文章编号:1004-0609(2015)12-3245-10

金属材料超高周疲劳的试验方法及失效特征

宋亚南,徐滨士,王海斗,邢志国

(装甲兵工程学院 装备再制造技术国防科技重点实验室,北京 100072)

摘 要:

摘 要:超高周疲劳是指材料经受1×107循环周次以上而发生断裂损伤的疲劳行为,彻底打破材料“无限寿命”的传统观点,逐渐成为疲劳研究领域一个新的热点问题。回顾近几十年国内外的研究成果,总结了超声疲劳试验方法的进展和应用,分析了金属材料超高周疲劳S-N曲线的典型特征以及内部断裂的裂纹萌生机制和扩展特征,探讨影响超高周疲劳行为的主要因素,即加载频率、材料组织和氢含量。在此基础上,提出了今后超高周疲劳研究的一些方向:裂纹源表面萌生和内部萌生的竞争性机制及影响因素,超高周疲劳的寿命预测和再制造零部件的超高周疲劳行为。

关键词:

中图分类号:TG113.2 文献标志码:A

Testing method and failure characters of very high cycle fatigue of metal materials

SONG Ya-nan XU Bin-shi, WANG Hai-dou, XING Zhi-guo

(National Key Laboratory for Remanufacturing, Academy of Armored Forces Engineering, Beijing 100072, China)

Abstract: The very high cycle fatigue (VHCF) regime is defined as where the cyclic of structural component is greater than 1×107 load applications, which thoroughly breaks the traditional concept of infinite life. The fatigue behaviors in the VHCF range is becoming a hot subject in the research field. The research achievements on the VHCF in the past decades were reviewed. The development and application of ultrasonic fatigue testing were summarized. The typical characteristics of S-N curves and the basic understandings of cracking initiation and propagation were analyzed. The influential factors for VHCF mainly including load frequencies, microstructure and hydrogen contents were discussed. In addition, some possible and prospective topics of future researches were proposed.

Key words: metal material; very high cycle fatigue; ultrasonic fatigue testing; S-N curve; failure characteristic

材料疲劳性能的研究起始于19世纪中期,在传统研究中,将材料疲劳分为低周疲劳和高周疲劳两种阶段[1]。前者的循环周次一般小于1×104次,后者一般为1×104~1×107周次。相应地,材料寿命超过1×107周次时所对应的应力值被定义为疲劳极限。一般认为,作用在材料试样的循环应力小于疲劳极限时的,材料试验的寿命无穷大,即无限寿命观点。20世纪80年代初,日本学者NAITO等[2]使用50 Hz频率的疲劳试验机研究渗碳钢承受低于疲劳极限的寿命循环,发现材料试样经过1×108次应力循环仍会发生疲劳断裂现象。之后,各国学者对多种材料的疲劳性能进行研究,发现材料并不无限寿命特征,彻底打破无限寿命的观点,逐渐萌生、形成了一个新的研究领域——超高周疲劳。所谓超高周疲劳,就是材料经受1×107循环周次以上而发生断裂损伤的疲劳过程(Ultra-high-cycle fatigue,Very-high-cycle fatigue或Gigacycle fatigue),其循环应力幅小于传统的材料疲劳极限。

随着21世纪的到来,许多高龄化设备的服役寿命达到了无限寿命极限(即1×107 cycle),这些设备继续服役的安全可靠性亟待论证。另外,随着现代工业的发展,在许多工程领域,如飞行器、高速列车、重载压塑机叶轮、桥梁工程、海洋工程等,其材料构件的设计要求能够承受高达千兆循环周次的重复载荷。工程需求促进了超高周疲劳研究的飞速发展。本文作者基于近几十年超高周疲劳的研究成果,总结了国内外的研究现状,并对超高周疲劳的研究前景进行了展望。

1 超声疲劳试验方法

常规疲劳试验机多采用液压式,其频率一般为50 Hz,完成1×107循环周次需要四个多月的时间;即使采用电磁谐振式高频疲劳试验机(其频率最多不高于1 kHz),也需要一周的时间。超长的试验时间和昂贵的试验费用严重制约了常规方法研究材料1×108甚至1×1012循环周次过程中的疲劳失效过程。超声技术的应用为材料超高周疲劳研究提供切实可行的实验方法,其工作频率可以达到20 kHz,进行1×107循环试验仅需9 min,完成1×109循环试验也在14 h之内。超声疲劳试验技术的应用进一步促进了超高周疲劳试验的研究[3]。

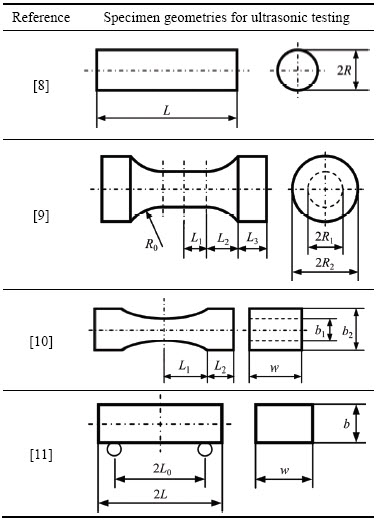

超声疲劳试验系统主要包括3个核心部分:超声波发生器、压电陶瓷环能器和位移放大器。其中,超声波发生器提供激振电源和高频率((20±0.5) kHz)交频可调振动电信号;压电陶瓷换能器将电信号转换为同频率的机械振动;位移放大器将换能器的机械振动振幅放大,以满足试样所需的应变振幅。早期的超声疲劳试验机只能进行简单的恒幅拉压疲劳试验,经过多年的发展,目前可以完成更为复杂的试验,包括变幅疲劳试验、弯曲疲劳试验、非对称拉压疲劳试验、扭转疲劳试验、微动疲劳试验等[4-7]。超声疲劳试样的特征尺寸的设计计算是超声疲劳试验的另一关键工作,使其具有与系统振动频率相同的固有频率,常用的设计方法主要有解析法和数值有限元法两种。表1所列为采用解析法设计的不同疲劳试样的特征尺寸[8-11]。而对于形状复杂的试样,例如缺口试样、悬臂梁式弯曲疲劳试样、双悬臂梁式弯曲疲劳试样等,只能采用数值有限元法进行设计计算[12-14]。

1) 对于等截面圆柱试样[8]:

(1)

(1)

表1 超声疲劳试样的解析计算

Table 1 Analytical solution of resonance length for ultrasonic fatigue samples

(2)

(2)

式中:Ed为材料的动态弹性模量;ρ为材料的密度;f为系统的振动频率;CS为试样的振动应力位移系数。

2) 对于变截面圆柱试样[9]:

(3)

(3)

(4)

(4)

(5)

(5)

式中: ;

; ;

;

;

;

;

;

。

。

3) 对于板状试样[10]:

(6)

(6)

(7)

(7)

式中: ;

; ;

; ;

;

。

。

4) 对于三点弯曲超声疲劳试样[11]:

(8)

(8)

(9)

(9)

(10)

(10)

式中: 。

。

2 超高周疲劳的研究现状

2.1 超高周疲劳的应力-寿命(S-N)曲线特征

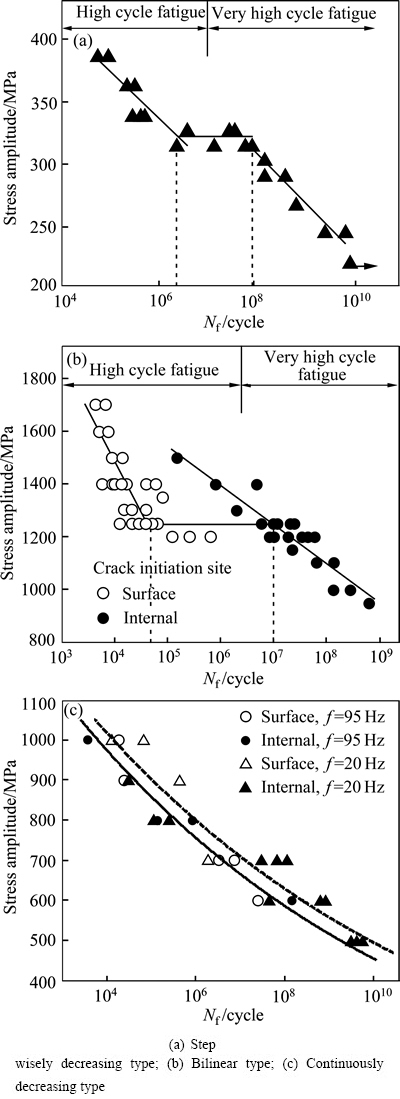

S-N曲线反映了材料疲劳断裂的整个信息,包括裂纹的萌生与扩展,是表征材料疲劳性能的基本图示。不同种材料或不同试验方法获得的超高周S-N曲线呈现一定的差异,主要分为阶梯状、双线型和持续下降型3种,如图1所示[15-17]。阶梯状和双线型 S-N曲线显现出两个拐点,前半段的疲劳失效裂纹源多发生在试样表面,后半段疲劳裂纹多在试样内部萌生;而在1×107循环周次附近出现类似于传统疲劳的典型“平台”特征。对于多数经过表面处理的材料试样,其S-N曲线在整个疲劳寿命范围则会呈现持续下降的趋势[17-18],不存在传统的疲劳极限段,这类S-N曲线称为持续下降型。

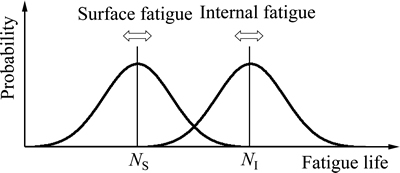

总结大多数材料S-N曲线的特征,在高应力短寿命阶段,疲劳裂纹的萌生与扩展多发生在试样表面;而在低应力长寿命阶段,试样的疲劳断裂多发生在材料内部。图2所示为内部失效和表面失效两种模式所对应的疲劳寿命(NI和NS)概率分布图[19]。当NI NS,且NI超出试验所涉及的循环周次时,就会出现传统无限寿命型 S-N曲线;当NI>NS,NI和NS的概率分布存在交集,且NI在试验范围之内,就会双线型 S-N曲线;当NI和NS相近时,则会出现连续下降型S-N曲线[10]。

NS,且NI超出试验所涉及的循环周次时,就会出现传统无限寿命型 S-N曲线;当NI>NS,NI和NS的概率分布存在交集,且NI在试验范围之内,就会双线型 S-N曲线;当NI和NS相近时,则会出现连续下降型S-N曲线[10]。

图1 超高周疲劳典型S-N曲线[15-17]

Fig. 1 S-N curves of very high cycle fatigue[15-17]

图2 表面断裂和内部断裂的疲劳寿命概率分布[19]

Fig. 2 Probability distribution for occurrence of surface and internal fatigue fracture modes[19]

2.2 超高周疲劳失效的断口特征及萌生机理

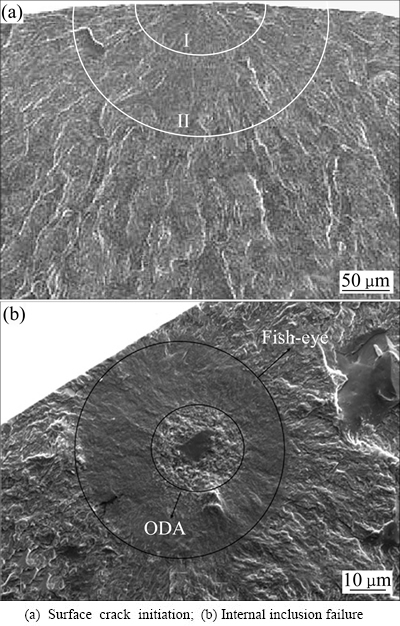

在低高周疲劳失效分析中,其断裂裂纹源均来自于试样表面,其机理为滑移造成材料表面的挤入与挤出,逐渐形成驻留滑移带PSB,由PSB发展成与主应力方向约成45°角的表面裂纹(第Ⅰ阶段),在跨过几个晶粒之后,逐步转向垂直于主应力方向的主裂纹(第Ⅱ阶段),迅速扩展导致试样断裂,断裂形貌可以分为裂纹萌生区、扩展区以及迅速断裂区[20-22]。超高周疲劳寿命阶段的断裂形貌如图3所示[23-24]。表面裂纹源诱导疲劳失效的断口形貌具有相似的特征,如图3(a)所示[23];而对于内部疲劳失效模式,单一的裂纹源在断口显示一个白色的亮点,其周围在显微镜下为黑色,此处为“光学暗区”(Optically dark area, ODA),呈现“鱼眼”的形状,如图3(b)所示。

图3 超高周疲劳的断裂形貌[23-24]

Fig. 3 Morphologies on fatigue fracture surface after very high cycle fatigue failure[23-24]

有关超高周疲劳裂纹源从试样表面转移到内部的机理研究很多,MILLER等[25]认为,载荷的降低使得由PSB发展成的表面裂纹不能穿越界面而形成主裂纹;MUGHRABI[26]将传统意义的疲劳极限认为是“PSB极限”,超高周疲劳试验的低应力幅根本无法形成PSB,而材料内部缺陷(包括长晶界、夹杂物或小晶粒)则会因应力集中而萌生裂纹并逐渐转向主裂纹扩展。BATHIAS[27]对这种现象又给出了另一种解释,他认为在低载荷作用下,只有少数承受应力集中的晶粒才有可能产生塑性变形并萌生疲劳裂纹导致疲劳失效,而在材料内部这种晶粒的出现概率要大于材料表面的出现概率。MURAKAMI等[28]认为材料缺陷(表面或内部)的尺寸是导致裂纹源位置改变的重要原因,并给出了其与应力强度因子幅ΔKinc的计算公式,当ΔKinc大于临界值ΔKth时,裂纹即在缺陷处萌生、扩展。

(11)

(11)

式中:ΔKinc为缺陷周围的应力强度因子幅;C为位置系数,表面裂纹取0.65,内部裂纹取0.50;σ为缺陷处的应力;Ainc为缺陷在断裂面上的投影面积。

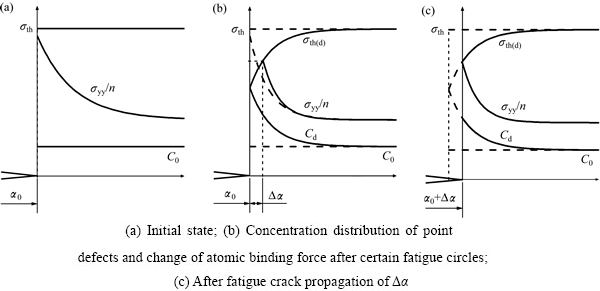

王弘[10]在研究40Cr、50车轴钢的超高周疲劳行为时,提出了点缺陷沉积的微观理论模型,描述疲劳裂纹从材料内部微观缺陷处的形核和长大过程,如图4所示。假设循环载荷开始时,点缺陷在金属材料中均匀存在,其浓度为C0,初始微裂纹长度为α0。裂纹尖端应力场为 ,若单位面积的原子数为n,则每个原子受到的集中力为

,若单位面积的原子数为n,则每个原子受到的集中力为 ,设金属材料的原子键和力为

,设金属材料的原子键和力为 ,则由于σth>

,则由于σth> ,微裂纹不扩展(见图4(a))。经过一段时间的循环载荷,点缺陷在裂纹尖端富集,点缺陷的浓度变为Cd,此时由Oriani假定可知[29],金属材料的原子键合力

,微裂纹不扩展(见图4(a))。经过一段时间的循环载荷,点缺陷在裂纹尖端富集,点缺陷的浓度变为Cd,此时由Oriani假定可知[29],金属材料的原子键合力 变为

变为

(12)

(12)

式中: 称为比较系数(见图4(b))。当裂纹尖端Δα区域内,

称为比较系数(见图4(b))。当裂纹尖端Δα区域内, >

> ,此区域内的原子破裂,裂纹扩展Δα(见图4(c))。微裂纹扩展后,原裂纹尖端富集的点缺陷进入扩展的裂纹中,裂纹尖端进入点缺陷浓度较低的材料组织中,裂纹停止扩展。随着时间的积累,点缺陷在微裂纹尖端再次富集,微裂纹再次扩展。上述过程反复进行,直至微裂纹称为可扩展裂纹,此过程亦称为疲劳裂纹内部萌生寿命。

,此区域内的原子破裂,裂纹扩展Δα(见图4(c))。微裂纹扩展后,原裂纹尖端富集的点缺陷进入扩展的裂纹中,裂纹尖端进入点缺陷浓度较低的材料组织中,裂纹停止扩展。随着时间的积累,点缺陷在微裂纹尖端再次富集,微裂纹再次扩展。上述过程反复进行,直至微裂纹称为可扩展裂纹,此过程亦称为疲劳裂纹内部萌生寿命。

3 超高周疲劳行为的影响因素

影响金属材料疲劳行为的因素很多,主要包括试验方法(加载频率、加载方式、载荷特征)、材料自身性能(化学成分、组织形态、表面状况、材料强度等)和外界环境(温度、氢含量、环境介质),以及各个因素的交互作用。然而在超高周疲劳行为研究中较受关注的主要有以下几个因素。

3.1 加载频率对超高周疲劳行为的影响

超声疲劳试验方法是研究金属材料超高周疲劳性能的有效途径,其试验频率高达20 kHz,比实际工程应用的频率范围高出2~4个数量级,因此,超声疲劳试验过程中频率对试验结果的影响备受关注[30]。疲劳裂纹的萌生和扩展与局部塑性变形有关,而塑性变形是通过位错增殖和滑移而实现的[31]。频率的改变将通过影响应力应变响应、应变局部化、断裂模式而影响材料的疲劳性能,本质上是以改变应变率而体现[32-35]。假设疲劳试验采用正弦波加载,应力比为 ,则加载应力(

,则加载应力( )随时间t的变化公式为

)随时间t的变化公式为

(13)

(13)

式中: 为疲劳试验应力幅。

为疲劳试验应力幅。

假设金属材料位错运动的阻力为 ,材料缺陷处的应力集中系数为n,则位错运动的有效驱动力(

,材料缺陷处的应力集中系数为n,则位错运动的有效驱动力( )为[36]

)为[36]

(14)

(14)

由式(4)可知,只有当 > 0时,位错运动才会发生;而当

> 0时,位错运动才会发生;而当 ≤ 0时,材料在疲劳试验过程中不会产生疲劳变形,即材料存在无限寿命。令

≤ 0时,材料在疲劳试验过程中不会产生疲劳变形,即材料存在无限寿命。令 = 0,可得

= 0,可得 为金属材料的传统疲劳极限。研究表明,大多数材料并不存在无限寿命,因此,不妨假设位错运动的阻力

为金属材料的传统疲劳极限。研究表明,大多数材料并不存在无限寿命,因此,不妨假设位错运动的阻力 = 0,则式(4)可改写为

= 0,则式(4)可改写为

(15)

(15)

假设位错能够沿着滑移面自由运动,根据Johnston-Gilman公式,位错运动的速率(v)可以写为[37]

(16)

(16)

式中:Q为位错运动的激活能;k是Boltzmann常数;T为绝对温度;A和m为材料参数。针对疲劳试验,采用间歇式加载方式和冷空气冷却的方法可以有效控制试样的温升问题,消除了温升对试验结果的影响,因此,可以认为T为常数。

结合式(3)、(5)和(6),可得1/4个循环周期内位错移动的距离L为

(17)

(17)

一般地,对于强度较低的金属材料,其组织结构对位错移动和增值的阻碍作用很小,则根据式(7),提高加载频率f可以有效减小L值,从而提升疲劳寿命,很好地解释了这些材料在疲劳试验过程中呈现的频率效应[33-34, 37];对于高强度的金属材料,其组织内部存在的大量固定位错、杂质粒子、晶界等障碍,会有效地阻碍位错的运动,显著降低加载频率f对位错移动距离L的影响,材料疲劳性能的频率效应随之降低,甚至消除[38-41]。

虽然在某些情况下,超声加载频率可能会提高金属材料的疲劳寿命和疲劳强度,但不会影响疲劳失效的断裂机制和断口形貌[42-45]。且频率效应仅仅存在于裂纹的萌生阶段,疲劳裂纹的扩展过程则不会受到加载频率的影响[46-49]。

图4 点缺陷沉积的微观机理示意图[10]

Fig. 4 Diagrammatic drawing of point defect deposition mechanism[10]

3.2 材料组织结构对超高周疲劳行为的影响

超高周疲劳断裂的裂纹源不仅会在表面萌生,而且更倾向于材料内部萌生,因此,材料表面状态和内部组织结构对材料的疲劳行为有着很大程度的影响。

试样表面的粗糙度及残余应力是反映试样表面质量的两个重要指标,而表面处理方法可以有效改善加工表面应力分布状态,降低表面粗糙度。材料表面引入残余压应力可以阻碍表面裂纹的萌生与扩展,较低的表面粗糙度又降低了表面缺陷的密度,最终使得表面断裂的疲劳失效寿命趋向于更高周次的循环周次,疲劳裂纹源内部萌生的概率增加[50-58]。

疲劳裂纹内部萌生是材料超高周疲劳常见的失效原因,因此,材料的组分和微观结构对超高周疲劳行为将有着显著的影响[59-60]。金属材料微观组织的晶粒细化是常见的材料强韧化方法,一方面可以提高位错滑移的阻滞效应[61],阻碍疲劳裂纹的扩展过程;另一方面却使得疲劳裂纹扩展的临界应力强度因子幅降低,在两者的交互作用下,存在最优的细化晶粒范围[62]。ZHAO等[38]研究了不同热处理温度对轴承钢GCr15超高周疲劳裂纹萌生和扩展的影响规律,随着热处理温度的升高,溶解于基体的碳原子浓度降低,阻碍位错运动的能力随之降低,材料的超高周疲劳性能也随之下降。

3.3 氢的作用

MURAKAMI等[63]采用不同热处理工艺制备了不同氢浓度的两组试样,结果发现氢含量直接影响裂纹源夹杂处光学暗区的形成、大小及形貌等;而当裂纹扩展至一定尺寸,裂纹的扩展将不再受氢的影响,而只取决于循环载荷,在此基础上提出了“氢脆模型”。另外,减少氢的含量可以减慢ODA的长大并增加试样的疲劳寿命[64-65]。在同样的氢浓度下,试样的寿命和ODA的大小成正比,这反过来说明在裂纹进入宏观裂纹扩展阶段之前的扩展是氢的参与造成的。李永德等[66]通过不同的热处理工艺制备了3中不同氢含量的高强弹簧钢50CrV4试样,利用超声疲劳试验机对试样的超高周疲劳行为进行研究,结果表明氢含量对超高周疲劳阶段对材料的疲劳强度有着显著影响[67],近似按照 规律降低,对材料的S-N曲线也有明显的影响。

规律降低,对材料的S-N曲线也有明显的影响。

然而,有些研究却发现氢虽然能够降低裂纹萌生的数量,但对疲劳寿命没有明显的影响,认为二者之间并无直接关系[68-69]。由于实验数据的缺乏,现有结果又相互矛盾,进一步确定氢与循环载荷的相互作用以及ODA区的扩展速率是值得研究的内容。

4 焊接接头超高周疲劳行为

焊接技术是目前工程实际广泛应用的再制造工程技术,焊接过程中不可避免地给母材引起组织缺陷和残余应力等[70-72],加之焊接材料与母材的不匹配性,都可能会影响焊接件的超高周疲劳性能。

大量研究发现:母材和焊接件在1×107循环周次后仍会发生断裂失效,不存在传统的疲劳极限,但焊接件的疲劳性能明显低于母材;焊接试样在低周疲劳区大多在焊接接头结合处发生疲劳断裂,而在高周疲劳区多发生在焊接热影响区处。断裂形貌表明焊接所引入的空洞、微裂纹和夹杂是焊接接头疲劳性能降低的主要原因[73-78]。对低强度钢埋弧焊接件在室温和370 ℃下的疲劳性能进行研究,发现室温下疲劳失效基本发生在试样材料表面;而在370 ℃下,失效发生在表面、非金属夹杂、微观非连续处以及内部空洞,分析表明母材的软化、表面的氧化以及表面残余压应力是370 ℃下疲劳失效位置发生改变的主要原因[79]。

5 结束语

随着工业技术的发展,在现代航空航天、交通运输、能源动力等许多工程领域,很多关键零部件都会面临高频低幅循环载荷,要求能够承受高达1×109~1×1012周次的应力循环,因此,国内外学者对金属材料超高周疲劳行为的关注度日益提升。特别是超声疲劳试验技术的日臻完善,使得这一领域的深入研究成为可能。虽然近十年开展的研究取得了丰硕的成果,但还远不能满足工程领域疲劳设计的需要。以目前的研究成果作为基础,以下几个方面的研究值得进一步深入关注。

研究超高周疲劳裂纹的萌生机制及影响因素,明确裂纹源表面萌生和内部萌生的竞争性机制,定量研究萌生位置转移控制因子,准确预测和控制疲劳断裂失效模式;研究裂纹萌生和扩展在超高周寿命中所占的比例,准确界定裂纹萌生阶段、初期裂纹扩展阶段以及长裂纹扩展阶段;借助断裂力学理论和有限元模拟,建立裂纹萌生寿命以及裂纹扩展寿命的预测公式;以大样本数据为基础,结合统计学方法,研究寿命预测模式的准确性和可靠性。

再制造工程因具有优质、高效、低成本、少污染等优点,在工程应用领域发挥着重要作用。常用的再制造工程技术主要包括沉积技术、焊接技术、熔覆技术等,各种技术给母材引入的界面效应都可能是影响再制造产品超高周疲劳性能。系统地研究界面效应对再制造产品超高周疲劳失效行为和寿命评估的影响,对推动再制造产业的工业化发展具有重大意义。

REFERENCES

[1] 陈 军, 段雨露, 彭小燕, 肖 丹, 徐国富, 尹志民. 7475-T7351铝合金厚板的疲劳性能[J]. 中国有色金属学报, 2015, 25(4): 890-899.

CHEN Jun, DUAN Yu-lu, PENG Xiao-yan, XIAO Dan, XU Guo-fu, YIN Zhi-min. Fatigue performance of 7475-T7351 aluminum alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 890-899.

[2] NAITO T, ASAMI K, KIKUCHI M. Fatigue behavior of carburized steel with internal oxides and nonmartensitic microstructure near the surface[J]. Metallurgical and Materials Transactions A, 1984, 15(7): 1431-1436.

[3] STANZL-TSCHEGG S E, MAYER H. Fatigue and fatigue crack growth of aluminium alloys at very high numbers of cycles[J]. International Journal of Fatigue, 2001, 23(S): s231-s237.

[4] BATHIAS C. Piezoelectric fatigue testing machines and devices[J]. International Journal of Fatigue, 2006, 28: 1438-1445.

[5] MAYER H. Ultrasonic torsion and tension compression fatigue testing: Measuring principle and investigations on 2024-T351 Aluminum alloy[J]. International Journal of Fatigue, 2006, 28: 1446-1455.

[6] GEORGE T J, SEIDT J, SHEN M H H, NICHOLAS T, CROSS C J. Development of a novel vibration based fatigue testing methodology[J]. International Journal of Fatigue, 2004, 26: 477-486.

[7] 王 弘, 高 庆. 40Cr钢超高周疲劳性能及疲劳断口分析[J]. 中国铁道科学, 2003, 24(6): 93-98.

WANG Hong, GAO Qing. Study on the gigacycle fatigue behavior and fracture surface[J]. China Railway Science, 2003, 24(6): 93-98.

[8] 王 弘, 高 庆. 超声疲劳扭转试样谐振长度的解析法计算[J]. 西南交通大学学报, 2001, 36(6): 595-598.

WANG Hong, GAO Qing. Analytical solution of the resonance length for ultrasonic torsional fatigue samples[J]. Journal of Southwest Jiaotong University, 2001, 36(6): 595-598.

[9] 薛红前, 陶 华, BATHIAS C. 超声疲劳试样设计[J]. 航空学报, 2004, 25(4): 425-428.

XUE Hong-qian, TAO Hua, BATHIAS C. The design of specimen for fatigue test at ultrasonic frequency[J]. Acta Aeronautica Et Astronautica Sinica, 2004, 25(4): 425-428.

[10] 王 弘. 40Cr、50车轴钢超高周疲劳性能研究及疲劳断裂机理探讨[D]. 成都: 西南交通大学, 2004.

WANG Hong. Study of fatigue behavior and mechanism of fatigue failure in the ultra-high-cycle regime in 40 Cr steel and 50 axles steel[D]. Chengdu: Southwest Jiaotong University, 2004.

[11] 闫桂玲, 王 弘, 高 庆. 超声疲劳试验方法及其应用[J]. 力学与实践, 2004, 26(6): 25-29.

YAN Gui-ling, WANG Hong, GAO Qing. Ultrasonic fatigue testing and its applications[J]. Mechanics in Engineering, 2004, 26(6): 25-29.

[12] 李全通, 刘青川, 申景生, 程 礼, 高 潮, 陈 卫. TC17钛合金超高周弯曲振动疲劳试验[J]. 航空动力学报, 2012, 27(3): 617-622.

LI Quan-tong, LIU Qing-chuan, SHEN Jing-sheng, CHENG Li, GAO Chao, CHEN Wei. Experiment on ultra-high cycle bending vibration fatigue of titanium alloy TC17[J]. Journal of Aerospace Power, 2012, 27(3): 617-622.

[13] 代景安, 王 弘, 唐维维. 基于ANSYS的薄板弯曲疲劳试样的有限元模拟[J]. 四川大学学报(工程科学版), 2010, 42(S2): 90-92.

DAI Jing-an, WANG Hong, TANG Wei-wei. Finite element simulation based on ANSYS of the thin plate bending fatigue specimen[J]. Journal of Sichuan University (Engineering Science Edition), 2010, 42(S2): 90-92.

[14] 唐维维, 王 弘. 超声弯曲疲劳试验方法及其应用[J]. 力学与实践, 2008, 30(6): 43-46.

TANG Wei-wei, WANG Hong. Method of ultrasonic bending fatigue and applications[J]. Mechanics in Engineering, 2008, 30(6): 43–46.

[15] 闫桂玲, 王 弘, 高 庆. 超声频率加载下50#车轴钢超长寿命疲劳性能研究[J]. 中国铁道科学, 2004, 25(2): 78-81.

YAN Gui-ling, WANG Hong, GAO Qing. On ultra-long life fatigue behavior of 50# axle steel under ultrasonic frequency[J]. China Railway Science, 2004, 25(2): 78-81.

[16] SHIOZAWA K, LU L, ISHIHARA S. S-N curve characteristics and sub-surface crack initiation behavior in ultra-long life fatigue of a high Carbon-chromium bearing steel[J]. Fatigue & Fracture of Engineering Materials & Structures, 2001, 24: 781-790.

[17] 李 伟, 李 强, 鲁连涛, 王 平. 不同加载频率下GCr15钢超高周疲劳行为的研究[J]. 材料热处理学报, 2008, 29(6): 53-57.

LI Wei, LI Qiang, LU Lian-tao, WANG Ping. Research on the very high cycle fatigue behavior of GCr15 steel in different load frequency[J]. Transactions of Materials and Hear Treatment, 2008, 29(6): 53-57.

[18] LI Wei, SAKAI T, WAKITA M, MIMURA S. Effect of surface finishing and loading condition on competing failure mode of clean spring steel in very high cycle fatigue regime[J]. Materials Science and Engineering A, 2012, 552: 301-309.

[19] SHIOZAWA K, LU L. Very high-cycle fatigue behaviour of shot-peened high-carbon-chromium bearing steel[J]. Fatigue & Fracture of Engineering Materials & Structures, 2002, 25: 813-822.

[20] 钟 申, 郑子樵, 钟俐萍, 李红萍, 吴秋萍. 7449合金高周疲劳及裂纹萌生行为[J]. 中国有色金属学报, 2012, 22(10): 2734-2742.

ZHONG Shen, ZHENG Zi-qiao, ZHONG Li-ping, LI Hong-ping, WU Qiu-ping. High-cycle fatigue and crack initiation behavior of 7449 alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2734-2742.

[21] 黄昌军, 刘春辉, 陈江华, 冯佳妮, 桑 益, 廖元飞, 陈 刚. Al-Mg-Si-Cu合金时效状态对疲劳过程及断裂特征的影响[J]. 中国有色金属学报, 2013, 23(1): 35-43.

HUANG Chang-jun, LIU Chun-hui, CHEN Jiang-hua, FENG Jia-ni, SANG Yi, LIAO Yuan-fei, CHEN Gang. Effect of precipitation state on fatigue process and fracture characteristics of Al-Mg-Si-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 35-43.

[22] ZHONG Jing, ZHONG Shen, ZHENG Zi-qiao, ZHANG Hai-feng, LUO Xian-fu. Fatigue crack initiation and early propagation behavior of 2A97 Al-Li alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 303-309.

[23] AKINIWA Y, STANZL-TSCHEGG S, MAYER H, WAKITA M, TANAKA K. Fatigue strength of spring steel under axial and torsional loading in the very high cycle regime[J]. International Journal of Fatigue, 2008, 30: 2057-2063.

[24] ZHAO A, XIE J, SUN C, LEI Z, HONG Y. Prediction of threshold value for FGA formation[J]. Materials Science and Engineering A, 2011, 528: 6872-6877.

[25] MILLER K J, O’DONNELL W J. The fatigue limit and its elimination[J]. Fatigue & Fracture of Engineering Materials & Structures, 1999, 22: 545-557.

[26] MUGHRABI H. On the life-controlling microstructural fatigue mechanisms in ductile metals and alloys in the gigacycle regime[J]. Fatigue & Fracture of Engineering Materials & Structures, 1999, 22: 633-641.

[27] BATHIAS C. There is no infinite fatigue life in metallic materials[J]. Fatigue & Fracture of Engineering Materials & Structures, 1999, 22: 559-565.

[28] MURAKAMI Y, KODAMA S, KONUMA S. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels (Ⅰ)[J]. International Journal of Fatigue, 1989, 11(5): 291-298.

[29] 褚武杨. 断裂与环境断裂[M]. 北京: 科学出版社, 2000.

CHU Wu-yang. Fracture and environment sensitive fracture[M]. Beijing: Science Press, 2000.

[30] GUENNEC B, NAKAMURA Y, SAKAI T, UENO A, NONAKA I. Reconfirmation and new discussions on frequency effect of fatigue property of materials based on numerous published data[J]. International Journal of Materials and Structural Integrity, 2014, 8(4): 221-242.

[31] 洪友士, 赵爱国, 钱桂安. 合金材料超高周疲劳行为的基本特征和影响因素[J]. 金属学报, 2009, 45(7): 769-780.

HONG You-shi, ZHAO Ai-guo, QIAN Gui-an. Essential characteristics and influential factors for very-high-cycle fatigue behavior of metallic materials[J]. Acta Merallurgica Sinica, 2009, 45(7): 769-780.

[32] HOLPER B, MAYER H, VASUDEVAN A K, STANZL-TSCHEGG S E. Near threshold fatigue crack growth at positive load ratio in aluminum alloys at low and ultrasonic frequency: Influences of strain rate, slip behaviour and air humidity[J]. International Journal of Fatigue, 2004, 26(1): 27-38.

[33] GUENNEC B, UENO A, SAKAI T, TAKANASHI M, TABASHI Y. Effect of the loading frequency on fatigue properties of JIS S15C low carbon steel and some discussions based on micro-plasticity behavior[J]. International Journal of Fatigue, 2014, 66:29-38.

[34] GUENNEC B, UENO A, SAKAI T, TAKANASHI M, TABASHI Y. OTA M. Dislocation-based interpretation on the effect of the loading frequency on the fatigue properties of JIS S15C low carbon steel[J]. International Journal of Fatigue, 2015, 70: 328–341.

[35] ZENG Rong-chang, HAN En-hou, KE Wei. A critical discussion on influence of loading frequency on fatigue crack propagation behavior for extruded Mg-Al- Z n alloys[J]. International Journal of Fatigue, 2012, 36(1): 40–46.

[36] JOHNSTON W G, GILMAN J J. Dislocation velocities, dislocation densities, and plastic flow in lithium fluoride crystals[J]. Journal of Applied Physics, 1959, 30(2): 129–144.

[37] ZHANG Yang-yang, DUAN Zheng, SHI Hui-Ji. Comparison of the very high cycle fatigue behaviors of INCONEL 718 with different loading frequencies[J]. Science China Physics, Mechanics and Astronomy, 2013, 56(3): 617-623.

[38] ZHAO Ai-guo, XIE Ji-jia, SUN Cheng-qi, LEI Zheng-qiang, HONG You-shi. Effects of strength level and loading frequency on very-high-cycle fatigue behavior for a bearing steel[J]. International Journal of Fatigue, 2012, 38: 46-56.

[39] 张忠健, 赵声志, 彭 文, 张倩霞, 陈 鼎. 硬质合金疲劳裂纹的萌生与扩展行为[J]. 中国有色金属学报, 2014, 24(12): 3031-3041.

ZHANG Zhong-jian, ZHAO Sheng-zhi, PENG Wen, ZHANG Qian-xia, CHEN Ding. Behavior of fatigue crack initiation and propagation of cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3031-3041.

[40] STANZL-TSCHEGG S. Fatigue crack growth and thresholds at ultrasonic frequencies[J]. International Journal of Fatigue, 2006, 28(11): 1456-1464.

[41] FURUYA Y, MATSUOKA S, ABE T, YAMAGUCHI , K. Gigacycle fatigue properties for high-strength low-alloy steel at 100 Hz, 600 Hz, and 20 kHz[J]. Scripta Materialia, 2002, 46(2): 157-162.

[42] ZHANG Ji-wang, SONG Qing-peng, ZHANG Ning, LU Lian-tao, ZHANG Min-tang, CUI Guo-dong. Very high cycle fatigue property of high-strength austempered ductile iron at conventional and ultrasonic frequency loading[J]. International Journal of Fatigue, 2015, 70: 235-240.

[43] YAN N, KAWAGOISHI N, MAEDA Y, CHEN Q. Effect of loading frequency on fatigue properties of Ni-base super alloy Inconel 718[J]. Structural Longevity, 2009, 2(3): 139-146.

[44] PAPAKYRIACOU M, MAYER H, PYPEN C, PLENK H J, STANZL-TSCHEGG S. Influence of loading frequency on high cycle fatigue properties of b.c.c and h.c.p metals[J]. Materials Science and Engineering A, 2001, 308(1/2): 143-152.

[45] CHEN Q, KAWAGOISHI N, WANG Q Y, YAN N, ONO T, HASHIGUCHI G. Small crack behavior and fracture of nickel-based superalloy under ultrasonic fatigue[J]. International Journal of Fatigue, 2005, 27: 1227-1232.

[46] TAKEUCHI E, FURUYA Y, NAGASHIMA N, MATSUOKA S. The effect of frequency on the giga-cycle fatigue properties of a Ti-6Al-4V alloy[J]. Fatigue and Fracture of Engineering Material and Structures, 2008, 31(7): 599-605.

[47] SCHMID S, HAHN M, ISSLER S, BACHER-HOECHST M, FURUYA Y, MEHNER A, BOMAS H, ZOCH H W. Effect of frequency and biofuel E85 on very high cycle fatigue behaviour of the high strength steel X90CrMoV18[J] International Journal of Fatigue, 2014, 60: 90-100.

[48] MAYER H, PAPAKYRIACOU M, PIPPAN R, STANZL- TSCHEGG S. Influence of loading frequency on the high cycle fatigue properties of AlZnMgCu1.5 aluminium alloy[J]. Materials Science and Engineering A, 2001, 314: 48-54.

[49] BOYCE J B L, RITCHIE R O. Effect of load ratio and maximum stress intensity on the fatigue threshold in Ti-6Al-4V[J]. Engineering Fracture Mechanics, 2001, 68: 129-147.

[50] HUANG Z Y, WAGNER D, WANG Q Y, BATHIAS C. Effect of carburizing treatment on the “fish eye” crack growth for a low alloyed chromium steel in very high cycle fatigue[J]. Materials Science and Engineering A, 2013, 559: 790-797.

[51] SHIMAMURA Y, NARITA K, ISHII H, TOHGO K, FUJII T, YAGASAKI T, HARADA M. Fatigue properties of carburized alloy steel in very high cycle regime under torsional loading[J]. International Journal of Fatigue, 2014, 60: 57-62.

[52] BENEDETTI M, FONTANARI V, BANDINI M, SAVIO E. High- and very high-cycle plain fatigue resistance of shot peened high-strength aluminum alloys: The role of surface morphology[J]. International Journal of Fatigue, 2015, 70: 451-462.

[53] ZHANG Xing-quan, CHEN Liu-san, YU Xiao-liu, ZUO Li-sheng, ZHOU Yu. Effect of laser shock processing on fatigue life of fastener hole[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 969-974.

[54] MAYER H, SCHULLER R, FITZKA M, TRAN D, PENNINGS B. Very high cycle fatigue of nitrided 18Ni maraging steel sheet[J]. International Journal of Fatigue, 2014, 64: 140-146

[55] NIE B H, ZHANG Z, ZHAO Z H, ZHONG Q P. Very high cycle fatigue behavior of shot-peened 3Cr13 high strength spring steel[J]. Materials and Design, 2013, 50: 503-508.

[56] SHIMATANI Y, SHIOZAWA K, NAKADA T, YOSHIMOTO T, LU L. The effect of the residual stresses generated by surface-finishing methods on the very high cycle fatigue behaviour of matrix HSS[J]. International Journal of Fatigue, 2011, 33(2): 122-131.

[57] 陈国清, 田唐永, 张新华, 李志强, 周文龙. Ti-6Al-4V钛合金陶瓷湿喷丸表面强化微观组织与疲劳性能[J]. 中国有色金属学报, 2013, 23(1): 122-127.

CHEN Guo-qing, TIAN Tang-yong, ZHANG Xin-hua, LI Zhi-qiang, ZHOU Wen-long. Microstructure and fatigue properties of Ti-6Al-4V titanium alloy treated by wet shot peening of ceramic beads[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 122-127.

[58] KUMAR S A, SUNDAR R, RAMAN S G S, KUMAR H, KAUL R, RANGANATHAN K, OAK S M, KUKREJA L M, BINDRA K S. Influence of laser peening on microstructure and fatigue lives of Ti-6Al-4V[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3111-3117.

[59] ZHAO P, GAO G H, MISRA R D K, BAI B Z. Effect of microstructure on the very high cycle fatigue behavior of a bainite/martensite multiphase steel[J]. Materials Science and Engineering A, 2015, 630: 1-7.

[60] 窦强将, 赵子华, 聂宝华, 马 婧, 刘柯军, 张 铮. 回火温度对 42CrMo 钢超高周疲劳行为的影响[J]. 材料热处理学报, 2014, 35(S1): 175-180.

DOU Qiang-jiang, ZHAO Zi-hua, NIE Bao-hua, MA Jing, LIU Ke-jun, ZHANG Zheng. Effect of tempering temperature on very high cycle fatigue behavior of 42CrMo steel[J]. Transactions of Materials and Heat Treatment, 2014, 35(S1): 175-180.

[61] OGUMA H, NAKAMURA T. The effect of microstructure on very high cycle fatigue properties in Ti–6Al–4V[J]. Scripta Materialia, 2010, 63: 32-34.

[62] 张永健, 惠卫军, 项金钟, 董 瀚, 翁宇庆. 晶粒尺寸对42CrMoVNb钢超高周疲劳性能的影响[J]. 金属学报, 2009, 45(7): 880-886.

ZHANG Yong-jian, HUI Wei-jun, XIANG Jin-zhong, DONG Han, WENG Yu-qing. Effect of grain size on ultra-high-cycle fatigue properties of 42CrMoVNb steel[J]. Acta Metallurgica Sinica, 2009, 45(7): 880-886.

[63] MURAKAMI Y, NOMOTO T, UEDA T, MURAKAMI Y. On the mechanism of fatigue failure in the superlong life regime (N>107 cycles). Part Ⅰ: Influence of hydrogen trapped by inclusions[J]. Fatigue & Fracture of Engineering Materials & Structures, 2000, 23(11): 893-902.

[64] ZHOU Chao, ZHANG Yong-jian, HUI Wei-jun, WANG Lei. Influence of hydrogen on GBF in very high cycle fatigue of high strength steel[J]. Journal of Iron and Steel Research, International, 2013, 20(12): 92-97.

[65] 周 超, 张永健, 惠卫军, 王 磊. 氢对60Si2CrVA弹簧钢超高周疲劳性能的影响[J]. 钢铁研究学报, 2013, 25(9): 45-51.

ZHOU Chao, ZHANG Yong-jian, HUI Wei-jun, WANG Lei. Effect of hydrogen on very high cycle fatigue properties of high strength spring steel 60Si2CrVA[J]. Journal of Iron and Steel Research, 2013, 25(9): 45-51.

[66] 李永德, 李守新, 杨振国, 柳洋波, 戎利建. 氢对高强弹簧钢50CrV4超高周疲劳性能的影响[J]. 金属学报, 2008, 44(1): 64-68.

LI Yong-de, LI Shou-xin, YANG Zhen-guo, LIU Yang-bo, RONG Li-jian. Influence of hydrogen on ultrahigh cycle fatigue properties of high strength spring steel 50CrV4[J]. Acta Merallurgica Sinica, 2008, 44(1): 64-68.

[67] 周 超, 张永健, 惠卫军, 王 磊. 氢对42CrMoVNb钢超高周疲劳性能的影响[J]. 钢铁研究学报, 2013, 25(12): 52-57.

ZHOU Chao, ZHANG Yong-jian, HUI Wei-jun, WANG Lei. Effect of hydrogen on fatigue properties of high strength steel 42CrMoVNb[J]. Journal of Iron and Steel Research, 2013, 25(12): 52-57.

[68] OCHI Y, MATSUMURA T, MASAKI K, YOSHIDA S. High-cycle rotating bending fatigue property in very long-life regime of high-strength steels[J]. Fatigue & Fracture of Engineering Materials & Structures, 2002, 25: 823-830.

[69] WU H, HAMADA S, ODA Y, NOGUCHI H. Effect of internal hydrogen on very high cycle fatigue of precipitation- strengthened steel SUH660[J]. International Journal of Fatigue, 2015, 70: 406-416.

[70] DAS H, CHAKRABORTY D, KUMAR PAL T. High-cycle fatigue behavior of friction stir butt welded 6061 aluminium alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3): 648-656.

[71] SIVARAJ P, KANAGARAJAN D, BALASUBRAMANIAN V. Fatigue crack growth behaviour of friction stir welded AA7075-T651 aluminium alloy joints[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2459-2467.

[72] LIU Xue-song, ZHANG Liang, WANG Lin-sen, WU Shuang-hui, FANG Hong-yuan. Fatigue behavior and life prediction of A7N01 aluminium alloy welded joint[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2930-2936.

[73] 吴良晨, 王东坡, 王 康, 邓彩艳, 刘 哲. Q235B焊接接头超高周疲劳性能[J]. 天津大学学报, 2008, 41(12): 1480-1484.

WU Liang-chen, WANG Dong-po, ANG Kang, DENG Cai-yan, LIU Zhe. Super high cycle fatigue properties of Q235B steel welded joint[J]. Journal of Tianjin University, 2008, 41(12): 1480-1484.

[74] 方冬慧, 刘永杰, 陈宜言, 王清远. Q345桥梁钢焊接接头超高周疲劳性能[J]. 焊接学报, 2011, 32(8): 77-80.

FANG Dong-hui, LIU Yong-jie, CHEN Yi-yan, WANG Qing-yuan. Ultra-high cycle fatigue behaviors of Q345 bridge steel welded joint[J]. Transactions of the China Welding Institution, 2011, 32(8): 77-80.

[75] 刘永杰, 何 超, 方冬慧, 王清远. 焊接接头超高周疲劳实验研究[J]. 实验力学, 2011, 26(5): 617- 624.

LIU Yong-jie, HE Chao, FANG Dong-hui, WANG Qing-yuan. Experimental investigation on very high cycle fatigue behavior of welded joint[J]. Journal of Experimental Mechanics, 2011, 26(5): 617- 624.

[76] 何 超, 田仁慧, 王清远. 钛合金焊接接头超长寿命疲劳特性研究[J]. 中国测试, 2012, 38(3): 20-26.

HE Chao,TIAN Ren-hui,WANG Qing-yuan. Study on ultra-long-life fatigue properties of welded joints under high-frequency loading[J]. China Measurement & Test, 2012, 38(3): 20-26.

[77] CREMER M, ZIMMERMANN M, CHRIST H J. High- frequency cyclic testing of welded aluminium alloy joints in the region of very high cycle fatigue (VHCF)[J]. International Journal of Fatigue, 2013, 57: 120-130.

[78] 刘龙隆, 轩福贞, 朱明亮. 25Cr2Ni2MoV钢焊接接头的超高周疲劳特性[J]. 机械工程学报, 2014, 50(4): 25-31.

LIU Long-long, XUAN Fu-zhen, ZHU Ming-liang. Very high cycle fatigue behavior of 25Cr2Ni2MoV steel welded joint[J]. Journal of Mechanical Engineering, 2014, 50(4): 25-31.

[79] ZHU M L, XUAN F Z, DU Y N, TU S T. Very high cycle fatigue behavior of a low strength welded joint at moderate temperature[J]. International Journal of Fatigue, 2012, 40: 74-83.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2011CB013405);国家杰出青年科学基金资助项目(51125023)

收稿日期:2014-11-27;修订日期:2015-10-12

通信作者:王海斗,教授,博士;电话:010-66718475;E-mail: wanghaidou@aliyun.com

[1] 陈 军, 段雨露, 彭小燕, 肖 丹, 徐国富, 尹志民. 7475-T7351铝合金厚板的疲劳性能[J]. 中国有色金属学报, 2015, 25(4): 890-899.

[7] 王 弘, 高 庆. 40Cr钢超高周疲劳性能及疲劳断口分析[J]. 中国铁道科学, 2003, 24(6): 93-98.

[8] 王 弘, 高 庆. 超声疲劳扭转试样谐振长度的解析法计算[J]. 西南交通大学学报, 2001, 36(6): 595-598.

[9] 薛红前, 陶 华, BATHIAS C. 超声疲劳试样设计[J]. 航空学报, 2004, 25(4): 425-428.

[10] 王 弘. 40Cr、50车轴钢超高周疲劳性能研究及疲劳断裂机理探讨[D]. 成都: 西南交通大学, 2004.

[11] 闫桂玲, 王 弘, 高 庆. 超声疲劳试验方法及其应用[J]. 力学与实践, 2004, 26(6): 25-29.

[12] 李全通, 刘青川, 申景生, 程 礼, 高 潮, 陈 卫. TC17钛合金超高周弯曲振动疲劳试验[J]. 航空动力学报, 2012, 27(3): 617-622.

[13] 代景安, 王 弘, 唐维维. 基于ANSYS的薄板弯曲疲劳试样的有限元模拟[J]. 四川大学学报(工程科学版), 2010, 42(S2): 90-92.

[14] 唐维维, 王 弘. 超声弯曲疲劳试验方法及其应用[J]. 力学与实践, 2008, 30(6): 43-46.

[15] 闫桂玲, 王 弘, 高 庆. 超声频率加载下50#车轴钢超长寿命疲劳性能研究[J]. 中国铁道科学, 2004, 25(2): 78-81.

[17] 李 伟, 李 强, 鲁连涛, 王 平. 不同加载频率下GCr15钢超高周疲劳行为的研究[J]. 材料热处理学报, 2008, 29(6): 53-57.

[20] 钟 申, 郑子樵, 钟俐萍, 李红萍, 吴秋萍. 7449合金高周疲劳及裂纹萌生行为[J]. 中国有色金属学报, 2012, 22(10): 2734-2742.

[29] 褚武杨. 断裂与环境断裂[M]. 北京: 科学出版社, 2000.

CHU Wu-yang. Fracture and environment sensitive fracture[M]. Beijing: Science Press, 2000.

[31] 洪友士, 赵爱国, 钱桂安. 合金材料超高周疲劳行为的基本特征和影响因素[J]. 金属学报, 2009, 45(7): 769-780.

[39] 张忠健, 赵声志, 彭 文, 张倩霞, 陈 鼎. 硬质合金疲劳裂纹的萌生与扩展行为[J]. 中国有色金属学报, 2014, 24(12): 3031-3041.

[57] 陈国清, 田唐永, 张新华, 李志强, 周文龙. Ti-6Al-4V钛合金陶瓷湿喷丸表面强化微观组织与疲劳性能[J]. 中国有色金属学报, 2013, 23(1): 122-127.

[60] 窦强将, 赵子华, 聂宝华, 马 婧, 刘柯军, 张 铮. 回火温度对 42CrMo 钢超高周疲劳行为的影响[J]. 材料热处理学报, 2014, 35(S1): 175-180.

[62] 张永健, 惠卫军, 项金钟, 董 瀚, 翁宇庆. 晶粒尺寸对42CrMoVNb钢超高周疲劳性能的影响[J]. 金属学报, 2009, 45(7): 880-886.

[65] 周 超, 张永健, 惠卫军, 王 磊. 氢对60Si2CrVA弹簧钢超高周疲劳性能的影响[J]. 钢铁研究学报, 2013, 25(9): 45-51.

[66] 李永德, 李守新, 杨振国, 柳洋波, 戎利建. 氢对高强弹簧钢50CrV4超高周疲劳性能的影响[J]. 金属学报, 2008, 44(1): 64-68.

[67] 周 超, 张永健, 惠卫军, 王 磊. 氢对42CrMoVNb钢超高周疲劳性能的影响[J]. 钢铁研究学报, 2013, 25(12): 52-57.

[73] 吴良晨, 王东坡, 王 康, 邓彩艳, 刘 哲. Q235B焊接接头超高周疲劳性能[J]. 天津大学学报, 2008, 41(12): 1480-1484.

[74] 方冬慧, 刘永杰, 陈宜言, 王清远. Q345桥梁钢焊接接头超高周疲劳性能[J]. 焊接学报, 2011, 32(8): 77-80.

[75] 刘永杰, 何 超, 方冬慧, 王清远. 焊接接头超高周疲劳实验研究[J]. 实验力学, 2011, 26(5): 617- 624.

[76] 何 超, 田仁慧, 王清远. 钛合金焊接接头超长寿命疲劳特性研究[J]. 中国测试, 2012, 38(3): 20-26.

[78] 刘龙隆, 轩福贞, 朱明亮. 25Cr2Ni2MoV钢焊接接头的超高周疲劳特性[J]. 机械工程学报, 2014, 50(4): 25-31.