Mechanical properties and corrosion resistance of low rigidity quaternary titanium alloy for biomedical applications

Han-Cheol CHOE, Viswanathan S. SAJI, Yeong-Mu KO

Department of Dental Materials, College of Dentistry, Chosun University, Gwangju, 501-759, Korea

Received 8 July 2008; accepted 10 March 2009

Abstract:

Electrochemical corrosion of Ti-35Nb-5Ta-7Zr alloy fabricated by arc melting and heat treatment process was studied in 0.9% NaCl at (37±1) ℃. Phase and microstructure of the fabricated alloy were investigated using X-ray diffractometer and scanning electron microscope. Mechanical properties such as yield strength and elastic modulus of the alloy were determined by tensile test. Potentiodynamic polarization technique and impedance spectroscopy were employed to study the corrosion behavior. The results of the study were compared with those obtained for Ti-6Al-4V commercial alloy. The result of the study supports feasibility of Ti-35Nb-5Ta-7Zr alloy for implant applications.

Key words:

Ti-35Nb-5Ta-7Zr; biomaterial; mechanical properties; corrosion;

1 Introduction

Quaternary β titanium alloys of Ti-Nb-Ta-Zr system receive high attention as orthopedic and dental implant materials because of their very low elastic modulus analogous to human bone and excellent biocompatibility [1-8]. The aim of developing such low elastic modulus titanium alloys was to decrease the elastic modulus difference between the bone (10-30 GPa) and the implant material, thereby promoting load sharing between them[9]. When insufficient load sharing occurs, natural bone resorption and loosening of the joint may occur[10]. Major quaternary alloys of Ti-Nb-Ta-Zr system investigated include Ti-4Nb-4Ta-15Zr[3], Ti-29Nb-13Ta-4.6Zr[4-5] and Ti-35Nb-5Ta-7Zr[1, 8]. Among them, Ti-35Nb-5Ta-7Zr has a lower elastic modulus(55 GPa) than other alloys and can be considered one of the best choices for orthopedic implants[1, 11]. However, reported works on corrosion behavior of such quaternary alloys are limited[3, 7, 12].

In the present work, Ti-35Nb-5Ta-7Zr alloy was fabricated by arc melting and heat treatment process. Mechanical characterization of the prepared alloy was done by micro-hardness measurement and tensile test. Methods such as open circuit potential measurement, potentiodynamic and potentiostatic polarization, and impedance spectroscopy(EIS) were employed to study the corrosion behavior of the alloy in deaerated 0.9% NaCl at (37±1) ℃. The results of electrochemical studies were compared with those obtained for Ti-6Al-4V commercial alloy.

2 Experimental

The alloy was fabricated by arc melting with non- consumable tungsten electrode and water cooled copper hearth under ultra pure argon atmosphere. Commercially high pure Ti, Nb, Ta and Zr were employed for this purpose. All the ingots were melted and inverted 10 times in order to homogenize the chemical composition of the alloy. To stabilize the β phase and to homogenize the microstructure, the cast alloy was heat treated at 1 000 ℃ for 2 h in Ar atmosphere, followed by water quenching. The homogenized alloy was sectioned, mounted using epoxy, polished by silicon carbide papers of different grades from 100 to 2 000 and finally polished with alumina.

The phase structure and chemical composition of the alloy were identified by X-ray diffractometry(XRD, X’pert Pro, Philips, Netherlands) using a Cu Kα radiation and energy dispersive spectroscopy(EDS, JXA-8900M, Jeol, Japan), respectively. Chemical etching was performed using HF+HCl+HNO3+H2O solution and the microstructure was observed with optical microscope (OM, Olympus BX 60MF, Japan) and scanning electron microscope (FE-SEM Hitachi 4800, Japan).

Micro-hardness was measured using Vickers micro- hardness tester (AFFRI, DM2D, Italy). Tensile tests were carried out using a universal testing machine (AGS- 1000, Shimadzu, Japan) as per ASTM E8. Elastic modulus was determined according to ASTM E111.

Electrochemical studies were carried out using a potentiostat/galvanostat (EG&G, 263A) and electro- chemical impedance spectroscopy (EIS, EG&G, 1025). A conventional three electrode system with high density graphite as counter electrode and saturated calomel electrode(SCE) as reference was used. The electrolyte was 0.9% (mass fraction) NaCl, prepared in doubly de-ionized water. The sample was mounted on a cold mount epoxy resin. The sample edges were carefully covered with epoxy to avoid the possible crevice attack. The electrolyte was de-aerated with high purity Ar gas for 30 min before starting the experiment. De-aeration was continued at a uniform rate during the experiment and the solution was subjected to mild stirring using a magnetic stirrer. The scan rate used for potentiodynamic polarization was 1.667 mV/s. Potentiostatic polarization experiments were performed at 300 mV (corresponding to the maximum potential occurring in the mouth environment). EIS studies were performed on the potentiostatically polarized samples. The frequency range used for EIS studies was 10-1-105 Hz. The amplitude of AC signal was 10 mV and 5 points per decade were used. The similar three electrode set-up was employed.

For comparison, Ti-6Al-4V commercial alloy was also studied for its corrosion behavior in similar experimental conditions. The Ti-6Al-4V alloy was heat treated at 1 000 ℃ for 12 h followed by water quenching.

3 Results and discussion

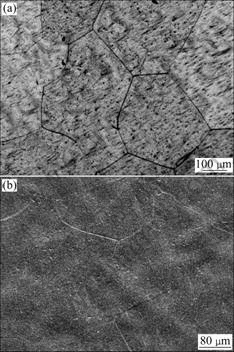

The chemical composition of the alloy as determined by EDS was w(Ti)?w(Nb)?w(Ta)?w(Zr)=51.6? 35.5?5.1?7.8. Fig.1 shows representative OM and SEM images of the alloy investigated after chemical etching. The micrographs revealed equiaxed β grains. The black spots in the optical image correspond to the pits developed during etching. An X-ray analysis (not shown here) revealed distinct peaks of body centered cubic, (110), (200), (211) and (220), corresponding to single β phase. From the phase diagram[13] and the heat treatment followed in this study, it was inferred that the β phase was retained completely. However, the presence of early stage athermal ω phase formation has been detected through TEM observation in quaternary β titanium alloys [13].

Fig.1 Representative OM (a) and SEM (b) micrographs of Ti-35Nb-5Ta-7Zr alloy

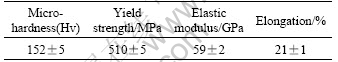

Mechanical characterization of the prepared alloy was done by hardness and tensile test. Micro-hardness measurements were carried out with a load of 0.98 N applied for 30 s. Tensile tests were carried out with a cross-head speed of 8.33×10-6 m/s in air at room temperature. Three measurements were carried out under the same experimental conditions and the average values obtained are shown in Table 1. The properties are in agreement with the reported values[13-14]. It has been reported that the dynamic modulus of the quaternary alloys is the minimum when Zr content was 5% (molar fraction) and Nb-to-Ta molar ratio was 12[11]. Tensile strength and elastic modulus of Ti-6Al-4V lie in the range of 890-930 MPa and 110-114 GPa, respectively [15].

Table 1 Mechanical properties

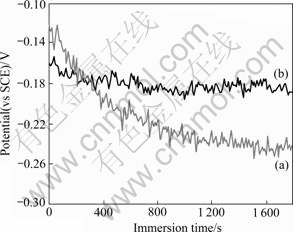

Fig.2 represents the variation of open circuit potential(OCP) of Ti-35Nb-5Ta-7Zr alloy as a function of immersion time in 0.9% NaCl. For comparison, the plot obtained for the Ti-6Al-4V alloy is also shown in the same graph. The initial OCP of the quaternary alloy was about -0.12 V and gradually reached a steady state value of -0.23 V. The steady state OCP of Ti-6Al-4V alloy (about -0.18 V) was nobler than that of the quater- nary alloy.

Fig.2 OCP as function of immersion time for Ti-35Nb-5Ta-7Zr (a) and Ti-6Al-4V (b)

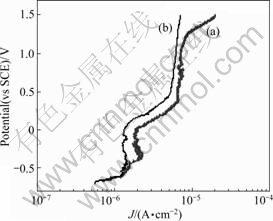

Potentiodynamic anodic polarization plots obtained for the quaternary and ternary alloys are shown in Fig.3. An immersion period of 30 min was given for stabilization of OCP before starting the experiment. An initial passivation region was observed in both alloys when being polarized above -0.50 V. A stable passive region appeared at about 0.50 V. This passive region was characterized by a current density of the order of 10-6 A/cm2 for both the quaternary and ternary alloys, indicating high corrosion resistance. However, the passivation current density of the ternary alloy was nobler. The further increase in current density observed at about 1.5 V for the quaternary alloy probably corresponds to the passive film breakdown.

Fig.3 Potentiodynamic anodic polarization plots of Ti-35Nb- 5Ta-7Zr (a) and Ti-6Al-4V (b)

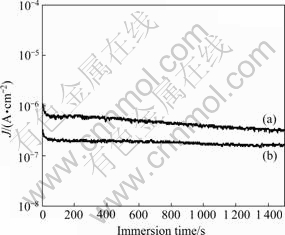

Fig.4 represents the potentiostatic polarization plots obtained at 300 mV for the two alloys. The current densities were in the order of 10-6, indicating typical passive behaviour. The current density for the quaternary alloy was marginally higher compared with the ternary alloy.

Fig.4 Potentiostatic polarization plots of Ti-35Nb-5Ta-7Zr (a) and Ti-6Al-4V (b)

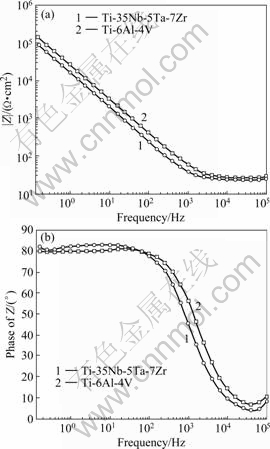

Non-destructive EIS studies were carried out for the potentiostatically polarized samples and the results are shown in Fig.5. The impedance behavior of the quaternary and ternary alloy was same, indicating a similar nature of passivation. This can be due to the fact that TiO2 based passivation is controlling by the interface. High impedance values of the order of 106 Ω?cm2 were obtained at low and medium frequencies, suggesting high corrosion resistance of the alloys in the electrolyte. Phase shift plot exhibited pure capacitive behavior with one time constant. The phase angle in the middle and high frequency regions was nearly 90?, indicating single and compact passive layer at the interface.

Fig.5 Bode plots of Ti-35Nb-5Ta-7Zr and Ti-6Al-4V

The α+β Ti-6Al-4V alloy is the most worldwide utilized titanium alloy for biomedical applications. However, the release of Al and V ions from Ti-6Al-4V alloy was reported to be toxic and their accumulation in the body was of great concern[16]. Also the alloy has comparatively higher modulus than that of natural bone, which is unfavorable for bone healing and remodeling. The quaternary alloy has an added advantage of biocompatible alloying elements and low elastic modulus.

The lower corrosion resistance property obtained for the quaternary alloy compared with the ternary alloy in this study may be attributed to the differences in the heat treatments followed. However, earlier studies suggested that pure β phases may possess lower corrosion resistance[17]. Hence, more works are suggested to investigate the effect of heat treatment conditions on the corrosion resistance of Ti-35Nb-5Ta- 7Zr alloy.

4 Conclusions

Microstructure and mechanical properties of β type Ti-35Nb-5Ta-7Zr alloy fabricated by arc melting and heat treatment process were studied. Corrosion behavior of the alloy was investigated along with Ti-6Al-4V commercial alloy in 0.9% NaCl solution.

1) The mechanical properties and corrosion resistance obtained for the quaternary alloy suggest that the alloy is suitable for biomedical applications.

2) The corrosion resistance of the Ti-35Nb-5Ta-7Zr alloy is marginally inferior to Ti-6Al-4V commercial alloy.

References

[1] TADDEI E B, HENRIQUES V A R, SILVA C R M, CAIRO C A A. Production of new titanium alloy for orthopedic implants [J]. Mater Sci Eng C, 2004, 24: 683-687.

[2] OKAZAKI Y, GOTOH E. Comparison of metal release from various metallic biomaterials in vitro [J]. Biomaterials, 2005, 26: 11-21.

[3] OKAZAKI Y. A new Ti-15Zr-4Nb-4Ta alloy for medical applications [J]. Current Opinion in Solid State and Materials Science, 2001, 5: 45-53.

[4] NIINOMI M, AKAHORI T, MORIKAWA K, KASUGA T, SUZUKI A, FUKUI H, NIWA S. Development of low rigidity β type titanium alloy for biomedical applications [J]. Materials Transactions, 2002, 43: 2970-2977.

[5] NIINOMI M. Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti-29Nb-13Ta-4.6Zr [J]. Biomaterials, 2003, 24: 2673-2683.

[6] SAKAGUCHIA N, NIINOMI M, AKAHORI T, TAKEDA J, TODA H. Effect of Ta content on mechanical properties of Ti-30Nb-XTa- 5Zr [J]. Mat Sci Eng C, 2005, 25: 370-376.

[7] KARTHEGA M, RAMAN V, RAJENDRAN N. Influence of potential on the electrochemical behavior of beta titanium alloys in Hank’s solution [J]. Acta Biomaterialia, 2007, 3: 1019-1023.

[8] QAZI J I, MARQUARDT B, RACK H J. High strength metatable beta titanium alloys for biomedical applications [J]. JOM, 2004, 56(11): 49-51.

[9] LONG M, RACK H J. Titanium alloys in total joint replacements—A materials science perspective [J]. Biomaterials, 1998, 19: 1621- 1639.

[10] SUMNER D R, GALANTE J O. Determinants of stress shielding: Design versus materials versus interface [J]. Clinical Orthopedics and Related Research, 1992, 274: 202-212.

[11] ASTM designation draft #3. Standard Specification for Wrought Titanium-35Nb-7Zr-5Ta Alloy for Surgical Implant Applications (UNS R58350) [S]. ASTM, Philadelphia, PA, 2000.

[12] RAMAN V, NAGARAJAN S, RAJENDRAN N. Electrochemical impedance spectroscopic characterization of passive film formed over β-Ti-29Nb-13Ta-4.6Zr alloy [J]. Electrochemical Communications, 2006, 8: 1309-1314.

[13] TANG X, AHMED T, RACK H J. Phase transformations in Ti-Nb-Ta and Ti-Nb-Ta-Zr alloys [J]. Journal of Materials Science, 2000, 35: 1805-1811.

[14] ELIAS L M, SCHNEIDER S G, SCHNEIDER S, SILVA H M, MALVISI F. Microstructural and mechanical characterization of biomedical Ti-Nb-Zr(-Ta) alloys [J] Mat Sci Eng A, 2006, 432: 108-112.

[15] BALAZIC M, KOPAC J, JACKSON M J, AHMED W. Review: Titanium and titanium alloy applications in medicine [J]. International Journal of Nano and Biomaterials, 2007, 1: 3-34.

[16] JATSY M. Clinical reviews: Particulate debris and failure of total hip replacements [J]. Journal of Applied Biomaterials, 1993, 4: 273-276.

[17] ROSA S, BARBOSA P F, BUTTON S T, BERTAZZOLI R. In vitro corrosion resistance study of hot worked Ti-6Al-7Nb alloy in isotonic medium [J]. Brazilian Journal of Chemical Engineering, 2001, 18: 47-59.

Corresponding author: Han-Cheol CHOE; Tel: +82-62-230-6896; E-mail: hcchoe@chosun.ac.kr

DOI: 10.1016/S1003-6326(08)60365-9