal of Magnesium and Alloys, 2013, 1: 139-144.

[7] LIU X, WU R, NIU Z, ZHANG J, ZHANG M. Superplasticity at elevated temperature of an Mg-8%Li-2%Zn alloy [J]. Journal of Alloys and Compounds, 2012, 541: 372-375.

[8] KIM Y H, SON H T. Effects of Li addition on microstructure and mechanical properties of Mg-6Al-2Sn-0.4Mn alloys [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 697-703.

[9] ZENG R C, SUN X X, SONG Y W, ZHANG F, LI S Q, CUI H Z, HAN E H. Influence of solution temperature on corrosion resistance of Zn-Ca phosphate conversion coating on biomedical Mg-Li-Ca alloys [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 3293-3299.

[10] PARK S H, KIM S H, KIM H S, YOON J, YOU B S. High-speed indirect extrusion of Mg-Sn-Al-Zn alloy and its influence on microstructure and mechanical properties [J]. Journal of Alloys and Compounds, 2016, 667: 170-177.

[11] PAN H, QIN G, XU M, FU H, REN Y, PAN F, GAO Z, ZHAO C, YANG Q, SHE J, SONG B. Enhancing mechanical properties of Mg-Sn alloys by combining addition of Ca and Zn [J]. Materials & Design, 2015, 83: 736-744.

[12] HUANG Q, PAN H, TANG A, REN Y, SONG B, QIN G, ZHANG M, PAN F. On the dynamic mechanical property and deformation mechanism of as-extruded Mg-Sn-Ca alloys under tension [J]. Materials Science and Engineering A, 2016, 664: 43-48.

[13] QIU D, ZHANG M X, TAYLOR J A, KELLY P M. A new approach to designing a grain refiner for Mg casting alloys and its use in Mg-Y-based alloys [J]. Acta Materialia, 2009, 57: 3052-3059.

[14] WU R, QU Z, ZHANG M. Effects of the addition of Y in Mg-8Li- (1,3)Al alloy [J]. Materials Science and Engineering A, 2009, 516: 96-99.

[15] LASALMONIE A, STRUDEL J L. Influence of grain size on the mechanical behaviour of some high strength materials [J]. Journal of Materials Science, 1986, 21: 1837-1852.

[16] KUBOTA K, MABUCHI M, HIGASHI K. Processing and mechanical properties of fine-grained magnesium alloys [J]. Journal of Materials Science, 1999, 34: 2255-2262.

[17] JIANG B, ZENG Y, ZHANG M X, YIN H M, YANG Q S, PAN F S. Effects of Sn on microstructure of as-cast and as-extruded Mg-9Li alloys [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 904-908.

[18] YANG Q, JIANG B, JIANG W, LUO S, PAN F. Evolution of microstructure and mechanical properties of Mg-Mn-Ce alloys under hot extrusion [J]. Materials Science and Engineering A, 2015, 628: 143-148.

[19] SUN S, QIN Y, ZHOU H, DU Y, HE C. Experimental investigation of the isothermal section at 400°C of the MgCeSr ternary system [J]. Journal of Magnesium and Alloys, 2016, 4: 30-35.

[20] XU T C, PENG X D, JIANG J W, XIE W D, CHEN Y F, WEI G B. Effect of Sr content on microstructure and mechanical properties of Mg-Li-Al-Mn alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2752-2760.

[21] SUN C C, LIU K, WANG Z H, LI S B, DU X, DU W B. Hot deformation behaviors and processing maps of Mg-Zn-Er alloys based on Gleeble–1500 hot compression simulation [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 3123-3134.

[22] ZHU T, CUI C, ZHANG T, WU R, BETSOFEN S, LENG Z, ZHANG J, ZHANG M. Influence of the combined addition of Y and Nd on the microstructure and mechanical properties of Mg-Li alloy [J]. Materials and Design, 2014, 57: 245-249.

[23] PENG Q Z, ZHOU H T, ZHONG F H, DING H B, ZHOU X, LIU R R, XIE T, PENG Y. Effects of homogenization treatment on the microstructure and mechanical properties of Mg-8Li-3Al-Y alloy [J]. Materials and Design, 2015, 66: 566-574.

[24] ZHANG M X, KELLY P M. Edge-to-edge matching model for predicting orientation relationships and habit planes-The improvements [J]. Scripta Materialia, 2005, 52: 963-968.

[25] ZHANG M X, KELLY P M, QIAN M, TAYLOR J A. Crystallography of grain refinement in Mg-Al based alloys [J]. Acta Materialia, 2005, 53: 3261-3270.

[26] SHIFLET G J, MERWE J H. The role of structural ledges as misfit- compensating defects: fcc-bcc interphase boundaries [J]. Metallurgical and Materials Transactions A, 1994, 25: 1895-1903.

添加Sn和Y元素改善双相Mg-9Li-3Al合金的力学性能

常丽丽1,史春昌1,崔红卫2

1. 山东大学 材料科学与工程学院,济南 250061;

2. 山东理工大学 材料科学与工程学院,淄博 255000

摘 要:为提高Mg-9Li-3Al 双相镁合金的力学性能,向其中添加Sn和Y元素。通过金相显微镜观察、扫描电镜分析、X射线测试及拉伸试验分析研究Sn和Y元素对Mg-9Li-3Al合金显微组织演变和力学性能的影响。研究结果表明,Sn元素添加改变了块状初生α-Mg的形貌,使其呈板条状;Y元素添加使合金中α-Mg相呈现块状和板条状两种形态。 铸态Mg-9Li-3Al-1Sn-1Y合金的屈服强度约为118 MPa, 抗拉强度为148 MPa,断裂伸长率约为21%。在MgLi2Sn和Al2Y金属间化合物的共同作用下,添加Sn和Y元素的Mg-9Li-3Al合金的强度和伸长率获得提升。

关键词:镁锂合金;晶粒组织;拉伸性能;析出相强化

(Edited by Bing YANG)

Foundation item: Project (51401115) supported by the National Natural Science Foundation of China; Project (GN2013001) supported by the Independent Innovation Foundation of Shandong University, China

Corresponding author: Li-li CHANG, Tel: +86-531-88392157; E-mail: lilichang@sdu.edu.cn

DOI: 10.1016/S1003-6326(18)64635-7

Abstract: For enhancement of mechanical properties in Mg-9Li-3Al alloys, Mg-9Li-3Al duplex alloys were alloyed by addition of Sn and Y. Microstructure evolution and mechanical property response of as-cast Mg-9Li-3Al alloys by alloying with Sn and Y were investigated by optical microscopy, scanning electron microscopy, X-ray diffractometry and tensile tests. The results indicate that considerable blocky dendrites of primary α phase in Mg-9Li-3Al alloys become lath-like due to the addition of Sn. With addition of Y, Mg-9Li-3Al alloy consists of both block-like and lath-like α-Mg dendrites. The as-cast Mg-9Li-3Al-1Sn-1Y alloy shows a yield strength of 118 MPa, ultimate tensile strength of 148 MPa and the elongation to failure of 21%. Improvement in both strength and elongation of Mg-9Li-3Al alloys with Sn and Y addition is attributed to the combined action of MgLi2Sn and Al2Y intermetallic compounds.