DOI: 10.11817/j.issn.1672-7207.2015.01.008

纳米-微米颗粒增强复合钎料研究最新进展

张亮1, 2,Tu K N 3,孙磊1,郭永环1,何成文1

(1. 江苏师范大学 机电工程学院,江苏 徐州,221116;

2. 江苏科技大学 先进焊接技术省级重点实验室,江苏 镇江,212003;

3. Department of Materials Science and Engineering, University of California, Los Angeles, CA, 90095)

摘 要:

-微米颗粒无铅钎料研究与应用现状,分别介绍国内外针对金属、化合物、陶瓷、碳纳米管及高分子几种颗粒对无铅钎料性能的影响。主要从无铅钎料内部组织、界面组织、熔化特性、润湿性、力学性能和蠕变性能几方面探讨颗粒对钎料组织和性能的影响。同时简述颗粒增强的无铅钎料在应用过程中出现的问题及相应的解决措施,并对颗粒增强无铅钎料的发展趋势进行分析和展望。

关键词:

中图分类号:TG454 文献标志码:A 文章编号:1672-7207(2015)01-0049-17

Reviews on latest advances in micro/nano-sized particles enhanced composite solders

ZHANG Liang1, 2, Tu K N3, SUN Lei1, GUO Yonghuan1, HE Chengwen1

(1. School of Mechanical & Electrical Engineering, Jiangsu Normal University, Xuzhou 221116, China;

2. Provincial Key Laboratory of Advanced Welding Technology, Jiangsu University of Science and Technology,

Zhengjiang 212003, China;

3. Department of Materials Science and Engineering, University of California, Los Angeles, CA 90095)

Abstract: The investigation and application of lead-free solders bearing micro/nano-sized particles were reviewed synthetically. Moreover, the effects of additives such as metals, compounds, ceramics, carbon nano-tube, polymer on lead-free solders were reported and analyzed synchronously. Based on the works on microstructures, interface structure, melting temperature, mechanical property and creep behaviors, the effects of particles on properties and microstructures of solders were discussed systematically. In addition, the problems and difficulty in the process of the applications of lead-free solders bearing particles were analyzed synchronously, some suggestions were put forward on how to solve those problems mentioned above, and the prospect on lead-free solders with particle reinforcement was analyzed.

Key words: lead-free solders; interface structure; mechanical properties; particle reinforcement

在电子工业中,SnPb钎料以其独特的性能得到广泛应用,但是铅的毒性却引起了国际社会的普遍的关注,一时之间“禁铅”呼声也越来越高,致使无铅钎料的研究成为电子工业的热门课题[1-3]。在诸多无铅钎料中,基于性能和成本的考虑,SnAgCu[4-5],SnCu[6-7],SnAg[8-9]和SnZn[10-11]等成为替代SnPb较为优良的无铅钎料。但这些无铅钎料仍然具有一些缺点,例如熔化温度较高、组织中存在大块的脆性相、抗疲劳性能较差、抗氧化性较差、可靠性较低等[12-15]。因此,诸多研究者针对系列无铅钎料的这些缺陷进行了进一步改良,希望新型的无铅钎料的性能达到甚至超过传统的SnPb钎料。为了进一步提高无铅钎料的性能,业界研究者主要采取以下2种方法:1) 钎料的微合金化。主要在无铅钎料中添加微量的合金元素,进而提高钎料的某一性能或者综合性能, 例如Ga可以改善钎料的润湿性[16]、稀土元素可以提高钎料的综合性 能[17]。但是,并不是添加合金元素起到的都是积极作用,例如稀土添加过量时可以使焊点表面生长出锡须[18-19],会造成焊点的早期失效。目前微合金化是研究者开发新型无铅钎料主要的研究手段,同时该系列新型钎料的部分产品已经在相关单位得到产业化以及进一步的应用和推广,例如日本千住金属株式会社以及鲁科斯钎焊材料公司等。2) 添加纳米-微米颗粒,通过颗粒强化来改善钎料的性能。添加的颗粒主要包含金属颗粒、化合物颗粒、陶瓷颗粒,同时也有研究者添加碳纳米管和高分子颗粒等[20]。随着添加颗粒的种类和尺寸的变化,无铅钎料的组织和性能有很大的不同。金属颗粒的添加不仅可以改变无铅钎料的内部组织,同时在钎料内部往往会有新相形成,而化合物颗粒和陶瓷颗粒的添加并不能形成新相,对性能影响的机制也各不相同。因此有必要针对含不同类型及不同尺寸颗粒的无铅钎料的性能和组织进行综合分析,探讨颗粒的影响及作用。本文作者综合分析纳米-微米颗粒对无铅钎料组织和性能的影响,研究颗粒对无铅钎料内部组织、界面组织、熔化特性、润湿性、力学性能、蠕变性能以及可靠性的影响。评述含纳米-微米颗粒无铅焊点的可靠性,以便为颗粒增强新型无铅钎料的研发提供基础理论指导。

1 对软钎料组织的影响

1.1 内部组织

材料科学与工程的4个要素是材料的化学成分、组织结构、加工工艺与使用性能[21],具有一定化学成分的材料,经过一定的加工工艺,获得特定的组织结构,从而满足其规定的使用性能要求,由于特定组织结构决定了材料特性的性能,因此,首先研究颗粒对无铅钎料内部组织的影响。

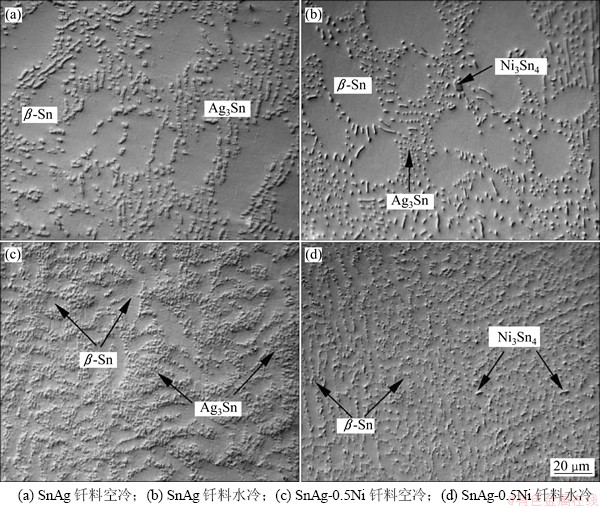

Ni颗粒(粒度为2~3 μm)作为Sn3.5Ag强化相,会使钎料基体组成有明显的改变,图1[22]所示为SnAg和SnAg-0.5Ni 2种钎料不同冷却方式下的组织图。由图1可以看出:SnAg钎料组织中主要由β-Sn和Ag3Sn两相组成,添加Ni颗粒以后,β-Sn和Ag3Sn相的尺寸均明显减小,同时出现了Ni3Sn4相。Yao等[23]发现添加Ni颗粒(微米级)可以细化Sn3.8Ag0.7Cu内部的Ag3Sn尺寸,但未提到对β-Sn尺寸的影响。Al纳米颗粒添加到Sn3.5Ag0.5Cu钎料中,钎料基体中的Cu6Sn5和Ag3Sn的尺寸均得到显著降低,研究者将其归结于金属间化合物颗粒的“异相形核”的作用[24]。纳米Ag颗粒添加到Sn9Zn钎料中,析出AgZn3均匀分布于钎料基体中,同时针状的富Zn相和β-Sn得到一定程度的细化[25]。Lin等[26]研究了Cu颗粒(1~5 μm)对Sn3.5Ag钎料快速凝固组织的影响,SnAg钎料凝固组织主要由富Sn相的柱状树枝晶和共晶组织(树枝晶间的富Sn相和Ag3Sn)组成,Cu颗粒添加可以细化基体组织相的尺寸,这主要是归因于钎料基体中Cu6Sn5相的析出及均匀分布。

在SnAgCu中添加SiC颗粒,随着SiC颗粒质量分数增加,钎料内部Ag3Sn晶粒尺寸逐渐变小;加入量为0.05%时尺寸最小,为0.24 μm,继续增加SiC颗粒含量,Ag3Sn晶粒尺寸有所增大,到0.20%时,Ag3Sn尺寸与0.01%颗粒钎料基体Ag3Sn尺寸近似,另外β-Sn相的亚晶粒也明显细化[27]。刘晓英等[28]采用在Y2O3粉(1 μm)中加入RMA钎剂,搅拌均匀后添加Sn3.0Ag0.5Cu粉末(30~50 μm)制成焊膏。研究发现Y2O3均匀弥散分布在钎料基体中,对晶界起到一定的“定扎”作用,由此抑制了β-Sn的粗化,同时减小Ag3Sn和Cu6Sn5的尺寸。同时在Sn58Bi钎料中添加Al2O3,Fe2O3,SiO2和TiO2,发现类似的细化作用[29]。

1.2 界面组织

在钎焊过程中,由于钎料的熔化,钎料和基板之间会发生反应,形成一层脆性金属间化合物(IMC),同时在服役期间,由于元素的扩散,IMC的厚度会明显增加。当界面层IMC过厚时,焊点的性能会明显恶化[30]。因此,IMC的形成对焊点的可靠性有着重要的影响。

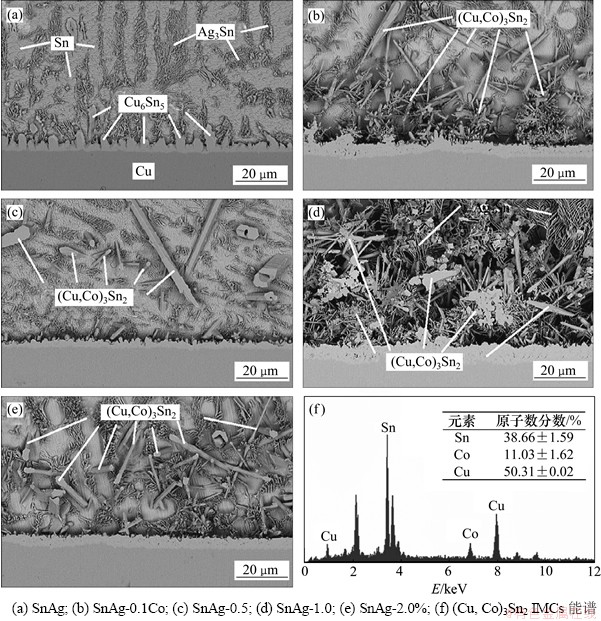

通过机械混合方法将Co微米颗粒加入到Sn3.5Ag钎料中,发现界面金属间化合物层的厚度几乎没有变化,但是Cu6Sn5的形态由扇贝状转变为小面针状,同时随着Co添加量的增加,界面处出现大量的(Cu,Co)3Sn2相,如图2所示[31]。通过Co纳米颗粒混合Sn3.8Ag0.7Cu焊膏,研究Co颗粒对SnAgCu界面组织的影响,发现Co纳米颗粒可以显著抑制Cu3Sn的生长,主要由于Co可以降低Cu3Sn的界面互扩散系数,但是会明显促进Cu6Sn5的生长[32]。在Sn3.8Ag0.7Cu焊膏中混合Mo纳米颗粒,发现Mo纳米颗粒在熔融的钎料中阻止Cu基板中Cu元素的扩散,同时随着Mo颗粒的增加Cu的扩散速率明显降低,Mo颗粒明显抑制界面层的生长,界面层Cu6Sn5颗粒的尺寸明显减小,Cu3Sn的生长速度得到明显降低[33]。聂京凯等[34]在Sn3.5Ag焊膏中添加Ni颗粒(粒径为1~3 μm), 发现由于Ni的加入,导致大量的三维的Cu-Ni-Sn管道的形成。这就促使界面元素的扩散,进而增加界面层的厚度。

图1 SnAg-xNi钎料组织[22]

Fig. 1 Microstructure of SnAg-xNi solder[22]

卫国强等[35]选择在Sn9Zn钎料中添加Cu颗粒(粒径8μm),发现在长时间再流焊时,加入Cu 颗粒可有效降低SnZn/Cu 接头界面Cu-Zn 金属间化合物的生长速度,从而减小界面IMC 层的厚度,界面IMC 层厚度随钎料中Cu 颗粒加入量的增加而减小。在SnZn 钎料中加入Cu 颗粒降低界面IMC 层的厚度,其原因可解释为由于Cu 颗粒的加入,增加了和钎料中Zn 反应的Cu 的面积,降低了液态钎料中Zn 的含量,因此Zn 的扩散速度降低,导致钎料SnZn/Cu 试样界面IMC厚度降低。Amagai[36]研究了Co,Ni,Pt,Al,P,Cu,Zn,Ge,Ag,In,Sb和Au等纳米颗粒对Sn3Ag焊点界面金属间化合物生长行为的影响,发现Co,Ni和Pt 3种纳米颗粒并不能明显增加界面层金属间化合物的厚度,3种元素可以熔解在界面层金属间化合物中;Al,P,Cu,Zn,Ge,Ag,In,Sb和Au可以显著提高界面层的厚度,在界面 层中没有发现Al,P,Ge,In和Sb等合金元素。Co,Ni和Pt 3种纳米颗粒相对Cu,Sb,In,Bi,Ge,Al和Zn等纳米颗粒添加到Sn3Ag焊点可以减小界面断裂的发生概率。纳米Ag颗粒添加到SnZn钎料中对SnZn/Ni焊点的界面组织也有明显的影响,含质量分数为1%的Ag的焊点界面层没有发现类似SnZn/Ni焊点界面较为显著的金属间化合物分离现象,焊点内部的纳米颗粒分布较为均匀,同时界面层出现明显的两层组织,当纳米颗粒质量分数为2%~4%时,界面组织演化为明显的三层组织[37]。主要是因为纳米颗粒在界面处参与界面反应,从而形成新的物相。

图2 界面组织图[31]

Fig. 2 Microstructure of interface[31]

Gain等[38]研究了纳米Al和Ni颗粒对SnAgCu/OSP-Cu界面组织的影响,发现0.5%纳米Ni颗粒会使界面层出现Sn-Cu-Ni金属间化合物,0.5%的Al颗粒也会使界面出现Sn-Ag-Al金属间化合物相。添加纳米和微米颗粒,焊点界面组织中纳米颗粒部分参加内部和界面反应,和冶金制备的合金化无铅钎料相类似。例如通过冶金方式研发的含稀土Ce的SnAgCu无铅钎料,在焊点中稀土元素Ce参与内部Sn元素反应,形成Ce-Sn新相[39]。但是在长时间的服役过程中,微量的纳米-微米颗粒只能短暂影响界面的生长,在长时间的交变温度循环过程中,当纳米微米颗粒消耗殆尽时,界面组织仍以Cu-Sn(SnAgCu/Cu,SnCu/Cu和SnAg/Cu)或者Cu-Zn(SnZn/Cu)生长为主,目前在新型钎料研究中,研究成果均是研究短时间的时效过程中界面层的生长,分析纳米微米颗粒的影响机制,缺乏长时间甚至超长时间界面的组织演化。

通过冶金方法在Sn3.5Ag0.7Cu钎料中添加Ni涂层碳纳米管,发现在等温时效和热循环过程中,界面层的生长速度得到明显的降低,这主要是因为Ni-CNT的添加可以明显抑制界面Sn的扩散,从而抑制界面层Cu-Ni-Sn相的生长[40]。有研究者研究含多壁碳纳米管SnAgCu焊点界面组织结构,发现了类似的抑制界面生长现象[41]。TiO2纳米颗粒添加到Sn3.0Ag0.5Cu,发现纳米颗粒可以显著降低界面层的厚度和晶粒尺寸,当纳米颗粒的添加量为0.1%时,对界面层的金属间化合物的生长达到最大抑制[42]。微米Si3Ni4添加到Sn0.7Cu钎料中,可以在一定程度上减小金属间化合物的厚度,但是减小的幅度较小[43]。化合物颗粒在无铅钎料中不会与基体组织发生反应,仅仅依靠颗粒自身的分布对焊点组织产生影响,因此,在长时间服役期间,纳米颗粒的影响依然存在,但是部分纳米颗粒会被服役期间界面层因元素扩散形成的金属间化合物包覆,纳米颗粒的影响将会有一定程度减弱。

为了研究纳米-微米颗粒对焊点界面金属间化合物的影响,根据经验公式[44]计算元素的扩散系数、拟合界面金属间化合物和时效时间之间的关系式、计算焊点界面金属间化合物的生长激活能。t时刻界面层的金属间化合物厚度可以表示为

(1)

(1)

其中:Xt为t时刻的界面层的厚度;X0为界面层初始厚度;k是温度相关的扩散系数。

而元素的扩散系数k的经验公式为

(2)

(2)

对式(2)两边取对数,可以得到

(3)

(3)

通过构建ln k-1/T图,可以计算金属间化合物的激活能Q。

2 对软钎料性能的影响

2.1 熔化特性

对无铅钎料而言,钎料的熔点决定了钎料的再流焊的峰值温度,传统的SnPb共晶钎料的熔化温度为183 ℃,针对传统SnPb钎料的再流温度也较低,而无铅钎料的熔化温度相对较高,例如SnAgCu的熔点为217 ℃,无疑提高了钎料的再流焊峰值温度,一般为245 ℃左右。因此,在研究含纳米-微米颗粒无铅钎料时,钎料的熔化温度也成为评价其性能的一个重要指标。

Co微米颗粒添加到Sn3.5Ag钎料,对熔化温度几乎没有影响,但是钎料熔化过冷度得到明显降低,这主要归因于Co颗粒增加了钎料在凝固过程中的形核位置[31]。纳米Ag颗粒对SnZn钎料的液相线的温度有明显影响,SnZn的液相线温度为199 ℃,当纳米Ag颗粒的添加量为3%和4%时,温度在210 ℃[37]。刘彬等[45]研究发现高分子材料POSS颗粒的添加对Sn3.5Ag钎料的熔化温度影响不大,液相线温度在220~226 ℃之间。纳米Al2O3添加到SnZn钎料也具有类似的效果,对钎料的熔化温度影响较小,SnZn-3Al2O3的熔化温度为198.98 ℃,而SnZn的熔化温度为198.5 ℃[46]。因此,对于添加纳米-微米颗粒的新型钎料的再流焊峰值温度可以和未添加颗粒的母合金相同,故可以不改变其再流焊工艺。

微米Fe粉(1~2 μm)添加到Sn3Ag0.5Cu基体金属粉体,制备成焊膏,DSC测试发现Fe对SnAgCu钎料的熔化温度几乎没有影响,在SnAgCu中添加SiC颗粒和在SnAg中添加ZrO2纳米颗粒熔化温度变化也较小[47]。微米级Ni颗粒添加到SnAgCu钎料,液相线的温度由219.9℃转变为220.5~221.8℃,Ni颗粒的添加对复合钎料的熔化温度影响较小[27],在SnAgCu-xNi钎料的研究,也发现了类似的现象[48]。有研究者选择在Sn58Bi钎料中添加碳纳米管,发现纳米管对钎料熔化温度的影响不明显[49]。对于目前研究者采用的添加颗粒方法,几乎在钎料的熔化温度方面没有贡献。邹长东[50]采取液相化学还原法和自耗电极直流电弧法将SnAgCu钎料纳米化,将钎料制备成纳米级粉末,可以将Sn3.0Ag0.5Cu纳米粒子的熔化温度降为180.5 ℃,和传统SnPb共晶钎料的熔化温度相当。但是考虑到大规模生产和成本问题,纳米钎料在工业中的推广和应用还需进行大量的研究工作。

2.2 润湿性

钎料的润湿性是评价无铅钎料的一个重要指标[51]。钎料的润湿性是指液态钎料在母材表面铺展的能力[52],对于工艺而言,在一定的加热温度下,钎料只有具有良好的润湿性,才能在母材表面润湿铺展形成良好的接头,即为焊点,而焊点在整个电子器件中承担着机械支撑和电气连接的作用,因此,焊点成形工艺也直接决定了电子产品的使用性能。对于传统的SnPb钎料,因为Pb元素的存在,钎料的润湿性能较好,但是随着无铅钎料替代传统的SnPb钎料后,钎料的润湿性也明显变差。为了更好提高无铅钎料的润湿性,合金化提高无铅钎料的润湿性是目前研究者研究的热点。目前评价钎料润湿性的主要有2种:一种是采用润湿平衡法,通过润湿时间和润湿力表征钎料润湿性的优劣;另一种是将定量的钎料在基板表面润湿,测量铺展面积,或者直接测量钎料的润湿角。

Lee等[31]发现添加Co微米颗粒到SnAg钎料中,钎料的润湿性几乎没有变化。纳米Ni颗粒能够显著提高Sn0.65Cu亚共晶钎料的润湿性,最佳添加量为0.10%,当纳米颗粒的添加量进一步增加,润湿性有一定的下降,研究者将该现象归结于键能较低导致原子力推动Ni原子的移动,Ni添加量的增加致使熔融钎料表面膜增加,润湿性变差[53]。在Sn3.5Ag钎料中添加纳米Ni颗粒,也发现了类似的促进作用,而纳米Cu颗粒的添加则显著恶化钎料的润湿性[54]。SnAgCu钎料中添加纳米Ag颗粒,钎料的润湿性能得到显著改善[55]。目前对含纳米颗粒的无铅钎料制备主要是采用机械搅拌制成焊膏的方式,由于纳米颗粒容易团聚,在机械搅拌不当时,容易使纳米颗粒的作用走向反面。因此含纳米颗粒无铅钎料的制备工艺是其中一项关键的技术。

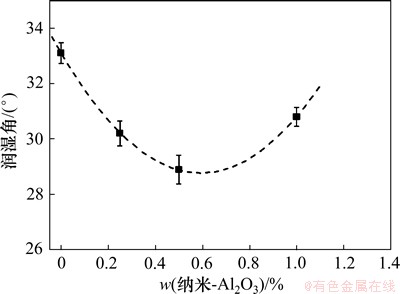

Al2O3纳米颗粒添加到Sn3.5Ag0.5Cu钎料,钎料的润湿角得到明显的减小,如图3所示。当纳米颗添加为0.5%时,润湿角的最小值为28.9°[56]。在Sn3.5Ag0.7Cu中添加TiB2颗粒和碳纳米管(NWCNTs)(直径为3~20 nm,长为几十μm), 钎料的润湿角与添加量之间有明显的内在联系,发现最优添加量分别为1.50%和0.04%,此时润湿角减小了22.2%和15.7%[57]。POSS颗粒的添加可以提高Sn3.5Ag钎料的润湿铺展面积,添加最佳值为2%[45]。分析认为这是由于POSS 颗粒增强相中包括1~3 个Si—OH 基团,同时包含了键能较高的惰性球笼和表面活性 Si—O 基团,在钎焊过程中与基体钎料结合,降低界面能,从而润湿母材。微米Si3Ni4添加到Sn0.7Cu钎料中,可以显著减小钎料的润湿角,最优添加量为1%,润湿角由30.38°变为14.25°[43]。在Sn3.5Ag0.7Cu中添加Ni涂层碳纳米管,发现钎料的润湿角明显减小,加入质量分数为0.05%和0.10%能使其润湿角降低大约12.5%和13.2%,研究者认为这主要是因为Ni-CNTs强化相的加入减小了液态复合钎料在Cu基板处的表面张力[58]。石墨烯纳米片作为添加颗粒可以显著降低SnAgCu钎料的润湿角,随着石墨烯纳米片的增加,钎料的润湿角显著降低,当添加量增加到0.10%时,润湿角降为最小值,比母合金的润湿角下降近15.5%[59]。

图3 含纳米Al2O3颗粒SnAgCu钎料润湿角[59]

Fig. 3 Contact angle of SnAgCu solder bearing Al2O3 particles[59]

钎料润湿性的影响因素主要有5个,包括钎料成分、温度、母材表面状态、钎剂及控制气氛[60]。在这几个影响因素中钎料成分的研究是目前研究者主攻的方向,尽管改变钎料成分可以在一定层次上提高钎料的润湿性,但是提高幅度相对不大,甚至被有些研究者[61]确定为改善钎料润湿性的“死胡同”。有研究者[62]认为选择合适的钎剂应该成为改善钎料润湿性的主要手段,并且通过实验证实了不同钎剂对钎料的润湿性影响差别较大。

2.3 力学性能

力学性能指标是评价新型钎料的又一指标。目前主要进行两方面探讨:一是做成棒状的钎料,直接进行拉伸或者剪切测试,这种方法是金属材料常用的方法;另一种方法是用钎料进行钎焊实验,对焊点进行力学性能测试,例如QFP器件的45°拉伸,片式电阻/焊球剪切,模拟件拉伸等[63-64]。针对目前新型钎料的研究,第2种方法应用相对较多,第2种方法也相对较为符合实际情况。因为钎料最终都要经过焊接试验,最终转变为焊点,因此,对焊点进行力学性能测试更符合实际情况。

有研究者采用双板搭接制备钎焊接头的剪切样品,在SnAgCu钎料中添加纳米Fe颗粒,发现0.5%的纳米Fe颗粒可以使焊点的剪切强度提高18%,当纳米Fe颗粒含量为1.0%时,剪切强度提高39%[47]。纳米Al颗粒作为添加物可以显著提高SnAgCu焊点的剪切强度,且随着纳米颗粒添加量增加焊点的剪切强度明显增加,在热循环和时效过程中,焊点剪切强度仍然保持类似的趋势[24]。纳米Mo添加到SnAgCu钎料可以显著提高其屈服应力,研究者探讨了含纳米颗粒1.0%和2.0% 2种,采用的力学性能测试方式是“狗骨头”状的钎料棒进行分析[65]。微量的Co颗粒可以提高Sn3.5Ag焊点的剪切强度,当Co的添加过量如为2.0%时,焊点的剪切强度会明显下降。这主要是此时焊点界面处出现大块的(Cu,Co)3Sn2相,会明显恶化焊点的性能[31]。Ag纳米颗粒加入到SnZn钎料后,SnZn焊点的剪切力明显增加,同时随着Ag添加量的增加,焊点剪切力由42.1 MPa变为48.9 MPa,这主要是因为Ag纳米颗粒的增加,导致大量的AgZn3相析出,产生第二相颗粒强化[25]。

添加3%TiB2,Sn3.5Ag0.7Cu钎料的最大抗拉强度和屈服强度分别提高23%和26%,而钎料的韧性都得到不同程度的降低,这主要归结于脆性的陶瓷颗粒会成为潜在的裂纹源,导致在拉伸过程中韧性的明显下降[57]。添加POSS可以显著提高Sn3.5Ag钎焊接头的剪切强度,增加幅度可以达到33.7%,POSS的促进作用与其化学活性有直接的联系[45]。为分析纳米粒子对焊点强度,可以采用式(4)来解释,该式是描述材料强度与粒子体积/直径之间的函数,可以发现粒子直径越小,焊点的剪切强度越高,故而纳米颗粒的添加可以提高接头的剪切强度[66]。

(4)

(4)

其中: 为焊点的剪切强度;

为焊点的剪切强度; 为基体的剪切强度;Vf为填料的体积填充分数;G为基体的剪切模量;b为伯格斯矢量;d为填料颗粒直径;kd为颗粒聚集参数。

为基体的剪切强度;Vf为填料的体积填充分数;G为基体的剪切模量;b为伯格斯矢量;d为填料颗粒直径;kd为颗粒聚集参数。

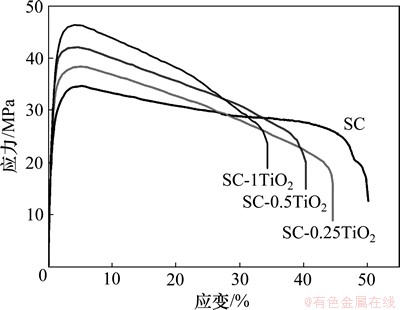

碳纳米管的添加也会对Sn3.5Ag0.7Cu钎料起到强化的效果,研究者将其归结于碳纳米管导致的热应力和对位错的定扎作用[67]。石墨烯纳米片作为添加颗粒可以显著提高SnAgCu钎料的最大拉伸力,提高幅度近10%,减小其延展性;当添加量为0.03%时,减小幅度为20%[59]。纳米Al2O3颗粒作为添加颗粒可以显著提高SnAgCu复合钎料的屈服应力和硬度,研究者将其归因于纳米Al2O3和Ag3Sn颗粒作为强化相提高材料的性能,符合弥散强化理论[56]。在Sn0.7Cu钎料中添加纳米TiO2颗粒,拉伸曲线如图4所示。由图4可以看出:纳米颗粒的添加可显著提高钎料的最大拉伸力(UTS),纳米颗粒添加为1%时,UTS提高幅度为33.4%,屈服应力提高幅度为43%[68]。

图4 SnCu复合钎料室温拉伸应力-应变曲线[68]

Fig. 4 Tensile stress-strain of SnCu solders at room temperature[68]

纳米SrTiO3颗粒作为添加物可显著提高SnAgCu焊球的剪切强度,在热循环和时效过程中含纳米颗粒SnAgCu均保持较高的焊球剪切强度,且保持较高的数据稳定性,下降幅度较小[69]。纳米ZrO2颗粒添加在Sn3.0Ag0.5Cu中也发现纳米颗粒可以使焊点的剪切强度显著提高,研究者将其归因于第二相颗粒强化机制[70]。纳米ZrO2颗粒在Sn9Zn钎料中也表现相类似的增强效果,同时还使焊点的力学性能在热循环过程中保持数据稳定性[71]。在Sn3.5Ag中添加微量的纳米SnO2颗粒(0.5%,0.7%和1.0%),发现纳米颗粒的添加钎料的最大拉伸力/屈服应力和纳米颗粒的添加量有密切关系,纳米颗粒添加0.5%可以显著提高钎料的最大拉伸力和屈服应力,当纳米颗粒添加量为0.7%时,促进作用达到最大,但是当纳米颗粒的添加量为1.0%时,钎料的性能明显低于Sn3.5Ag钎料的性能[72]。为了解释这种现象,研究者采用计算缩松的方法探讨纳米颗粒的影响机制。另外,在研究无铅钎料/焊点力学性能影响机制上,研究者还是倾向于从Ag3Sn和Cu6Sn5颗粒组织的变化探讨对性能的影响[73]。

纳米颗粒的添加细化基体组织,同时减小Ag3Sn和Cu6Sn5颗粒的尺寸,为了定量研究纳米颗粒对焊点力学性能的促进机制,可以从纳米颗粒表面的应力来分析,对于纳米颗粒塞积位错所产生的应力[74]可以表示为

(5)

(5)

其中: 为颗粒表面的应力;n为塞积位错数;

为颗粒表面的应力;n为塞积位错数; 为合金的屈服应力。塞积位错数n为

为合金的屈服应力。塞积位错数n为

(6)

(6)

其中: ;

; 为泊松比;L为颗粒之间的平均距离。颗粒表面的应力为

为泊松比;L为颗粒之间的平均距离。颗粒表面的应力为

(7)

(7)

假设 为第二相颗粒的断裂应力,

为第二相颗粒的断裂应力, 和b为常数,那么合金的屈服应力为

和b为常数,那么合金的屈服应力为

(8)

(8)

由于纳米颗粒的添加,基体中的Ag3Sn和Cu6Sn5颗粒尺寸变小,且均匀分布在钎料基体中,颗粒间距L明显减小,根据式(8),钎料的屈服应力 则明显增加,因此,在理论上也证明了纳米颗粒的添加使钎料的力学性能显著提高。

则明显增加,因此,在理论上也证明了纳米颗粒的添加使钎料的力学性能显著提高。

2.4 蠕变特性

对于无铅钎料而言,钎料的熔化温度较低,例如SnAgCu的熔点为217 ℃,在室温下钎料的归一化温度达到0.61。在金属材料中,规定材料的工作归一化温度超过0.5,则定义为材料的高温蠕变变形[75-76]。故而无铅钎料在室温下发生了高温蠕变变形,蠕变变形也是评估无铅钎料的一个重要指标。

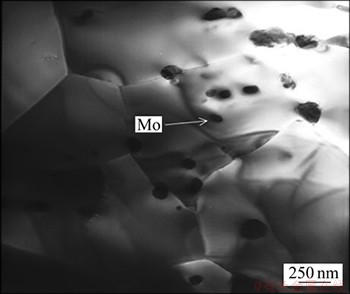

Niranjani等[77]研究了含纳米Ni和Mo颗粒的Sn3.5Ag钎料的蠕变行为,发现钎料的蠕变数据符合Modified-Garofalo方程,稳态蠕变速率、初始蠕变阶段位移和初始稳态阶段时间均随着纳米Ni和Mo颗粒的增加而降低。另外在纳米Mo颗粒为1.5%时可以明显看出基体中均匀分布纳米颗粒,如图5所示。纳米Ag颗粒添加到Sn0.7Cu钎料后,焊点的抗蠕变性能有着明显的变化:纳米Ag颗粒增强的Sn-Cu基复合钎料的蠕变断裂寿命显著提高,且具有更高的蠕变激活能[78]。纳米Ag颗粒对位错有定扎作用,阻碍位错和晶界的运动,从而提高复合钎料接头的蠕变断裂寿 命[79]。Shi等[80]选择在Sn37Pb和Sn0.7Cu钎料中添加纳米Ag,Cu,Al2O3和TiO2颗粒,发现无铅钎料的蠕变阻抗得到显著提高。同时发现纳米颗粒的添加存在最优添加量。纳米Ag颗粒添加到SnPb钎料中,有研究者也发现了类似的规律[81]。在无铅钎料中添加颗粒,由于强化颗粒均匀分布在基体组织中,而β-Sn则围绕颗粒结晶,使钎料晶粒发生晶格畸变,这种结构在外力作用下不易发生晶界滑移和变形,因此,抗蠕变性能明显增加[82-85]。

图5 Sn3.5Ag1.5Mo合金TEM组织[77]

Fig. 5 TEM image of Sn3.5Ag1.5Mo alloy[77]

在Sn3.5Ag0.7Cu中添加碳纳米管,钎料的抗蠕变性能显著提高,同时蠕变失效时间明显增加[86]。在Sn1.7Sb1.5Ag中添加2.3%Al2O3亚微米颗粒,钎料的蠕变速率明显减小,钎料的抗蠕变性能显著增加[87]。主要归因于颗粒对晶粒滑移和晶粒边界移动的阻碍作用。在SnPb钎料中添加纳米TiO2颗粒也具有类似的效果[88]。微米Cu6Sn5颗粒添加到Sn3.5Ag钎料中,钎料的抗蠕变性能得到显著提高,含微米Cu6Sn5颗粒的钎料的稳态蠕变速率为7.69×10-6 s-1,应力因子为12.34,Sn3.5Ag钎料的稳态蠕变速率为8.98×10-6 s-1,应力因子为10.11[89]。纳米结构的有机-无机笼型硅氧烷(POSS)颗粒的添加也可以显著提高Sn3.5Ag蠕变断裂寿命,对于SnAgCu基无铅钎料也具有类似的规律,同时,SnAgCu基复合钎料的性能优于SnAg基复合钎料的性能[90]。研究含纳米-微米颗粒无铅钎料的抗蠕变性能的影响机制问题,研究者均从颗粒和位错、晶粒、晶粒边界之间的关系进行解释,同时从钎料蠕变断口断裂模式[91]也可以分析钎料蠕变变形机制。

针对无铅钎料蠕变性能的研究,研究者探讨了无铅钎料的蠕变本构关系,较为常用的蠕变本构模型有Dorn模型和Garofalo-Arrhenius模型。在研究无铅钎料蠕变变形中,宏观的蠕变变形主要是拉伸和压缩2种[92-93],微观的蠕变变形主要是采用纳米压痕的方法分析物相(Cu6Sn5和Cu3Sn)的变形[94-95]。因为无铅钎料的熔化温度较低,在服役期间将发生明显的蠕变变形,蠕变变形也是焊点失效的主要原因[96-97],因此,蠕变特性也是无铅钎料研究中的一个重要方面,而蠕变本构关系在力学上能更好地描述材料的蠕变性能,对含纳米-微米颗粒无铅钎料的蠕变本构方程有必要进行深入探讨。Shi等[98]探讨含纳米Ag颗粒Sn0.7Cu焊点蠕变变形,拟合其蠕变本构方程,分阶段探讨其应力-应变关系,如式(9)~(12)所示。

含纳米Ag颗粒SnCu焊点本构方程:

(低应力) (9)

(低应力) (9)

(高应力) (10)

(高应力) (10)

SnCu焊点本构方程:

(低应力) (11)

(低应力) (11)

(高应力) (12)

(高应力) (12)

其中: 和

和 为应变速率;R为气体常数;T为热力学温度;

为应变速率;R为气体常数;T为热力学温度; 为施加的剪切力。

为施加的剪切力。

Dorn模型[99]如式(13)所示,该模型在力学上直观的描述了无铅钎料在稳态蠕变阶段的本构关系。对于SnAgCu,SnCu和SnAg等系列钎料有大量的研究成果,且在焊点可靠性研究中已经应用于有限元模拟。但是基于含纳米-微米颗粒复合钎料的成果还缺乏相关报道。

(13)

(13)

其中: 为材料的蠕变速率;A为材料常数;

为材料的蠕变速率;A为材料常数; 为施加的应力;Q为蠕变激活能。

为施加的应力;Q为蠕变激活能。

Garofalo-Arrhenius模型[100-101]也是目前应用较为广泛的蠕变本构关系之一:

(14)

(14)

其中:C1,C2,C3和C4为材料的4个常数。

研究该模型主要是采用单轴拉伸蠕变测试的方 法[102],诸多研究者采用该模型基于有限元模拟分析焊点的蠕变变形[103-104]。关于含纳米-微米颗粒复合钎料以及焊点可靠性中鲜有报道。

3 颗粒强化无铅焊点可靠性

在大规模的集成电路中焊点的数量数以千计,焊点在电路中既承担着电气连接,又承担着机械支撑的作用[105]。由于焊点尺寸较小且数量较大,在实际的电子产品中,单个焊点的可靠性直接决定了整个电子产品甚至整个设备的可靠性[106-107]。影响焊点可靠性的因素较多,美国航空工业部门统计发现电子器件失效原因55%是由于温度变化引起的,20%是振动引起的,19%是潮气引起引起的,另有6%是灰尘的原因[108]。因此,在焊点可靠性研究中,诸多的研究者倾向于研究焊点在温度载荷作用下的可靠性,特别是热循环和时效[109-112]。

针对含纳米-微米颗粒无铅焊点可靠性的研究成果较少。有研究者探讨了含纳米Ag颗粒Sn0.7Cu焊点在热循环过程中界面的生长行为,发现含纳米颗粒焊点界面层金属间化合物的生长速率明显小于Sn0.7Cu焊点的生长速率,含纳米Ag颗粒焊点表现出较小的界面扩散系数[113]。Sivasubramaniam等[114]在短时间时效(150 ℃)过程中研究了Sn4.0Ag0.5Cu含微米Cu颗粒(3~20 μm)和纳米Cu2O(~150 nm)的界面反应,发现添加颗粒可以显著减小界面层金属间化合物的生长速度,在时效过程中含颗粒焊点保持较高的强度。由于界面处金属间化合物相为脆性相,在服役期间由于界面层的快速生长,以及线膨胀系数的失配导致焊点在该区域萌生裂纹,裂纹扩展导致焊点的失 效[115-117]。

含纳米-微米无铅焊点可靠性研究中还包含了诸多内容的研究还处于空白阶段,例如焊点的电子迁移,由于电子器件一直在电流的作用下工作,焊点内部的电迁移显得尤为重要[118],纳米-微米颗粒的添加对焊点电子迁移是否有影响目前还没有相关的报道。同时,在含纳米-微米颗粒焊点可靠性中的跌落、振动等试验研究也处于未知状态,而这些因素也直接关系到该系列新型无铅钎料能否在电子工业中获得推广和应用。有限元模拟可以辅助、快速地进行焊点可靠性的研究[119],该部分研究工作还没有相关研究工作者涉猎,这也主要是因为新型无铅钎料的资料缺乏,无法进行更深入的探讨和研究。一类新型钎料的应用和推广必须在无铅钎料的性能和焊点可靠性方面有充足、系统的数据基础之上。因此,还需对含纳米-微米颗粒无铅焊点的可靠性进行大量研究。

4 颗粒增强无铅钎料研究中所存在的问题

目前纳米-微米颗粒增强复合钎料成为研究者研究的一个重要热点。近年来,相关的论文、专利较多,纷纷探讨颗粒的添加对钎料性能的改善。尽管研究成果较丰富,但是具体在电子工业中使用和推广的颗粒增强复合钎料案例几乎没有。这主要是因为该系列新型无铅钎料还缺乏系列的数据证明其可行性。传统的无铅钎料因为其具有良好的性能而被电子工业界广为使用,即使是在今天人们对环境保护要求极高的情况下,民品已经使用了无铅钎料,而军品却拿到了豁免权[120],仍然坚持使用传统的SnPb钎料,主要是业界已经对这种钎料的性能较了解,且能够预知该钎料在服役期间的可靠性。相反,含纳米-微米颗粒复合钎料的研究成果较单一,仅仅是研究者针对一种钎料的某一个甚至几个方面性能进行了研究,缺乏对这一种钎料的整体认识。

针对含纳米-微米颗粒复合钎料的研究,本文作者综合分析发现该系列钎料存在以下5个问题需进一步研究:

1) 钎料的制备方法。对于目前的研究成果发现,大部分的研究者采用焊膏混合颗粒制备含纳米-微米复合钎料,这种制备方法在一定程度上可以使颗粒混合在焊膏中,但是很难保证颗粒的均匀性和焊接过程中钎料中颗粒溢出。特别是纳米颗粒容易团聚,一般的搅拌工艺都无法使纳米颗粒均匀分布在钎料的基体,纳米颗粒的团聚[121]会导致后期焊点的力学性能的下降和可靠性降低,直接使研究的最终目的走向反面。而在再流焊的过程中,熔融钎料表面容易使纳米颗粒溢出,特别是纳米氧化物颗粒,因为氧化物颗粒不与钎料基体发生反应,很容易溢出停留在钎料表面,反而在一定程度上抑制了钎料的润湿,从而恶化钎料的性能。

2) 匹配钎剂的研究。含纳米-微米复合钎料熔化温度和润湿性能一般变化不大,纳米-微米颗粒在这两方面的促进作用不是很显著,在焊点力学性能方面作用突出,熔化温度和润湿性却决定了钎料的再流焊工艺,因此,含纳米-微米颗粒的复合钎料工艺性能相对较差。若选择合适的钎剂,则可以弥补该系列钎料的缺陷,有研究者分析发现仅对SnZn钎料选择合适的钎剂,其润湿性可以提高116.1%[122],因此,可以从研究钎剂的角度来提高含纳米-微米颗粒复合钎料的工艺性能。

3) 焊点的可靠性。目前对于新型钎料的研究成果较多,针对每一种新型钎料的可靠性研究成果则相对较少,恰恰焊点可靠性才能真实反映钎料在使用过程中的真实情况。对于一种新型钎料在服役期间的情况带有系列的不可以测性,必须深入探讨才可以在工业中推广应用。在可靠性研究中会不同程度地出现一些“意外”状况,例如含稀土无铅钎料诸多研究者已经在工艺性能、力学性能等方面取得了系列成果,但是在可靠性研究中出现了“锡须”问题[123-124],直接导致含稀土无铅钎料推广受阻。因此,在新型无铅钎料推广应用之前,必须进行焊点热循环、时效、跌落、振动、湿气、灰尘等[125-130]系列测试,只有保证焊点可靠性测试中焊点具有较高的可靠性,才可以将新型复合钎料在电子工业中推广使用。

4) 钎料的本构方程和疲劳寿命预测方程。钎料的本构方程主要是通过实验研究测试材料应力-应变之间的关系,目前较为常用的有Anand黏塑性本构模型、Garofalo-Arrhenius蠕变模型、Dorn蠕变模型等[131-136],通过本构方程的研究可以从力学上更好地认识新型钎料的性能,从而完善新型钎料的性能数据。另外,焊点疲劳寿命预测模型也是需要研究的一个重要方面,采用有限元模拟的结果可以结合寿命预测方程快速地计算焊点的使用寿命,目前的寿命预测模型主要是基于塑性应变、单一蠕变、综合塑性和蠕变、基于蠕变和应变能密度等[137-142],目前还没有专门针对含纳米-微米颗粒无铅焊点疲劳寿命模型的相关研究成果。焊点寿命预测的研究可以为焊点可靠性研究提供理论 支撑。

5) 结合电子器件的试验研究。近年来含纳米-微米复合钎料的研究成果基本上为模拟件,结合具体的电子器件成果较少。无铅钎料的研究最终都要在电子工业中使用,那么均要结合电子器件进行再流焊工艺,例如QFP,BGA和WLCSP等器件[143-146],而针对不同的电子器件,焊点的尺寸会从毫米级到微米级甚至亚微米级[147],以至于发生明显的尺寸效应[148],同时不同形态焊点对应焊点的性能也大不相同[149-150]。因此,在实际的研究中,含纳米-微米颗粒复合钎料结合具体的电子器件进行研究更具有实际意义。

5 结论

随着电子工业的快速发展,无铅钎料的研究成为电子工业中一个重要的研究热点。目前针对含纳米-微米颗粒复合钎料也成为诸多研究者青睐的对象,针对该系列钎料的研究国内外已经具有丰富的研究成果。系列的研究成果主要是针对纳米-微米颗粒对无铅钎料性能和微观组织的影响,大多数颗粒对钎料的力学性能、蠕变性能有明显改善作用,同时对钎料内部组织有细化作用、对焊点界面生长有抑制作用。但主要是针对钎料的性能和焊点的部分性能进行研究,缺乏系统的研究成果。同时,通过纳米-微米颗粒提高钎料的性能具有明显的局限性,仅仅通过这一方法改善钎料的性能可行性较小,但是可以配合钎剂等措施进一步改善其性能。对于新型钎料的研究应该进一步从钎料的制备、焊接工艺、可靠性等方面深入的研究,从而为含纳米-微米颗粒新型钎料的推广和应用提供详实的资料。

参考文献:

[1] Chiang H W, Chen J Y, Chen M C, et al. Reliability testing of WLCSP lead-free solder joints[J]. Journal of Electronic Materials, 2006, 35(5): 1032-1040.

[2] 胡玉华, 薛松柏, 陈文学, 等. Sn-9Zn-xCe钎料组织及钎焊性能的分析[J]. 焊接学报, 2010, 31(6): 77-80.

HU Yuhua, XUE Songbai, CHEN Wenxue, et al. Microstructure and solderability of Sn-9Zn-xCe lead-free solder[J]. Transactions of the China Welding Institution, 2010, 31(6): 77-80.

[3] 张亮, 韩继光, 郭永环, 等. 含纳米铝颗粒SnAgCu钎料组织与性能[J]. 焊接学报, 2013, 34(6): 65-68.

ZHANG Liang, HAN Jiguang, GUO Yonghuan, et al. Microstructure and properties of SnAgCu solders bearing Al nano-particles[J]. Transactions of the China Welding Institution, 2013, 34(6): 65-68.

[4] Zhang L, Xue S B, Chen Y, et al. Effects of cerium on Sn-Ag-Cu alloys based on finite element simulation and experiments[J]. Journal of Rare Earths, 2009, 27(1): 138-144.

[5] Su Y A, Tan L B, Tee T Y, et al. Rate-dependent properties of Sn-Ag-Cu based lead-free solder joints for WLCSP[J]. Microelectronics Reliability, 2010, 50(4): 564-579.

[6] Wang Y W, Lin Y W, Kao C R. Inhibiting the formation of microvoids in Cu3Sn by additions of Cu to solders[J]. Journal of Alloys and Compounds, 2010, 493(1/2): 233-239.

[7] Li G D, Shi Y W, Hao H, et al. Effects of phosphorus element on the comprehensive properties of Sn-Cu lead-free solder[J]. Journal of Alloys and Compounds, 2010, 491(1/2): 382-385.

[8] Xu R L, Liu Y C, Wei C, et al. Effects of Zn additions on the structure of the soldered Sn-3.5Ag and Cu interfaces[J]. Soldering & Surface Mount Technology, 2010, 22(2): 13-20.

[9] Garcia L R, Osório W R, Garcia A. The effect of cooling rate on the dendritic spacing and morphology of Ag3Sn intermetallic particles of a SnAg solder alloy[J]. Materials & Design, 2011, 32(5): 3008-3012.

[10] Zhang L, Xue S B, Gao L L, et al. Development of Sn-Zn lead-free solders bearing alloying elements[J]. Journal of Materials Science: Materials in Electronics, 2011, 21(1): 1-15.

[11] Hu J, Hu A M, Mao D L. Depressing effect of 0.1wt.% Cr addition into Sn-9Zn solder alloy on the intermetallic growth with Cu substrate during isothermal aging[J]. Materials Characterization, 2010, 61(3): 355-361.

[12] Song J M, Huang C F, Chuang H Y. Microstructural characteristics and vibration fracture properties of Sn-Ag-Cu-TM (TM=Co, Ni and Zn) alloys[J]. Journal of Electronic Materials, 2006, 35(12): 2154-2163.

[13] Zhang L, Xue S B, Gao L L, et al. Effects of trace amount addition of rare earth on properties and microstructure of Sn-Ag-Cu alloys[J]. Journal of Materials Science: Materials in Electronics, 2010, 20(12): 1193-1199.

[14] 王慧. 微合金化对Sn-9Zn无铅钎料性能影响及润湿机理研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2010: 1-112.

WANG Hui. Study on solderability and wetting mechanisms of micro-alloyed Sn-9Zn lead-free solder[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Materials Science and Technology, 2010: 1-112.

[15] Chen W X, Xue S B, Wang H. Wetting properties and interfacial microstructures of Sn-Zn-xGa solders on Cu substrate[J]. Materials & Design, 2010, 31(4): 2196-2200.

[16] 陈文学. Ag、Ga、Al及Ce对Sn-9Zn无铅钎料性能的影响[D]. 南京: 南京航空航天大学材料科学与技术学院, 2010: 1-60.

CHEN Wen-xue. Effects of Ag, Ga, Al and Ce on the properties of Sn-9Zn lead-free solder[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Materials Science and Technology, 2010: 1-60.

[17] Wang J X, Xue S B, Han Z J, et al. Effects of rare earth Ce on microstructures, solderability of Sn-Ag-Cu and Sn-Cu-Ni solders as well as mechanical properties of soldered joints[J]. Journal of Alloys and Compounds, 2009, 467(1/2): 219-226.

[18] Ye H, Xue S B, Zhang L, et al. Sn whisker growth in Sn-9Zn-0.5Ga-0.7Pr lead-free solder[J]. Journal of Alloys and Compounds, 2011, 509(5): 52-55.

[19] Chuang T H. Rapid whisker growth on the surface of Sn-3Ag-0.5Cu-1.0Ce solder joints[J]. Scripta Materialia, 2006, 55(11): 983-986.

[20] Shi Y W, Yan Y F, Liu J P, et al. Constitutive modeling on creep deformation for a SnPb-based composite solder reinforced with microsized Cu particles[J]. Microelectronics Reliability, 2010, 50(12): 2020-2025.

[21] 韩宗杰. 电子组装元器件半导体激光无铅软钎焊技术研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2009: 1-98.

HAN Zongjie. Diode laser soldering to electronic mounting components/devices with lead-free solder[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Materials Science and Technology, 2009: 1-98.

[22] Lee H T, Lee Y H. Adhesive strength and tensile fracture of Ni particle enhanced Sn-Ag composite solder joints[J]. Materials Science and Engineering A, 2006, 419(1/2): 172-180.

[23] Yao P, Liu P, Liu J. Interfacial reaction and shear strength of SnAgCu-xNi/Ni solder joints during aging at 150 ℃[J]. Microelectronic Engineering, 2009, 86(10): 1969-1974.

[24] Gain A K, Fouzder T, Chan Y C, et al. The influence of addition of Al nano-particles on the microstructure and shear strength of eutectic Sn-Ag-Cu solder and Au/Ni metalized Cu pads[J]. Journal of Alloys and Compounds, 2010, 506(1): 216-223.

[25] Gain A K, Chan Y C, Sharif A, et al. Interfacial microstructure and shear strength of Ag nano particle doped Sn-9Zn solder in ball array packages[J]. Microelectronics Reliability, 2009, 49(7): 746-753.

[26] Lin D C, Srivatsan T S, Wang G X, et al. Microstructural development in a rapidly cooled eutectic Sn-3.5%Ag solder reinforced with copper powder[J]. Powder Technology, 2006, 166(1): 38-46.

[27] 刘平. 颗粒增强Sn3.8Ag0.7Cu复合无铅焊料的研究[D]. 天津: 天津大学材料科学与工程学院, 2009: 1-107.

LIU Ping. Study on particles reinforced Sn3.8Ag0.7Cu composite lead free solders[D]. Tianjin: Tianjin University. School of Materials Science and Engineering, 2009: 1-107.

[28] 刘晓英, 于大全, 马海涛, 等. Y2O3增强Sn-3Ag-0.5Cu复合无铅钎料[J]. 电子工艺技术, 2004, 25(4): 156-158, 161.

LIU Xiaoying, YU Daquan, MA Haitao, et al. Effects of Y2O3 on Sn-3Ag-0.5Cu alloy and joint[J]. Electronics Process Technology, 2004, 25(4): 156-158, 161.

[29] 刘晓英, 马海涛, 王来. 超细氧化物颗粒对Sn-58Bi钎料组织及性能影响[J]. 大连理工大学学报, 2008, 48(1): 51-57.

LIU Xiaoying, MA Haitao, WANG Lai, et al. Effect of super-fine oxide powders on mechanical properties and microstructures of Sn-58Bi[J]. Journal of Dalian University of Technology, 2008, 48(1): 51-57.

[30] 张亮, Tu K N, 郭永环, 等. 时效对SnAgCu/SnAgCu-TiO2焊点界面与性能影响[J]. 焊接学报, 2013, 34(8): 43-46.

ZHANG Liang, Tu K N, GUO Yonghuan, et al. Effect of aging on the interface and properties of SnAgCu/SnAgCu-TiO2 solder joints[J]. Transactions of the China Welding Institution, 2013, 34(8): 43-46.

[31] Lee J S, Chu K M, Patzelt R, et al. Effects of Co addition in eutectic Sn-3.5Ag solder on shear strength and microstructural development[J]. Microelectronic Engineering, 2008, 85(7): 1577-1583.

[32] Haseeb A S M A, Leng T S. Effects of Co nanoparticle addition to Sn-3.8Ag-0.7Cu solder on interfacial structure after reflow and ageing[J]. Intermetallics, 2011, 19(5): 707-712.

[33] Arafat M M, Haseeb A S M A, Fohan M R. Interfacial reaction and dissolution behavior of Cu substrate in molten Sn-3.8Ag-0.7Cu in the presence of Mo nanoparticles[J]. Soldering & Surface Mount Technology, 2011, 23(3): 140-149.

[34] 聂京凯, 郭福, 郑菡晶, 等. Ni颗粒增强无铅复合钎料中IMC形态值演变[J]. 电子元件与材料, 2007, 26(9): 43-46.

NIE Jingkai, GUO Fu, ZHENG Hnajing, et al. Morphology evolution of intermetallic compounds in nickel particle reinforced lead-free composite solder[J]. Electronic Components and Materials, 2007, 26(9): 43-46.

[35] 卫国强, 况敏, 杨永强. Cu颗粒增强的Sn-9Zn复合钎料/Cu钎焊接头界面反应[J]. 焊接学报, 2007, 28(5): 105-108.

WEI Guoqiang, KUANG Min, YANG Yongqiang. Interfacial reaction of Sn-9Zn/Cu joint with Cu particle-reinforced composite solder Sn-9Zn[J]. Transactions of the China Welding Institution, 2007, 28(5): 105-108.

[36] Amagai M. A study of nanoparticles in Sn-Ag based lead free solders[J]. Microelectronics Reliability, 2008, 48(1): 1-16.

[37] Das S K, Sharif A, Chan Y C, et al. Effect of Ag micro-particles content on the mechan ical strength of the interface formed between Sn-Zn binary solder and Au/Ni/Cu bond pads[J]. Microelectronic Engineering, 2009, 86(10): 2086-2093.

[38] Gain A K, Chan Y C. The influence of a small amount of Al and Ni nano-particles on the microstructure, kinetics and hardness of Sn-Ag-Cu solder on OSP-Cu pads[J]. Intermetallics, 2012, 29: 48-55.

[39] Zhang L, Xue S B, Gao L L, et al. Microstructure characterization of SnAgCu solder bearing Ce for electronic packaging[J]. Microelectronic Engineering, 2011, 88(9): 2848-2851.

[40] Han Y D, Jing H Y, Nai S M L, et al. Interfacial reaction and shear strength of Ni-coated carbon nanotubes reinforced Sn-Ag-Cu solder joints during thermal cycling[J]. Intermetallics, 2012, 31: 72-78.

[41] Nai S M L, Wei J, Gupta M. Interfacial intermetallic growth and shear strength of lead-free composite solder joints[J]. Journal of Alloys and Compounds, 2009, 473(1/2): 100-106.

[42] Tang Y, Li G Y, Pan Y C. Influence of TiO2 nanoparticles on IMC growth in Sn-3.0Ag-0.5Cu-xTiO2 solder joints in reflow process[J]. Journal of Alloys and Compounds, 2013, 554(25): 195-203.

[43] Mohd S M A A, Bakri A M M A, Kamarudin H, et al. Solderability of Sn-0.7Cu/Si3N4 lead-free composite solder on Cu-substrate[J]. Physics Procedia, 2011, 22: 299-304.

[44] Zhang L, Xue S B, Zeng G, et al. Interface reaction between SnAgCu/SnAgCuCe solders and Cu substrate subjected to thermal cycling and isothermal aging[J]. Journal of Alloys and Compounds, 2012, 510(1): 38-45.

[45] 刘彬, 邰枫, 郭福, 等. 纳米结构强化的新型Sn-Ag基无铅复合钎料[J]. 材料工程, 2009(8): 38-48.

LIU Bin, TAI Feng, GUO Fu, et al. Research of new Sn-Ag based lead-free composite solders containing nano-structured reinforcements[J]. Journal of Materials Engineering, 2009(8): 38-48.

[46] Fouzder T, Gain A K, Chan Y C, et al. Effect of nano Al2O3 additions on the microstructure, hardness and shear strength of eutectic Sn-9Zn solder on Au/Ni metalized Cu pads[J]. Microelectronics Reliability, 2010, 50(12): 2051-2058.

[47] 刘晓英, 马海涛, 罗忠兵, 等. Fe粉对Sn-3Ag-0.5Cu复合钎料组织及性能的影响[J]. 中国有色金属学报, 2012, 22(4): 1169-1176.

LIU Xiaoying, MA Haitao, LUO Zhongbin, et al. Effect of Fe particles on microstructures and properties of Sn-3Ag-0.5Cu lead-free solder[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1169-1176.

[48] Gao L L, Xue S B, Zhang L, et al. Effect of alloying elements on properties and microstructures of SnAgCu solders[J]. Microelectronic Engineering, 2010, 87(11): 2025-2034.

[49] 安晶. 含碳纳米管的Sn-58Bi无铅钎料的制备及其性能研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2010: 1-38.

AN Jing. Investigation on the preparation method and properties of Sn-58Bi lead-free solder with carbon nanotubes[D]. Harbin: Harbin Institute of Technology. School of Materials Science and Engineering, 2010: 1-38.

[50] 邹长东. 应用纳米尺寸效应降低Sn基无铅焊料熔化温度的基础研究[D]. 上海: 上海大学材料科学与工程学院, 2010: 1-122.

ZOU Changdong. Fundamental research on the melting temperature depression of the Sn-based lead-free solder alloy via size effect of nanoparticles[D]. Shanghai: Shanghai University. School of Materials Science and Engineering, 2010: 1-122.

[51] Zhang L, Han J G, Guo Y H, et al. Microstructures and properties of SnZn lead-free solder joints bearing La for electronic packaging[J]. IEEE Transactions on Electron Devices, 2012, 59(12): 3269-3272.

[52] 张亮, 韩继光, 何成文, 等. 稀土元素对无铅钎料组织和性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1680-1696.

ZHANG Liang, HAN Jiguang, HE Chengwen, et al. Effect of rare earth on microstructures and properties of lead-free solders[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1680-1696.

[53] 黄文超, 甘贵生, 唐明, 等. 纳米Ni颗粒对Sn0.65Cu亚共晶钎料润湿性和抗氧化性的影响[J]. 精密成型工程, 2013, 5(1): 16-19.

HUANG Wenchao, GAN Guisheng, TANG Ming, et al. The effect of nano-Ni particles on the wettability and oxidation resistance of Sn0.65Cu hypoeutectic solder[J]. Journal of Netshape Forming Engineering, 2013, 5(1): 16-19.

[54] 孙莉. 添加纳米颗粒的复合无铅钎料及其微连接接头性能研究[D]. 石家庄: 石家庄铁道学院材料科学与工程学院, 2008: 1-69.

SUN Li. Researches on properties of nanoparticles composite lead-free solders and its micro-joined joint[D]. Shijiazhuang: Shijiazhuang Railway Institute. School of Materials Science and Engineering, 2008: 1-69.

[55] Bukat K, Koscielski M, Sitek J, et al. Silver nanoparticles effect on the wettability of Sn-Ag-Cu solder pastes and solder joints microstructure and copper[J]. Soldering & Surface Mount Technology, 2011, 23(3): 150-160.

[56] Tsao L C, Chang S Y, Lee C I, et al. Effects of nano-Al2O3 additions on microstructure development and hardness of Sn3.5Ag0.5Cu solder[J]. Materials and Design, 2010, 31(10): 4831-4835.

[57] Nai S M L, Wei J, Gupta M. Influence of ceramic reinforcements on the wettability and mechanical properties of novel lead-free solder composites[J]. Thin Solid Films, 2006, 504(1/2): 401-404.

[58] 韩永典. Ni涂层碳纳米管增强Sn-Ag-Cu无铅钎料的可靠性研究[D]. 天津: 天津大学材料科学与工程学院, 2009: 1-108.

HAN Yongdian. Reliability study on a Sn-Ag-Cu lead-free solder reinforced with Ni coated carbon nanotubes[D]. Tianjin: Tianjin University. School of Materials Science and Engineering, 2009: 1-108.

[59] Liu X D, Han Y D, Jing H Y, et al. Effects of graphene nanosheets reinforcement on the performance of Sn-Ag-Cu lead-free solder[J]. Materials Science & Engineering A, 2013, 562(1): 25-32.

[60] 王福学. 微结构铜基底上无铅SnAgCu焊料润湿的形貌研究[D]. 大连: 大连交通大学材料科学与工程学院, 2006: 1-52.

WANG Fuxue. Morphology of lead-free SnAgCu solder wetting on Cu with artifical non-wetting zone[D]. Dalian: Dalian Jiaotong University. School of Materials Science and Engineering, 2006: 1-52.

[61] 张启运. 无铅钎焊的困惑、出路和前景[J]. 焊接, 2007(2): 6-10.

ZHANG Qiyun. A puzzle in lead free soldering, its outlet and application prospect[J]. Welding & Joining, 2007(2): 6-10.

[62] 王慧, 薛松柏, 陈文学, 等. 不同钎剂对Sn-Zn系无铅钎料润湿特性的影响[J]. 焊接学报, 2009, 30(1): 5-8.

WANG Hui, XUE Songbai, CHEN Wenxue, et al. Effect of Ag, Al, Ga addition on wettability of Sn-9Zn lead-free solder[J]. Transactions of the China Welding Institution, 2007, 28(8): 33-36.

[63] Zhang L, Han J G, He C W, et al. Effect of Zn on properties and microstructure of SnAgCu alloy[J]. Journal of Materials Science: Materials in Electronics, 2012, 23(11): 1950-1956.

[64] Liu D S, Hsu C L, Kuo C Y, et al. A novel high speed impact testing method for evaluating the low temperature effects of eutectic and lead-free solder joints[J]. Soldering & Surface Mount Technology, 2012, 24(1): 22-29.

[65] Rao B S S C, Kumar K M, Kripesh V, et al. Tensile deformation behavior of nano-sized Mo particles reinforced SnAgCu solders[J]. Materials Science and Engineering A, 2011, 528(12): 4166-4172.

[66] 刘彬, 邰枫, 郭福, 等. 纳米结构强化无铅焊点的力学性能[J]. 复合材料学报, 2009, 26(2): 11-17.

LIU Bin, TAI Feng, GUO Feng, et al. Mechanical properties of lead-free solder joint containing nano-structured reinforcements[J]. Acta Materiae Compositae Sinica, 2009, 26(2): 11-17.

[67] Nai S M L, Wei J, Gupta M. Lead-free solder reinforced with multiwalled carbon nanotubes[J]. Journal of Electronic Materials, 2006, 35(7): 1518-1522.

[68] Tsao L C, Huang C H, Chung C H, et al. Influence of TiO2 nanoparticles addition on the microstructural and mechanical properties of Sn0.7Cu nano-composite solder[J]. Materials Science and Engineering A, 2012, 545: 194-200.

[69] Fouzder T, Shafiq I, Chan Y C, et al. Influence of SrTiO3 nano-particles on the microstructure and shear strength of Sn-Ag-Cu solder on Au/Ni metalized Cu pads[J]. Journal of Alloys and Compounds, 2011, 509(5): 1885-1892.

[70] Gain A K, Chan Y C, Yung W K C. Effect of additions of ZrO2 nano-particles on the microstructure and shear strength of Sn-Ag-Cu solder on Au/Ni metalized Cu pads[J]. Microelectronics Reliability, 2011, 51(12): 2306-2313.

[71] Shen J, Chan Y C. Effects of ZrO2 nanoparticles on the mechanical properties of Sn-Zn solder joints on Au/Ni/Cu pads[J]. Journal of Alloys and Compounds, 2009, 477(1/2): 552-559.

[72] Babaghorbani P, Nai S M L, Gupta M. Development of lead-free Sn-3.5Ag/SnO2 nanocomposite solders[J]. Journal of Materials Science: Materials in Electronics, 2009, 20(6): 571-576.

[73] 张亮, 韩继光, 郭永环, 等. SnAgCu/SnAgCuCe焊点的显微组织与性能[J]. 机械工程学报, 2012, 48(8): 67-73.

ZHANG Liang, HAN Jiguang, GUO Yonghuan, et al. Microstructures and property of SnAgCu/SnAgCuCe solder joints[J]. Journal of Mechanical Engineering, 2012, 48(8): 67-73.

[74] Dieter G E. Mechanical metallurgy[M]. New York: McGraw-Hill Book Company, 1988: 145-240.

[75] 时海芳, 任鑫. 材料力学性能[M]. 北京: 北京大学出版社, 2010: 218-238.

SHI Haifang, REN Xin. Mechanical properties of materials[M]. Beijing: Peking University Press, 2010: 218-238.

[76] 皋利利. 稀土Pr和Nd对SnAgCu无铅钎料组织和性能影响研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2012: 43-52.

GAO Lili. Effect of Pr and/or Nd on the microstructures and properties of SnAgCu solder[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Materials Science and Technology, 2012: 43-52.

[77] Niranjani V L, Rao B S S C, Sarkar R, et al. The influence of addition of nanosized molybdenum and nickel particles on creep behavior of Sn-Ag lead free solder alloy[J]. Journal of Alloys and Compounds, 2012, 542(12): 136-141.

[78] 邰枫, 郭福, 申灏, 等. 纳米Ag颗粒增强复合钎料蠕变性能的研究[J]. 稀有金属材料与工程, 2010, 39(6): 1005-1008.

TAI Feng, GUO Fu, SHEN Hao, et al. Creep properties of Ag nanoparticle reinforced Sn-Cu composite solders[J]. Rare Metal Materials and Engineering, 2010, 39(6): 1005-1008.

[79] Shi Y W, Liu J P, Yan Y F, et al. Creep properties of composite solders reinforced with nano- and microsized particles[J]. Journal of Electronic Materials, 2008, 37(4): 507-514.

[80] Shi Y W, Liu J P, Xia Z D, et al. Creep property of composite solders reinforced by nano-sized particles[J]. Journal of Materials Science: Materials in Electronics, 2008, 19(4): 349-356.

[81] Liu J P, Guo F, Yan Y F, et al. Development of creep-resistant, nanosized Ag particle-reinforced Sn-Pb composite solders[J]. Journal of Electronic Materials, 2004, 33(9): 958-963.

[82] 杜长华, 王涛, 甘贵生, 等. 纳米颗粒复合钎料的研究进展[J]. 重庆理工大学学报(自然科学), 2012, 26(6): 36-41, 49.

DU Changhua, WANG Tao, GAN Guisheng, et al. Research progress on nano-composite solders[J]. Journal of Chongqing University of Technology (Natural Science), 2012, 26(6): 36-41, 49.

[83] 王涛, 程东海, 陈益平, 等. Ag颗粒增强Sn-58Bi无铅钎料力学性能研究[J]. 现代焊接, 2011(10): 49-51.

WANG Tao, CHONG Donghai, CHEN Yiping, et al. Study on the mechanical properties of Ag particle reinforced Sn-58Bi lead-free solder[J]. Modern Welding Technology, 2011(10): 49-51.

[84] 陈燕. 稀土铈对锡银铜无铅钎料组织性能的影响[D]. 哈尔滨: 机械科学研究总院, 2006: 1-63.

CHEN Yan. Effect of cerium on property and microstructure for SnAgCu lead free solder[D]. Harbin: China Academy of Machinery Science and Technology, 2006: 1-63.

[85] 闵文锦, 宣天鹏. 锡基无铅电子焊料的研究进展与发展趋势[J]. 金属功能材料, 2009, 16(2): 55-59.

MIN Wenjin, XUAN Tianpeng. Research progress and development tendency of tin-based lead-free electronic solder[J]. Metallic Functional Materials, 2009, 16(2): 55-59.

[86] Nai S M L, Wei J, Gupta M. Using carbon nanotubes to enhance creep performance of lead free solder[J]. Materials Science and Technology, 2008, 24(4): 443-448.

[87] Kangooie M, Mahmudi R, Geranmayeh A R. Impression creep of a lead-free Sn-1.7Sb-1.5Ag solder reinforced by submicro-size Al2O3 particles[J]. Journal of Electronic Materials, 2010, 39(2): 215-222.

[88] Mavoori H, Jin S. New, creep-resistant, low melting point solders with ultrafine oxide dispersions[J]. Journal of Electronic Materials, 1998, 27(11): 1216-1222.

[89] Tai F, Guo F, Han M T, et al. Creep and thermomechanical fatigue properties of in situ Cu6Sn5 reinforced lead-free composite solder[J]. Materials Science and Engineering A, 2010, 527(15): 3335-3342.

[90] 邰枫, 郭福, 刘彬, 等. 新型纳米结构颗粒增强无铅复合钎料性能[J]. 复合材料学报, 2010, 27(1): 144-149.

TAI Feng, GUO Fu, LIU Bin, et al. Properties of new nano-structured particles reinforced lead-free composite solders[J]. Acta Materiae Compositae Sinica, 2010, 27(1): 144-149.

[91] 张新平, 于传宝, 张宇鹏, 等. 两种无铅钎料的抗蠕变性能与Sn60Pb40钎料的对比分析[J]. 焊接学报, 2007, 28(2): 1-4.

ZHANG Xinping, YU Chuanbao, ZHANG Yupeng, et al. Creep resistance performance of two lead-free solder and comparison with Sn60Pb40 solder[J]. Transactions of the China Welding Institution, 2007, 28(2): 1-4.

[92] 张莉. 焊锡钎料温度与应变率相关拉伸性能的本构描述[D]. 天津: 天津大学材料科学与工程学院, 2004: 1-27.

ZHANG Li. Constitutive description of temperature and strain rate dependent tensile behavior of solder[D]. Tianjin: Tianjin University. School of Materials Science and Engineering, 2004: 1-27.

[93] 刘家麟, 曾明, 张聪正, 等. Sn-3.7Ag-0.9Zn无铅钎料合金压入蠕变性能研究[J]. 电子元件与材料, 2010(10): 61-64.

LIU Jialin, ZENG Ming, ZHANG Congzheng, et al. Impression creep property of Sn-0.7Ag-0.9Zn lead-free solder alloy[J]. Electronic Components and Materials, 2010, 29(10): 61-64.

[94] 杨雪霞, 肖革胜, 袁国政, 等. 基于纳米压痕法分析无铅焊点内Cu6Sn5金属间化合物的力学性能[J]. 稀有金属材料与工程, 2013, 42(2): 316-319.

YANG Xuexia, XIAO Gesheng, YUAN Guozheng, et al. Nanoindentation identifications of mechanical properties of Cu6Sn5 intermetallic compounds derived by lead-free solder joints[J]. Rare Metal Materials and Engineering, 2013, 42(2): 316-319.

[95] Marques V M F, Wunderle B, Johnston C, et al. Nanomechanical characterization of Sn-Ag-Cu/Cu joints. Part 2: nanoindentation creep and its relationship with uniaxial creep as a function of temperature[J]. Acta Materialia, 2013, 61(7): 2471-2480.

[96] 韩永典, 荆洪阳, 徐连勇, 等. 热循环作用下SnAgCu-CNT搭接焊点蠕变行为数值模拟[J]. 焊接学报, 2007, 28(11): 85-88, 92.

HAN Yongdian, JING Hongyang, XU Lianyong, et al. Numerical simulation of creep behavior of SnAgCu-CNT lap shear solder under thermal cycles[J]. Transactions of the China Welding Institution, 2007, 28(11): 85-88, 92.

[97] 张柯柯, 王要利, 樊艳丽, 等. RE含量及环境条件对SnAgCu钎焊接头蠕变断裂寿命的影响[J]. 稀有金属材料与工程, 2007, 36(8): 1473-1476.

ZHANG Keke, WANG Yaoli, FAN Yanli, et al. Effect of Ce-La mixed rare earth content and environment conditions on the creep rupture life of SnAgCu solder joints[J]. Rare Metal Materials and Engineering, 2007, 36(8): 1473-1476.

[98] Shi Y W, Yan Y F, Liu J P, et al. Constitutive relations for creep in a SnCu-based composite solder reinforced with Ag particles[J]. Journal of Electronic Materials, 2009, 38(9): 1866-1873.

[99] Zhang L, Xue S B, Gao L L, et al. Creep behavior of SnAgCu solders with rare earth Ce doping[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(3): 412-417.

[100] Wang T H, Wang C C, Lai Y S, et al. Optimization of board-level thermomechanical reliability of high performance flip-chip package assembly[J]. Microelectronic Engineering, 2008, 85(4): 659-664.

[101] 盛重, 薛松柏, 张亮, 等. 基于蠕变模型倒装芯片焊点疲劳寿命预测[J]. 焊接学报, 2008, 29(10): 53-56.

SHENG Zhong, XUE Songbai, ZHANG Liang, et al. Fatigue life prediction for flip chip soldered joints based on creep strain model[J]. Transactions of the China Welding Institution, 2008, 29(10): 53-56.

[102] 张亮. SnAgCu系无铅焊点可靠性及相关理论研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2011: 46-57.

ZHANG Liang. Study on reliability of SnAgCu based lead-free soldered joint and related theory[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Materials Science and Technology, 2011: 46-57.

[103] Lai Y S, Wang T H. Optimal design towards enhancement of board-level thermomechanical reliability of wafer-level chip-scale packages[J]. Microelectronics Reliability, 2007, 47(1): 104-110.

[104] Zhang L, Xue S B, Gao L L, et al. Reliability study of Sn-Ag-Cu-Ce soldered joints in quad flat packages[J]. Microelectronics Reliability, 2010, 50(12): 2071-2077.

[105] 吴玉秀. QFP焊点可靠性及其翼形引线尺寸的优化模拟[D]. 南京: 南京航空航天大学材料科学与技术学院, 2007: 1-30.

WU Yuxiu. Research on the reliability of soldered joints and optimum simulation for QFP gull wing lead sizes[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Materials Science and Technology, 2007: 1-30.

[106] 盛重. QFP焊点可靠性研究及其热循环疲劳寿命预测[D]. 南京: 南京航空航天大学材料科学与技术学院, 2010: 1-20.

SHENG Zhong. Prediction on thermal fatigue life & study on the reliability of QFP soldered joint[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Materials Science and Technology, 2010: 1-20.

[107] 张亮, 韩继光, 郭永环, 等. WLCSP器件Sn3.9Ag0.6Cu焊点疲劳寿命预测[J]. 焊接学报, 2012, 33(3): 97-100.

ZHANG Liang, HAN Jiguang, GUO Yonghuan, et al. Fatigue life prediction of Sn3.9Ag0.6Cu soldered joints in WLCSP device[J]. Transactions of the China Welding Institution, 2012, 33(3): 97-100.

[108] Gao Q, Zhao M, Wang H F. SMT solder joints’ semi-experimental fatigue model[J]. Mechanics Research Communications, 2005, 32(3): 351-358.

[109] Zhang L, Xue S B, Gao L L, et al. Effect of thermal cycling on properties and microstructure of SnAgCuCe soldered joints in QFP devices[J]. Chinese Journal of Mechanical Engineering, 2011, 24(4): 561-566.

[110] Pang J H L, Low T H, Xiong B S, et al. Thermal cycling aging effects on Sn-Ag-Cu solder joint microstructure, IMC and strength[J]. Thin Solid Films, 462/463: 370-375.

[111] 肖克来提, 杜黎光, 孙志国, 等. SnAgCu表面贴装焊点在时效和热循环过程中的组织及剪切强度变化[J]. 金属学报, 2001, 37(4): 439-444.

SHAWKRET Ahat, DU Liguang, SUN Zhiguo, et al. Effects of aging and thermal cycling on the microstructure and shear strength of SnAgCu surface mount solder joint[J]. Acta Metallurgica Sinica, 2001, 37(4): 439-444.

[112] 张柯柯, 韩丽娟, 王要利, 等. Sn2.5Ag0.7CuxRE钎料时效焊点界面IMC研究[J]. 材料工程, 2010(10): 18-21, 37.

ZHANG Keke, HAN Lijuan, WANG Yaoli, et al. Research of intermetallic compounds at interface of Sn2.5Ag0.7CuxRE solder joints during aging[J]. Journal of Materials Engineering, 2010(10): 18-21, 37.

[113] Tai F, Guo F, Xia Z D, et al. Effects of nano-sized Ag reinforcing particulates on the microstructure of Sn0.7Cu solder joints[J]. International Journal of Minerals, Metallurgy and Materials, 2009, 16(6): 677-684.

[114] Sivasubramaniam V, Bosco N S, Janczak-rusch J, et al. International intermetallic growth and strength of composite lead-free solder alloy through isothermal aging[J]. Journal of Electronic Materials, 2008, 37(10): 1598-1604.

[115] Zhang Q K, Zhu Q S, Zou H F, et al. Fatigue fracture mechanisms of Cu/lead-free solders interfaces[J]. Materials Science and Engineering A, 2010, 527(6): 1367-1376.

[116] Jen Y M, Chiou Y C, Yu C L. Fracture mechanics study on the intermetallic compound cracks for the solder joints of electron packages[J]. Engineering Failure Analysis, 2010, 18(2): 797-810.

[117] 薛松柏, 吴玉秀, 崔国平, 等. 热循环对QFP焊点强度及其微观组织影响规律的数值模拟[J]. 焊接学报, 2006, 27(11): 1-4.

XUE Songbai, WU Yuxiu, CUI Guoping, et al. Numerical simulation of effect of thermal cycling on tensile strength and microstructure of QFP soldered joint[J]. Transactions of the China Welding Institution, 2006, 27(11): 1-4.

[118] 张新平, 尹立孟, 于传宝. 电子和光子封装无铅钎料的研究和应用进展[J]. 材料研究学报, 2008, 22(1): 1-9.

ZHANG Xinping, YIN Limeng, YU Chuanbao. Advances in research and application of lead-free solders for electronic and photonic packaging[J]. Chinese Journal of Materials Research, 2008, 22(1): 1-9.

[119] Zhang L, Han J G, He C W, et al. Reliability behavior of lead-free soldered joints in electronic components[J]. Journal of Materials Science: Materials in Electronics, 2013, 24(1): 172-190.

[120] 薛松柏, 张亮, 皋利利, 等. 微量元素对无铅钎料性能影响的研究现状与发展趋势[J]. 焊接, 2009(3): 24-33.

XUE Songbai, ZHANG Liang, GAO Lili, et al. Current situation and prospect on effects of micro alloying elements on properties of lead-free solders[J]. Welding & Joining, 2009(3): 24-33.

[121] 周衡志, 李子全, 曾光, 等. 纳米CeO2/Zn-4.5Al-RE-Mg-Ti的复合搅拌制备工艺研究[J]. 稀有金属材料与工程, 2010, 39(3): 534-537.

ZHOU Hengzhi, LI Ziquan, ZENG Guang, et al. Research on combination stirring fabrication technology of nano-CeO2/Zn-4.5Al-RE-Mg-Ti composites[J]. Rare Metal Materials and Engineering, 2010, 39(3): 534-537.

[122] 韩若男, 薛松柏, 胡玉华, 等. Sn-Zn系钎料专用助焊剂[J]. 焊接学报, 2012, 33(10): 101-104.

HAN Ruonan, XUE Songbai, HU Yuhua, et al. Development of flux for Sn-Zn lead-free solder[J]. Transactions of the China Welding Institution, 2012, 33(10): 101-104.

[123] 郝虎, 李广东, 史耀武, 等. Sn晶须形态的研究[J]. 材料科学与工艺, 2010, 18(1): 111-115.

HAO Hu, LI Guangdong, SHI Yaowu, et al. Study of morphologies for tin whiskers[J]. Materials Science & Technology, 2010, 18(11): 111-115.

[124] Ye H, Xue S B, Petch M. Effects of thermal cycling on rare earth (Pr)-induced Sn whisker/hillock growth[J]. Materials Letters, 2013, 98: 78-81.

[125] Maleki M, Cugnoni J, Botsis J. Microstructure-based modeling of the ageing effect on the deformation behavior of the eutectic micro-constituent in SnAgCu lead-free solder[J]. Acta Materialia, 2013, 61(1): 103-114.

[126] Chen W H, Yu C F, Cheng H C, et al. IMC growth reaction and its effects on solder joint thermal cycling reliability of 3D chip stacking packaging[J]. Microelectronics Reliability, 2013, 53(1): 30-40.

[127] Sabri M F M, Shnawah D A, Badruddin I A, et al. Microstructural stability of Sn-1Ag-0.5Cu-xAl (x=1, 1.5, and 2 wt.%) solder alloys and the effects of high-temperature aging on the mechanical properties[J]. Materials Characterization, 2013, 78: 129-143.

[128] 杨雪霞, 肖革胜, 树学峰. 板级跌落冲击载荷下无铅焊点形状对BGA封装可靠性的影响[J]. 振动与冲击, 2013, 32(1): 104-107.

YANG Xuexia, XIAO Gesheng, SHU Xuefeng. Effects of solder joint shapes on reliability of BGA packages under board level drop impact loads[J]. Journal of Vibration and Shock, 2013, 32(1): 104-107.

[129] 刘芳, 孟光. 随机振动载荷下电路板组件三维有限元模拟[J]. 振动与冲击, 2012, 31(20): 61-64.

LIU Fang, MENG Guang. Three-dimension finite element simulation for a PCB assembly under random vibration loading[J]. Journal of Vibration and Shock, 2012, 31(20): 61-64.

[130] 王栋, 马孝松. 湿热环境下倒装焊无铅焊点的可靠性[J]. 电子元件与材料, 2008, 27(8): 68-71.

WANG Dong, MA Xiaosong. Reliability of lead-free solder joint for FCOB in hygrothermal environment[J]. Electronic Components and Materials, 2008, 27(8): 68-71.

[131] 王旭艳, 徐仁春, 刘刚. Anand本构方程在焊点可靠性研究中的应用[J]. 电焊机, 2012, 42(12): 66-69.

WANG Xuyan, XU Renchun, LIU Gang. Application of anand constitutive equations in solder joints reliability[J]. Electric Welding Machine, 2012, 42(12): 66-69.

[132] Zhang L, Xue S B, Gao L L, et al. Determination of Anand parameters for SnAgCuCe solder[J]. Modelling and Simulation in Materials Science and Engineering, 2009, 17(7): 075014.

[133] Bai N, Chen X, Gao H. Simulation of uniaxial tensile properties for lead-free solders with modified Anand model[J]. Materials & Design, 2009, 30(1): 122-128.

[134] Zhang G S, Jing H Y, Xu L Y, et al. Creep behavior of eutectic 80Au/20Sn solder alloy[J]. Journal of Alloys and Compounds, 2009, 476(1/2): 138-141.

[135] Wiese S, Feustel F, Meusel E. Characterisation of constitutive behavior of SnAg, SnAgCu and SnPb solder in flip chip joints[J]. Sensors and Actuators A: Physical, 2002, 99(1/2): 188-193.

[136] Li X Y, Wang Z S. Thermo-fatigue life evaluation of SnAgCu solder joints in flip chip assemblies[J]. Journal of Materials Processing Technology, 2007, 183(1): 6-12.

[137] 张亮, 薛松柏, 禹胜林, 等. 有限元模拟在微连接焊点可靠性研究中的应用[J]. 电焊机, 2008, 38(9): 13-21, 72.

ZHANG Liang, XUE Songbai, YU Shenglin, et al. Application of FEM analysis in reliability of micro-soldered joints[J]. Electric Welding Machine, 2008, 38(9): 13-21, 72.

[138] 姜志忠, 孙凤莲, 王丽凤, 等. PBGA无铅焊点应力应变数值模拟及疲劳寿命预测[J]. 哈尔滨理工大学学报, 2007, 12(3): 156-159, 164.

JIANG Zhizhong, SUN Fenglian, WANG Lifeng, et al. Numerical simulation of stress-strain and life prediction for lead-free solder joints of PBGA package[J]. Journal of Harbin University of Science & Technology, 2007, 12(3): 156-159, 164.

[139] 张亮, 薛松柏, 韩宗杰, 等. FCBGA器件SnAgCu焊点疲劳寿命预测[J]. 焊接学报, 2008, 29(7): 85-88.

ZHANG Liang, XUE Songbai, HAN Zongjie, et al. Fatigue life prediction of SnAgCu soldered joints of FCBGA device[J]. Transactions of the China Welding Institution, 2008, 29(7): 85-88.

[140] 傅冰. 倒装焊焊点的可靠性分析[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2006: 6-9.

FU Bing. Reliability analysis of flip chip solder joint[D]. Harbin: Harbin Institute of Technology. School of Materials Science and Engineering, 2006: 6-9.

[141] 章霖. 热循环载荷下BGA复合焊点疲劳寿命的研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2011: 3-30.

ZHANG Lin. Fatigue life of BGA composite solder joint under thermal cycle loading[D]. Harbin: Harbin Institute of Technology. School of Materials Science and Engineering, 2011: 3-30.

[142] Chen F X, Pang J H L. Characterization of IMC layer and its effect on thermomechanical fatigue life of Sn-3.8Ag-0.7Cu solder joints[J]. Journal of Alloys and Compounds, 2012, 541: 6-13.

[143] 张亮, 薛松柏, 卢方焱, 等. 基于蠕变模型细间距器件焊点疲劳寿命预测[J]. 机械工程学报, 2009, 45(9): 279-284.

ZHANG Liang, XUE Songbai, LU Fangyan, et al. Fatigue life prediction for fine pitch device soldered joints based on creep model[J]. Journal of Mechanical Engineering, 2009, 45(9): 279-284.

[144] Yu H, Shangguan D K. Solidification and reliability of lead-free solder interconnection[J]. Soldering & Surface Mount Technology, 2013, 25(1): 31-38.

[145] Zhang L, Xue S B, Gao L L, et al. Effect of thermal cycling on properties and microstructure of SnAgCu soldered joints in QFP devices[J]. Chinese Journal of Mechanical Engineering, 2011, 24(4): 561-566.

[146] 张亮, 韩继光, 郭永环, 等. WLCSP器件结构优化模拟及无铅焊点可靠性[J]. 焊接学报, 2012, 33(7): 53-56.

ZHANG Liang, HAN Jiguang, GUO Yonghuan, et al. Optimum simulation and soldered joints reliability of WLCSP device[J]. Transactions of the China Welding Institution, 2012, 33(7): 53-56.

[147] Chang Y W, Chiu S H, Chen C, et al. Effect of Si-die dimensions on electromigration failure time of flip-chip solder joints[J]. Materials Chemistry and Physics, 2011, 127(1/2): 85-90.

[148] 孙凤莲, 朱艳. 微焊点的几何尺寸效应[J]. 哈尔滨理工大学学报, 2012, 17(2): 100-104.

SUN Fenglian, ZHU Yan. Geometrical size effects on the performance of micro-joint[J]. Journal of Harbin University of Science and Technology, 2012, 17(2): 100-104.

[149] 吴兆华, 黄春跃, 周德俭. 基于焊点形态预测与塑性应变计算的工艺参数对QFP焊点可靠性影响分析[J]. 塑性工程学报, 2006, 13(6): 103-108.

WU Zhaohua, HUANG Chunyue, ZHOU Dejian. Study on the impact of process parameters on the reliability of quad flat package solder joints based on shape prediction and plastic strain calculation[J]. Journal of Plasticity Engineering, 2006, 13(6): 103-108.

[150] 郝秀云, 杨洁, 王玉鹏. 焊点形态对表面贴装元件无铅焊点可靠性的影响[J]. 热加工工艺, 2011, 40(19): 173-177.

HAO Xiuyun, YANG Jie, WANG Yupeng. Effect of solder joint shape on reliability of lead-free solder joint[J]. Hot Working Technology, 2011, 40(19): 173-177.

(编辑 杨幼平)

收稿日期:2014-02-14;修回日期:2014-04-18

基金项目(Foundation item):国家自然科学基金资助项目(51475220);江苏省自然科学基金资助项目(BK201244);江苏省高校自然科学基金资助项目(12KJB460005);江苏科技大学先进焊接技术省级重点实验室开放基金资助项目(JSAWS-11-05) (Project(51475220) supported by the Natural Science Foundation of China; Project (BK2012144) supported by the Natural Science Foundation of Jiangsu Province; Project(12KJB460005) supported by the Natural Science Foundation of the Higher Education Institutions of Jiangsu Province; Project(JSAWS-11-05) supported by Provincial Key Lab of Advanced Welding Technology Foundation, Jiangsu University of Science and Technology)

通信作者:张亮,博士,副教授,硕士生导师,从事电子封装材料与技术研究;E-mail: zhangliang@jsnu.edu.cn

摘要:综合评论含纳米-微米颗粒无铅钎料研究与应用现状,分别介绍国内外针对金属、化合物、陶瓷、碳纳米管及高分子几种颗粒对无铅钎料性能的影响。主要从无铅钎料内部组织、界面组织、熔化特性、润湿性、力学性能和蠕变性能几方面探讨颗粒对钎料组织和性能的影响。同时简述颗粒增强的无铅钎料在应用过程中出现的问题及相应的解决措施,并对颗粒增强无铅钎料的发展趋势进行分析和展望。

[2] 胡玉华, 薛松柏, 陈文学, 等. Sn-9Zn-xCe钎料组织及钎焊性能的分析[J]. 焊接学报, 2010, 31(6): 77-80.

[3] 张亮, 韩继光, 郭永环, 等. 含纳米铝颗粒SnAgCu钎料组织与性能[J]. 焊接学报, 2013, 34(6): 65-68.

[14] 王慧. 微合金化对Sn-9Zn无铅钎料性能影响及润湿机理研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2010: 1-112.

[16] 陈文学. Ag、Ga、Al及Ce对Sn-9Zn无铅钎料性能的影响[D]. 南京: 南京航空航天大学材料科学与技术学院, 2010: 1-60.

[21] 韩宗杰. 电子组装元器件半导体激光无铅软钎焊技术研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2009: 1-98.

[27] 刘平. 颗粒增强Sn3.8Ag0.7Cu复合无铅焊料的研究[D]. 天津: 天津大学材料科学与工程学院, 2009: 1-107.

[28] 刘晓英, 于大全, 马海涛, 等. Y2O3增强Sn-3Ag-0.5Cu复合无铅钎料[J]. 电子工艺技术, 2004, 25(4): 156-158, 161.

[29] 刘晓英, 马海涛, 王来. 超细氧化物颗粒对Sn-58Bi钎料组织及性能影响[J]. 大连理工大学学报, 2008, 48(1): 51-57.

[30] 张亮, Tu K N, 郭永环, 等. 时效对SnAgCu/SnAgCu-TiO2焊点界面与性能影响[J]. 焊接学报, 2013, 34(8): 43-46.

[34] 聂京凯, 郭福, 郑菡晶, 等. Ni颗粒增强无铅复合钎料中IMC形态值演变[J]. 电子元件与材料, 2007, 26(9): 43-46.

[35] 卫国强, 况敏, 杨永强. Cu颗粒增强的Sn-9Zn复合钎料/Cu钎焊接头界面反应[J]. 焊接学报, 2007, 28(5): 105-108.

[45] 刘彬, 邰枫, 郭福, 等. 纳米结构强化的新型Sn-Ag基无铅复合钎料[J]. 材料工程, 2009(8): 38-48.

[47] 刘晓英, 马海涛, 罗忠兵, 等. Fe粉对Sn-3Ag-0.5Cu复合钎料组织及性能的影响[J]. 中国有色金属学报, 2012, 22(4): 1169-1176.

[49] 安晶. 含碳纳米管的Sn-58Bi无铅钎料的制备及其性能研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2010: 1-38.

[50] 邹长东. 应用纳米尺寸效应降低Sn基无铅焊料熔化温度的基础研究[D]. 上海: 上海大学材料科学与工程学院, 2010: 1-122.

[52] 张亮, 韩继光, 何成文, 等. 稀土元素对无铅钎料组织和性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1680-1696.

[53] 黄文超, 甘贵生, 唐明, 等. 纳米Ni颗粒对Sn0.65Cu亚共晶钎料润湿性和抗氧化性的影响[J]. 精密成型工程, 2013, 5(1): 16-19.

[54] 孙莉. 添加纳米颗粒的复合无铅钎料及其微连接接头性能研究[D]. 石家庄: 石家庄铁道学院材料科学与工程学院, 2008: 1-69.

[58] 韩永典. Ni涂层碳纳米管增强Sn-Ag-Cu无铅钎料的可靠性研究[D]. 天津: 天津大学材料科学与工程学院, 2009: 1-108.

[60] 王福学. 微结构铜基底上无铅SnAgCu焊料润湿的形貌研究[D]. 大连: 大连交通大学材料科学与工程学院, 2006: 1-52.

[61] 张启运. 无铅钎焊的困惑、出路和前景[J]. 焊接, 2007(2): 6-10.

[62] 王慧, 薛松柏, 陈文学, 等. 不同钎剂对Sn-Zn系无铅钎料润湿特性的影响[J]. 焊接学报, 2009, 30(1): 5-8.

[66] 刘彬, 邰枫, 郭福, 等. 纳米结构强化无铅焊点的力学性能[J]. 复合材料学报, 2009, 26(2): 11-17.

[73] 张亮, 韩继光, 郭永环, 等. SnAgCu/SnAgCuCe焊点的显微组织与性能[J]. 机械工程学报, 2012, 48(8): 67-73.

[74] Dieter G E. Mechanical metallurgy[M]. New York: McGraw-Hill Book Company, 1988: 145-240.

[75] 时海芳, 任鑫. 材料力学性能[M]. 北京: 北京大学出版社, 2010: 218-238.

[76] 皋利利. 稀土Pr和Nd对SnAgCu无铅钎料组织和性能影响研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2012: 43-52.

[78] 邰枫, 郭福, 申灏, 等. 纳米Ag颗粒增强复合钎料蠕变性能的研究[J]. 稀有金属材料与工程, 2010, 39(6): 1005-1008.

[82] 杜长华, 王涛, 甘贵生, 等. 纳米颗粒复合钎料的研究进展[J]. 重庆理工大学学报(自然科学), 2012, 26(6): 36-41, 49.

[83] 王涛, 程东海, 陈益平, 等. Ag颗粒增强Sn-58Bi无铅钎料力学性能研究[J]. 现代焊接, 2011(10): 49-51.

[84] 陈燕. 稀土铈对锡银铜无铅钎料组织性能的影响[D]. 哈尔滨: 机械科学研究总院, 2006: 1-63.

[85] 闵文锦, 宣天鹏. 锡基无铅电子焊料的研究进展与发展趋势[J]. 金属功能材料, 2009, 16(2): 55-59.

[90] 邰枫, 郭福, 刘彬, 等. 新型纳米结构颗粒增强无铅复合钎料性能[J]. 复合材料学报, 2010, 27(1): 144-149.

[91] 张新平, 于传宝, 张宇鹏, 等. 两种无铅钎料的抗蠕变性能与Sn60Pb40钎料的对比分析[J]. 焊接学报, 2007, 28(2): 1-4.

[92] 张莉. 焊锡钎料温度与应变率相关拉伸性能的本构描述[D]. 天津: 天津大学材料科学与工程学院, 2004: 1-27.

[93] 刘家麟, 曾明, 张聪正, 等. Sn-3.7Ag-0.9Zn无铅钎料合金压入蠕变性能研究[J]. 电子元件与材料, 2010(10): 61-64.

[94] 杨雪霞, 肖革胜, 袁国政, 等. 基于纳米压痕法分析无铅焊点内Cu6Sn5金属间化合物的力学性能[J]. 稀有金属材料与工程, 2013, 42(2): 316-319.

[96] 韩永典, 荆洪阳, 徐连勇, 等. 热循环作用下SnAgCu-CNT搭接焊点蠕变行为数值模拟[J]. 焊接学报, 2007, 28(11): 85-88, 92.

[97] 张柯柯, 王要利, 樊艳丽, 等. RE含量及环境条件对SnAgCu钎焊接头蠕变断裂寿命的影响[J]. 稀有金属材料与工程, 2007, 36(8): 1473-1476.

[101] 盛重, 薛松柏, 张亮, 等. 基于蠕变模型倒装芯片焊点疲劳寿命预测[J]. 焊接学报, 2008, 29(10): 53-56.

[102] 张亮. SnAgCu系无铅焊点可靠性及相关理论研究[D]. 南京: 南京航空航天大学材料科学与技术学院, 2011: 46-57.

[105] 吴玉秀. QFP焊点可靠性及其翼形引线尺寸的优化模拟[D]. 南京: 南京航空航天大学材料科学与技术学院, 2007: 1-30.

[106] 盛重. QFP焊点可靠性研究及其热循环疲劳寿命预测[D]. 南京: 南京航空航天大学材料科学与技术学院, 2010: 1-20.

[107] 张亮, 韩继光, 郭永环, 等. WLCSP器件Sn3.9Ag0.6Cu焊点疲劳寿命预测[J]. 焊接学报, 2012, 33(3): 97-100.

[111] 肖克来提, 杜黎光, 孙志国, 等. SnAgCu表面贴装焊点在时效和热循环过程中的组织及剪切强度变化[J]. 金属学报, 2001, 37(4): 439-444.

[112] 张柯柯, 韩丽娟, 王要利, 等. Sn2.5Ag0.7CuxRE钎料时效焊点界面IMC研究[J]. 材料工程, 2010(10): 18-21, 37.

[117] 薛松柏, 吴玉秀, 崔国平, 等. 热循环对QFP焊点强度及其微观组织影响规律的数值模拟[J]. 焊接学报, 2006, 27(11): 1-4.

[118] 张新平, 尹立孟, 于传宝. 电子和光子封装无铅钎料的研究和应用进展[J]. 材料研究学报, 2008, 22(1): 1-9.

[120] 薛松柏, 张亮, 皋利利, 等. 微量元素对无铅钎料性能影响的研究现状与发展趋势[J]. 焊接, 2009(3): 24-33.

[121] 周衡志, 李子全, 曾光, 等. 纳米CeO2/Zn-4.5Al-RE-Mg-Ti的复合搅拌制备工艺研究[J]. 稀有金属材料与工程, 2010, 39(3): 534-537.

[122] 韩若男, 薛松柏, 胡玉华, 等. Sn-Zn系钎料专用助焊剂[J]. 焊接学报, 2012, 33(10): 101-104.

[123] 郝虎, 李广东, 史耀武, 等. Sn晶须形态的研究[J]. 材料科学与工艺, 2010, 18(1): 111-115.

[128] 杨雪霞, 肖革胜, 树学峰. 板级跌落冲击载荷下无铅焊点形状对BGA封装可靠性的影响[J]. 振动与冲击, 2013, 32(1): 104-107.

[129] 刘芳, 孟光. 随机振动载荷下电路板组件三维有限元模拟[J]. 振动与冲击, 2012, 31(20): 61-64.

[130] 王栋, 马孝松. 湿热环境下倒装焊无铅焊点的可靠性[J]. 电子元件与材料, 2008, 27(8): 68-71.

[131] 王旭艳, 徐仁春, 刘刚. Anand本构方程在焊点可靠性研究中的应用[J]. 电焊机, 2012, 42(12): 66-69.

[137] 张亮, 薛松柏, 禹胜林, 等. 有限元模拟在微连接焊点可靠性研究中的应用[J]. 电焊机, 2008, 38(9): 13-21, 72.

[138] 姜志忠, 孙凤莲, 王丽凤, 等. PBGA无铅焊点应力应变数值模拟及疲劳寿命预测[J]. 哈尔滨理工大学学报, 2007, 12(3): 156-159, 164.

[139] 张亮, 薛松柏, 韩宗杰, 等. FCBGA器件SnAgCu焊点疲劳寿命预测[J]. 焊接学报, 2008, 29(7): 85-88.

[140] 傅冰. 倒装焊焊点的可靠性分析[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2006: 6-9.

[141] 章霖. 热循环载荷下BGA复合焊点疲劳寿命的研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2011: 3-30.

[143] 张亮, 薛松柏, 卢方焱, 等. 基于蠕变模型细间距器件焊点疲劳寿命预测[J]. 机械工程学报, 2009, 45(9): 279-284.

[146] 张亮, 韩继光, 郭永环, 等. WLCSP器件结构优化模拟及无铅焊点可靠性[J]. 焊接学报, 2012, 33(7): 53-56.

[148] 孙凤莲, 朱艳. 微焊点的几何尺寸效应[J]. 哈尔滨理工大学学报, 2012, 17(2): 100-104.

[149] 吴兆华, 黄春跃, 周德俭. 基于焊点形态预测与塑性应变计算的工艺参数对QFP焊点可靠性影响分析[J]. 塑性工程学报, 2006, 13(6): 103-108.

[150] 郝秀云, 杨洁, 王玉鹏. 焊点形态对表面贴装元件无铅焊点可靠性的影响[J]. 热加工工艺, 2011, 40(19): 173-177.