Laser micromachining of CNT/Fe/Al2O3 nanocomposites

Kwang-Ryul KIM1, Byoung-Deog CHOI1, Jun-Sin YI1, Sung-Hak CHO2, Yong-Ho CHOA3,

Dong-Soo SHIN4, Dong-Ho BAE5, Myung-Chang KANG6, Young-Keun JEONG6

1. School of Information and Communication Engineering, Sungkyunkwan University, Suwon, 440-746, Korea;

2. Korea Institute of Machinery and Materials, Daejeon, 305-343, Korea;

3. Department of Chemical Engineering, Hanyang University, Ansan, 426-791, Korea;

4. NANOBASE Inc., B505 Woolim Lions Valley, Seoul, 153-786, Korea;

5. School of Mechanical Engineering, Sungkyunkwan University, Suwon, 440-746, Korea;

6. National Core Research Center for Hybrid Materials Solution, Pusan National University, Busan, 609-735, Korea

Received 2 March 2009; accepted 30 May 2009

Abstract:

CNT/Fe/Al2O3 mixed powders were synthesized from Fe/Al2O3 nanopowders using thermal CVD for the homogeneous dispersion of carbon nanotubes CNTs. CNTs consisted of MWNT, and the diameter was approximately 20-30 nm. After sintering, CNTs were homogenously located throughout Al2O3 grain boundary and were buckled. A femto-second laser installed with special optical systems was used for micromachining of the nanocomposites. The relationship between material ablation rate and energy fluence was theoretically investigated and compared with experimental results from cross-sectional SEM analysis. The nanocomposites which have higher content of CNT show a fairly good machining result due to its higher thermal conductivity and smaller grain size as well as lower light transmittance.

Key words:

nanocomposite; femto-second laser; micromachining; carbon nanotubes;

1 Introduction

Carbon nanotubes (CNTs) have been singled out for new applications in various fields because of their exceptional electrical properties [1-2]. Furthermore, it is suggested that dense CNT/ceramic composites prepared by hot-pressing possess electrical conductivity due to CNT dispersion [3-4]. Working to control the microstructure, ZHAN et al have reported that the grain growth of nano-grained ceramics could be significantly inhibited by the dispersion of carbon nanotubes in the Al2O3-based nanocomposites fabricated by pulse electric current sintering (PECS) [4]. However, it is known that the practical application of the CNT-dispersed composites is restricted. This is primarily because of The difficulty in obtaining a homogeneous dispersion of the CNTs into the ceramic matrix, which is due to the hard agglomeration of the synthesized CNTs. As a result, the sintered composites displayed an inhomogeneous microstructure that exhibits reduced electrical conductivity.

Therefore, the homogeneous dispersion of CNTs in the ceramic matrix is a requirement for any engineering application of CNT/dispersed ceramic composites [3]. In this study, ceramic nanocomposites with a homogeneous dispersion of CNTs were obtained by dispersing nano-sized Fe catalysts into Al2O3 powders using chemical processes and selective reduction. The CNTs were then synthesized on Fe/Al2O3 nanocomposite powders by a thermal chemical vapor deposition (CVD) method in a C2H2 atmosphere. The prepared CNT/Fe/ Al2O3 nanocomposite powders were consolidated by using PECS.

The carbon nanotube nanocomposites have many potential applications, because of its excellent properties. However, it is very difficult to fabricate for NEMS or MEMS devices due to the difficulty in machining of these nanocomposites. The materials researches for the metals and glasses using the femto-second laser are investigated, but there is little research for laser micromachining of crystalline monolithic ceramic or composite materials [5-10]. In this paper, a femto-second laser with specially equipped optical systems is prepared and tested for nano and micro scale micromachining of the material. In addition, we will theoretically and experimentally investigate the relationship between material ablation rate and energy fluence.

2 Experimental

In general, a femto-second laser has very short pulse duration of 100 fs. Because the energy transfer time from electrons to ions by Coulomb collisions is significantly longer than this duration, the conventional hydrodynamics and thermal analysis theory can not be applied to analyze this interaction [11]. Therefore, the mechanism of ablation of the nanocomposite by the femto-second laser is described in an explicit analytical form. Obtaining the laser threshold fluence from the equation for electron temperature and energy condition for the oblation threshold, we can easily derive the ablation depth which increases logarithmically with the laser fluence as follows [11]:

![]() (1)

(1)

where ls is the skin layer, F is the laser fluence and Fth is the laser threshold fluence for ablation. Since the total absorbed femto-second laser energy flux in the ablation mode balances by the outflow of the ablated atoms times the energy expenses per atoms which equals to Fermi energy, the ablation rate for the femto-second laser regime is expressed by

![]() (2)

(2)

where A is the ratio of absorption, I is the laser intensity, and εF is the Fermi energy. The starting materials included: α-Al2O3 powder (AKP-53, Sumitomo Chem. Co., Japan, 99.99%, average particle size 0.2 μm) used as a matrix material and Fe-nitrate used as a source for the Fe catalyst. The slurry was prepared by wet milling of Al2O3 powder and Fe-nitrate dissolved in ethanol. The slurry was dried and calcined. To prepare Fe/Al2O3 nanocomposite catalyst, the calcined powders were selectively reduced at 600 ℃ in a hydrogen atmosphere. The synthesis of CNTs was carried out at 800 ℃ for 10 min under a 10, 300, 1 000 cm3/min of C2H2, H2, Ar gas flow. CNT/Fe/Al2O3 dense nanocomposites were fabricated by using PECS at 1 600℃ (heating rate of 100 ℃/min) for 10 min under 30 MPa of pressure. The contents of CNT in this composite are 2% and 8%. Al2O3 monolithic ceramic was also prepared by conventional sintering process to compare with nanocomposites.

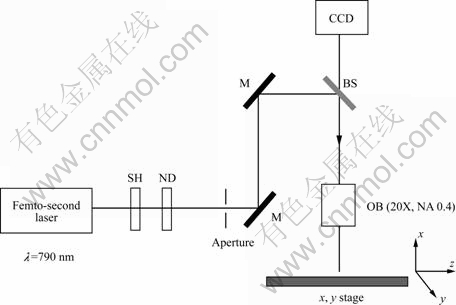

A femto-second laser was prepared and installed with special optical systems for micromachining of CNT/Fe/Al2O3 nanocomposites. The laser specifications are shown in Table 1. Radiations from the femto-second laser go through shutter (SH), neutral density filter (ND) and aperture and the light is delivered using mirrors (M) and focused through the 20X object lens. The beam splitter (BS) is used for real-time CCD camera. The system configurations are presented in Fig.1. The beam spot size of 8 mm is used for the tests.

Fig.1 System configurations for femto-second laser

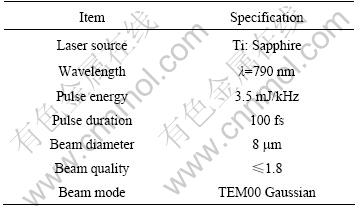

Table 1 Femto-second laser specifications

3 Results and discussion

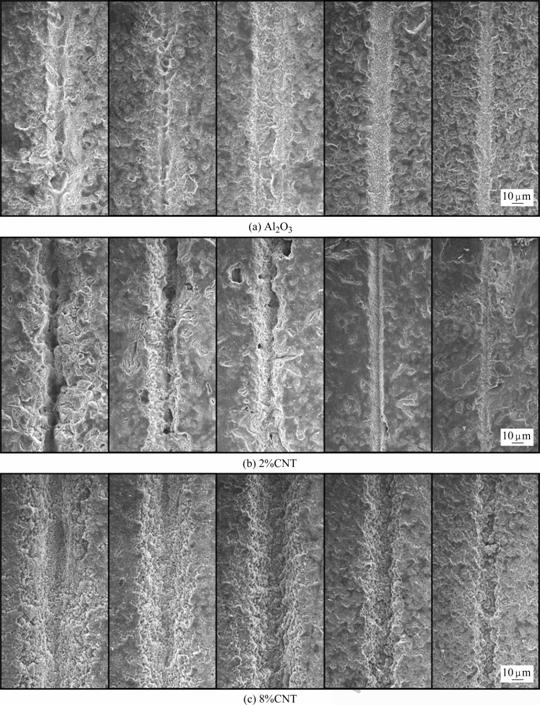

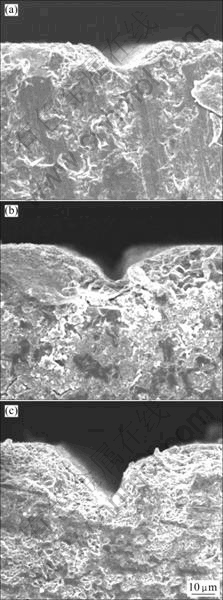

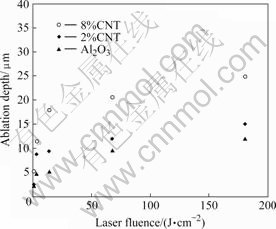

CNT/Fe/Al2O3 nanocomposites were successfully synthesized from Fe/Al2O3 nanopowders using thermal CVD for the homogeneous dispersion of CNTs. CNTs synthesized by thermal CVD consisted of MWNT, and the diameter of CNT was approximately 20-30 nm. After sintering, CNTs were homogenously located throughout the Al2O3 grain boundary and were buckled. Fig.2 shows the surface SEM micrographs for Al2O3, 2% and 8% CNT nanocomposites. The laser power used for the experiments are 910, 34, 7, 1.6 and 0.38 mW from the left side. Al2O3 was inhomogeneously machined by the femto-second laser. This phenomenon can be explained by the general keyhole dynamics. The evaporated materials and plumes of Al2O3 rapidly moved forward and backward inside the keyhole, so the propagating laser beam is absorbed and blocked by them. However, the results for CNT nanocomposites show relatively good surface condition compared with that of Al2O3 after same laser scans. As the contents of CNT increase, we can clearly find that machinability and surface roughness of the nanocomposites are getting better. The cross-sectional view of the grooves which are microfabricated using the femto-second lasers for the alumina and CNT nanocomposites is shown in Fig.3. It is obvious that the results form CNT nanocomposites presented better edge quality and machinability. The grooving depth of the fused silica is generally 120 mm at 910 mW, but those of above two materials are approximately 10-25 mm. The ablation depth of CNT nanocomposites is more than two times deeper than one of the monolithic alumina. Therefore, it is expected that the micromachining for the crystalline materials requires more time than glass. The relationship between the ablation depth and laser fluence is plotted in Fig.4. Comparing with Eqn.(1), the ablation depth of the alumina and CNT nanocomposites are increased logarithmically with the laser fluence.

Fig.2 SEM images for surface of Al2O3 (a), 2% CNT (b), and 8% CNT (c) nanocomposites after energy scan

Fig.3 SEM images for cross-sectional view of Al2O3 (a), 2%CNT (b), and 8%CNT (c) nanocomposites after energy scan

Fig.4 Relationship between ablation depth and laser fluence for Al2O3, 2% and 8% CNT nanocomposites

The good machinability of CNT/Fe/Al2O3 nanocomposites results from lower light transmittance, higher thermal conductivity due to addition of CNT and smaller grain size of nanocomposites than those of Al2O3. It is found that CNT/Fe/Al2O3 nanocomposites are fabricated using femto-second laser effectively and the surface roughness is acceptable for any NEMS or MEMS parts.

4 Conclusions

CNT/Fe/Al2O3 nanocomposites sintered by PECS process were fabricated using the laser microfabrication technology. The relationship between material ablation rate and energy fluence was theoretically investigated. In addition, the relationship was verified using cross-sectional SEM analysis on laser microfabricated alumina and CNT nanocomposites samples. The ablation depth of alumina and CNT nanocomposites increase logarithmically with the laser fluence.

The nanocomposites which have higher content of CNT showed a fairly good machining result and there was no microstructural damage by laser energy. In addition, the nanocomposites were clearly fabricated using femto-second laser due to its higher thermal conductivity and smaller grain size as well as lower light transmittance.

Acknowledgement

This work was supported by a grant from the National Core Research Center Program funded by KOSEF and MOST (R15-2006-022-01001-0 and R15-2006-022-01003-0).

REFERENCES

[1] ROCHIE S. Carbon nanotubes: exceptional mechanical and electrical properties [J]. Ann Chim Sci Mater, 2000, 25: 529-532.

[2] THOSTENSON E T, REN Z, CHOU T W. Advances in the science and technology of carbon nanotubes and their composites: A review [J]. Comp Sci Technol, 2001, 61: 1899-1912.

[3] LIM D S, AN J W, LEE H J. Effect of carbon nanotubes addition on the tribological behavior of carbon/carbon composites [J]. Wear, 2002, 252: 512-517.

[4] ZHAN G D, KUNTZ J D, WAN J, MUKHERJEE A K. Single-wall carbon nanotubes as attractive toughening agents in alumina-based nanocomposites [J]. Nature Mater, 2003, 2: 38-42.

[5] KONDRASHOV V I, SHITOVA L A, LITVINOV V A, SURKOV V V. Characteristics of cutting parameters and their effect on the glass edge quality [J]. Glass Ceram, 2001, 58: 303-305.

[6] CHENG J Y, YEN M H, WEI C W, CHUANG Y C, YOUNG T H. Crack-free direct-writing on glass using a low-power UV laser in the manufacturing of a microfluidics chip [J]. J Micromech Microeng, 2005, 15: 1147-1156.

[7] ZHENG H Y, LEE T. Studies of CO2 laser peeling of glass substrates [J]. J Micromech Microeng, 2005, 15: 2093-2097.

[8] TSAI C H, CHEN H W. The laser shaping of ceramic by a fracture machining technique [J]. Int J Adv Manuf Technol, 2004, 23: 342-349.

[9] KIM K R. Femto-second laser glass cutting for flat panel display [J]. Kor J Mater Res, 2008, 18(5): 247-252.

[10] KIM K R, KIM J H, FARSON D F, CHOI H W, KIM K H. Hybrid laser cutting for flat panel display glass [J]. Jpn J Appl Phys, 2008, 47(8): 6978-6981.

[11] GAMALY E G, RODE A V, LUTHER-DAVIES B, TIKHONCHUK V T. Ablation of solids by femtosecond lasers: Ablation mechanism and ablation thresholds for metals and dielectrics [J]. Phys Plasmas, 2002, 9: 949-957.

Corresponding author: Young-Keun JEONG, nano@pusan.ac.kr

(Edited by CHEN Ai-hua)