J. Cent. South Univ. (2018) 25: 2360-2372

DOI: https://doi.org/10.1007/s11771-018-3920-7

Texture features analysis on micro-structure of paste backfill based on image analysis technology

YIN Sheng-hua(尹升华)1, 2, SHAO Ya-jian(邵亚建)1, 2, WU Ai-xiang(吴爱祥)1, 2, WANG Yi-ming(王贻明)1, 2, GAO Zhi-yong(高志勇)1, 2

1. School of Civil and Resource Engineering, University of Science and Technology Beijing,Beijing 100083, China;

2. Key Laboratory of Ministry of Education for Efficient Mining and Safety of Metal Mines(University of Science and Technology Beijing), Beijing 100083, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract:

The strength of cement-based materials, such as mortar, concrete and cement paste backfill (CPB), depends on its microstructures (e.g. pore structure and arrangement of particles and skeleton). Numerous studies on the relationship between strength and pore structure (e.g., pore size and its distribution) were performed, but the micro-morphology characteristics have been rarely concerned. Texture describing the surface properties of the sample is a global feature, which is an effective way to quantify the micro-morphological properties. In statistical analysis, GLCM features and Tamura texture are the most representative methods for characterizing the texture features. The mechanical strength and section image of the backfill sample prepared from three different solid concentrations of paste were obtained by uniaxial compressive strength test and scanning electron microscope, respectively. The texture features of different SEM images were calculated based on image analysis technology, and then the correlation between these parameters and the strength was analyzed. It was proved that the method is effective in the quantitative analysis on the micro-morphology characteristics of CPB. There is a significant correlation between the texture features and the unconfined compressive strength, and the prediction of strength is feasible using texture parameters of the CPB microstructure.

Key words:

Cite this article as:

YIN Sheng-hua, SHAO Ya-jian, WU Ai-xiang, WANG Yi-ming, GAO Zhi-yong. Texture features analysis on micro-structure of paste backfill based on image analysis technology [J]. Journal of Central South University, 2018, 25(10): 2360–2372.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-018-3920-71 Introduction

Cemented paste backfill (CPB) is a homogeneous material in which tailings are bonded together by the hardened cement. Its components (tailings, water, cement) are mixed in a plant usually located on the ground of mine [1-5]. Cemented paste backfill is potentially one of the best practical approaches for the management of process tailings and is widely used by the modern mines all over the world since it alleviates the environmental impact of potentially hazardous mill tailings by their safe disposal into the underground (up to 60%–75% of the plant tailings), the support of underground stopes to provide a safe working environment and to minimize surface subsidence, as well as the reduction of the tailings disposal and rehabilitation costs [6-10].

An important parameter in judging the quality of backfill body is its uniaxial compressive strength (UCS) [11]. Indeed, the UCS is often used in the practice to evaluate its stability of structural integrity since the test is relatively inexpensive and can be incorporated into routing quality control programs at the mine [12]. Nevertheless, the UCS test is a one-time destructive experiment with no repeatability. So, how to predict the strength of the filling body by the nondestructive testing method has been the focus of the researchers. The UPV test method employs the principle of measuring the travel velocity of ultrasonic pulses through a material medium [13, 14]. High compactness of materials corresponds high travel velocity of ultrasonic pulses and denser cement-based materials have higher compression strength [15]. Therefore, the change of ultrasonic pulses in velocity should also correspond to the increase or decrease in the strength of cement-based materials. The hydration process of cement has a significant effect on cement-based materials. ER measurement can quantify the hydration process of cement due to the ion transport through the pore solution and hydration products media [14], so it is able to predict the strength of the cement-based materials. No matter the level of materials compaction or the degree of cement hydration, it will be reflected in the microstructures of cement-based materials.

It is recognized that the strength of cement-based materials, such as mortar, concrete and CPB, depends on its microstructures [16-18]. Numerous studies on the relationship between the strength and the pore structure (e.g., pore size and its distribution) were performed [19]. However, micro-morphology characteristics (e.g. the arrangement of particles) have been rarely concerned. YILMAZ et al [20, 21] and GHIRIAN et al [22] have pointed out that the arrangement of particles and skeleton plays an important role in the strength of CPB. But, there is limited study of quantitative analysis for this property. Texture describing the surface properties of the image corresponding to the sample is a global feature, which represents the features of the graphics area, rather than the characteristics of each pixel [23]. Texture analysis is an effective means of investigating the surface morphology characteristics. And, it is a comprehensive indicator to reflect the pore structure and the arrangement of particles and skeleton in microstructure. TOWNSEND et al [24] performed a comprehensive analysis for surface measurement technology and surface texture characterization pertained to surface metrology of metal additive manufacturing, and suggested the possible optimization of these methods in future research. AZAMI et al [25] proposed a new quantitative approach of texture feature-bidimensional distribution entropy to more efficiently quantify the irregularity of the image. The new way can detect different amounts of noise (e.g. white Gaussian and pepper noise) from textures and improve efficiency of texture analysis. For reaching a desired functionality and durability of constructed and existing concrete structures, SADOWSKI et al [26] presented the fundamentals and basic scale of metrology of concrete surface morphology, and proposed a new measurement to quantify the characterization of heterogeneous concrete surface. STOLZ et al [27] investigated the substrates texture of the contact area with different concentrations of air-entraining admixture and assessed the influence of the substrate texture of the mortars on the shear and tensile bond strength of rendering mortars. UKAR et al [28] elucidated that the fractures in the rock have significant texture features, and the advances in delineating textures could provide evidence for growth and occlusion of fractures porosity.

Among statistical methods, Tamura texture and gray level co-occurrence matrix (GLCM) features are the most representative methods for characterizing the texture features [29]. Tamura texture is an intuitive description of image morphology, which is built on the visual perception Psychology of human. The parameters of Tamura texture effectively describe the macroscopic characteristics (coarseness, contrast, directionality, linearity, regularity, roughness, etc.) in ocular. GLCM is a second-order statistics methods to represent the (local) information about image. Features of GLCM are derived from statistical analysis of the relative frequency of the occurrence of pairs of gray level values. In this paper, taking the cross-section texture characteristics and compressive strength of cement paste backfill with different concentration as the research objects, the Tamura texture and the gray level co-occurrence matrix of the cross-section SEM image were calculated, analyzed the correlation between the texture characteristic parameters and the solid concentration was analyzed and the parameters that effectively reflect the morphological changes from multiple texture features parameters were determined. Finally, it is verified that there is a significant correlation between texture parameters and unconfined compressive strength (UCS), and the method is effective in the quantitative analysis on the micro-morphology characteristics of cement paste backfill.

2 Materials and methods

2.1 Materials

The tailing sample was obtained from an underground copper mine located in the central of China. Particle size analysis indicated that the tailings can be classified as fine-grained tailings and similar to “Lean clay” [30]. The binder was the one currently used in the mine, the ordinary Portland cement (P.C 42.5, according to Chinese standard: GB175–2007).

2.2 CPB preparation

CPB samples (more than 20 in total) were prepared from the tailings sample, binder and mix water (tap water). Solid concentrations (72%, 76%, and 78%) were considered for preparing cement paste. The cement-sand ratio was 1: 12.

The dry mixture was combined with water in a planetary mortar mixer (Model No. JJ-5) for approximately 12 min. When the mixtures were completely mixed well, the slump of paste was tested as described in the ASTM C143 standard [31], and as the concentration increases, the slump values were 27.2, 23.5 and 14.3 cm, respectively. Then, CPB mixtures were cast into the standard mold (70.7 mm×70.7 mm×70.7 mm). After the molds were filled, the mixtures were rammed in 25 blows using a small steel rod in order to eliminate any large trapped air bubbles within CPB. Specimens were removed from the molds after 48 h and were left to cure for the desired days in the standard conservation box (Model No. JBY-60B) with constant temperature (20 °C±1 °C) and humidity (90% relative humidity). More details can be found in the literature [32].

2.3 Strength and SEM images acquisition

Following a predetermined period (up to 90 d) of curing, the CPB samples were tested for uniaxial compressive strength (UCS). Each group of strength tests required more than five specimens. After that, fractured samples obtained from UCS tests were examined under a scanning electron microscope (SEM). The samples were dried in an oven maintained at 50 ℃ and, then treated with acetone to halt further hydration prior to the SEM analysis [33, 34].

2.4 Texture feature extraction

2.4.1 Tamura texture extractor

TAMURA et al [35] proposed the Tamura texture based on the visual perception psychology. These features of Tamura texture correspond to the attributes of psychological texture features, which are the coarseness, contrast, directionality, linearity, regularity and roughness.

1) Coarseness

(i) Calculate the average at every point in local region on the image, the region sizes are 2k×2k, e.g.

Table 1 Chemical composition of binders and tailings

Table 2 Physical properties of binders and tailings

k=1, 2, …, 5. Its calculation formula is:

(1)

(1)

where f(i,j) is the gray-level at the point (x, y).

(ii) Calculate the deviation in both horizontal and vertical orientations

(2)

(2)

(iii) Determine the size of the calculation region

(3)

(3)

(iv) Calculate the coarseness

(4)

(4)

(5)

(5)

2) Contrast

The contrast is the moment of inertia about the main diagonal of the gray matrix. Its calculate equation is

(6)

(6)

where p(i, j) is the (i, j) th entry of the n×n gray-level spatial dependence matrix.

3) Directionality

(i) Calculate gradient of each pixel including horizontal gradient ΔH and vertical gradient ΔV, which represents the horizontal and vertical differences between pixels measured by following Eq. (7), respectively. In other words, the horizontal gradient equals the sum of three differences in grey values between the left and right pixels, while the vertical gradient is the deviation between up and down pixels following Eq. (8).

equals the sum of three differences in grey values between the left and right pixels, while the vertical gradient is the deviation between up and down pixels following Eq. (8).

(7)

(7)

(8)

(8)

(ii) Calculate the gradient vector

(9)

(9)

The resultant f is a real number (0≤f<π) measured counter clock wise.

(iii) Calculate the histogram HD(k)

(10)

(10)

where Nf(k) is the proportion of pixels at which and |ΔG|>t. In order to prevent counting of unreliable directions, the |ΔG| value is determined by the value of t. Previous studies have proven that the shape of HD(k) is not sensitive to the t value, so we take t=12 and n=16.

and |ΔG|>t. In order to prevent counting of unreliable directions, the |ΔG| value is determined by the value of t. Previous studies have proven that the shape of HD(k) is not sensitive to the t value, so we take t=12 and n=16.

(iv) Calculate the directionality of the image by summing the values changes surrounded the peak. More details can be found in the literature [35].

(11)

(11)

4) Linearity

The calculation formula of linearity is

(12)

(12)

where PDd is the n×n local direction co-occurrence matrix of points at distance.

5) Regularity

The regularity can be calculated using the fallowing equation.

(13)

(13)

where r is a normalizing factor and each σx means the standard deviation of Fx.

6) Roughness

Roughness reflects the influence of coarseness and contrast, and it can be obtained by using the following measures:

(14)

(14)

2.4.2 GLCM feature extractor

Grey level co-occurrence matrix characterizes the texture by calculating how often pairs of pixel with specific values and in a specified spatial relationship occur in an image, which has been widely used for quantitative analysis of image [29, 36]. Surface characteristics of the CPB image of scanning electrical microscopy (SEM) [37] can be measured quickly by the following method.

Grey level co-occurrence matrix is the spatial relation between pixels located at a certain distance (d) and from a given direction (θ) from the reference pixel. The elements of the matrix correspond to the relative frequency of occurrence of pairs of gray level values i and j of pixels separated by the spatial relation. The {I(x, y), 0<<>

(15)

(15)

where  and |·| is the cardinality of a set.

and |·| is the cardinality of a set.

HARALICK et al extracted 11 texture features from gray level co-occurrence matrix (GLCM). The paper only takes the most representative five texture features, including energy (or the angular second moment), contrast, correlation, entropy and variance.

1) Energy,

(16)

(16)

2) Contrast,

(17)

(17)

3) Correlation,

(18)

(18)

where μx, μy, σx and σy are the mean and the standard deviation of Px and Py .

4) Entropy,

(19)

(19)

5) Variance

(20)

(20)

3 Results and discussion

3.1 SEM images of test samples

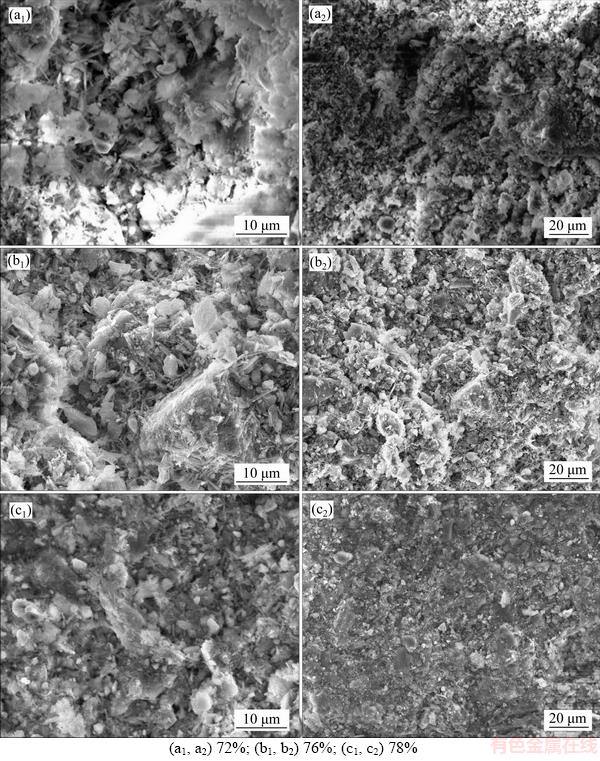

Electronic images obtained by scanning electron microscope are copied into a computer for unified processing, which was cut into 512×512 pixels, 256 grays scale. The results of electron microscopy are shown in Figure 1. The mechanical properties of CPB are greatly affected by its physical (bulk or geotechnical index) properties (e.g. water content, void ratio, wet unit weight or specific gravity, and degree of saturation). The solids concentration (or initial water content) of the CPB mixtures is undoubtedly the fundamental factor affecting its physical properties. The most intuitive effect of solid concentration is to change the porosity of the CBP. The figure shows that, with increasing of solid concentration, the void ratio of CPB gradually decrease and the surface of CPB section gradually flattened, no matter whether it was magnified 10000 times or 2000 times.

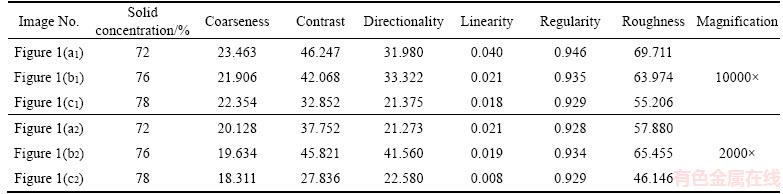

3.2 Tamura texture parameters

The features acquisition of Tamura texture was performed on the MATLAB software. We wrote the calculation program and calculated six features of the Tamura texture, i.e., coarseness, contrast, directionality, linearity regularity and roughness. Table 3 lists the calculated results of the test samples.

Among the Tamura texture features, part texture features (i.e. contrast, linearity, regularity and roughness) showed a significant correlation with the solid concentration, but the correlation of the remaining parameters (i.e., coarseness and directionality) was not obvious as shown in Figure 2. Analysis shows that the sensitivity of the coarseness is relatively low compared with other parameters such as contrast, linearity etc. The maximum coarseness of high magnification image was 23.463 and the minimum was 21.906 (Figure 2(a)). The concentration increased from 72% to 78%, the coarseness change of the high- and low-magnification image was only 6.64% and 9.03%, respectively. However, the corresponding change of the contrast was 28.96% and 39.43%. Directionality of gray scale image refers to the orientation of morphology and relates to the sharpness of gray-peaks. Perhaps the sharpness of gray-peaks is not obvious in the CPB SEM image, so the directionality does not vary according to certain rules as the concentration increases. Roughness is calculated based on the coarseness and contrast. In other words, the coarseness and contrast can reflect the characteristic of roughness. According to the aforementioned analysis, contrast, linearity and regularity of the Tamura texture were selected as the target parameters for quantitative analysis.

Figure 1 SEM images with different solid concentrations:

Table 3 Tamura texture parameters of test samples

In terms of observing scale, the correlation coefficient (i.e. R2) between the textures features and the solid concentration from the high magnification image (mag. 10000×) is bigger than that from the low magnification image (mag. 2000×). It is obvious that taking the images magnified 10 000 times as the object of analysis is more helpful to improve the reliability of quantitative analysis.

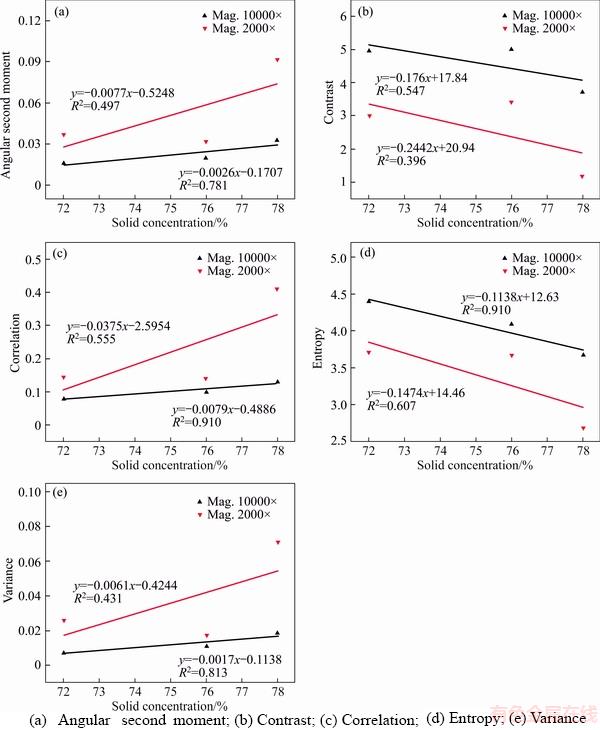

3.3 GLCM feature parameters

The parameters acquisition of GLCM was also performed on the MATLAB software. The field of calculation was taken 16×16 window. The distance between the pixels was taken d=1, the angle of direction taking θ=0°, 45°, 90°, 135°. Then five characteristic parameters (i.e., energy, contrast, correlation, entropy, and variance) of GLCM were calculated using calculation program written by the author. Table 4 lists the calculated results of the test samples.

Among the GLCM characteristic parameters, energy, correlation, entropy and variance showed a significant correlation with the solid concentration, but the correlation of the contrast was not obvious as shown in Figure 3.

Figure 2 Tamura texture parameters with different solid concentrations:

Table 4 GLCM characteristic parameters

The correlation coefficient (i.e., R2) between the contrast and the solid concentration of the high- and low-magnification image were only 0.547 and 0.396, respectively. Analogous to the directionality of the Tamura texture, maybe the contrast does not change according to certain rules as the concentration increases. According to the aforementioned analysis, energy, correlation, entropy and variance of the GLCM were selected as the target parameters for quantitative analysis.

In terms of observing scale, the correlation coefficient (i.e., R2) between the GLCM characteristic parameters and the solid concentration from the high magnification image is bigger than the low magnification image. Therefore, the image magnified 10000 times is also used as samples for quantitative analysis.

3.4 Relationship between strength and texture features

In order to illustrate the relationship between the Tamura texture features of SEM image of CPB section and the unconfined compressive strength (UCS). The Tamura texture features and UCS of the CPB with different solid concentrations were obtained and shown in Figure 4. It can be noted that there are significant negative correlations between the strength (UCS) and Tamura texture features (contrast, linearity and regularity), the correlation coefficients (i.e. R2) between them are very high (>98.0%). Meanwhile, each of them obeys different laws, for example, the correlation between linearity and strength may be power law, while that between regularity and strength perhaps is a linear relationship.

The GLCM characteristic parameters and UCS of the CPB with different solid concentration were obtained and shown in Figure 5. There are significant correlations between the strength (UCS) and GLCM characteristic parameters (energy, correlation, entropy and variance), the correlation coefficients (i.e., R2) between them are higher than 92.8%. Similar to the Tamura texture features, each of the correlations is following different laws. For example, the correlation between angular second moment/variance and strength may be logarithmic law, while that between correlation/entropy and strength perhaps is linear relationship.

3.5 Texture features discussion on micro- structure of paste backfill

At a certain cement dosage and curing age, the porosity (and hence density) of the paste backfill is determined solely by the solid concentration or water-to-solids ratio (w/s) of materials [10, 38]. The distribution of pores in the image show a certain texture features. CPB with low solid concentration has high porosity and thus more voids or pores present in the SEM image [39, 40]. Therefore, the number of pores at different solid concentration affects the texture characteristics. Meanwhile, after mixing of cement and water the hydration process begins. As a result, adhesion of hydrated products in the cemented-based materials is developed. This band effect among particles engenders an arrangement of tailings particles and thus a skeleton structure change in micro-structure [6, 18]. The changed arrangement leads to surface roughness and waviness in the SEM image and results in transformation of texture. Note that during this arrangement process, the cement is in a saturated or supersaturated state. When the initial solid concentration of materials is increased, more free water is present in pore-structure and the hydrated products are more difficult to achieve the concentration of precipitation [32]. So, the solid concentration determines the saturation degree and affects the hydration process. The level of hydration process impacts the band effect, which cause the change of texture features of micro structure [26].

Figure 3 GLCM characteristic parameters with different solid concentrations:

Figure 4 Unconfined compressive strength of CPB with different Tamura texture features:

Figure 5 Unconfined compressive strength of CPB with different GLCM characteristic parameters:

The mechanical properties of any backfill material are greatly affected by its physical (bulk or geotechnical index) properties, such as water content, void ratio, wet unit weight or specific gravity, and degree of saturation [41]. These geotechnical indexes are reflected in the microscopic morphology [26, 28], such as flatness or ruggedness, smoothness or roughness, regularity or randomness, et al. Texture features, regardless Tamura texture or GLCM texture, can effectively quantify these morphological characteristics and are able to predict the mechanical strength of CPB. But, not all texture parameters of Tamura texture and GLCM texture can effectively characterize the texture features of paste materials due to the level of the sensitivity of parameters. For Tamura texture, the effective parameters to predict the USC of paste are the contrast, linearity and regularity and for GLCM texture they are the angular second moment, correlation, entropy and variance, as shown in Figures 4 and 5.

4 Conclusions

This study indicates that significant texture features of micro-structure of CPB samples prepared at different solid concentrations were discovered based on image analysis technology and the obvious correlation between these texture features and strength was investigated. Overall, there is a positive correlation between strength and solid concentration of the paste specimen. First, the correlation between texture characteristics and solid concentration was analyzed and the effective characteristic parameters were selected. And then the relationship between these selected parameters and mechanical strength was analyzed and the existence of correlation was proved. Based on the experimental results, the conclusions were as follows:

1) Two texture features methods (Tamura texture features and GLCM features) were analysed on the SEM images of paste materials. Not all parameters of these texture features presented correlations to the solid concentration of paste and thus a part of these parameters are useful to quantify the paste microstructure. For the Tamura texture features, the useful parameters are contrast, linearity and regularity and for GLCM features are angular second moment, correlation, entropy and variance.

2) The observation scale (or magnification) of the SEM image has a significant impact on the correlation between the texture properties and the solid concentration. Test results showed that correlation coefficient between the textures features and the solid concentration from the high magnification image (mag. 10000×) is bigger than that from the low magnification image (mag.2000×) regardless the Tamura texture features or GLCM features. Therefore, the 10000× magnified image should be selected as a sample for quantitative analysis of paste microstructure.

3) Experiments proved that there are significant correlations between the strength (UCS) and texture features regardless the contrast, linearity and regularity of Tamura texture features or angular second moment, correlation, entropy and variance of GLCM characteristic parameters, and each of them obeys different laws. Therefore, it is possible to predict the CPB strength using the microstructure texture parameters.

References

[1] ARGANE R, BENZAAZOUA M, HAKKOU R, BOUAMRANE A. Reuse of base-metal tailings as aggregates for rendering mortars: Assessment of immobilization performances and environmental behavior [J]. Construction and Building Materials, 2015, 96: 296–306. DOI: https://doi.org/10.1016/j.conbuildmat.2015.08.029.

[2] POKHAREL M, FALL M. Combined influence of sulphate and temperature on the saturated hydraulic conductivity of hardened cemented paste backfill [J]. Cement and Concrete Composites, 2013, 38: 21–28. DOI: https://doi.org/10.1016/ j.cemconcomp.2013.03.015.

[3] WU Di, CAI Si-jing. Coupled effect of cement hydration and temperature on hydraulic behavior of cemented tailings backfill [J]. Journal of Central South University, 2015, 22(5): 1956–1964. DOI: https://doi.org/10.1007/s11771-015-2715- 3.

[4] LI Xi-bing, DU Jing, GAO Li, HE Su-ya, GAN Lei, SUN Cheng, SHI Ying. Immobilization of phosphogypsum for cemented paste backfill and its environmental effect [J]. Journal of Cleaner Production, 2017, 156: 137–146. DOI: https://doi.org/10.1016/j.jclepro.2017.04.046.

[5] YILMAZ E, FALL M. Paste tailings management [M]. Berlin: Springer International Publishing, 2017: 7–32. DOI: https://doi.org/10.1007/978-3-319-39682-8_4.

[6] ERCIKDI B, KULEKCI G, YILMZA T. Utilization of granulated marble wastes and waste bricks as mineral admixture in cemented paste backfill of sulphide-rich tailings [J]. Construction and Building Materials, 2015, 93: 573–583. DOI: https://doi.org/10.1016/j.conbuildmat.2015.06.042.

[7] YIN Sheng-hua, WU Ai-xiang, HU Kai-jian, WANG Yong, ZHANG Yan-kai. The effect of solid components on the rheological and mechanical properties of cemented paste backfill [J]. Minerals Engineering. 2012, 35: 61–66. DOI: 1 https://doi.org/10.1016/j.mineng.2012.04.008.

[8] KE Xing, HOU Hao-bo, ZHOU Min, WANG Yan, ZHOU Xian. Effect of particle gradation on properties of fresh and hardened cemented paste backfill [J]. Construction and Building Materials, 2015, 96: 378–382. DOI: https://doi.org/ 10.1016/j.conbuildmat.2015.08.057.

[9] FALL M, CELESTIN J C, POKHAREL M, TOURE M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill [J]. Engineering Geology, 2010, 114(3, 4): 397–413. https://doi.org/10.1016/j.enggeo.2010.05. 016.

[10] YILMAZ E, BELEM T, BENZAAZOUA M, KESIMAL A, ERCIKDI B, CIHANGIR F. Use of high-density paste backfill for safe disposal of copper/zinc mine tailings [J]. Gospodarka Surowcami Mineralnymi, 2011, 27(3): 81–94. DOI: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element. baztech-article-BPZ1-0068-0025.

[11] WU Ai-xiang, HUANG Ming-qing, HAN Bin, WANG Yi-ming, YU Shao-feng, MIAO Xiu-xiu. Orthogonal design and numerical simulation of room and pillar configurations in fractured stopes [J]. Journal of Central South University, 2014, 21(8): 3338–3344. DOI: https://doi.org/10.1007/ s11771-014-2307-7.

[12] FALL M, SAMB S S. Effect of high temperature on strength and microstructural properties of cemented paste backfill [J]. Fire Safety Journal, 2009, 44(4): 642–651. DOI: https://doi.org/10.1016/j.firesaf.2008.12.004.

[13] YILMAZ T, ERCIKDI B. Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulse velocity test [J]. Nondestructive Testing & Evaluation, 2015, 31(3): 247–266. DOI: https://doi.org/ 10.1080/10589759.2015.1111891.

[14] XU Wen-bin, TIAN Xi-chun, CAO Pei-wang. Assessment of hydration process and mechanical properties of cemented paste backfill by electrical resistivity measurement [J]. Nondestructive Testing & Evaluation, 2017, (3): 1–15. DOI: https://doi.org/10.1080/10589759.2017.1353983.

[15] ERCIKDI B, YILMAZ T, KULEKCI G. Strength and ultrasonic properties of cemented paste backfill [J]. Ultrasonics, 2014, 54(1): 195–204. DOI: https://doi.org/ 10.1016/j.ultras.2013.04.013.

[16] YILMAZ E, BELEM T, BUSSIERE B, BENZAAZOUA M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills [J]. Cement and Concrete Composites, 2011, 33(6): 702–715. DOI: https://doi.org/ 10.1016/j.cemconcomp.2011.03.013.

[17] HE Yong-jia, MOTE J, LANGE D A. Characterization of microstructure evolution of cement paste by micro computed tomography [J]. Journal of Central South University, 2013, 20(4): 1115–1121. DOI: https://doi.org/10.1007/s11771- 013-1592-x.

[18] CIHANGIR F, AKYOL Y. Mechanical, hydrological and microstructural assessment of the durability of cemented paste backfill containing alkali-activated slag [J]. International Journal of Mining, Reclamation and Environment, 2016, 32(2): 1–21. DOI: https://doi.org/10.1080/ 17480930.2016.1242183.

[19] JIN Shan-shan, ZHANG Jin-xi, HAN Song. Fractal analysis of relation between strength and pore structure of hardened mortar [J]. Construction and Building Materials. 2017, 135: 1–7. DOI: https://doi.org/10.1016/j.conbuildmat.2016.12. 152.

[20] YILMAZ E. Investigating the hydrogeotechnical and microstrural properties of cemented paste backfill using the CUAPS apparetus [D] Quebec, Canada: University du Quebec en Abitibi-Temiscamingue, 2010. http://depositum. uqat.ca/34/.

[21] YILMAZ E, BELEM T, BUSSIERE B, MBONIMPA M, BENZAAZOUA M. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents [J]. Construction and Building Materials, 2015, 75: 99–111. DOI: https://doi.org/10.1016/ j.conbuildmat.2014.11.008.

[22] GHIRIAN A, FALL M. Coupled thermo-hydro-mechanical- chemical behaviour of cemented paste backfill in column experiments [J]. Engineering Geology, 2014, 170: 11–23. DOI: https://doi.org/10.1016/j.enggeo.2013.12.004.

[23] YU Hai-peng, LIU Yi-xiang, LIU Zhen-bo. Wood species restrieval on base of image textural festure [J]. Scientia Silvae Sinicae, 2007(4): 77–81. DOI: https://doi.org/ 10.3321/j.issn: 1001–1488. 2007.04.013. (in Chinese)

[24] TOWNSEND A, SENIN N, BLUNT L, LEACH R K, TAYLOR J S. Surface texture metrology for metal additive manufacturing: A review [J]. Precision Engineering, 2016, 46: 34–47. DOI: https://doi.org/10.1016/j.precisioneng.2016. 06.001.

[25] AZAMI H, ESCUDERO J, HUMEAU-HEURTIER A. Bidimensional distribution entropy to analyze the irregularity of small-sized textures [J]. IEEE Signal Processing Letters, 2017, 24(9): 1338–1342. DOI: https://doi.org/10.1109/ lsp.2017.2723505.

[26] SADOWSKI L, MATHIA T G. Multi-scale metrology of concrete surface morphology: Fundamentals and specificity [J]. Construction and Building Materials, 2016, 113: 613–621. DOI: https://doi.org/10.1016/j.conbuildmat.2016. 03.099.

[27] STOLZ C M, MASUERO A B, PAGNUSSAT D T, KIRCHHEIM A P. Influence of substrate texture on the tensile and shear bond strength of rendering mortars [J]. Construction and Building Materials, 2016, 128: 298–307. DOI: https://doi.org/10.1016/j.conbuildmat.2016.10.097.

[28] UKAR E, LAUBACH S E. Syn- and postkinematic cement textures in fractured carbonate rocks: Insights from advanced cathodoluminescence imaging [J]. Tectonophysics, 2016, 690: 190–205. DOI: https://doi.org/10.1016/j.tecto.2016. 05.001.

[29] ZAMRI M I A P, CORDOVA F, KHAIRUDDIN A S M, MOKHTAR N, YUSOF R. Tree species classification based on image analysis using Improved-Basic Gray Level Aura Matrix [J]. Computers and Electronics in Agriculture, 2016, 124: 227–233. DOI: https://doi.org/10.1016/j.compag.2016. 04.004.

[30] ASTM. D2487-11 standard practice for classification of soils for engineering purposes (unified soil classification system) [S]. 2011. DOI: https://www.astm.org/Standards/D2487.htm.

[31] ASTM. C143-90 standard test method for slump of hydraulic-cement concrete [S]. 2015. https://www.astm.org/ Standards/C143.htm.

[32] RAO Yun-zhang, SHAO Ya-jian, XIAO Guang-zhe, SUN Xiang, HUANG Yong-gang. Effect of polycarboxylate- based superplasticizer on performances of super fine tailings paste backfill [J]. The Chinese Journal of Nonferrous Metals, 2016, 26(12): 2647–1655. DOI: https://doi.org/10.19476/ j.ysxb.1004. 0609.2016.12.021. (in Chinese)

[33] FELIPE-SOTELO M, HINCHLIFF J, EANS N D M, READ D. Solubility constraints affecting the migration of selenium through the cementitious backfill of a geological disposal facility [J]. Journal of Hazardous Materials, 2016, 305: 21–29. DOI: https://doi.org/10.1016/j.jhazmat.2015.11.024.

[34] CIHANGIR F, ERCIKDI B, KESIMAL A, DEVECI H, ERDEMIR F. Paste backfill of high-sulphide mill tailings using alkali-activated blast furnace slag: Effect of activator nature, concentration and slag properties [J]. Minerals Engineering, 2015, 83: 117–127. DOI: https://doi.org/ 10.1016/j.enggeo.2014.11.015.

[35] TAMURA H, MORI S, YAMAWAKI T. Textural features corresponding to visual perception [J]. IEEE Transactions on Systems, Man, and Cybernetics, 1978, 8(6): 460–473. DOI: https://doi.org/10.1109/tsmc.1978.4309999.

[36] XIE Yong-hua, WANG Jin-cong. Study on the identification of the wood surface defects based on texture features [J]. Optik-International Journal for Light and Electron Optics, 2015, 126(19): 2231–2235. DOI: https://doi.org/10.1016/ j.ijleo.2015.05.101.

[37] TIEN Chuen-lin, LYU You-ru, JYU Shiao-shan. Surface flatness of optical thin films evaluated by gray level co-occurrence matrix and entropy [J]. Applied Surface Science, 2008, 254(15): 4762–4767. DOI: https://doi.org/ 10.1016/j.apsusc.2008.01.088.

[38] SUN Wei, WU Ai-xiang, HOU Ke-peng, YANG Yi, LIU Lei, WEN Yi-ming. Real-time observation of meso-fracture process in backfill body during mine subsidence using X-ray CT under uniaxial compressive conditions [J]. Construction and Building Materials, 2016, 113: 153–162. DOI: https://doi.org/10.1016/j.conbuildmat.2016.03.050.

[39] PIA G, SILIGARDI C, CASNEDI L, SANNA U. Pore size distribution and porosity influence on Sorptivity of ceramic tiles: From experimental data to fractal modelling [J]. Ceramics International, 2016, 42(8): 9583–9590. DOI: https://doi.org/10.1016/j.conbuildmat.2016.05.037.

[40] TANG S W, CAI X H, HE Z, ZHOU W, SHAO H Y, LI Z J, WU T, CHEN E. The review of pore structure evaluation in cementitious materials by electrical methods [J]. Construction and Building Materials, 2016, 117: 273–284. DOI: https://doi.org/10.1016/j.ceramint.2016.03.041.

[41] YILMAZ E, BELEM T, BENZAAZOUA M. Specimen size effect on strength behavior of cemented paste backfills subjected to different placement conditions [J]. Engineering Geology, 2015, 185: 52–62. DOI: https://doi.org/10.1016/ j.mineng.2015.08.022.

(Edited by HE Yun-bin)

中文导读

基于图像识别技术的膏体微观结构纹理特征分析

摘要:胶结充填膏体(CPB)、砂浆及混凝土等水泥基材料的力学强度取决于其微观结构,如孔隙数量、孔径及结构,颗粒及骨架的排列形态等。对于该类材料的力学强度与其孔隙结构(如孔径及其分布)的关系研究目前已有很多,但与微观形态特征或纹理特性的相关性研究较少。纹理是一种反映图像中同质现象的视觉特征,体现了物体表面共有的内在属性,包含了物体表面结构组织排列以及它们与周围环境的联系,是量化微观形态特性的有效方法。在统计分析中,灰度共生矩阵(GLCM)纹理和Tamura纹理是表征纹理特征的最具代表性方法。本研究以3种不同质量浓度膏体制备的充填体试块为样本,养护至指定龄期后经单轴抗压强度试验获得其力学强度,再对试块断面进行电镜扫描(SEM)获得其微观结构图像;基于图像识别/分析技术提取SEM图像的纹理特征参数,分析纹理特性与SEM图像参数(放大倍数)间的关系,筛选出有效的SEM图像样品;分析各纹理参数与膏体浓度的相关性,识别出与膏体浓度呈正相关的纹理参数,并验证该纹理参数与力学强度存在严格的相关关系。

关键词:微观结构;纹理特征;Tamura纹理;灰度共生矩阵;单轴抗压强度;定量分析;膏体充填

Foundation item: Project(51722401) supported by the National Natural Science Foundation for Excellent Young Scholars of China; Project(FRF-TP-18-003C1) supported by the Fundamental Research Funds for the Central Universities, China; Project(51734001) supported by the Key Program of National Natural Science Foundation of China

Received date: 2017-09-21; Accepted date: 2017-12-06

Corresponding author: SHAO Ya-jian, PhD Candidate; Tel: +86-17319149005, E-mail: ustbsyj@126.com; ORCID: 0000-0002-7561- 2728

Abstract: The strength of cement-based materials, such as mortar, concrete and cement paste backfill (CPB), depends on its microstructures (e.g. pore structure and arrangement of particles and skeleton). Numerous studies on the relationship between strength and pore structure (e.g., pore size and its distribution) were performed, but the micro-morphology characteristics have been rarely concerned. Texture describing the surface properties of the sample is a global feature, which is an effective way to quantify the micro-morphological properties. In statistical analysis, GLCM features and Tamura texture are the most representative methods for characterizing the texture features. The mechanical strength and section image of the backfill sample prepared from three different solid concentrations of paste were obtained by uniaxial compressive strength test and scanning electron microscope, respectively. The texture features of different SEM images were calculated based on image analysis technology, and then the correlation between these parameters and the strength was analyzed. It was proved that the method is effective in the quantitative analysis on the micro-morphology characteristics of CPB. There is a significant correlation between the texture features and the unconfined compressive strength, and the prediction of strength is feasible using texture parameters of the CPB microstructure.