Trans. Nonferrous Met. Soc. China 20(2010) s821-s825

In-situ observation of crystal detachment behavior in NH4Cl-H2O system from chilling metal surface with vibration

ZHANG Ying(张 莹), WANG Meng(王 猛), DU Li-cheng(杜立成), LIN Xin(林 鑫), HUANG Wei-dong(黄卫东)

State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Received 13 May 2010; accepted 12 July 2010

Abstract:The crystal detachment behaviors from a chilling solid surface with vibration were investigated using a transparent NH4Cl-70%H2O alloy. The nucleation experiments of NH4Cl-70%H2O alloy were performed on a chilling surface generator with various vibration frequency from 20 to 1 000 Hz and vibration acceleration from 10 to 100 m/s2. The results indicate that the crystal detach rate increases and the grains are refined with increasing vibration acceleration under a certain vibration frequency. It is interesting to note that, when the frequency is 50 Hz, acceleration is 100 m/s2, the crystal detach rate increases sharply and the grain refinement effect is strengthened. A special grain refinement phenomenon can be observed, when the vibration acceleration and frequency are up to a critical value. A power-based definition was introduced in order to describe the relationship between the vibration parameters and imposed power on the system. It is found that a power criterion exists for the grain refinement in the current system.

Key words:

vibration; chilling; detachment; refinement; NH4Cl-H2O alloy;

1 Introduction

Evenly distributed equiaxed crystal microstructure is preferred in castings and ingots, as it leads to a good distribution of the chemical composition and a higher mechanical property under normal temperature conditions[1-4]. It is extensively accepted that vibration can be used for the grain refinement in solidification process. Experiments show that the vibration improves the microstructure, refines the grain and enhances the properties of alloy components[5-8]. In recent years, a new technology, namely nucleation in liquid metal excited by vibration[9-12], has been invented. This technology is characterized by inserting a vibrating chilling nuclei generator into liquid metal to excite the formation of numerous crystal nuclei on its surface while it is chilled. The crystal nuclei are ejected to molten metal continuously and serve as nuclei of equiaxed crystal during solidification. Generally speaking, the inputting vibration energy leads to the changes of flow field, temperature field and solute field of the nucleation surface material and melts, and induces and promotes the crystal refinement effects. However, the relationship between the energy input and the refinement effect is still to be discovered quantitatively.

In the former experiments attention was mainly paid on measuring the frequency and amplitude of vibration, and then the influences of them on detachment were directly displayed. However, the input of energy was neglected. In the present work, the nucleation and detachment on chilling surface by vibration is investigated via NH4Cl-70%H2O physical modeling. The acceleration and frequency are examined in the process of vibration in order to describe the crystal nucleation and detachment behavior of the chilling surface by vibration with in-situ observation.

2 Experimental

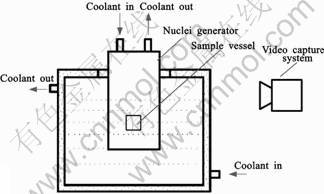

The experimental set-up is composed of the following elements (Fig.1[13]).

A cubic organic glass vessel with dimensions of 120 mm×80 mm×100 mm in inner dimension and 155 mm×115 mm×135 mm in outer dimension was used.

The NH4Cl-70%H2O solutions were prepared with 99.5% NH4Cl and de-ionized water for vibration experiment, with a liquidus of 34 ?C[14].

A nuclei generator, which is cooled by alcohol, is made up of aluminum alloy and pure aluminum with different roughness. The generator is mounted on an electric vibrator which can provide vibration with different frequency and magnitude. The temperature of the sample vessel and the nuclei generator is regulated by two thermostats with an accuracy of ±0.05 K.

Fig.1 Schematic of experimental apparatus

A microscope video-capture system was adopted, which allows to record the process of ammonium chloride crystals formation and detachment continuously.

Ammonium chloride-water mixture was kept at a constant overheat temperature after the solute homogenization. And then the undercooled nuclei generator was immerged into the melt while keeping a stable vibration condition. The detachment behavior of crystals is recorded by video-capture system.

3 Results and discussion

3.1 Effect of vibration on detachment of crystals

The former experiments[15] indicated that the crystal detach rate increases and the grains are refined with increasing the vibration frequency under certain vibration amplitude. In this work, the vibration acceleration and frequency were used as the control parameters, as the imposed force correlates directly with the vibration acceleration. While the crystal detach rate increases, the grains are refined with increasing vibration acceleration. It is interesting to note that a special grain refinement phenomenon can be observed, when the vibration acceleration is up to a critical value.

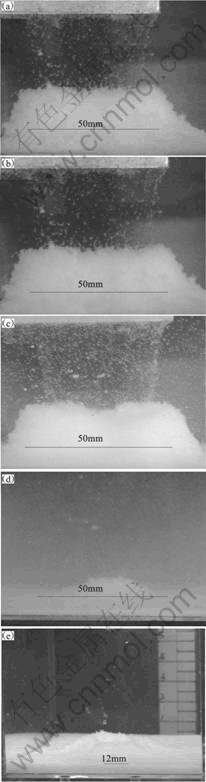

Fig.2 shows the nucleation and detachment process of NH4Cl crystal on the interface of the undercooled nuclei generator with vibration. The result indicates that the crystal detach rate and quantity increase with the acceleration enhancement when the frequency is 50 Hz, as shown in Figs.2(a)-(d). It should be noted that an interesting phenomenon is observed in Fig.2(d), where NH4Cl crystals were ejected from the interface of the generator as soon as they nucleate, and the crystals were dispersed in the melt throughout the whole solution volume, forming a suspension liquid composed of NH4Cl-70%H2O solution and the dispersed NH4Cl micro-crystals. The deposition of the NH4Cl micro- crystals takes about 7 min after shutting down of the electric vibrator, as shown in Fig.2(e).

Fig.2 Detachment of NH4Cl crystals with fixed frequency of 50 Hz for 15 min under different acceleration: (a) 10 m/s2; (b) 30 m/s2; (c) 50 m/s2; (d) 100 m/s2; (e) Ammonium chloride sediment bed for 7 min after stop the vibra tion with a=100 m/s2

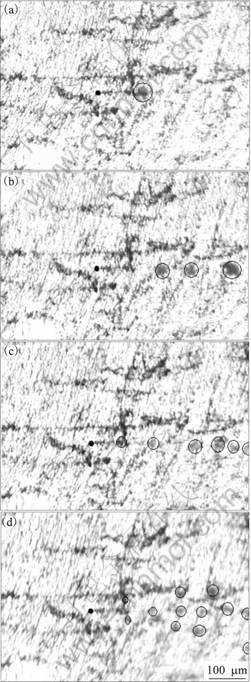

The microscopic pictures of crystal detachment are shown in Fig.3. It is also shown that the detachment of the crystals was enhanced with increasing vibration acceleration. Under the same frequency of vibration, with the improvement of vibration acceleration, the faster the rate of detachment is, the greater the quantity of crystals is and the smaller the dimension of crystals is. As the acceleration is up to 100 m/s2 as shown in Fig.3(d), the crystals are detached in a divergent manner, which corresponds to the dispersion phenomenon in Fig.2(d).

Fig.3 Microstructures of detached crystal under different acceleration: (a) f=50 Hz, a=10 m/s2; (b) f=50 Hz, a=30 m/s2; (c) f=50 Hz, a=50 m/s2; (d) f=50 Hz, a=100 m/s2

3.2 Temperature curve of nuclei generator

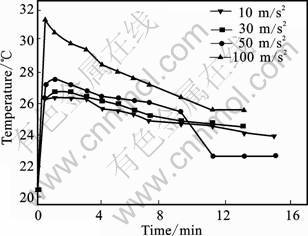

When the acceleration is set as different values at constant frequency, the temperature changes are shown in Fig.4. Under the special parameter (f=50 Hz, a=100 m/s2), it can be clearly seen that the temperature of generator rose more rapidly than under other conditions after it was inserted in the melt. It is well known that the undercooling is a necessary condition for nucleation. The nucleation occurs as the temperature cools down to attain a certain undercooled temperature. So, the temperature track always keeps the process that at first it rises, and then it gets cool. It spends more time in starting the nucleation behavior under the special parameter. It is the reason why the crystals detachment happened delay for 30 s. The temperature rises higher and higher with the increasing acceleration. Especially, the special point has the highest temperature.

Fig. 4 Temperature curves at f=50 Hz; a=10, 30, 50, 100 m/s2

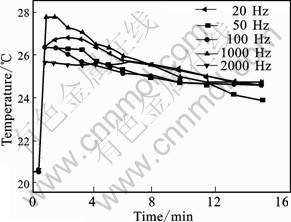

The temperature variety as the acceleration equal 10 m/s2 with different frequency is shown in Fig.5. It is seen that there is no obvious difference under the condition.

Fig.5 Temperature curves at a=10 m/s2; f=20, 50, 100, 1 000, 2 000 Hz

When the generator was reached into the melt, the temperature of nuclei generator will be raised quickly because of the heat conductivity and phase-change latent heat. Under the special parameter, the temperature of generator will be raised sharply, and the maximum temperature of the generator is higher than other parameters by 4 K. This phenomenon is as a result of the vibration makes the melt stirring acutely, flowing turbulently, thus the heat exchange condition will be changed between the nuclei generator with melt. The melt will be cooled enough and the generator will be heated adequately by the heat conductivity, especially under the special parameter. The nuclei interface needs more time to obtain the enough undercooled temperature, so the crystals detachment starts 30 s late. In addition, it is shown in Fig.4 and Fig.5, in the current experimental system, the effect of frequency on temperature has regularity less than the effect of acceleration, so that the acceleration represents energy input during the vibration but frequency.

3.3 Theory analysis

The effect of vibration on crystal detachment is closely related to the imposed energy. In order to analyze the energy of vibration, it is worthwhile to set out the movement equation of vibration.

Assume that the vibration is a simple harmonic motion.

A definition of simple harmonic motion is [6]

![]() (1)

(1)

where a is the acceleration, x is the amplitude,

![]() (2)

(2)

and f is the frequency.

From Eqs.(1) and (2), we have

![]() (3)

(3)

From Eq.(1), the force is given by

![]() (4)

(4)

The energy input in the T/4 s ,

![]() (5)

(5)

where A is the maximum amplitude.

From Eqs.(3) and (5), we have

![]() (6)

(6)

The power to generate the quantity of work in this period is

![]() (7)

(7)

Thus we have

![]() (8)

(8)

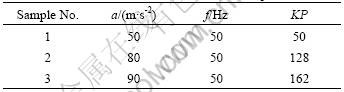

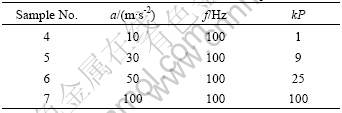

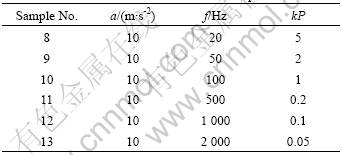

where m is the load mass of the nuclei generator on the vibrator. It can be seen from Eq.(8) that the imposed energy can be expressed by a function of vibration acceleration and frequency. Several experiments have been made and the critical value of kP is calculated for the phenomenon of atomization, as listed in Tables 1-4.

Table 1 Phenomenon of atomization

Table 2 Phenomenon of non-atomization of samples No.1-3

Table 3 Phenomenon of non-atomization of samples No.4-7

Table 4 Phenomenon of non-atomization of samples No.8-13

As a result of the above experiments, when the relationship between frequency and acceleration is satisfied with kP≥200, the phenomenon of atomization will happen and grain refinement will be enhanced dramatically. Consequently, Eq.(8) can be regard as an energy criterion to grain refinement in the current experimental system.

4 Conclusions

1) Exerting vibration on a rough chilling surface can enhance the detachment of the crystals.

2) The grain refinement effect under the vibration obeys a power criterion. There exists relationship between the vibration parameters and imposed power on the system.

3) In the current experimental system, when the ratio of the square of acceleration to frequency is equal to or more than 200, the optimal refinement effect will be obtained.

References

[1] FREDRIKSSON H, HILLERT M. On the formation of the central equiaxed zone in ingots [J]. Metallurgical Transactions, 1972, 3: 565-570.

[2] JACKSON K A, HUNT J D, UHLMAN D R, SEWARD T P. On the origin of the equiaxed zone in castings [J]. TMS-AIME, 1966, 236(2): 149-158.

[3] SOUTHIN R T. Nucleation of the equiaxed zone in cast metals [J]. Trans TMS of AIME, 1976, 239(2): 220-225.

[4] PILLAI N R. Effect of low frequency mechanical vibration on structure of modified aluminum-silicon eutectic [J]. Metallurgical Transactions, 1972, 3(5): 1313-1316.

[5] FEDOROV O P, ZHIVOLUB E L. Effect of low-frequency vibration on nucleation of crystals in supercooled melts [J]. Crystallography Reports, 2002, 47(3): 567-572.

[6] CAMPBELL J. Effects of vibration during solidification [J]. International Metals Reviews, 1981, (2): 71-108.

[7] DU L C, WANG M, ZHANF Y, LIN X, HUANG W D, GAN Y, ZHANG H, ZHAO P. Experimental study and dynamic analysis on the effect of grain refining with vibration and Chilling [J]. Special Casting and Nonferrous Alloys, 2009, 29(4): 327-330.(in Chinese)

[8] JONES H. Cooling slope casting to obtain thixotropic feedstock [C]// Proceedings of the 5th Decennial International Conference on Solidification Processing. Sheffield, UK: Department of Engineering Materials, University of Sheffield, 2007.

[9] GAN Y, ZHAO P, WANG M, ZHANG H, TAO H B, LV Y C. Physical analogue of liquid metal original position nucleation stirred by vibration [J]. Journal of Iron and Steel Research, 2006, 18(8): 9-13(in Chinese)

[10] TAO H B, ZHANG H, WANG M, ZHAO P, GAN Y. Effect of liquid metal nucleation stirred by vibration on solidification structure of Zinc [J]. China Metallurgy, 2007, 17(11): 45-48. (in Chinese)

[11] WANG W L, LIN X, HUANG W D, GAN Y, ZHANG H, ZHAO P. Research on characteristics and condition of crystal nucleation from a chilling solid surface with vibration [J]. Foundry Technology, 2007, 28(8):1036-1038. (in Chinese)

[12] ZHANG H, TAO H B, LI F, WANG M, HUANG W D, ZHAO P. Research on mechanism of nucleation in liquid metal excited by vibration [J]. Iron and Steel, 2008, 43(8): 20-24. (in Chinese)

[13] WANG M, ZHU S F, ZHANF Y, LIN X, HUANG W D. Researches on the nucleation behaviors of NH4Cl crystal on coarse aluminum surfaces [J]. Materials Science Forum, 2010, 654/655/656: 1343-1346.

[14] HANSEN G, LIU S, LU S Z, HELLAWELL A. Dendritic array growth in the systems NH4Cl-H2O and [CH2CN]2-H2O: steady state measurements and analysis [J]. Journal of Crystal Growth, 2002, 234: 731-739.

[15] HUANG W D, WANG W L, LIN X, WANG M. In-situ observation of SSM microstructure formation during cooling slope casting of an NH4Cl-H2O alloy with vibrating the slope [J]. Solid State Phenomena, 2006,116/117: 193-196.

(Edited by YUAN Sai-qian)

Foundation item: Projects(50571029, 50771083) supported by the National Natural Science Foundation of China; Projects(02-TZ-2008, 36-TP-2009) supported by State Key Laboratory of Solidification Processing in NWPU, China.

Corresponding author: ZHANG Ying; Tel: +86-29-88492374; E-mail: ying.zhang@mail.nwpu.edu.cn