文章编号:1004-0609(2010)S1-s0487-04

加载波形对Ti-60合金疲劳损伤行为的影响

杨丽娜,刘建荣,陈志勇,王清江,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:

研究了高应力水平下加载波形对Ti-60高温钛合金疲劳损伤行为的影响。结果发现:对于在峰值应力处保载2 min的加载波形,试样的疲劳寿命明显低于无保载的加载波形的试样的寿命;在保载疲劳条件下,单位循环周次内材料的疲劳变形明显增大。SEM观察表明,在保载波形下,疲劳源出现在样品内部,而无保载的加载波形下疲劳裂纹源于样品次表面。TEM观察表明,在两种疲劳加载条件下,都有(![]() 011)滑移系启动。

011)滑移系启动。

关键词:

中图分类号:TF804.3 文献标志码:A

Effect of loading waveform on fatigue damage behavior of Ti-60 alloy

YANG Li-na, LIU Jian-rong, CHEN Zhi-yong, WANG Qing-jiang, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The effect of loading waveform on fatigue damage behavior of Ti-60 alloys at high stress level was studied. The results show that, under the loading waveform with 2 min dwell at the peak stress, the fatigue life is shorter than that without dwell. The fatigue strain in a unit cycle under the dwell fatigue condition is obviously larger than that under the no-dwell fatigue condition. It is observed by SEM that, under the dwell fatigue condition, the fatigue crack originates from the interior of specimens, while under the no-dwell fatigue condition, the fatigue crack originates from the subsurface of specimens. TEM observation indicates that, under the two loading waveforms, (![]() 011) slip system is activated.

011) slip system is activated.

Key words: high-temperature titanium alloy; Ti-60 alloy; loading waveforms; dwell; fatigue damage

钛合金具有密度小、比强度高、耐蚀、可焊等优点,广泛应用在航空、航海、医药、化工、军工等领域。Ti-60合金是中国科学院金属研究所采用电子浓度法设计的一种使用温度在600 ℃的近α型高温钛合金,它兼具α型钛合金优异的蠕变性能和α+β型钛合金的高强度。该合金的综合性能不低于国外的IMI834合金,将用于我国新型发动机叶片、轮盘等部位,以提高航空发动机的推重比[1]。

航空发动机对材料的要求苛刻,它要求材料具有良好的室温性能、高温强度、蠕变性能、热稳定性、疲劳性能和断裂韧性等的匹配,以保证材料的使用寿命和发动机的安全可靠性。发动机用钛合金部件在服役过程中受到疲劳载荷的作用,改善疲劳性能,提高飞行器的安全性、可靠性和耐久性,可以避免发生飞行事故[2-5]。然而,钛合金对疲劳试验条件十分敏感,不同的加载方式对疲劳强度影响较大。本文作者研究了加载波形对不同显微组织Ti-60合金疲劳损伤行为的影响,以了解疲劳加载方式对该合金损伤行为及机理的影响,从而根据材料用途及疲劳载荷条件的不同,选择合理的材料显微组织及热加工工艺,以提高材料的使用安全。

1 实验

实验所用材料为Ti-60合金,该合金属于Ti-Al-Zr-Mo-Si-Sn系钛合金,名义成分为Ti-5.8Al-4.0Sn-3.5Zr- 0.4Mo-0.4Si-0.4Nb-1.0Ta-0.05C。实验材料为钛合金锻件,相变点为(1 045±5) ℃。采用固溶+时效的双重热处理制度,即先在高两相区(1 030 ℃)固溶处理,然后在700 ℃保温2 h后空冷。所用疲劳试样见图1。

图1 低周疲劳试样

Fig.1 Plain LCF specimen

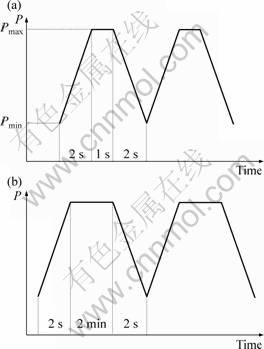

所有疲劳实验均采用应力控制,并在室温大气条件下进行。实验设备为100 kN液压伺服MTS810疲劳实验机。选择如图2所示的2种加载波形:一种为一般低周疲劳实验所用的三角波(见图2(a)波形1),加载和卸载时间均为2 s,为方便数据采集,在峰值应力处保持1 s;另一种如图2(b)所示波形2,在峰值应力处保持2 min,其它与波形1相同。轴向应变累积采用引伸计监测,通过计算机自动采集数据。最后通过数据处理,得到疲劳寿命、应变随时间的变化曲线。

采用MEF4A光学显微镜观察材料的显微组织,采用了HITACHIS-3400扫描电镜观察断口形貌。透射电镜分析试样选择在靠近断口附近,以观察变形最剧烈区域的位错形貌。

图2 两种加载波形

Fig.2 Two waveforms ultilized in present study

2 结果与讨论

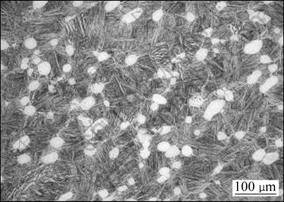

图3所示为在1 030 ℃固溶热处理后Ti-60合金锻件的显微组织。由图3可见,合金为典型的双态组织,白色等轴初生α相颗粒镶嵌在β转变组织基体内,其体积分数约为15%。

图3 Ti-60合金的显微组织

Fig.3 Microstructure of Ti-60 alloy billet

在图2所示的两种加载波形条件下试样的疲劳性能见表1。由表1可见,在相同的峰值应力和应力比条件下,采用波形2的加载方式,试样的疲劳寿命比采用波形1的下降2/3。可见试样在峰值应力处保拉2 min后,会比在无保拉实验条件下的疲劳寿命明显降低。在其它高温钛合金如IMI685[6]、IMI829[7]和IMI834[8]中都出现过同样的现象。

表1 Ti-60合金的疲劳性能

Table 1 Fatigue properties of Ti-60 alloy

图4所示为两种波形条件下的疲劳试样在疲劳实验过程中的循环累积变形。由图4可知,在相同峰值应力下,不同加载波形产生的循环累积变形量也不同。在相同循环周次下,峰值应力处有2 min保载的疲劳试样产生的变形明显比没有保载的样品大。根据疲劳损伤累积模型,疲劳失效是材料损伤累积的结果,单位循环周次内产生的损伤大,达到材料可承受最大损伤的循环周次就少,因此根据图4可以很好地解释表1中的实验现象。WOODFIELD等[9]认为,造成保载条件下应变大量累积的原因是由相当于在峰值应力处施加2 min的蠕变作用造成的,但相同应力条件下的蠕变实验结果似乎不支持该论述。因此波形2条件下单位循环周次变形大的原因尚需进行更深入的研究。

图4 两种波形应变—循环周次曲线

Fig.4 Accumulation of cyclic strain under cyclic and dwell(2 min) loading in Ti-60

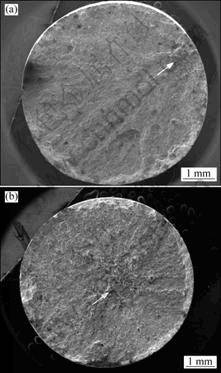

利用扫描电镜观察了两种不同加载波形的疲劳断口形貌(图5和6)。图5(a)所示为波形1条件下的疲劳断口形貌,图5(b)所示为波形2条件下的疲劳断口形貌。图6为图5中裂纹源区的放大。从图5可以看到,在波形1条件下,疲劳裂纹源于试样表面附近;而波形2条件下,裂纹萌生于样品内部。在两种波形条件下试样的裂纹源处都发现有平坦且明亮的疲劳小平面存在,见图5和6中箭头所示。这些疲劳小平面的形成被认为与α相晶粒相对于主应力轴的晶体学取向有关[8]。当滑移带在具有 “软取向”的晶粒内形成后,在具有“硬取向”的晶粒界面受阻,由于位错塞积导致的应力增加,使得具有“硬取向”的晶粒发生解理开裂,是这种疲劳小平面形成的原因。

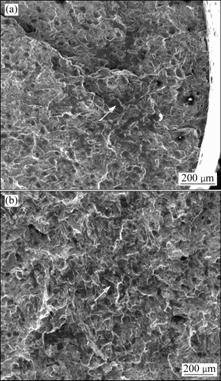

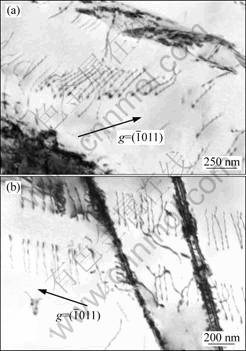

图7所示为Ti-60合金在不同加载波形下样品断口附近的透射电镜照片。由图7可以看出,位错平行排列,形成滑移带。这些滑移带可以通过相邻的α片层,而不发生方向改变,表明同一板条束内的α片层界面对滑移几乎没有阻碍作用,同时也表明同一板条束内的α片层具有相同的晶体学取向。密排六方结构的钛合金中有基面滑移、柱面滑移和锥面滑移3个滑移系,根据图7(a)和(b)给出的g矢量可以推断,两种疲劳波形条件下都有(![]() 011)滑移系启动。

011)滑移系启动。

图5 两种加载波形下试样的疲劳断口形貌

Fig.5 Optical micrographs of specimens under two loading waveforms: (a) Loading waveform 1; (b) Loading waveform 2

图6 放大后的两种波形下得到的疲劳断口形貌

Fig.6 Enlarged optical micrographs of specimens under two loading waveforms: (a) Loading waveform 1; (b) Loading waveform 2

图7 Ti-60合金疲劳试样的TEM像

Fig.7 TEM images of dislocations found in Ti-60 fatigued specimens under different loading waveforms: (a) Loading waveform 1, (b) Loading waveform 2

3 结论

1) 峰值应力处保载的疲劳条件下试样的疲劳寿命明显低于无保载疲劳条件下试样的疲劳寿命,单位周次内循环累积变形也明显高于无保载条件的。

2) 无保载疲劳条件下疲劳裂纹源于样品次表面,而在峰值应力处有保载2 min的疲劳条件下,疲劳裂纹源于样品内部,两种裂纹源处均有平坦明亮小平面存在。

3) 疲劳断口附近位错平行排列,两种疲劳波形条件下都启动了(![]() 011)滑移系。

011)滑移系。

REFERENCES

[1] 刘建荣, 朱绍祥, 石卫民, 杨慧丽, 王清江, 刘羽寅, 杨 锐. 轧制工艺对Ti-60A棒材显微组织及拉伸性能的影响[J]. 稀有金属材料与工程, 2008, 37(3): 283-286.

LIU Jian-rong, ZHU Shao-xiang, SHI Wei-min, YANG Hui-li, WANG Qing-jiang, LIU Yu-yin, YANG Rui. Effect of rolling process on microstructure and tensile properties of Ti-60A alloy bars[J]. Rare Metal Materials and Engineering, 2008, 37(3): 283-286.

[2] HINES J A, PETERS J O. Microcrack propagation in Ti-6Al-4V alloys[C]//Fatigue behavior of titanium alloys. Warrendal, Pennsylvanial, US: TMS Titanium Committee, 1998, 10: 15-22.

[3] THOMPSON A W. Relations between microstructure and fatigue properties of alpha-beta titanium alloys[C]//Fatigue behavior of titanium alloys. Warrendal, Pennsylvanial, US: TMS Titanium Committee, 1998, 10: 23-30.

[4] IVANOVA S G, COHEN F S, BIEDERMAN R R, SISSON R D. Role of microstructure in the mean stress dependence of fatigue strength in Ti-6Al-4V alloy[C]//Fatigue behavior of titanium alloys. Warrendal, Pennsylvanial, US: TMS Titanium Committee, 1998, 10: 39-46.

[5] PETERS J O, SAUER C. Nucleation and propagation of fatigue cracks in beta-titanium alloys[C]//Fatigue behavior of titanium alloys. Warrendal, Pennsylvanial, US: TMS Titanium Committee, 1998, 10: 127-134.

[6] BACHE M R. A review of dwell sensitive fatigue in titanium alloys: the role of microstructure, texture and operating conditions[C]//4th International Conference on Fatigue Damage of Structural Materials. 2002, 9: 22-27.

[7] WHITE J, LORETTO M H, SMALLMAN R E. The effect of dwell on low cycle fatigue in IMI829 (Ti5331S)[C]//Proc 5th Int Conf on Titanium. D.G.M., Oberursel, Germany, 1984: 2297-2304.

[8] BACHE M R, COPE M, DAVIES H M, EVANS W J, HARRISON G. Dwell sensitive fatigue in a near alpha titanium alloy at ambient temperature[C]// 9th International Conference in Fracture (ICF9). 1997: 351-358.

[9] WOODFIELD A P, GORMANM D, SUTLIFF J A, CORDERMAN R R. Effect of microstructure on dwell fatigue behavior of Ti-6242[C]//Titatium’95-Science and Technology. Processings of the 8th World Conference on Titanium. Birminghan, UK, 1996: 1116-1123.

(编辑 袁赛前)

通信作者:杨丽娜;电话:024-83978842;E-mail:lnyang@imr.ac.cn