DOI: 10.11817/j.ysxb.1004.0609.2020-39572

热输入对5A06-6061铝合金搅拌摩擦焊接头断裂特征的影响

彭光健1,严 奇1,张泰华2,吴江敬3

(1. 浙江工业大学 机械工程学院,杭州 310023;

2. 北京航空航天大学 固体力学研究所,北京 100191;

3. 爱励铝业有限公司,镇江 212000)

摘 要:

在自然冷却和压缩空气强制冷却条件下,搅拌摩擦对接焊接5A06-H112和6061-T651异种铝合金,借助单轴拉伸、纳米压入和显微观测手段,研究热输入对接头拉伸断裂特征的影响规律,揭示其影响机制。结果表明:当转速焊速比(γ)为1.5 r/mm(热输入过低)时,焊核区材料因混合不充分形成S线缺陷,导致接头沿此缺陷在焊核区发生脆性断裂;当转速焊速比达到3.0 r/mm后,焊核区材料混合充分,韧性断裂均发生在6061侧的热影响区。随着热输入增加,断裂角度由41°逐渐减小至3°,断裂类型由切断断裂演化成正断断裂。纳米压入硬度分布显示6061侧的热影响区为接头的弱化区域,该区域的宽度和倾角直接影响断裂角度。断口微观形貌分析表明,抑制热输入有助于增大断裂角度,使接头以切断断裂为主,从而产生更多剪切韧窝,提高接头的断裂伸长率。

关键词:

5A06铝合金;6061铝合金;搅拌摩擦焊;热输入;断裂角度;

文章编号:1004-0609(2020)-09-2041-07 中图分类号:TG453.9 文献标志码:A

5A06是一种不可热处理强化的Al-Mg系铝合金,具有良好的耐蚀性和较高的强度;6061是一种可热处理强化的Al-Mg-Si系铝合金,具有良好的塑性和较高的屈服强度,通过焊接集合两种铝合金各自优点有助于其广泛应用于航空航天、船舶和建筑等领域[1]。搅拌摩擦焊(Friction stir welding, FSW)作为一种固相连接技术,具有焊接变形小、热输入小等优点,在铝合金这类低熔点金属的连接方面有独特优势,且因无需焊料而适用于异种材料的焊接[2]。

搅拌摩擦焊接时选择不同焊接工艺参数会影响焊接接头各区域的力学性能,导致接头断裂方式有所区别。ELANGOVAN等[3]系统研究了不同转速、焊接速度和搅拌头形状对6061铝合金FSW接头断裂部位的分布情况,指出不同焊接参数导致接头断裂部位的差异。FADAEIFARD等[4]研究6061铝合金FSW接头性能时表明焊接参数通过影响接头材料混合程度和软化程度,从而决定了接头断裂在材料混合不充分的焊 核区或受热软化作用最严重的某一侧热影响区。BENAVIDES等[5]发现FSW过程中通过冷却措施可使接头软化区宽度变窄,接头沿软化区断裂时表现出了更高的强度。PALANIVEL等[6]等研究5xxx系和6xxx系异种铝合金FSW时选取不同焊接速度导致接头断裂部位有所区别,但未对其结果进行详细解释。PENG等[7]借助数字图像相关(DIC)技术,发现5A06和6061的搅拌摩擦焊接试样在单轴拉伸过程中,焊接接头附近的应变场演化和最终的断裂角度均随热输入量变化。近期,PENG等[8]又针对5A06-6061异种铝合金搅拌摩擦焊,分别考虑自然冷却和强制冷却工况,研究了热输入对焊接接头强度的影响规律及其机理,但热输入对接头断裂特征的影响并未进行深入分析。

本文以5A06-H112和6061-T651铝合金作为焊接材料,选取不同转速、焊接速度和冷却方式进行异种铝合金搅拌摩擦焊接,借助单轴拉伸测试、纳米压入测试、光学显微镜和扫描电子显微镜,系统分析焊接热输入对接头力学性能、拉伸断裂角度和断裂伸长率的影响规律,揭示其影响机制。

1 实验

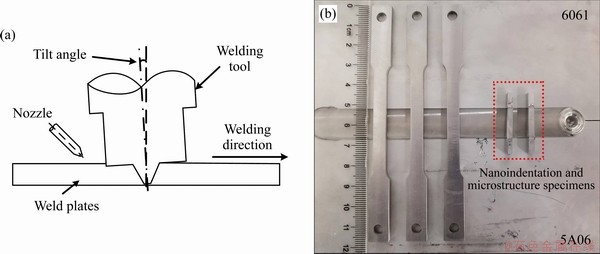

试验选用5 mm厚的5A06-H112和6061-T651轧制板材作为焊接母材,两种铝合金的化学成分如表1所示。焊接母材被加工成尺寸为155 mm×65 mm的矩形板材,搅拌摩擦焊接之前用无水乙醇清洗以去除表面污渍。焊接试验在HT-JL10X12/2H型搅拌摩擦焊接设备(上海航天设备制造总厂有限公司)上进行。转速选择300、600、900和1200 r/min,焊接速度为100和200 mm/min,选取的转速焊速比γ为1.5、3.0、4.5、6.0、9.0和12.0 r/min。搅拌头用H-13模具钢制成,轴肩直径为15 mm,搅拌针为锥形带右旋螺纹形状,螺距2 mm,端部直径3 mm,底部直径6 mm,长4.6 mm。焊接过程中,主轴倾角为2.8°,轴肩下压量为0.36 mm。分别选用自然冷却(Nature cooling, NC)和压缩空气强制冷却(Forced air cooling, FAC)进行搅拌摩擦焊接,其中FAC方式为焊接过程中在搅拌头后侧喷射压缩空气进行强制冷却。压缩空气压强为0.5 MPa,喷嘴置于距搅拌头侧面约20 mm,距焊材表面高约20 mm处,尺寸为10 mm×2 mm的矩形,斜对焊缝表面喷射空气(见图1(a))。

单轴拉伸试样和纳米压入试样沿垂直于焊接方向截取(见图1(b))。单轴拉伸试验每组取3个试样在MTS CMT4204材料试验机上进行,所有试样在拉伸前上下表面各去除1 mm厚度以保证试样表面平整,避免部分区域应力集中。拉伸试验以2 mm/min的拉伸速度在室温下进行。拉断的试样在Zeiss SIGMA扫描电子显微镜(SEM)下观察断口微观形貌,分析韧窝演化情况。为研究焊接接头的硬度分布和局部力学性能,利用Agilent Nano Indenter G200纳米压入仪进行纳米压入试验。试验采用玻氏压头在焊接试样侧面按480 μm的间距压入56×6的矩阵压痕点,以表征接头附近区域的硬度分布情况。压入试验过程中,热漂移率控制在±0.05 nm/s范围内,压入载荷以线性方式在30 s加载到120 mN,保载10 s后在30 s内卸载到0 mN。

2 结果与分析

2.1 单轴拉伸强度与断裂伸长率

母材和部分焊接接头典型的工程应力-应变曲线如图2所示。5A06铝合金母材的平均抗拉强度、屈服强度和断裂伸长率分别为307.87 MPa、125.78 MPa和22.13%,6061铝合金母材的平均抗拉强度、屈服强度和断裂伸长率分别为277.67 MPa、236.17 MPa和13.08%。搅拌摩擦焊接后接头的抗拉强度、屈服强度和断裂伸长率都低于母材的。在转速300 r/min,焊接速度200 mm/min(即γ =1.5 r/min)下得到的焊接接头,其抗拉强度最低(仅为140.98 MPa),断裂前未观察到明显的屈服和塑性变形,属于脆性断裂破坏。这是由于此焊接参数下的热输入和搅拌作用不足,焊核区的材料软化和混合不充分,导致焊核区存在S线缺陷,最终接头在焊核区沿S线断裂(见图2)。随着转速焊速比γ的提高,焊核区的材料混合充分并形成洋葱环,焊接接头的断裂均发生在6061侧热影响区,这说明6061侧热影响区成为焊接接头的最弱区域,且转速焊速比γ为3.0 r/mm时的热输入和搅拌作用足以使焊核区材料充分混合连接。

表1 5A06-H112和6061-T651铝合金化学成分

Table 1 Chemical composition of base 5A06 and 6061 aluminum alloys

图1 试验方案及试样加工图

Fig. 1 Schematic diagram of FAC (a) and processing diagram of specimens (b)

图2 不同焊接参数下焊接试样的工程应力-应变曲线

Fig. 2 Typical engineering stress-strain curves for joints welded using different welding parameters

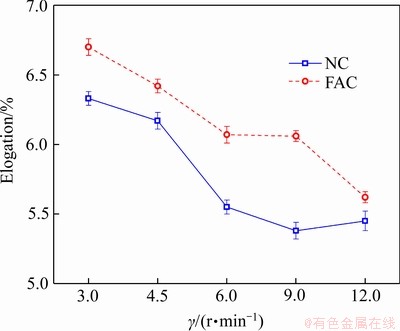

图3所示为在自然冷却下、当转速焊速比为3.0 r/min时,焊接接头的抗拉强度最高(为201.25 MPa)。随着转速焊速比的增加,焊接接头的抗拉强度缓慢降低,当转速焊速比γ为12.0 r/mm时,接头抗拉强度降低到184.48 MPa。采用压缩空气冷却得到的焊接接头,其抗拉强度普遍比自然冷却下的接头强度高10%左右。这是因为6061铝合金属于热敏感合金,转速焊速比(热输入)的增加导致6061侧热影响区的轧制硬化状态被破坏、晶粒长大、沉淀强化相熔解,从而引起抗拉强度的下降[9];压缩空气冷却通过加速焊接试样的冷却,抑制6061铝合金热影响区的晶粒长大和沉淀强化相熔解,从而提升焊接接头的抗拉强度。图4显示了各焊接参数下两种冷却方式得到的接头断裂伸长率对比情况。随着转速焊速比的增加,接头断裂伸长率总体呈下降的趋势。且从图2可知虽然FSW接头断裂伸长率低于母材的,但图4表明经压缩空气强制冷却处理后,接头断裂伸长率获得了部分提升。即在较低的热输入情况下,接头能得到更佳的断裂伸长率。鉴于铝合金搅拌摩擦焊接的力学性能与微观机理的研究较多[9-13],此处不再赘述,本文着重分析热输入对焊接接头断裂特征的影响及其机理。

图3 不同转速焊速比条件下搅拌摩擦焊接头的抗拉强度

Fig. 3 Ultimate tensile strength of joints welded at different rotational speeds and welding speeds

图4 不同转速焊速比条件下搅拌摩擦焊接头的断裂伸长率

Fig. 4 Fracture elongation of joints welded at different rotational speeds and welding speeds

2.2 单轴拉伸断裂角度

除了前文提到过的转速焊速比γ为1.5 r/mm的接头存在S线缺陷,断裂在焊核区外,其他焊接参数下均获得无缺陷的接头,且都断裂在6061侧热影响区。不同焊接参数下接头断裂角度如图5所示。由图5可知,无论在自然冷却还是气冷条件下,随着转速焊速比的提高,试样拉伸断裂的角度随之减小。

图5 不同焊接参数下搅拌摩擦焊接接头的断裂角度

Fig. 5 Fracture angle of FSW joints welded at different welding parameters

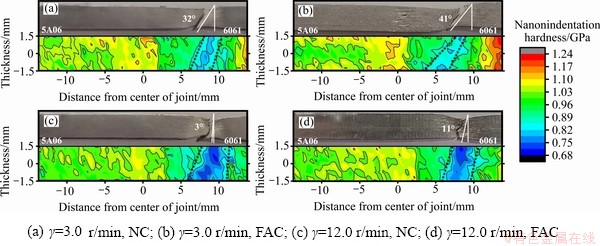

在自然冷却状态下,当转速焊速比为3.0 r/mm时(低热输入),接头断裂角度为32°,经气冷处理后达到41°的最大断裂角。当转速焊速比为12.0 r/mm时(高热输入),接头近似垂直于拉伸方向断裂,断裂角仅为3°。相同转速焊速比情况下经气冷处理后,接头断裂角度都得到增加,平均增幅约7.5°。整体而言,随着热输入的增加,焊接接头从近似斜45°断裂逐渐演化成近似垂直断裂,断裂角度从41°减小到3°。究其原因为,焊接过程中,热输入改变了接头断裂区域附近的局部力学性能和分布,导致接头在不同热输入时呈现不同的拉伸断裂角度。下面结合焊接接头区域的纳米压入硬度分布详细分析。

2.3 纳米压入硬度分布

图6显示了焊接接头区域侧面的纳米压入硬度分布及其拉伸断裂角度对比情况。由于焊接的前进侧与后退侧为异种铝合金,接头两侧硬度呈现不对称分布。5A06铝合金侧的硬度则几乎保持不变,主要因为5A06是不可热处理强化铝合金,其力学性能对热不敏感,搅拌摩擦焊接过程产生的高温并不显著影响其硬度值。然而,6061铝合金侧热影响区的硬度出现急剧下降,这是因为高温破坏了该区域材料原有的轧制硬化状态[14],同时热输入使得晶粒粗化长大,导致其硬度明显低于其他区域的[15]。纳米压入硬度分布显示6061铝合金侧的热影响区为接头的弱化区域,这也直观解释了为什么拉伸断裂都发生在该区域。对比接头的弱化区域角度和拉伸断裂角度,发现两者近似相等。自然冷却状态下,当转速焊速比为3.0 r/mm时,弱化区域的宽度较窄、倾斜角较大,接头呈现较大的断裂角度;当转速焊速比增加到12.0 r/mm时,弱化区域的宽度明显增大,角度近似垂直于拉伸方向,接头的断裂角也接近0°。采用气冷处理抑制热输入后,弱化区域的宽度减小、倾斜角度增大,接头的断裂角度也随之增大。综上所述,搅拌摩擦焊接过程中的热输入通过影响接头弱化区域的宽度和倾角,进而影响接头的拉伸断裂角度。具体的影响分析讨论如下。

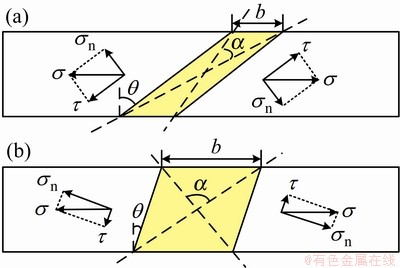

图7(a)所示为当热输入较低时焊接接头弱化区域的宽度b较窄、倾角θ较大。根据最小势能原理,材料的变形或塑性流动将在弱化区域内进行(即不超出弱化区域的边界),因此,裂纹可能沿着 角度内任意方向扩展。在拉伸试验中,接头受到的拉应力

角度内任意方向扩展。在拉伸试验中,接头受到的拉应力 可分解为沿着弱化区域的剪应力分量

可分解为沿着弱化区域的剪应力分量 和垂直于弱化区域的正应力分量

和垂直于弱化区域的正应力分量 。由于弱化区域较窄且倾斜角较大,

。由于弱化区域较窄且倾斜角较大, 角较小,此时沿着弱化区域的剪应力分量

角较小,此时沿着弱化区域的剪应力分量 占主导,弱化区域内的材料将沿剪应力方向发生剪切变形,直至断裂,从而形成与弱化区域倾角相当的断裂角度。随着焊接过程中热输入的增加,接头弱化区域的宽度b增加、倾角

占主导,弱化区域内的材料将沿剪应力方向发生剪切变形,直至断裂,从而形成与弱化区域倾角相当的断裂角度。随着焊接过程中热输入的增加,接头弱化区域的宽度b增加、倾角 减小,可能的断裂角区间

减小,可能的断裂角区间 也随之增大。此时,拉伸应力沿弱化区域的剪应力分量

也随之增大。此时,拉伸应力沿弱化区域的剪应力分量 较小,垂直于弱化区域的正应力分量

较小,垂直于弱化区域的正应力分量 成为主导,根据最小势能原理,接头将沿最优路径(即正应力方向)拉伸变形至断裂,最终形成与弱化区倾角相当的小断裂角。此外,焊接接头的断裂类型也由切断为主演变成正断为主。

成为主导,根据最小势能原理,接头将沿最优路径(即正应力方向)拉伸变形至断裂,最终形成与弱化区倾角相当的小断裂角。此外,焊接接头的断裂类型也由切断为主演变成正断为主。

图6 搅拌摩擦焊接接头纳米压入硬度分布和接头断裂角度对比图

Fig. 6 Nanoindentation hardness distribution and fracture angle of FSW joints welded at different welding parameters

图7 搅拌摩擦焊接接头弱化区域及断裂角度示意图

Fig. 7 Schematic diagrams of weakened area and fracture angle obtained at lower for FSW joints heat input(a) and higher heat input(b)

2.4 断口微观形貌

为进一步阐明焊接接头的断裂特性,图8所示为自然冷却情况下接头断口表面的SEM像。所有断口表面均观察到韧窝组织,表明接头的断裂属于韧性断裂。当转速焊速比为3.0 r/mm(热输入较低)时,韧窝往同一方向倾斜分布。这种特征主要由剪切变形引起,结合图6和图7分析可知,对于较大的断裂角度,占主导的剪切应力分量驱使材料沿断裂面向两个相反的方向流动,在断口表面相互撕扯形成为剪切韧窝。当转速焊速比为12.0 r/mm(热输入较高)时,接头断口表面为等轴韧窝,表明接头断裂时主要受到垂直于断裂面的法向正应力作用发生正断断裂,这与2.3节的分析相吻合。此外,由图4可知,低转速焊速比(即低热输入)下得到的焊接接头具有更好的断裂伸长率。这是因为与正断断裂比,材料在剪切应力作用下沿近似45°方向切断断裂,将形成更多的剪切韧窝,表现出更好的延伸性。综上分析,在搅拌摩擦焊接过程中降低热输入有助于增加断裂角度,提高断裂面上的剪切韧窝数量,使接头拥有更好的延伸性能。

图8 自然冷却时不同转速焊速比下搅拌摩擦焊接接头断口的SEM像

Fig. 8 SEM images of fracture surface of FSW specimens welded at 3.0 r/mm(a) and 12.0 r/mm(b) with nature cooling

3 结论

1) 当转速焊速比为1.5 r/mm(热输入过低)时,焊核区材料混合不充分,易形成S线缺陷,导致焊接接头沿此缺陷在焊核区发生脆性断裂;当转速焊速比达到3.0 r/mm后,焊核区材料混合充分并形成洋葱环,断裂均发生在焊接接头的弱化区域(即6061侧的热影响区)。

2) 纳米压入硬度分布显示随着热输入增加,接头弱化区倾角减小、宽度增大。焊接接头的断裂角度由41°逐渐减小至3°,断裂角度与弱化区倾角大小相当,断裂类型由切断断裂演化成正断断裂。

3) 无缺陷的接头断口表面均发现韧窝组织,表明接头为韧性断裂。抑制热输入,断口表面由等轴韧窝转变为剪切韧窝,剪切韧窝数量的增加有助于提高焊接接头的断裂伸长率。

REFERENCES

[1] GHARAVI F, MATORI K A, YUNUS R, OTHMAN N K, FADAEIFARD F. Corrosion evaluation of friction stir welded lap joints of AA6061-T6 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(3): 672-681.

[2] 张亮亮, 王希靖, 刘 骁. 6082铝合金搅拌摩擦焊焊接过程中晶粒取向演化[J]. 材料工程, 2018, 46(10): 55-59.

ZHANG Liang-liang, WANG Xi-jing, LIU Xiao. Crystal orientation evolution during friction stir welding of 6082 aluminum alloys[J]. Journal of Materials Engineering, 2018, 46(10): 55-59.

[3] ELANGOVAN K, BALASUBRAMANIAN V. Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy[J]. International Journal of Advanced Manufacturing Technology, 2008, 29(2): 362-373.

[4] FADAEIFARD F, MATORI K A, AZIZ S A, .ZOLKARNAIN L, RAHIM M. Effect of the welding speed on the macrostructure, microstructure and mechanical properties of AA6061-T6 friction stir butt welds[J]. Metals, 2017, 7(2): 48-59.

[5] BENAVIDES S, LI Y, MURR L E, BROWN D, MCCLURE J C. Low-temperature friction-stir welding of 2024 aluminum[J]. Scripta Materialia, 1998, 41(8): 809-815.

[6] PALANIVEL R, KOSHY M P, DINAHARAN I, MURUGAN N. Mechanical and metallurgical properties of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 58-65.

[7] PENG G J, MA Y, HU J J, JIANG W F, HUAN Y, CHEN Z T, ZHANG T H. Nanoindentation hardness distribution and strain field and fracture evolution in dissimilar friction stir-welded AA 6061-AA 5A06 aluminum alloy joints[J]. Advances in Materials Science and Engineering, 2018, 2018: 1-11.

[8] PENG G J, YAN Q, HU J J, CHEN P J, CHEN Z T, ZHANG T H. Effect of forced air cooling on the microstructures, tensile strength, and hardness distribution of dissimilar friction stir welded AA5A06-AA6061 joints[J]. Metals, 2019, 9(3): 304-314.

[9] 董 鹏, 孙大千, 李洪梅, 宫文彪, 刘 杰. 6005A-T6铝合金搅拌摩擦焊接头组织与力学性能特征[J]. 材料工程, 2012(4): 27-31.

DONG Peng, SUN Da-qian, LI Hong-mei, GONG Wen-biao, LIU Jie. Microstructural and mechanical characteristics of friction stir welded 6005A-T6 aluminium alloy[J]. Journal of Materials Engineering, 2012(4): 27-31.

[10] BAHEMMAT P, HAGHPANAHI M, BESHARATI M K, BESHARATI M K, AHSANIZADEH S, REZAEU H. Study on mechanical, micro-, and macrostructural characteristics of dissimilar friction stir welding of AA6061-T6 and AA7075-T6[J]. Proceedings of the Institution of Mechanical Engineers Part B (Journal of Engineering Manufacture), 2010, 57(1): 1-12.

[11] HSIEH H T, CHEN J L. Influence of welding parameters on mechanical properties of friction stir welded 6061-T6 launch box[J]. Materials Transactions, 2008, 49(10): 2179-2184.

[12] MOSHWAN R, YUSOF F, HASSAN M A, RAHMAT S M. Effect of tool rotational speed on force generation, microstructure and mechanical properties of friction stir welded Al-Mg-Cr-Mn (AA 5052-O) alloy[J]. Materials & Design, 2015, 66: 118-128.

[13] TRONCI A, MCKENZIE R, LEAL R M, RODRIGUES D M. Microstructural and mechanical characterisation of 5XXX-H111 friction stir welded tailored blanks[J]. Science & Technology of Welding & Joining, 2013, 16(5): 433-439.

[14] PEEL M, STEUWER A, PREUSS M, WITHERS P J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds[J]. Acta Materialia, 2003, 51(16): 4791-4801.

[15] ZHANG H J, LIU H J, YU L. Microstructural evolution and its effect on mechanical performance of joint in underwater friction stir welded 2219-T6 aluminium alloy[J]. Science and Technology of Welding and Joining, 2013, 16(5): 459-464.

Effect of heat input on fracture behavior of friction stir welded 5A06-6061 aluminum alloy joints

PENG Guang-jian1, YAN Qi1, ZHANG Tai-hua2, WU Jiang-jing3

(1. College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou 310023, China;

2. Institute of Solid Mechanics, Beihang University, Beijing 100191, China;

3. Aleris Co., Ltd., Zhenjiang 212000, China)

Abstract: To investigate the influence of heat input on the fracture behavior of the joints, the 5A06-H112 and 6061-T651 aluminum alloys were friction stir welded in both nature cooling and forced air cooling. When the ratio of rotational speed to transverse speed is 1.5 r/mm, the materials in the nugget zone were insufficiently mixed to form a kissing bond, resulting in brittle fracture along this defect. As the ratio reaches 3.0 r/mm, the materials in the nugget zone were well mixed, and ductile fracture occurs in the heat affected zone of 6061 aluminum alloy. With the increase of heat input, the fracture angle gradually decreases from 41° to 3°, and the fracture mechanism changes from shear fracture to normal fracture. The distribution of nanoindentation hardness of the FSW joints indicates that the heat affected zone of 6061 aluminum alloy is the weakest area, and the fracture angle of the joint is directly influenced by the width and angle of this weakened area. SEM images of the fracture surface reveal that supressing the heat input could increase the fracture angle and cause shear fracture, which is conducive to form more shear dimples on the fracture surfaces to improve the elongation of the joints.

Key words: 5A06 aluminum alloy; 6061 aluminum; friction stir welding; heat input; fracture angle

Foundation item: Projects(11772302, 11727803, 11672356) supported by the National Natural Science Foundation of China

Received date: 2019-09-05; Accepted date: 2019-12-05

Corresponding author: ZHANG Tai-hua; Tel: +86-18667102163; E-mail: zhangth66@buaa.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(11772302,11727803,11672356)

收稿日期:2019-09-05;修订日期:2019-12-05

通信作者:张泰华,研究员;电话:18667102163;E-mail:zhangth66@buaa.edu.cn

摘 要:在自然冷却和压缩空气强制冷却条件下,搅拌摩擦对接焊接5A06-H112和6061-T651异种铝合金,借助单轴拉伸、纳米压入和显微观测手段,研究热输入对接头拉伸断裂特征的影响规律,揭示其影响机制。结果表明:当转速焊速比(γ)为1.5 r/mm(热输入过低)时,焊核区材料因混合不充分形成S线缺陷,导致接头沿此缺陷在焊核区发生脆性断裂;当转速焊速比达到3.0 r/mm后,焊核区材料混合充分,韧性断裂均发生在6061侧的热影响区。随着热输入增加,断裂角度由41°逐渐减小至3°,断裂类型由切断断裂演化成正断断裂。纳米压入硬度分布显示6061侧的热影响区为接头的弱化区域,该区域的宽度和倾角直接影响断裂角度。断口微观形貌分析表明,抑制热输入有助于增大断裂角度,使接头以切断断裂为主,从而产生更多剪切韧窝,提高接头的断裂伸长率。