- Abstract:

- 1 Introduction▲

- 2 Graft copolymer and EVA...▲

- 3 Analysis of modified EV...▲

- 4 Pour point depressant e...▲

- 5 Conclusions▲

- References

- Figure

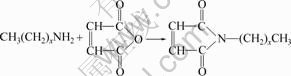

- Fig.1 Infrared spectrum of octadecyl amine

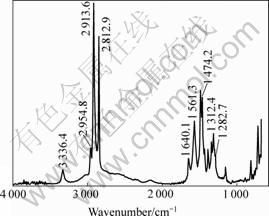

- Fig.2 Infrared spectrum of maleic anhydride octadecyl maleimide

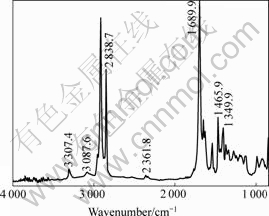

- Fig.3 Infrared spectrum of octadecyl maleic anhydride

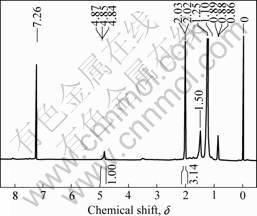

- Fig.4 Nuclear magnetic resonance spectrum of EVA

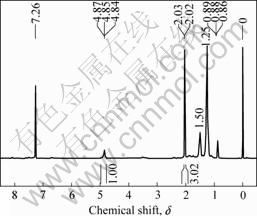

- Fig.5 Nuclear magnetic resonance spectrum of EVA-16

- Fig.6 Nuclear magnetic resonance spectrum of EVA-18

J. Cent. South Univ. Technol. (2008) 15(s1): 488-491

DOI: 10.1007/s11771-008-406-z

![]()

Synthesis of new EVA graft copolymer and its pour point depressant performance evaluation for Daqing crude oil

WU Li-juan(伍丽娟)1, 2, ZHANG Fan(张 帆)1, GUAN Zhong-yuan(关中原)3, GUO Shu-feng(郭淑凤)3

(1. Beijing Key Laboratory of Urban Oil and Gas Distribution Technology, China University of Petroleum, Beijing 102249, China;

2. Petroleum Engineering College, Yangtze University, Jingzhou 434023, China;

3. Scientific and Technical Center of China Petroleum Pipeline Corporation, Langfang 065000, China)

Abstract:

EVA was widely used as the pour point depressant for waxy oil. In order to improve its effect, some graft copolymerization methods should be used to modify EVA’s property. EVA has long side chains and nitrogen polar groups to enforce its adaptability and effect of waxy oil. The pure amine, maleicanhydride and their reaction product were tested using infrared spectra and the NMR spectral. The results show that when the modified EVA is added into oil, the wax deposits not only on the main chain but also on the side chains. And the polar groups have the function to avoid and resist the wax crystals connection each other to form the net. Using the reaction product of maleicanhydride and high carbonic amine (C12, C16, C18 amine) as the graft component, the toluene as the solvent and BPO as the initiator, the series of new EVA graft copolymer with special side chains are prepared under controlled condition. A series of cylmaleimide exist indeed in modified EVA and the highest grafted percentage is 18.8%. EVA-16, the new graft copolymer, is better than EVA about 3 ℃ more in depressant the pour-point of Daqing waxy crude oil.

Key words:

modification EVA; copolymer; pour point depressants; performance evolution; Daqing crud;

1 Introduction

Pour point of Daqing crude oil is 31 ℃, which is typical waxy oil. Its fluidity is too poor to pipeline at ambient temperature. In order to pipeline it, heating stations were built along the pipeline and ran all the time to keep its temperature higher than pour point. When the pipeline is shutdown, the waxy crude oil will be gradually cooled and lose fluidness, and then change into gel and be hard restarted[1]. Obviously, considering the energy consumption and the operation safety, heating is not the best way to pipeline waxy oil. The key of improving low-temperature fluidity of waxy crude is to depress its pour point. One of the best way is using chemistry additives which are often called pour point depressant (PPD)[2]. Although PPD can effectively decrease the pour-point of waxy crude, there is very strong compatibility between PPD and waxy crude[3]. It means that different waxy crudes match with different PPD. At present, the majority of the pour point depressants is macromolecule polymer, such as EVA (ethylene-vinylacetate copolymer)[4]. Although EVA is widely applicated as the crude oil flowing modifying agent, yet it dose not satisfy for any waxy crude oil, for example Daqing crude. In order to improve the effect of pour point depressant, the polar groups and the branch chain should be introduced into macromolecule of EVA. American patent[5] introduced the graft copolymerization reaction between the foundation polymer (ethylene copolymer) and the dicarboxylic acid amide, and it was proved that the graft polymer had better effect than the foundation polymer. But if there are strong polar groups (such as —OH, —NH2 and —COOH) grafted on the polymer chain, it may sometimes block the hydroxyl and the actions of groups sol-inhibitory in crude oil. For this reason, the groups which want to graft to EVA should be chosen to adapt the waxy crude oil to obtain the better pour point depressant effect[6].

2 Graft copolymer and EVA grafted reaction

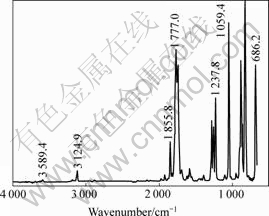

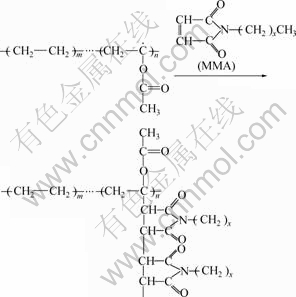

Alkyl maleimide was synthesized by high-carbonic amine (C12, C16, C18 amine) and the maleic anhydride with the ratio of 1?1. The chemical react formula is shown as follows. In the formula, x=11, 15, 17, represent amine molecular formula 12, 16 and 18, separately.

(1)

(1)

Maleic anhydride was dissolved in toluene firstly,then the ration acid catalyst and high-carbonic amine were slowly added into it with continuous stirring. The reaction temperature was maintained for 6 h at 80-90 ℃. Put the reacted product of graft copolymer in the ventilation chamber and roast it with infrared lamp to remove water and solvent. Then, graft copolymer was dissolved with the ether and filtrated to remove un-reacted amine and maleic anhydride.

In order to graft alkyl maleimide on EVA, the two components were dissolved with toluene and the initiator BPO was added into the solution. During the graft raction, the nitrogen protection was used. After reaction put the grafted copolymer and modified EVA into the ventilation chamber and roast it with infrared lamp to remove solvent and un-reacted raw material.

3 Analysis of modified EVA

Infrared spectrum and nuclear magnetic resonance were used to analyze modified EVA[7]. The infrared absorption peaks of octadecyl amine, maleic anhydride and octadecyl alkyl maleimide are shown in Figs.1-3. Compared with absorption peaks of octadecyl amine,

Fig.1 Infrared spectrum of octadecyl amine

Fig.2 Infrared spectrum of maleic anhydride octadecyl maleimide

Fig.3 Infrared spectrum of octadecyl maleic anhydride

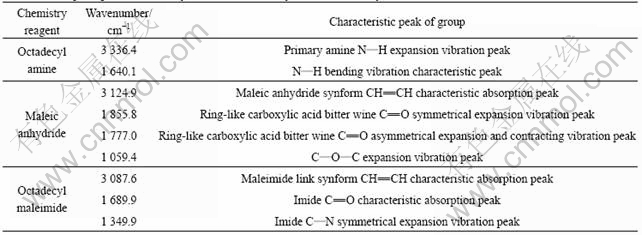

maleic anhydride and octadecyl maleimide (shown in Table 1). The test results indicate that the synthesis of octadecyl maleimide is successfully grafted with EVA. Vibration absorption peaks of N—H and C=O of octadecyl-amine and maleic anhydride move to the right lateral, which indicate that octadecyl amines and the primary amine group had been transformed into the imines and maleic anhydride acid anhydride group had been transformed into imide.

Table 1 Absorption peaks of octadecyl amines, maleic anhydride and octadecyl maleimide

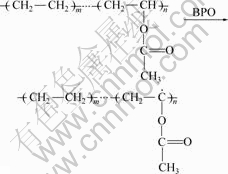

Generally, the grafting reaction occurs in vinyl acetate amorphous part[8]. In grafting reaction of ethylene-vinyl acetate, the free radical produced by heating decomposition captures tertiary hydrogen atom (Ha) of principal chain and forms the free radical active spot and reacts with the graft component. The chemical formula of EVA is shown in Eqn.(2).

![]() (2)

(2)

With the help of free radical, the graft monomer opens the duplet bond. It is shown in Eqn.(3)

(3)

(3)

Then graft component reacts with losing H free radical union in the stem chain of the VA to form the grafting product. It is shown in Eqn.(4)

(4)

(4)

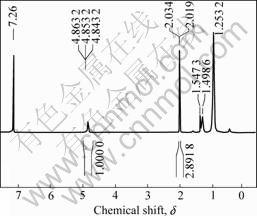

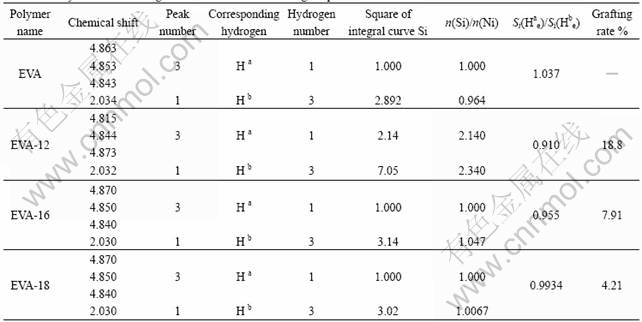

According to the chemical shift rule, the peak of grafted product of EVA can be detected with Ha and Hb using nuclear magnetic resonance spectrum, and the grafting rate can be calculated by the change of the integral curve square on Ha and Hb in VA before and after grafting reaction. The test results are shown in Figs.4-6.

Fig.4 Nuclear magnetic resonance spectrum of EVA

Fig.5 Nuclear magnetic resonance spectrum of EVA-16

Fig.6 Nuclear magnetic resonance spectrum of EVA-18

The graft rates of EVA and different modified EVA are listed in Table 2. It can be seen from Table 2 that the graft rate decreases with the increase of branched chain carbon numbers of graft group. EVA-12 has the highest graft rate of 18.8%.

Table 2 Analysis of nuclear magnetic resonance for EVA and graft products

4 Pour point depressant effect on DQ oil

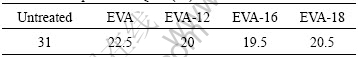

Different kinds of EVA are added into Daqing crude oil (DQ) at 65 ℃ with the concentration of 50 mg/kg. The pour points are tested and shown in Table 3.

Table 3 Pour point of DQ oil (℃)

The results indicate that modified EVA is better than EVA in pour point depressant effect on Daqing crude oil. And EVA-16 has the best effect. It also proves that, among the modified EVAs, the carbon chain length of EVA-16 is much closer to the carbon chain length of wax in DQ crude oil than the others.

In theory, if the carbon chain length including side alkyl chain lengths of PPD is close to all carbon chain lengths of wax in crude oil, the best pour point depressant effect should be gained. But it is almost imposible to do so. It is very difficult to graft all groups on EVA at the same time. And as mentioned above, the longer the branched chain carbon of grafted group is, the lower the grafting rate is. So, how to improve the grafting rate and match the wax better are to further researched the modified EVA of waxy crude oil.

5 Conclusions

1) Dodecyl-amine, hexadecyl-amine and octadecyl- amine can react with the maleic anhydride to produce series of alkyl maleimide intermediary products, which are raw material used to form grafted groups.

2) The graft groups of copolymers EVA grafting are synthesized by EVA and alkyl maleimide. The result of nuclear magnetic resonance analysis indicates that the grafting react is successfully made. The grafting rate decreases with the increase of branched chain carbon numbers of grafted group. EVA-12 has the highest graft rate of 18.8%.

3) The modified EVAs are better than EVA in pour point depressant effect on Daqing crude oil. And EVA-16 is the best one.

References

[1] MALCOLM R, DAVIDSON Q, DZUY N. A model for restart of a pipeline with compressible gelled waxy crude oil [J]. Journal of non-Newtonian Fluid Mechanics, 2004, 123: 267-280.

[2] ISMAIL M. Polymer additive for improving the flow properties of waxy dissipate fuels and crude [J]. Fuel, 1996, 75(6): 743-750.

[3] HUO Jian-zhong. The synthesis and performance study of crude oil pour point depressant [J]. Journal of Tianjin Normal University: Natural Sciences, 2002, 2(2): 9-10.

[4] ZENG Hui-yang, ZHANG Wei-bang. Synthesis of polymers with long side chains of N-alkyl esters and their effects on pour point depression of oil [J]. Applied Polymer Science, 1991, 43: 919-924.

[5] FRANKFURT J B. Graft polymers, their preparation and use as pour point depressants and flow improvers for crude oils, residual oils and middle distillates: US, 5439981[P]. 1995.

[6] GUAN Zhong-yuan. Preparation, analysis and application of EVA graft copolymer [J]. Journal of Xi’an Petroleum Institute: Natural Sciences, 2002, 17(2): 52-55.

[7] SHEN De-yan. The application of infrared spectrometry in high polymer research [M]. Beijing: Scientific Press, 1982. (in Chinese)

[8] WU Pei-xi, ZHANG Liu-cheng. Polymer blending modified technology[M]. Beijing: Chinese Light Industry Press, 1996. (in Chinese)

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: WU Li-juan; Tel: +86-10-89733543; E-mail: wljytz@163.com, rheo@cup.edu.cn

- Synthesis of new EVA graft copolymer and its pour point depressant performance evaluation for Daqing crude oil