电沉积Cr/ZrO2复合镀层的结构和摩擦性能

舒绪刚1,何湘柱2,黄慧民2,李大光2,谢绍俊2,雷华山2,赵国鹏3

(1. 仲恺农业工程学院 化学化工学院,广东 广州,510225;

2. 广东工业大学 轻工化工学院,广东 广州,510006;

3. 广州市二轻工业科学技术研究所,广东 广州,510663)

摘 要:

摘 要:采用复合电沉积工艺制备Cr/ZrO2 纳米复合镀层,分别用扫描电子显微镜(SEM)、扫描电子显微镜附带能谱仪(EDS)、X线衍射(XRD)等技术较系统地研究了Cr/ZrO2 纳米复合镀层的表面形貌、成分、结构和耐磨性。研究结果表明:复合镀层的中ZrO2的复合量质量分数为1.47%,在ZrO2纳米粒子的弥散强化作用下,Cr/ZrO2复合镀层无裂纹,组织致密,结构呈现明显的非晶态特征;在干摩擦条件下,纳米Cr/ZrO2复合镀层的摩擦性能明显优于3价铬镀层的摩擦性能;纳米Cr/ZrO2复合镀层的磨损主要表现为疲劳磨损特征,而3价铬镀层的磨损机制为磨料磨损。

关键词:

中图分类号:TQ153.11;TG174.4 文献标志码:A 文章编号:1672-7207(2010)03-0871-05

Structure and friction behavior of electrodeposited Cr/ZrO2 nano-composite coatings

SHU Xu-gang1, HE Xiang-zhu2, HUANG Hui-min2, LI Da-guang2,

XIE Shao-jun2, LEI Hua-shan2, ZHAO Guo-peng3

(1. College of Chemistry and Chemical Engineering, Zhongkai University of Agriculture and Engineering,

Guangzhou 510225, China;

2. Faculty of Light and Chemical Engineering, Guangdong University of Technology, Guangzhou 510006, China;

3. Guangzhou Etsing Plating Research Institute, Guangzhou 510663, China)

Abstract: New Cr/ZrO2 nano-composite layers were prepared by composite electrodeposition technology. The morphology, composition, structure and friction resistance properties of the coatings were systematically characterized by means of SEM, EDS, X-ray diffraction and potentiostat methods. The worn surfaces of Cr coatings and Cr matrix composite coatings, were analyzed with a SEM and XPS. The results show that the mass composition of the obtained ZrO2 composite coating is 1.47%, the crack condition of Cr coatings is improved markedly by the dispersion strengthening effect of the ZrO2 nano-particle. Meanwhile, the composite coatings present an obvious amorphous characteristics, compact structure, and uniform composition. The friction and wear properties of the composite coatings is investigated using a pin-on-disc sliding wear machine under dry friction conditions. In comparison with Cr coatings, the friction resistance of the composite coatings is higher, the wear mechanism of nanometer ZrO2 particles reinforced Cr matrix composite coating is characterized by slight fatigue wear,while that of trivalent Cr coating is characteristic of abrasive wear.

Key words: electrodeposition; nano-composite coating; amorphous; friction resistance

耐磨性镀铬(硬铬)由于具有较高的硬度、较强的结合力以及较低分子摩擦因数而广泛应用于机械零件表面,以提高其耐磨和耐蚀性能[1]。但在电镀过程中,废水中6价铬对环境造成严重的污染,各国都限制6价铬的使用,研究替代6价铬电镀工艺,其中3价铬镀铬工艺被认为是最有效的。3价铬电镀装饰性铬工艺已有工业化生产的报道,但是,3价铬镀硬铬工艺还不成熟[2-4]。近年来,对复合镀层的研究[5]表明:在镀液中加入ZrO2,CeO2[6]和Al2O3[7]等微粒,用复合电沉积技术将固体微粒与基质金属共沉积在零件表面形成复合镀层,可以有效地改善镀层的表面状态,提高其硬度和耐磨性等。本文作者尝试在3价铬镀液中添加ZrO2 纳米微粒,采用复合电沉积技术制备Cr/ZrO2纳米复合镀层,研究ZrO2纳米微粒复合量对镀层表面形貌和结构的影响,并将该镀层与传统3价铬镀层的结构与耐磨性进行了比较。

1 实验

1.1 Cr/ZrO2纳米复合镀层的制备

以工业紫铜片试样为阴极,工作面积为20 mm×20 mm,非工作区域用AB胶绝缘,以大面积DSA为阳极,所用电镀槽为自制的体积为500 mL、底面积为8 cm×10 cm有机玻璃方形槽,电镀液组成主要为[8]:0.5 mol/L CrCl3,0.6 mol/L Glycine,0.5 mol/L AlCl3,10 g/L ZrO2。所有试剂均为化学纯,采用的高分子聚电解质分散剂为自制,电沉积过程中用磁力搅拌器搅拌镀液,控制电流密度15 A/dm2左右,温度为20 ℃左右。

1.2 测试方法

使用FEI-XL30环境扫描电子显微镜观察镀层表面形貌,用扫描电镜附属EDS 能谱仪测定镀层断面成分和分布;采用Y-4Q型全自动X线衍射仪进行镀层结构分析,衍射源为铜靶(Cu Kα=0.154 06 nm),扫描角度10?~90?,扫描速度为0.1 (?)/s,扫描步宽为0.1,管流为25 mA,管压为40 kV;用WTM-2E型可控气氛微型摩擦磨损试验仪测定涂层样品的摩擦因数,主轴转速为300 r/min,对磨件采用直径<3 mm淬火态GCr15钢球,回转直径为6 mm,载荷砝码为100 g,室温时无润滑干磨损时间为10 min。

2 结果与讨论

2.1 镀层成分分析与表面形貌

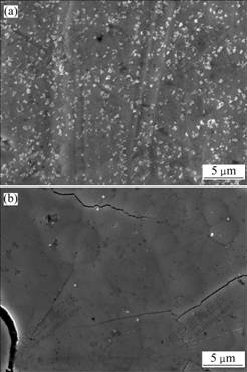

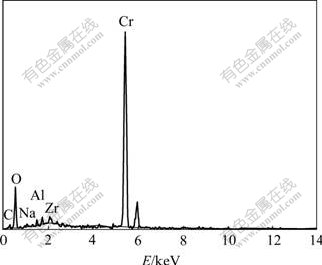

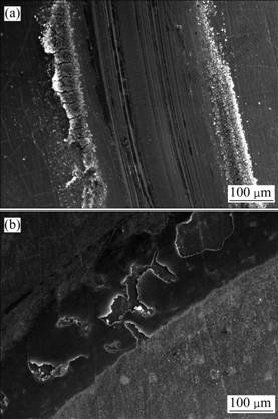

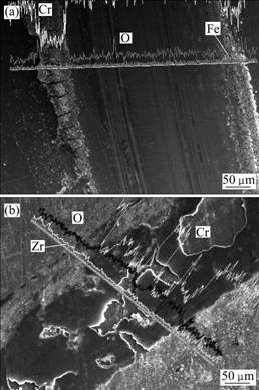

镀层表面SEM形貌如图1所示。由图1可见:3价铬镀层结晶细小均匀,镀层裂纹明显,表面有明显的针孔。用肉眼观察,试样表面光滑细致,具有亚光不锈钢外观。而Cr/ZrO2复合镀层SEM表明镀层表面上存在许多极细小的颗粒,这应是外部裹有铬镀层的ZrO2纳米微粒,其分布较均匀。基本不见复合镀层表面裂纹和针孔,可能是镶嵌其中的ZrO2纳米微粒使表面应力减少,其防腐蚀性能较好,硬度较大。图2所示的EDX分析结果表明:镀层表面的确存在着锆元素,表明含有ZrO2纳米微粒。从横断表面上看(表1),复合镀层与基体较难区分,这表明ZrO2纳米微粒已经进入基体。利用能谱图进行分析,w(Zr)为1.47%。

(a) Cr/ZrO2复合渡层;(b) 铬镀层

图1 Cr/ZrO2复合镀层SEM形貌和铬镀层试样的

SEM形貌

Fig.1 SEM of morphology of Cr coatings(a) and morphology of Cr/ZrO2 composition coatings(b)

图2 Cr/ZrO2复合镀层能谱图

Fig.2 Cr/ZrO2 composition coatings

2.2 镀层的结构表征

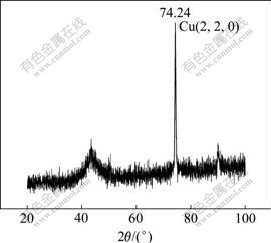

图3所示为ZrO2/Cr复合镀层的XRD图谱,Zr原子数分数为1.3%。从图3可看出:ZrO2/Cr复合镀层在2θ=42?左右出现1个“馒头包”状的漫散峰,在2θ=74.24?呈现的峰为Cu峰,这是X线穿透铬镀层到铜基质所致,没有其他明显的衍射峰存在,具有典型的非晶态衍射谱线特征。

图3 ZrO2/Cr复合镀层X线衍射曲线

Fig.3 X-ray diffraction patterns of ZrO2/Cr deposit

2.3 铬镀层的耐磨性

2.3.1 镀层摩擦因数分析

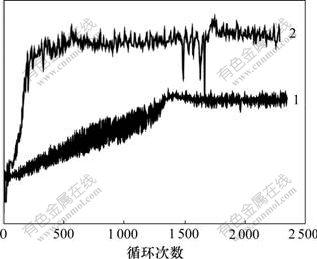

图4所示为室温下镀层与GCr15钢球对磨时干摩擦因数随循环次数的变化关系曲线。可以看出:在摩擦起始阶段,3价铬镀层摩擦因数随滑动距离增加而急剧增大,随后摩擦因数随滑动距离增加而逐渐平稳;复合镀层的摩擦因数随滑动距离增加表现出缓慢升高,而后逐渐平稳。由图4可见:复合镀层的摩擦因数小于3价铬镀层摩擦因数,其摩擦性能较好。

1—3价铬镀层;2—Cr/ZrO2复合镀层

图4 室温干摩擦因数随循环次数的关系曲线

Fig.4 Test curve of dry friction coefficient vs cycle number

2.3.2 镀层摩擦磨损部位的显微分析

图5所示为ZrO2/Cr复合镀层和铬镀层磨损表面形貌的扫描电子显微镜(SEM)照片。由图5可知:复合镀层的磨痕宽度明显小于3价铬镀层的磨痕宽度,这说明镀层中加入纳米ZrO2可以大幅度提高镀层的耐磨性。经比较还可以发现:3价铬镀层的磨损表面呈现经典的磨损形貌[9-10],有明显的平行于滑动方向的划痕;磨损表面上平行排列着比较深的连续分布的犁沟,塑性变形严重,其磨损机制为磨料磨损,这与Fedrizzi等[11]的报道结果基本一致。复合镀层的磨损表面没有明显的划痕,只有少量不连续的磨损,表面凸起的胞状颗粒被严重磨损,磨损痕迹呈黑色,产生许多小空洞,其磨损机制主要呈现为疲劳磨损[12-13]。

纳米颗粒弥散在镀层中,对镀层的强化在多方面发挥作用[14]:(1) 由于有高硬度的ZrO2粒子在镀层中存在,起着支撑强化作用,镀层硬度提高,磨损减轻;(2) 纳米ZrO2在磨损过程中具有自润滑作用,也使镀层磨损减小。

(a) 3价铬镀层;(b) ZrO2/Cr复合镀层

图5 磨损试验后镀层表面形貌的SEM

Fig.5 SEM images of worn surfaces

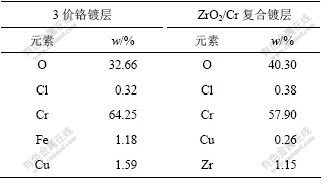

2.3.3 镀层摩擦磨损元素含量分析

磨损结束后,观察摩擦副组元外观,可见有较多的黑色粉末。对涂层磨损区域的成分进行能谱分析(见图6),其结果见表1。由表1可知:磨损区域含有摩擦副组元的材料,而且在这种干磨损条件下,磨损区域含有较多的氧,这应该是干摩擦条件下,接触面大量放热导致局部氧化所致。因此,在此试验条件下也存在部分氧化磨损的特征,磨损试验后镀层的SEM照片如图5所示。

(a) 3价铬镀层;(b) ZrO2/Cr复合镀层

图6 磨损试验后镀层的EDS

Fig.6 EDS of worn surfaces

表1 镀层摩擦面元素含量

Table 1 Materials content of worn surfaces

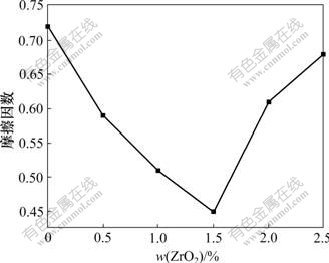

2.3.4 镀层的耐磨性与镀层中纳米ZrO2含量的关系

图7所示为镀层摩擦因数随镀层中纳米ZrO2粒子悬浮量的变化关系。可以发现:随着镀液中ZrO2颗粒的增加,复合镀层的耐磨性能不断改善,这与复合镀层显微硬度的变化规律是一致的。可见:复合镀层的显微硬度越高,耐磨性能越好。但是,镀层中的纳米粒子太多,纳米粒子几乎都是以团聚的形式存在于镀层中,在摩擦过程中被带出,从而破坏了铬基体,使耐磨能力下降[15]。

图7 镀层中纳米ZrO2含量与镀层的耐磨性的关系曲线

Fig.7 Effect of ZrO2 content in coatings on coefficient of friction

3 结论

(1) Cr/ZrO2(Zr复合量质量分数为1.47%)纳米复合镀层结构呈非晶态,镀层组织细小致密,ZrO2 纳米颗粒在复合镀层内部分布均匀,无明显团聚现象,而且Cr/ZrO2 纳米复合镀层表面的缺陷和孔洞也较少,明显地消除了3价铬镀层内部存在的裂纹和微孔。

(2) 在干摩擦条件下,纳米ZrO2颗粒增强复合镀层的摩擦性能明显优于3价铬镀层的摩擦性能。在复合量质量分数为1.5% Zr时,摩擦因数达到最小0.45,纳米ZrO2/Cr复合镀层的磨损主要表现为疲劳磨损特征,而3价铬镀层的磨损机制为磨料磨损。

参考文献:

[1] 王为, 郭鹤桐. 纳米复合镀技术[J]. 化学通报, 2003, 3(3): l78-l83.

WANG Wei, GUO He-tong. Development of nano-composite plating technology[J]. Chemistry, 2003, 3(3): l78-l83.

[2] 杨余芳, 龚竹青, 邓丽元, 等. 3价铬镀液中电沉积纳米晶体Fe-Ni-Cr合金箔[J]. 中南大学学报: 自然科学版, 2006, 37(3): 509-515.

YANG Yu-fang, GONG Zhu-qing, DENG Li-yuan, et al. Electrodeposition of nanocrystalline Fe-Ni-Cr alloy foil in trivalent chromium bath[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 509-515.

[3] 何湘柱, 龚竹青, 蒋汉瀛. Cr(Ⅲ)水溶液电沉积非晶态铬的电化学[J]. 中国有色金属学报, 2000, 10(1): 95-100.

HE Xiang-zhu, GONG Zhu-qing, JIANG Han-ying. Electro- deposition of amorphous chromium from Cr(Ⅲ) aqueous solution[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(1): 95-100.

[4] Vykhodtseva L N, Edigaryan A A, Lubnin E N, et al. Composition, structure, and corrosion-electrochemical properties of chromium coatings deposited from chromium(Ⅲ) electrolytes containing formic acid and its derivatives[J]. Russian Journal of Electrochemistry, 2004, 40(4): 387-393.

[5] 舒绪刚, 何湘柱, 黄慧民, 等. 纳米ZrO2在复合镀中的应用[J]. 机械工程材料, 2008, 32(3): 1-4.

SHU Xu-gang, HE Xiang-zhu, HUANG Hui-min, et al. Development in applied of nano-ZrO2 powder in composite plating[J]. Materials for Mechanical Engineering, 2008, 32(3): 1-4.

[6] Vinokurov E G, Arsenkin A M, Grigorovich K V, et al. Electrodeposition and physico-mechanical properties of chromium coatings modified with disperse particles[J]. Protection of Metals, 2006, 42(3): 290-294.

[7] SUN Ke-ning, HU Xin-ning, ZHANG Ji-hai. Electrodeposited Cr-A12O3 composite coating for wear resistance[J]. Wear, 1996(196): 295-297.

[8] 舒绪刚, 黄慧民, 何湘柱, 等. 纳米ZrO2/Cr复合电沉积工艺条件的研究[J]. 腐蚀与防护, 2009, 31(11): 10-14.

SHU Xu-gang, HUANG Hui-min, HE Xiang-zhu, et al. The electroplating process of nano-ZrO2/Cr composite coatings[J]. Corrosion and Protection, 2009, 31(11): 10-14.

[9] 李君, 胡信国, 王殿龙, 等. 电沉积Ni-PSZ复合镀层摩擦磨损行为的研究[J]. 摩擦学学报, 1997, 17(4): 308-313.

LI Jun, HU Xin-guo, WANG Dian-long, et al. A study on the friction and wear behaviour of electrodeposited Ni-PSZ composite coatings[J]. Tribology, 1997, 17(4): 308-313.

[10] Garcia I, Fransaer J, Celis J P. Electrodeposition and sliding wear resistance of nickel composite coatings containing micron and submicron SiC particles[J]. Surface and Coatings Technology, 2001, 148(2/3): 171-178.

[11] Fedrizzi L, Rossi S, Bellei F. Wear-corrosion mechanism of hard chromium coatings[J]. Wear, 2002(253): 1173-1181.

[12] 金亚旭, 华林. 镍-磷-钛酸钾晶须化学复合镀层的制备及性能[J]. 中国有色金属学报, 2007, 17(8): 1280-1285.

JIN Ya-xu, HUA Lin. Preparation and properties of electroless composite plating of nickel-phosphous-potassium titanate whisker[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1280-1285.

[13] 廖晨棵, 赵文轸, 张春婉. PEI复合润滑膜的制备与摩擦性能[J]. 复合材料学报, 2008(3): 80-86.

LIAO Chen-ke, ZHAO Wen-zhen, ZHANG Chun-wan. Preparation and tribological performances of PEI composite films with low friction coefficients[J]. Acta Materiae Compositae Sinica, 2008(3): 80-86.

[14] 薛玉君, 段明德, 李济顺, 等. 纳米和微米La2O3颗粒增强镍基复合镀层的摩擦磨损性能[J]. 中国机械工程, 2006, 17(3): 311-314.

XUE Yu-jun, DUAN Ming-de, LI Ji-shun, et al. Friction and wear properties of nano- and micron-sized La2O3 particles reinforced Ni matrix composite coatings[J]. China Mechanical Engineering, 2006, 17(3): 311-314.

[15] 张学玲. 铬基耐磨复合镀层的制备及性能研究[D]. 镇江: 江苏大学材料科学与工程学院, 2006: 27-32.

ZHANG Xue-ling. Study on the fabrication and properties of composite chromium plating[D]. Zhenjiang: Jiangsu University. School of Materials Science and Engineering, 2006, 27-32.

收稿日期:2009-04-02;修回日期:2009-06-20

基金项目:国家自然科学基金资助项目(50004003);广东省科委重大工业攻关项目(045040037)

通信作者:黄慧民(1944-),男,湖南郴州人,教授,从事材料电化学研究;电话:020-39322231;E-mail: hanghm@gdut.edu.cn

(编辑 任楚威)