DOI: 10.11817/j.ysxb.1004.0609.2020-35843

快速冷冲对喷射成形Al-Cu-Mg合金长片状S' 相的演变规律

范才河1, 3,范语楠2,胡泽艺1,欧 玲1, 3,阳建君1, 3

(1. 湖南工业大学 冶金与材料工程学院,株洲 412007;

2. 湘潭大学 材料科学与工程学院,湘潭 411105;

3. 安徽建业科技有限公司,淮北 235000)

摘 要:

采用高分辨透射电镜(TEM)、X射线衍射仪(XRD)、能谱仪(EDS)和硬度测试等手段,研究快速冷冲强变形过程中喷射成形细晶Al-Cu-Mg合金长片状S'相的演变规律。结果表明:挤压态Al-Cu-Mg合金在快速冷冲强变形过程中长片状S'相发生扭曲、脆断、回溶和缩颈,长片状S'相的形貌、尺寸、分布及与基体的取向关系发生显著变化,从有规律分布的长片状纳米析出相演变为无规律分布的短棒状S'相和弥散分布的颗粒状再析出相。长片状S'相的扭曲和脆断,显著增大析出相与铝基体的接触面,提高了析出相与铝基体的界面畸变能,促进了S'相的回溶,导致铝基体重新达到过饱和状态,从而发生再析出以降低基体自由能。挤压态Al-Cu-Mg合金在快速冷冲过程中合金硬度显著增加,由53HB增加到127HB,升高139.6%。

关键词:

文章编号:1004-0609(2020)-07-1544-08 中图分类号:TG146.21 文献标志码:A

Al-Cu-Mg合金因具有强度高、加工成形性及耐热性好等优点,已被广泛应用于航空航天及军工领域[1-2]。已有研究表明长片状钠米析出相S'相是低Cu/Mg比高强韧Al-Cu-Mg合金的主要强化相,强塑性变形(SPD)不仅可以改善铝合金S'相特征,如形貌、尺寸、分布及与基体的取向关系,还能改善铝合金微结构、获得微米甚至纳米级细晶组织[3-11]。STYLES等[12]研究Al-Cu-Mg合金过饱和固溶体的分解顺序与平衡相S相在合金中的形成关系,发现S相在高温下形成的时间远小于低温环境下的形成时间。杨培勇等[13]研究了外加应力对Al-Cu-Mg合金时效动力学及析出相形态的影响,发现外加应力通过改变竞争析出过程中S'相θ'相的力量对比来促进S'相的析出。NOURBAKHSH等[14]对A1-4%Cu合金进行大压下量冷轧后发现片状θ'相发生严重弯曲和破断。MURAYAMA等[15]在A1-Cu合金的等径挤压变形中观察到呈针状的θ′过渡相在数道次等径角挤压过程中逐步分解成短链状颗粒直至回溶进入基体。HUANG等[16]采用冷轧工艺改变低Cu/Mg比Al-Cu-Mg合金中的位错胞结构,获得了高密度细小弥散的S″相。ZHAO等[17]通过对2024铝合金进行冷轧变形,发现S相随着冷变形程度的增加不断转变为Ω相。张孜昭等[18-19]研究了多向压缩变形对Al-Cu合金析出相的影响,发现由强塑性变形诱导析出相回溶形成的过饱和固溶体,再析出相的析出顺序与加热温度、变形量及变形后的晶粒尺寸相关。

可见,强塑性变形对Al-Cu-Mg合金中纳米析出相特征有重要影响,但目前尚缺乏对这一领域的系统研究。为了阐明强塑性变形对长片状纳米析出相特征的影响规律,本实验基于喷射成形快速凝固细晶Al-Cu-Mg合金坯料,研究快速冷冲过程中Al-Cu-Mg合金长片状S'相演变规律,探索和分析长片状S'相的破断机制,旨在为制备高强韧Al-Cu-Mg合金薄壁件奠定理论基础。

1 实验

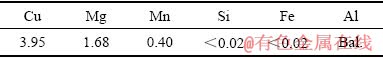

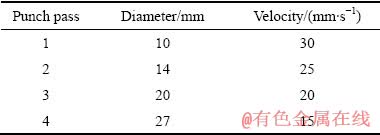

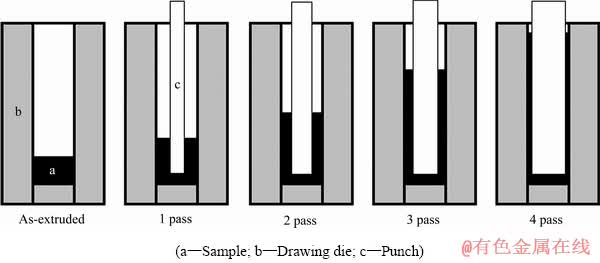

在自行研制的SD380大型喷射成形装置上制备喷射成形快速凝固细晶Al-Cu-Mg合金圆柱坯,合金的化学成分如表1所示。在1250T挤压机上将圆柱坯挤压成d 30 mm的圆棒,挤压温度为450 ℃,挤压比为15:1;在线切割机上将圆棒切割成d 30 mm×20 mm长的小圆柱,置于自行设计的冲压成型模具中进行4道次快速冷冲,快速冷冲的温度为25 ℃。快速冷冲过程示意图如图1所示,先将小圆柱试样置于模具中,采用第一个小冲头沿试样中心快速冷冲,完成第一道次快速冷冲成形,然后再更换另一个直径更大的冲头进行第二次冷冲成形,依次完成4道次快速冷冲,快速冷冲工艺参数如表2所示。

表1 实验样品的合金成分

Table 1 Compositions of alloy studied (mass fraction, %)

表2 快速冷冲工艺参数

Table 2 Technological parameter of rapid cold punching

在快速冷冲成型筒壁的1/2处截取一圆环,在圆环上选取试样进行微观组织观察和硬度测试。采用JEM-F200型透射电镜(TEM)分析试样的纳米析出相形貌、尺寸和分布,透射试样采用机械预减薄至80 μm左右后进行电解双喷,电解液为硝酸+甲醇(硝酸与甲醇体积比为1:3),温度低于-25 ℃。高角环形暗场扫描透射电镜(HAADF-STEM)观察的电镜参数如下:加速电压为200 keV,电子束半汇聚角为 0.01 rad,高角环形探头收集内半角为0.036 rad,束斑直径为 0.20 nm。采用D/max2500型18 kW转靶X射线衍射仪对试样进行物相分析,采用HBRV-187.5型电动布洛维硬度计测试试样的布氏硬度,每个试样测6个点取平均值,硬度测试的位置为筒壁外表面中间部位。

2 实验结果

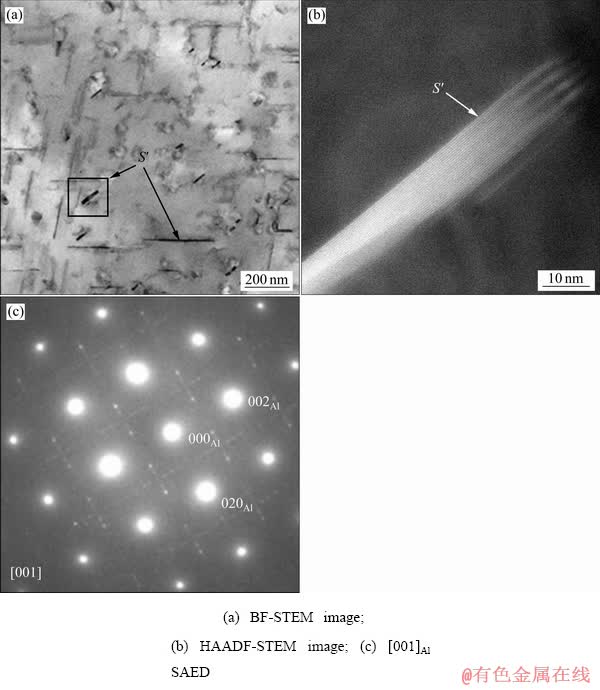

2.1 挤压态试样S'相特征

图2所示为挤压态Al-Cu-Mg合金的STEM像。图2(a)所示为挤压态合金中S'相的BF-STEM像,由图2(a)可见,挤压态合金中长片状S'相有规律地分布于铝基体中,长片状S'相的长度方向尺寸小于300 nm,析出相周围分布着一定数量的位错。图2(b)所示为沿着铝基体 方向观察到的长片状S'相的HAADF- STEM像,由图2(b)可见,S'相形状规则,沿长度方向与铝基体之间的界面平整。图2(c)所示为沿

方向观察到的长片状S'相的HAADF- STEM像,由图2(b)可见,S'相形状规则,沿长度方向与铝基体之间的界面平整。图2(c)所示为沿 晶带轴的电子衍射图,发现S'相与Al基体有很好的取向关系,[001]S'//[001]Al。

晶带轴的电子衍射图,发现S'相与Al基体有很好的取向关系,[001]S'//[001]Al。

2.2 快速冷冲过程中S'相演变

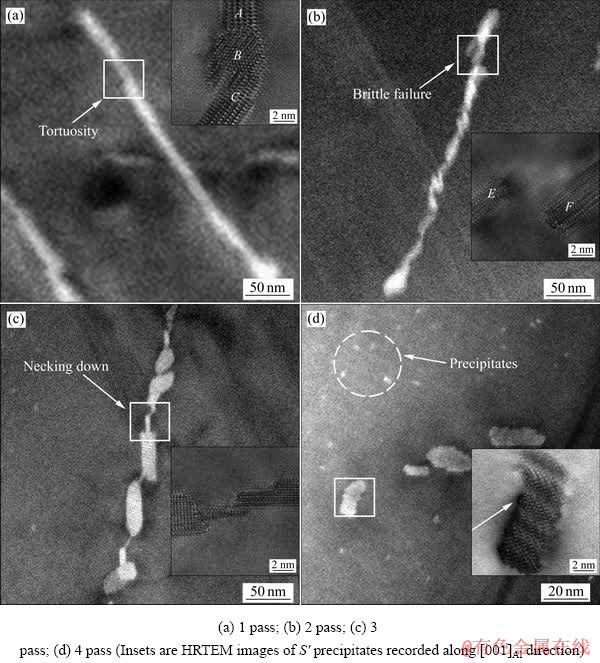

图3所示为挤压态Al-Cu-Mg合金在快速冷冲变形过程中长片状S'相演变过程的STEM像。由图3可见,在快速冷冲强变形过程中长片状S'相的形貌、尺寸、分布及与基体的取向关系均发生了明显变化,可明显地观察到扭曲、脆断、回溶和缩颈四种典型的演变机制。经1道次快速冷冲变形后,长片状S'相发生明显的扭曲(见图3(a)),S'相与铝基体间平直的界面基本消失,S'相上A、B、C 3个部分的原子排列方向发生偏移(见图3(a)中的插图)。经2道次快速冷冲变形后,长片状S'相扭曲更为严重,与基体的界面呈锯齿状(见图3(b)),部分区域发生脆断,E部分与F部分脆断后发生了一定程度的位移(见图3(b)中插图)。经3道次快速冷冲变形后,长片状S'相扭曲程度进一步加剧,破断部分加速与母体分离(见图3(c)),从TEM高倍明场像中可以观察到,长片状S'相部分区域在强塑性变形作用下发生回溶现象,出现了明显的“缩颈”,且“缩颈”两端部分趋向分离(见图3(c)中的插图)。经4道次快速冷冲变形后,挤压态试样中的长片状S'相在扭曲、脆断、回溶和缩颈的共同作用下发生破断,基本上全部破断成短棒状,导致铝基体中S'相尺寸明显变小,并在铝基体中呈无规律分布,同时,在铝基体中可清晰地观察到大量细小的颗粒状纳米析出相(见图3(d));在TEM高倍明场像中可以观察到,短棒状S'相上有明显的“回溶台阶”(见图3(d)中插图箭头所示)。

图1 快速冷冲合金试样示意图

Fig. 1 Sketch maps of rapid cold punching process

图2 挤压态Al-Cu-Mg合金的STEM图

Fig. 2 Microstructure of as-extruded Al-Cu-Mg alloy

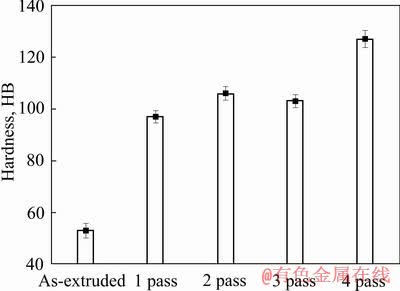

2.3 硬度变化

不同道次快速冷冲变形中Al-Cu-Mg合金的硬度变化曲线如图4所示。由图4可见,挤压态合金在快速冷冲变形过程中硬度值得到显著提高,由53HB增加到127HB,升高139.6%。硬度值增长最快的两个阶段是第1道次和第4道次快速冷冲变形,第2、3道次合金硬度值略有增加,但增长幅度小,尤其是第3道次快速冷冲过程中,合金硬度值还出现了小幅下降。

3 分析和讨论

3.1 快速冷冲过程中S'相破断机制

本实验中,快速冷冲变形工艺具有三大特点:变形温度低(25 ℃)、应变量大、应变速率高。根据 PUGH的一般性准则和相关研究表明,Al2CuMg相是典型的脆性相[20-21]。因此,结合本实验结果,快速冷冲强变形诱导挤压态Al-Cu-Mg合金中长片状S'相的破断机制主要如下。

图3 不同道次快速冷冲后Al-Cu-Mg合金中S'相HAADF-STEM像

Fig. 3 HAADF-STEM images of S' precipitates in Al-Cu-Mg alloy samples undergoing different passes

图4 不同道次快速冷冲变形中Al-Cu-Mg合金硬度变化 曲线

Fig. 4 Hardness as function of various passes of rapid cold punching process

1) 扭曲和脆断。长片状S'相作为挤压态Al-Cu-Mg合金的主要强化相,有规律地分布于铝基体中,S'相与铝基体界面平整(见图2)。在快速冷冲强变形过程中,较软的铝基体率先发生剧烈的剪切变形,导致较硬的长片状S'相在强烈的剪切变形力作用下发生扭曲,当扭转达到一定程度时,脆性S'相发生脆断,在E与F之间形成脆断面(见图3(b))。

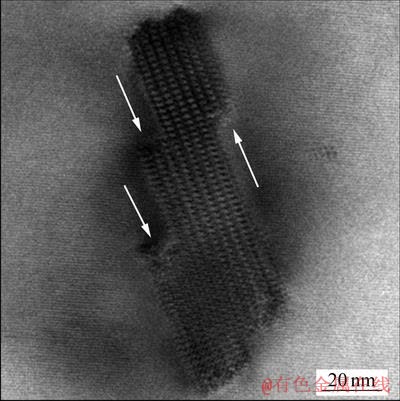

2) 回溶和缩颈。由图3(d)中的插图可见,在脆断的S'相上可清晰地观察到“回溶台阶”,“回溶台阶”是S'相在合金强塑性变形过程中发生扭曲和脆断的产物,这是因为长片状S'相的扭曲和破断显著提高了 S'相与铝基体的界面畸变能,导致S'相畸变能高的部位的溶质原子更易发生回溶。S'相上局部的加速回溶,导致该区域S'相的尺寸明显减小,即形成“缩颈”(见图3(c)),“缩颈”的产生进一步增大析出相与铝 基体的界面畸变能,从而加速“缩颈”处的回溶直至消失,“缩颈”的消失导致析出相两个部分的分离,从而形成大量短棒状颗粒相分布在铝基体中(见图3(d))。

3.2 快速冷冲过程中S'相回溶再析出机制

随着长片状S'相的扭曲和脆断,脆断面明显增加,这显著增大了析出相与铝基体的接触面,提高了析出相与铝基体的界面畸变能,为溶质原子回溶至基体创造了扩散条件,加快了快速冷冲强变形过程中S'相的回溶。快速冷冲过程中S'相上的回溶台阶如图5所示。S'相上的“回溶台阶”越多,破断颗粒与铝基体的接触面就越大,溶质原子的扩散就越容易。依据经典的热力学观点[22],在任何一个温度下,晶体中都有一定的平衡空位浓度存在,且它们总是不断地移动位置,空位的存在和移动为原子扩散创造了条件。本实验合金在快速冷冲强变形过程中,位错密度显著增加,位错在交割和运动时将在基体中产生大量的空位,而且每经一道次快速冷冲变形,就会产生大量新的空位。同时,长片状S'相在快速冷冲强变形过程中不断扭曲和破断,在增加S'相与铝基体接触界面的同时,也会伴随着大量空位的产生。文献[19, 23]中的研究表明,强变形过程中空位数量的剧增,溶质原子的扩散速度可提高5个数量级,体积扩散可提高8个数量级。其次,本实验合金采用喷射成形快速凝固技术制备,晶粒细小,组织均匀,平均晶粒尺寸5 μm左右,合金在快速冷冲强变形过程中,晶粒进一步细化成纳米级,因而晶界面积显著增大,这也为析出相的回溶提供了原子扩散通道,大大促进了析出相的回溶。

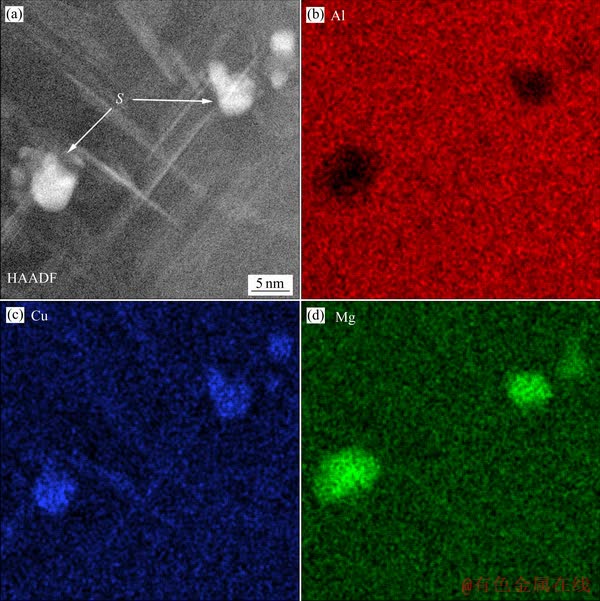

本实验研究结果表明,挤压态Al-Cu-Mg合金中主要析出相S'相经4道次快速冷冲强变形后,发生明显的再析出形为(见图3(d)),这说明当强塑性变形达到一定程度时,S'相的回溶和再析出同时进行,且析出相不是长片状S'相,而是颗粒状S相,如图6所示。

图5 快速冷冲3道次后Al-Cu-Mg合金中S'相的BF-STEM像

Fig. 5 BF-STEM image of S' precipitates in Al-Cu-Mg alloy samples undergoing 3 pass

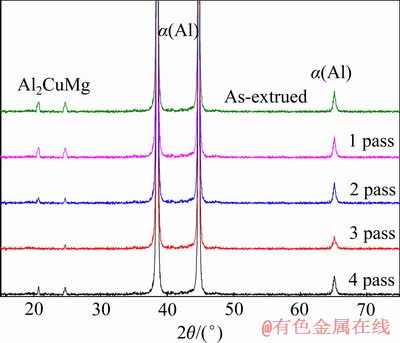

图7所示为不同道次快速冷冲变形过程中Al-Cu-Mg合金的XRD谱,这与图3的研究结果一致。可见,本实验合金在强变形过程中,长片状S'相破断后造成畸变自由能提高,再加上冷变形过程中储存的形变能,促进了S'相的回溶,基体重新出现过饱和度,这为溶质原子的集聚及再析出相的形核提供了条件。再析出相的析出是在快速冷冲强塑性变形条件下进行的,因而合金的原子间距、晶格畸变及位错密度将发生显著变化,导致过饱和度的基体处于高能态,从而发生再析出以降低基体自由能,其驱动力主要为形变能。同时,本实验合金的再析出是在低温、高应变和高应变速率条件下进行的,此时已经产生严重晶格畸变的基体很难生成具有共格和半共格关系的GP区和过渡相,因为过渡相与基体的界面关系会引起合金应变能进一步增大,导致自由能变高,使析出不能自发进行,因此在晶界形成与基体没有共格关系的平衡相有利于降低自由能。采用第一性原理可以计算出S′相的结合能Ecoh和形成焓 [20-21]:

[20-21]:

(1)

(1)

(2)

(2)

式中: 为每一种金属间化合物平均每个原子的能量;

为每一种金属间化合物平均每个原子的能量; 和

和 为自由原子A和B的能量;

为自由原子A和B的能量; 和

和 为稳定单质A和B中平均每个原子的能量;xA表示化合物中A的摩尔分数。

为稳定单质A和B中平均每个原子的能量;xA表示化合物中A的摩尔分数。

3.3 纳米析出相的回溶及再析出对力学性能的影响

由图4可见,挤压态Al-Cu-Mg合金在多道次快速冷冲变形过程中,合金硬度的变化经历了前期快速增长、中期小幅波动增长和后期再快速增长三个阶段。根据文献[18-19, 24]及本实验研究结果综合分析认为,快速冷冲过程中合金硬度的变化受析出相回溶软化、加工硬化和再析出相析出强化的综合影响。挤压态合金经2道次快速冷冲强变形后,长片状S'相发生严重扭曲和脆断,S'相与铝基体的界面畸变能明显提高,脆断的S'相开始回溶(见图3(b)),从而减少了对位错运动的阻碍,在一定程度上降低了堆积位错的密度,削弱了加工硬化的作用,从而导致硬度变化曲线趋于平缓。挤压态合金经3道次快速冷冲强变形后,由于S'相发生明显“缩颈”而导致界面畸变能进一步提升,S'相回溶程度进一步加大,部分小尺寸破断相基本全部回溶(见图3(c)),这时析出强化显著减弱,位错运动的阻碍进一步减小,回溶软化大于加工硬化的作用,导致合金硬度小幅下降。挤压态合金经4道次快速冷冲强变形后,发生明显的再析出形为,基体中析出大量的、尺寸细小的颗粒状平衡相S相(见图3(d)),这时位错运动阻碍显著增强,析出强化和加工硬化共同作用导致合金硬度显著增加(见图4)。

图6 4道次快速冷冲后Al-Cu-Mg合金析出相HAADF-STEM像及EDS谱

Fig. 6 HAADF-STEM image (a) and EDS spectra((b), (c), (d)) of precipitated phase in Al-Cu-Mg alloy undergoing 4 pass

图7 不同道次快速冷冲后Al-Cu-Mg合金XRD谱

Fig. 7 XRD patterns of Al-Cu-Mg alloy samples undergoing different passes of rapid cold punching process

4 结论

1) 挤压态Al-Cu-Mg合金在快速冷冲强变形过程中,长片状S'相的形貌、尺寸、分布及与基体的取向关系均发生显著变化,其演变机制主要为扭曲、脆断、回溶和缩颈。

2) 长片状S'相的扭曲和脆断显著增大了析出相与铝基体的接触面,提高了析出相与铝基体的界面畸变能,促进了S'相的回溶,基体重新达到过饱和状态,从而发生再析出以降低基体自由能。

3) 挤压态Al-Cu-Mg合金快速冷冲过程中合金硬度的变化受析出相回溶软化、加工硬化和再析出相析出强化的综合影响,挤压态合金经4道次快速冷冲变形后,合金硬度值由53HB增加到127HB,升高139.6%。

REFERENCES

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 3版. 长沙: 中南大学出版社, 2007.

WANG Zhu-tang, TIAN Rong-zhang. User manual for Al alloys and processing version[M]. 3rd ed. Changsha: Central South University Press, 2007.

[2] HU Ze-yi, FAN Cai-he, ZHENG Dong-sheng, LIU Wen-liang, CHEN Xi-hong. Microstructure evolution of Al-Cu-Mg alloy during rapid cold punching and recrystallization annealing [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(9): 1816-1823.

[3] FAN Cai-he, OU Ling, HU Ze-yi, YANG Jian-jun, CHEN Xi-hong. Re-dissolution and re-precipitation behavior of nano-precipitated phase in Al-Cu-Mg alloy subjected to rapid cold stamping[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(12): 2455-2462.

[4] LIU Zi-ran, CHEN Jiang-hua, WANG Shuang-bao, YUAN Ding-wang, YIN Mei-jie, WU Cui-lan. The structure and the properties of S-phase in AlCuMg alloys[J]. Acta Materialia, 2011, 59(19): 7396-7405.

[5] 胥福顺, 张 劲, 邓运来, 张新明.蛇形轧制对Al-Cu-Mg合金板材强韧性能及微观组织的影响[J].中国有色金属学报, 2017, 27(10): 2005-2011.

XU Fu-shun, ZHANG Jin,DENG Yun-lai,ZHANG Xin-ming. Effect of snake rolling on strength, toughness and microstructure of Al-Cu-Mg alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(10): 2005-2011.

[6] WANG Jian-qiu, ZHANG Bo, ZHOU Yang-tao, MA Xiu-liang. Multiple twins of a decagonal approximant embedded in S- Al2CuMg phase resulting in pitting initiation of 2024Al alloy[J]. Acta Materialia, 2015, 82(1): 22-31.

[7] MURAYAMA M, HORITA Z, HONO K. Microstructure of two-phase Al-1.7 at. % Cu alloy deformed by equal-channel angular pressing [J]. Acta Materialia, 2001, 49(5): 21-49.

[8] 宋宇峰, 肖来荣, 丁学锋, 陈宇强, 刘文辉, 赵小军. 残余应力和第二相对Al-Cu-Mg合金微尺寸变化的影响[J]. 中国有色金属学报, 2019, 29(3): 467-473.

SONG Yu-feng, XIAO Lai-rong, DING Xue-feng, CHEN Yu-qiang, LIU Wen-hui, ZHAO Xiao-jun. Effect of residual stress and second phases on dimensional change of Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(3): 467-473.

[9] WANG Shuang-bao, CHEN Jiang-hua, YIN Mei-jie, LIU Zi-ran, YUAN Ding-wang. Double atomic wall based dynamic precipitates of the early-stage S-phase in AlCuMg alloys[J]. Acta Materialia, 2012, 60(19): 6573-6580.

[10] 景慧博, 柏振海, 罗兵辉, 尹 远, 高 阳. 2124合金淬火后的室温停留效应[J].中国有色金属学报, 2017, 27(7): 1344-1351.

JING Hui-bo, BAI Zhen-hai, LUO Bing-hui, YIN Yuan, GAO Yang. Effect of room temperature delay on quenched 2124 alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(7): 1344-1351.

[11] YIN Mei-jie, CHEN Jiang-hua, WANG Shuang-bao, LIU Zi-ran, CHA Li-mei. Anisotropic and temperature-dependent growth mechanism of S-phase precipitates in Al-Cu-Mg alloy in relation with GPB zones[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 1-11.

[12] STYLES M J, MARCEAU R K W, BASTOW T J, BRAND H E A, GIBSON M A, HUTCHINSON C R. The competition between metastable and equilibrium S(Al2CuMg) phase during the decomposition of Al-Cu-Mg alloys[J]. Acta Materialia, 2015, 98(1): 64-80.

[13] 杨培勇, 郑子樵, 胥福顺, 李世晨, 李 剑, 周 明. 外加应力对高Cu/Mg比Al-Cu-Mg合金沉淀动力学及析出相形态的影响[J]. 稀有金属, 2006, 30(3): 324-328.

YANG Pei-yong, ZHENG Zi-qiao, XU Fu-shun, LI Shi-chen, LI Jian, ZHOU Ming. Effect of external stress on kinetics of precipitation and morphologies of precipitates in Al-Cu-Mg alloy with high Cu/Mg ratio[J]. Chinese Journal of Rare Metals, 2006, 30(3): 324-328.

[14] NOURBAKHSH S, NUTTING J. The high strain deformation of an Aluminium-4% copper alloy in the supersaturated and aged conditions[J]. Acta Metallurgica, 1980, 28(3): 357-365.

[15] MURAYMA M, HORITA Z, HONO K. Microstructure of two-phase AI-1.7at%Cu alloy deformed by equal-channel angular pressing[J]. Acta Mater, 2001, 49(1): 21-29.

[16] HUANG Yu-jin, CHEN Zhi-guo, ZHENG Zhi-qiao. A conventional thermo-mechanical process of Al-Cu-Mg alloy for increasing ductility while maintaining high strength[J]. Scripta Materialia, 2011, 64(5): 382-385.

[17] ZHAO Yun-long, YANG Zhi-qing, ZHANG Zhen-jun, SU Guo-yue, MA Xiu-liang. Double-peak age strengthening of cold-worked 2024 aluminum alloy[J]. Acta Materialia, 2013, 61(5): 1624-1638.

[18] 张孜昭, 许晓嫦, 胡 楠, 屈 啸, 陈振湘. 强变形诱导析出相回溶后的Al-Cu合金再时效行为[J]. 中南大学学报(自然科学版), 2010, 41(5): 1782-1790.

ZHANG Zi-zhao, XU Xiao-chang, HU Nan, QU Xiao, CHEN Zhen-xiang. Re-ageing behavior of Al-Cu alloy after re-dissolution of precipitated phases caused by severe plastic deformation[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1782-1790.

[19] 张孜昭, 许晓嫦, 刘志义, 夏卿坤, 曾苏民. 强变形诱导形成的A1-Cu合金过饱和固溶体在继续变形时的再析出行为[J]. 中国有色金属学报, 2009, 19(11): 1962-1968.

ZHANG Zi-zhao, XU Xiao-chang, LIU Zhi-yi, XIA Qing-kun, ZENG Su-min. Re-precipitate behavior of supersaturated solid solution of Al-Cu alloy caused by severe plastic deformation during subsequent deformation[J]. TheChinese Journal of Nonferrous Metal, 2009, 19(11): 1962-1968.

[20] PUGH S F. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals[J]. Philosophical Magazine, 1954, 45(367): 823-843.

[21] ZHANG Jian, HUANG Ya-ni, MAO Cong. Structural, elastic and electronic properties of θ(Al2Cu) and S(Al2CuMg) strengthening precipitates in Al-Cu-Mg series alloys: First-principles calculations[J]. Solid State Communications, 2012, 152(23): 2100-2104.

[22] 廖 飞, 范世通, 邓运来, 张 劲. 高强铝合金中间相Al2Cu, Al2CuMg和MgZn2性能的第一性原理计算[J]. 航空材料学报, 2016, 36(6): 1-8.

LIAO Fei, FAN Shi-tong, DENG Yun-lai, ZHANG Jin. First-principle calculations of mechanical properties of Al2Cu, Al2CuMg and MgZn2 intermetallics in high strength Aluminum alloys[J]. Journal of Aeronautical Materials, 2016, 36(6): 1-8.

[23] 余永宁. 金属学原理[M]. 第2版. 北京: 冶金工业出版社, 2013.

YU Yong-ling. Principles of metallography[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2013.

[24] XU Xiao-chang, LIU Zhi-yi, LI Yun-tao. Evolution of precipitates of Al-Cu alloy during equal-channel angular pressing at room temperature[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1047-1052.

Effect of rapid cold stamping on evolution of long strip S′ phase in spray-formed Al-Cu-Mg alloy

FAN Cai-he1, 3, FAN Yu-nan2, HU Zi-yi1, OU Ling1, 3, YANG Jian-jun1, 3

(1. College of Metallurgy and Material Engineering, Hunan University of Technology, Zhuzhou 421007, China;

2. School of Materials Science and Engineering, Xiangtan University, Xiangtan 411105, China;

3. Anhui Jianye Science and Technology Co., Ltd., Huaibei 235000, China)

Abstract: The high resolution transmission electron microscopy (TEM), X-ray diffractometry (XRD), energy dispersive spectroscopy (EDS) and hardness test were used to study the evolution of long strip-shaped S' phase of the spray-formed fine-grained Al-Cu-Mg alloy during rapid cold-stamping deformation. The results show that the elongated S' phase of the extruded Al-Cu-Mg alloy is distorted, brittle fracture, re-dissolution and necking during the rapid cold-stamping deformation, and the morphology, size, distribution and the orientation relationship with the matrix of the long strip-shaped S' phase changes significantly. The regularly distributed long strip-shaped nano-scale precipitates evolve into irregularly distributed short rod-shaped S' phases and diffusely distributed granular re-precipitates. The twist and brittle fracture of the long strip S' phase significantly increases the contact surface between the precipitated phase and the aluminum matrix, improves the interfacial distortion energy of the precipitated phase and the aluminum matrix, and promotes the re-dissolution of the S' phase. The supersaturation state is reached, so that re-precipitation occurs to lower the matrix free energy. The hardness of the alloy in the extruded Al-Cu-Mg alloy increases from 53 HB to 127 HB during the rapid cold stamping process.

Key words: Al-Cu-Mg alloy; rapid cold-stamping; S' phase; fracture; re-dissolution

Foundation item: Project(2019JJ60050) supported by the National Natural Science Foundation of Hunan Province, China; Project (19A131) supported by the Key Scientific Research Project of Hunan Province, China

Received date: 2019-08-20; Accepted date: 2020-01-13

Corresponding author: FAN Cai-he; Tel: +86-13787062698; E-mail: 369581813@qq.com

(编辑 李艳红)

基金项目:湖南省自然科学基金资助项目(2019JJ60050);湖南省教育厅科学研究重点项目(19A131)

收稿日期:2019-08-20;修订日期:2020-01-13

通信作者:范才河,副教授,博士;电话:13787062698;E-mail:369581813@qq.com

摘 要:采用高分辨透射电镜(TEM)、X射线衍射仪(XRD)、能谱仪(EDS)和硬度测试等手段,研究快速冷冲强变形过程中喷射成形细晶Al-Cu-Mg合金长片状S'相的演变规律。结果表明:挤压态Al-Cu-Mg合金在快速冷冲强变形过程中长片状S'相发生扭曲、脆断、回溶和缩颈,长片状S'相的形貌、尺寸、分布及与基体的取向关系发生显著变化,从有规律分布的长片状纳米析出相演变为无规律分布的短棒状S'相和弥散分布的颗粒状再析出相。长片状S'相的扭曲和脆断,显著增大析出相与铝基体的接触面,提高了析出相与铝基体的界面畸变能,促进了S'相的回溶,导致铝基体重新达到过饱和状态,从而发生再析出以降低基体自由能。挤压态Al-Cu-Mg合金在快速冷冲过程中合金硬度显著增加,由53HB增加到127HB,升高139.6%。

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 3版. 长沙: 中南大学出版社, 2007.

[5] 胥福顺, 张 劲, 邓运来, 张新明.蛇形轧制对Al-Cu-Mg合金板材强韧性能及微观组织的影响[J].中国有色金属学报, 2017, 27(10): 2005-2011.

[8] 宋宇峰, 肖来荣, 丁学锋, 陈宇强, 刘文辉, 赵小军. 残余应力和第二相对Al-Cu-Mg合金微尺寸变化的影响[J]. 中国有色金属学报, 2019, 29(3): 467-473.

[10] 景慧博, 柏振海, 罗兵辉, 尹 远, 高 阳. 2124合金淬火后的室温停留效应[J].中国有色金属学报, 2017, 27(7): 1344-1351.

[18] 张孜昭, 许晓嫦, 胡 楠, 屈 啸, 陈振湘. 强变形诱导析出相回溶后的Al-Cu合金再时效行为[J]. 中南大学学报(自然科学版), 2010, 41(5): 1782-1790.

[22] 廖 飞, 范世通, 邓运来, 张 劲. 高强铝合金中间相Al2Cu, Al2CuMg和MgZn2性能的第一性原理计算[J]. 航空材料学报, 2016, 36(6): 1-8.

[23] 余永宁. 金属学原理[M]. 第2版. 北京: 冶金工业出版社, 2013.

YU Yong-ling. Principles of metallography[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2013.