Creep behavior of SnAgCu solders with rare earth Ce doping

ZHANG Liang(张 亮)1, XUE Song-bai(薛松柏)1, GAO Li-li(皋利利)1, ZENG Guang(曾 广)1,

CHEN Yan(陈 燕)2, YU Sheng-lin(禹胜林)1,3, SHENG Zhong(盛 重)1

1. College of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China;

2. Harbin Welding Institute, Harbin 150080, China;

3. The 14th Research Institute, China Electronics Technology Group Corporation, Nanjing 210013, China

Received 27 February 2009; accepted 22 June 2009

Abstract:

Extensive testing was carried out to study the effects of rare earth Ce doping on the properties of SnAgCu solder alloys. The addition of 0.03% (mass fraction) rare earth Ce into SnAgCu solder may improve its mechanical properties, but slightly lower its melting temperature. The tensile creep behavior of bulk SnAgCuCe solders was reported and compared with SnAgCu solders. It is found that SnAgCuCe solders show higher creep resistance than SnAgCu alloys. Moreover, Dorn model and Garofalo model are successfully used to describe the creep behavior of SnAgCu and SnAgCuCe alloys. The parameters of the two creep constitutive equations for SnAgCu and SnAgCuCe solders are determined from separated constitutive relations and experimental results. Nonlinear least-squares fitting is selected to determine the model constants. The experimental data of the stress—creep strain rate curves are in good agreement with the theoretical ones.

Key words:

rare earth Ce; SnAgCu solder; creep behavior; constitutive equations;

1 Introduction

The mechanical properties of traditional SnPb solder alloys have been investigated widely and are well understood[1-3]. In recent years, environmental concerns, legislation, and even customer preference are driving the microelectronics industry towards implementation of lead-free solder alloys, although the Pb metal used for electronic solders is reported to be less than 1% of the total Pb consumption worldwide[4-7]. Among all lead-free solder alloys, the SnAgCu solder system, which has better thermo-mechanical properties compared with those of SnPb solder, is proven to be one of the promising candidates for electronic assembly[8-9]. In order to further improve the properties of SnAgCu solder alloys, rare earth elements were used. With the addition of rare earth, the wettability, mechanical properties and microstructure were all improved[10-12].

It has been confirmed previously that adding rare earth Ce can improve the mechanical properties of SnAgCu solder joints[13-14]; however, there is little literature report about reliability of SnAgCuCe solder joints. The mechanical properties of lead-free solders are highly influenced by their creep behavior due to their low melting points. However, these lead-free solders are often operated at temperatures higher than 0.5Tm (Tm, the melting point). Moreover, solder joints undergo the temperature cycle and power cycle during service. So, understanding creep behavior and mechanism is fundamental to design of reliable electronic joints, since thermal creep fatigue is the primary failure mechanism of soldered joints[15-16].

The objective of this work is to report the creep behavior of SnAgCu solders with rare earth Ce doping. SnAgCu is a eutectic solder that is used for electrical interconnections and die bonding.

2 Determination of creep parameters

2.1 Experimental

The raw materials were pure Sn, Cu metals, SnAg, CuCe alloys with purity of 99.9%. In this study, SnAgCu alloys with the rare earth Ce content of 0.03% (mass fraction) were chosen. The raw materials of Sn, Cu, SnAg, CuCe were placed in a ceramic crucible, and were melted at (550±1) ℃ for 40 min. To homogenize the solder alloys, mechanical stirring was performed every 10 min using a glass rod. During the melting, KCl+LiCl(1.3?1, mass ratio) were used to cover the surface of liquid solder to prevent oxidation. The melted solder was chill cast into rods. Finally, they were solidified by air-cooling. The tensile tests of SnAgCu and SnAgCuCe were carried out at different temperatures (25 ℃, 50 ℃, 75 ℃ and 100 ℃). At each temperature, different strain rates were used. The solders were cast to solid rods with 18 mm in diameter and 128 mm in length and the bars were machined to specimens with the shape and dimensions shown in Fig.1. Specimens have a gage length of 50 mm and a diameter of 10 mm, and have two pyramid collars at both ends of gage part. An extensometer was attached to the two pyramid collars for measuring the elongation of the gage part during test. All solder specimens were heat treated at 373 K for 1 h to stabilize the microstructure of the solder alloys. These specimens were then polished with 1 μm diamond paste.

Fig.1 Sample shape and dimensions for tensile test

2.2 Creep model

In this work, the dependence of steady-state creep rate, ![]() , on applied stress (σ) and the temperature (T) can be characterized using the Dorn power equation[17-18] in the following form:

, on applied stress (σ) and the temperature (T) can be characterized using the Dorn power equation[17-18] in the following form:

![]() (1)

(1)

where ![]() is the creep rate; D0 is a constant; G is the shear module; b is the Burgers vector; d is the grain size; σ is the applied stress; n is the stress exponent; A1 and p are constants relevant to the microstructure; Q is the creep-active energy; R is the gas constant; and T is absolute temperature. Q and n are two important mechanical and thermodynamic parameters for describing the creep deformation of solders.

is the creep rate; D0 is a constant; G is the shear module; b is the Burgers vector; d is the grain size; σ is the applied stress; n is the stress exponent; A1 and p are constants relevant to the microstructure; Q is the creep-active energy; R is the gas constant; and T is absolute temperature. Q and n are two important mechanical and thermodynamic parameters for describing the creep deformation of solders.

Eq.(1) can be further simplified as

![]() (2)

(2)

Taking logarithms of both sides of Eq.(2), we obtain the simplified transformation:

![]() (3)

(3)

After taking the partial derivative of both sides of Eq.(3) with respect to lnσ, the stress exponent can be written as

![]() (4)

(4)

After taking the partial derivative of both sides of Eq.(3) with respect to ![]() , there is a following approximation[19-20]:

, there is a following approximation[19-20]:

![]() (5)

(5)

Eq.(2) can be transferred:

![]() (6)

(6)

Eq.(6) can be transferred:

![]() (7)

(7)

Therefore, lnA is the intercept of the straight line of ![]() on the y-axis, and the slope of this straight line is just the best-fit of exponent parameter n.

on the y-axis, and the slope of this straight line is just the best-fit of exponent parameter n.

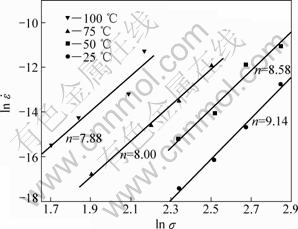

Creep deformation mechanisms are identified by the values of the stress exponent n and the activation energy Q[21]. Dislocation creep occurs as a result of glide and climb of edge dislocations. The steady-state creep rates at different levels of load were plotted against their respective stress on a double logarithm scale. Fitting four data points was used to calculate the line slope to determine the stress exponent. It should be noted that the stress exponent at a certain temperature is the apparent exponent, which needs to be best fitted. The final exponent is the best-fit exponent. In Fig.2 and Fig.3, the slope of each fitted straight line represents the value of stress exponent n, for SnAgCu and SnAgCuCe solder alloys at a given temperature. It has been recognized that the value of stress exponent n is an index of creep deformation mechanism. Based on the deformation mechanism map and previous studies[22-23], higher values of stress exponent (n=8.2 for SnAgCu, n=8.0 for SnAgCuCe, Fig.4 and Fig.5) were observed for lead-free solders, implying a creep deformation mechanism related to and dominated by a dispersion-strengthening mechanism, such as Orowan mechanism.

Fig.2 ![]() curves to calculate stress exponents of bulk SnAgCu solder

curves to calculate stress exponents of bulk SnAgCu solder

Fig.3 ![]() curves to calculate stress exponents of bulk SnAgCuCe solder

curves to calculate stress exponents of bulk SnAgCuCe solder

Fig.4 ![]() curves to calculate creep-active energy of bulk SnAgCu solder

curves to calculate creep-active energy of bulk SnAgCu solder

Fig.5 ![]() curves to calculate creep-active energy of bulk SnAgCuCe solder

curves to calculate creep-active energy of bulk SnAgCuCe solder

Determination of activation energy was made by stepped, load creep tests. The specimen was immersed in a constant temperature bath and loaded until a steady-state creep rate is achieved. Then, the load was removed, and the specimen was immersed in another constant temperature bath. About 0.5 h later, thermal equilibrium was ensured at the new temperature, and the same load was applied again and maintained until the state was obtained, and so on. The activation energy for creep, Q, is determined from a plot of ![]() against reciprocal of absolute temperature. The slope of the line is just the measurement of (-Q/R), where R is the gas constant. The plots are shown in Fig.6 and Fig.7 for SnAgCu and SnAgCuCe solders. The calculated value of Q is 71 kJ/mol for SnAgCu solder, and 80 kJ/mol for SnAgCuCe solder.

against reciprocal of absolute temperature. The slope of the line is just the measurement of (-Q/R), where R is the gas constant. The plots are shown in Fig.6 and Fig.7 for SnAgCu and SnAgCuCe solders. The calculated value of Q is 71 kJ/mol for SnAgCu solder, and 80 kJ/mol for SnAgCuCe solder.

Fig.6 ![]() curves to calculate creep parameters of bulk SnAgCu solder

curves to calculate creep parameters of bulk SnAgCu solder

Fig.7 ![]() curves to calculate creep parameters of bulk SnAgCuCe solder

curves to calculate creep parameters of bulk SnAgCuCe solder

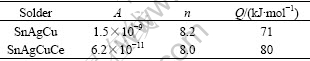

The parameters of Dorn model determined by iterative multivariable nonlinear fitting to the SnAgCu and SnAgCuCe solders are given in Table 1. The activation energy Q of the SnAgCuCe solder is much larger than that of the SnAgCu eutectic solder. A difference is likely due to the presence of the fine intermetallic compound particles in the β-Sn matrix.

Table 1 Creep parameters of solders with Dorn model

Many scholars[24-26] have proposed Garofalo-Arrhenius model to describe material steady-state creep behavior and stress—strain relations:

![]() (8)

(8)

where γ is the creep shear strain; ![]() is the creep shear strain rate; t is the time (s); C is a material constant; G is the temperature-dependent shear modulus; T is the absolute temperature (K); ω defines the stress level; τ is the shear stress (Pa); n is the stress exponent; Q is the activation energy; and R is Boltzmann constant.

is the creep shear strain rate; t is the time (s); C is a material constant; G is the temperature-dependent shear modulus; T is the absolute temperature (K); ω defines the stress level; τ is the shear stress (Pa); n is the stress exponent; Q is the activation energy; and R is Boltzmann constant.

If the solder materials obey the von Mises criterion, the equation can be rearranged and express as

![]() (9)

(9)

where C1, C2, C3 and C4 are material parameters; σ is the equivalent stress (Pa); T is the absolute temperature; and ![]() is the equivalent creep strain rate. Data are fitted by iterative multivariable nonlinear regression method similar to that of Dorn model. Table 2 provides the parameters of the Garofalo-Arrhenius model.

is the equivalent creep strain rate. Data are fitted by iterative multivariable nonlinear regression method similar to that of Dorn model. Table 2 provides the parameters of the Garofalo-Arrhenius model.

Table 2 Creep parameters of solders with Garofalo-Arrhenius model

3 Verification of creep behavior

Fig.8 shows the best fit between the experimental data and the creep constitutive models for SnAgCu solders. As the representative results, in Fig.8 and Fig.9, the Dorn model and Garofalo model can be used to describe the creep deformation behavior of SnAgCu and SnAgCuCe solders, respectively. The calculated result is found to be in agreement with that obtained from experiments at special temperature and strain rate. In addition, the data present here suggest that the creep behavior of SnAgCu and SnAgCuCe solders is dominated by the behavior of tin, and has anomalous temperature dependence at temperatures slightly above room temperature. In conclusion, these creep models are suitable to represent the deformation behavior well.

Fig.8 Comparison of creep rates between creep model and experimental results of SnAgCu solders: (a) Dorn model; (b) Garofalo model

Fig.9 Comparison of creep rates between creep model and experimental results of SnAgCuCe solders: (a) Dorn model; (b) Garofalo model

HUANG[27] demonstrated that the Sn3.8Ag0.7Cu alloy showed much lower absolute creep rates than 63Sn37Pb. Furthermore, it has been reported that the reliability of Sn3.8Ag0.7Cu soldered joints was better than that of 63Sn37Pb micro-joints[28]. Therefore, SnAgCu alloy can be regarded as the most promising lead free substitute for the conventional SnPb solder. Fig.10 shows that the creep strain rate of SnAgCu and SnAgCuCe solders under different stress amplitudes. Adding the rare earth Ce decreases the creep strain rate of the Sn3.8Ag0.7Cu solders, reflecting the increase of the creep-fatigue resistance in the solder joint to some extent. It has been reported[29-30] that adding a small amount of rare earth, for example, La and Ce, can evidently increase the creep-fatigue rupture lifetime of the lead-free solder joint, and the increase in creep-fatigue property can be attributed to the reduction of the creep-fatigue damages and the change of microcrack propagation sites during the fracture process, which depends on the refinement of intermetallic compounds due to the rare earth elements. Based on the present study, it can be concluded that the addition of rare earth Ce in SnAgCu solder alloys has potential to improve alloys properties, making the resulting alloy a better alternative for SnPb solder replacement.

Fig.10 Steady-state creep rates vs stress of lead-free solder alloys

4 Conclusions

1) Creep experiments on SnAgCu and SnAgCuCe solders have been conducted systematically. The creep behavior of these solders in tensile is a complex function of stress and temperature. The SnAgCuCe solders show a superior anti-creep property over SnAgCu alloys.

2) The experimental data are successfully fitted with Dorn model and Garofalo model. In addition, in service, solder joints bearing micro-amounts of rare earth elements experience high homologous temperatures. These creep models are essential for assessing lead-free alloys performance under similar in-service conditions, and they provide crucial input to finite element models that examine the structural integrity of lead-free solder joints bearing micro-amounts of rare earth elements.

References

[1] HAN Zong-jie, XUE Song-bai, WANG Jian-xin, ZHANG Xin, ZHANG Liang, YU Sheng-lin, WANG Hui. Mechanical properties of QFP micro-joints soldered with lead-free solders using diode laser soldering technology [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 814-818.

[2] WU Yu-xiu. Research on the reliability of soldered joints and optimum simulation for QFP gull wing lead sizes [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2007. (in Chinese)

[3] MA Xin. Analysis of mechanical and metallurgical factors relative to the failure of microelectronic surface mount solder joint [D]. Harbin: Harbin Institute of Technology, 2000. (in Chinese)

[4] PEI Min. Effects of lanthanum doping on the microstructure and mechanical behavior of a SnAg alloy [D]. Georgia: Georgia Institute of Technology, 2007.

[5] ZHANG Liang, XUE Song-bai, HAN Zong-jie, WANG Jian-xin, GAO Li-li, SHENG Zhong. Mechanical properties of fine pitch devices soldered joints based on creep model [J]. Chinese Journal of Mechanical Engineering, 2008, 21(6): 82-85.

[6] NURMI S, SUNDELIN J, RISTOLAINEN, LEPIST? T. The effect of solder paste composition on the reliability of SnAgCu joints [J]. Microelectronics Reliability, 2004, 44(3): 485-494.

[7] PANG J H L, LOW T H, XIONG B S, XU L H, NEO C C. Thermal cycling aging effects on Sn-Ag-Cu solder joint microstructure, IMC and strength [J]. Thin Solid Films, 2004, 462/463(9): 370-375.

[8] HAO Hu, SHI Yiao-wu, XIA Zhi-dong, LEI Yong-ping, GUO Fu. Microstructure evolution of SnAgCuEr lead-free solders under high temperature aging [J]. Journal of Electronic Materials, 2008, 37(1): 2-8.

[9] ZHANG Liang, XUE Song-bai, LU Fang-yan, HAN Zong-jie, WANG Jian-xin. Numerical simulation of soldered joints and reliability analysis of PLCC components with J-shape leads [J]. China Welding , 2008, 17(2): 37-41.

[10] YU D Q, ZHAO J, WANG L. Improvement on the microstructure stability, mechanical and wetting properties of Sn-Ag-Cu lead-free solder with the addition of rare earth elements [J]. Journal of Alloys and Compounds, 2004, 376(1/2): 170-175.

[11] LAW C M T, WU C M L, YU D Q, WANG L, LAI J K L. Microstructure, solderability, and growth of intermetallic compounds of SnAgCu-RE lead-free solder alloys [J]. Journal of Electronic Materials, 2006, 35(1): 89-93.

[12] RAMIREZ A G, MAVOORI H, JIN S. Bonding nature of rare-earth-containing lead-free solders [J]. Applied Physical Letters, 2002, 80(3): 338-340.

[13] ZHANG Liang, XUE Song-bai, ZENG Guang, GAO Li-li, CHEN Yan, SHENG Zhong, YU Sheng-lin. Effects of cerium on microstructure and properties of SnAgCu solders [J]. Journal of the Chinese Rare Earth Society, 2009, 27(2): 246-250. (in Chinese)

[14] ZHANG Liang, XUE Song-bai, CHEN Yan, HAN Zong-jie, WANG Jian-xin, YU Sheng-lin, LU Fang-yan. Effects of rare earths on Sn-Ag-Cu alloys based on finite element simulation and experiments [J]. Journal of Rare Earths, 2009, 27(1): 138-144.

[15] XIAO Q, NGUYEN L, ARMSTRONG W D. Anomalously high tensile creep rates from thin cast Sn3.9Ag0.6Cu lead-free solder [J]. Journal of Electronic Materials, 2005, 34(7): 1065-1075.

[16] CHEN Zhi-gang, SHI Yiao-wu, XIA Zhi-dong. Constitutive relations on creep for SnAgCuRE lead-free solder joints [J]. Journal of Electronic Materials, 2004, 33(9): 964-971.

[17] ZHANG X P, YU C B, ZHANG Y P, SHRESTHA S, DORN L. Processing treatment of a lead-free Sn-Ag-Cu-Bi solder by rapid laser-beam reflowing and creep property of its soldered connection [J]. Journal of Materials Processing Technology, 2007, 192/193: 539-542.

[18] CHOI S, LEE J G, GUO F, BIELER T R, SUBRAMANIAN K N, LUCAS J P. Creep properties of Sn-Ag solder joints containing intermetallic particles [J]. Journal of the Minerals, Metals and Materials Society, 2001, 53(6): 22-26.

[19] ZHANG X P, SHRESTHA C B Y S, DORN L. Creep and fatigue behaviors of the lead-free Sn-Ag-Cu-Bi and Sn60Pb40 solder interconnections at elevated temperatures [J]. Journal of Materials Science: Materials in Electronics, 2007, 18(6): 665-670.

[20] WANG Feng-jiang. Study on mechanical properties and size effects of lead-free BGA solder joint by nanoidentation [D]. Harbin: Harbin Institute of Technology, 2006. (in Chinese)

[21] McCABE R J, FINE M E. Creep of tin, Sb-solution-strengthened tin, and SbSn-precipitate-strengthened tin [J]. Metallurgical and Materials Transaction A, 2002, 33(5): 1531-1539.

[22] LIN C K, CHU D Y. Creep rupture of lead-free Sn-3.5Ag and Sn-3.5Ag-0.5Cu solders [J]. Journal of Materials Science: Materials in Electronics, 2005, 16(6): 355-365.

[23] JOO D K, YU J, SHIN S W. Creep rupture of lead-free Sn-3.5Ag-Cu solders [J]. Journal of Electronic Materials, 2003, 32(6): 541-547.

[24] LAI Y S, WANG T H. Verification of submodeling technique in theromechanical reliability assessment of flip-chip package assembly [J]. Microelectronics Reliability, 2005, 45(3/4): 575-582.

[25] TSENG S C, CHEN R S, LIO C C. Stress analysis of lead-free solders with under bump metallurgy in wafer level chip scale package [J]. The International Journal of Advanced Manufacturing Technology, 2006, 31(1/2): 1-9.

[26] WANG T H, LAI Y S, WU J D. Effect of underfill thermomechanical properties on thermal cycling fatigue reliability of flip-chip ball grid array [J]. Journal of Electronic Packaging, 2004, 126(4): 560-564.

[27] HUANG Ming-liang. Development of lead-free solder alloys in electronic packaging [D]. Dalian: Dalian University of Technology, 2001. (in Chinese)

[28] ZHANG Liang, XUE Song-bai, LU Fang-yan, HAN Zong-jie. Finite element analysis on soldered joints reliability of QFP with different solders [J]. Transactions of the China Welding Institution, 2007, 28(10): 45-48, 52. (in Chinese)

[29] CHEN Zhi-gang. Study on the creep behavior of SnAgCuRE solder joints [D]. Beijing: Beijing University of Technology, 2003. (in Chinese)

[30] WU C M L, YU D Q, LAW C M T, WANG L. Properties of lead-free solder alloys with rare earth additions [J]. Materials Science and Engineering R, 2004, 44(1): 1-44.

Foundation item: Project(BCXJ09-07) supported by Doctoral Dissertation Innovation and Excellence Producing Foundation of Nanjing University of Aeronautics and Astronautics, China; Project(CX07B_087z) supported by the Jiangsu General Colleges and Universities Postgraduate Scientific Research Innovative Plan, China

Corresponding author: XUE Song-bai; Tel: +86-25-84896070; Fax: +86-25-52112626; E-mail: xuesb@nuaa.edu.cn

DOI: 10.1016/S1003-6326(09)60155-2