文章编号:1004-0609(2016)-08-1668-07

含孔隙及界面热阻的复合材料有效导热系数

庞旭明1,周剑秋1,杨晶歆2,廖铭宏2

(1. 南京工业大学 机械与动力工程学院,南京 211816;

2. 南京工业大学 能源学院,南京 211816)

摘 要:

以最小热阻力法则及比等效导热系数法,通过修正串-并联模型,建立含界面热阻的固-固相复合材料等效导热模型,将固-固相复合材料转换为导热系数为等效热导率的单相固体材料,再利用含孔隙的单相材料导热系数模型推导含孔隙和界面热阻的复合材料有效导热系数。计算含孔隙及界面热阻的复合材料的有效导热系数并讨论气孔、分散相的含量及颗粒尺寸对其有效热导率的影响。将有效导热系数的理论值与相关实验数据进行比较。结果表明两者吻合较好,证明公式的准确性。

关键词:

中图分类号:TB33;TB131 文献标志码:A

近年,金属基复合材料在国防、电子技术、航空航天、汽车工业等诸多领域的应用越来越广泛,其传热特性一直是研究热点[1-8]。对于电子封装材料,随着电子元器件更高集成度、更快运行速度和更大容量的要求,散热问题直接影响电子器件的可靠性。SiC/Al、金刚石/Cu等为代表的金属基复合材料具有较好的可焊接性,但导热性能不高,严重制约现代电子技术的发展[9]。科研人员研究了成分及热处理工艺对复合材料显微组织和相结构的关系,并深入探索其对导热性能的影响[2-5]。目前,研究人员通过等离子喷涂等方法制备金属陶瓷复合材料太阳能选择性吸收涂层,研究表明其导热系数不仅显著影响太阳能集热器的总热损系数,且较低的热导率将使涂层本身的温度升高,进而涂层发射率随温度的升高迅速增加,降低光热转换效率[10-12]。此外,利用激光熔敷技术,制备新型梯度金属陶瓷热障涂层,通过改变涂层中金属及陶瓷的相对含量,得到性能平稳连续变化梯度涂层,有效地解决了涂层容易开裂和剥落等失效问题[13],而作为隔热材料,导热系数是其最为重要的物理性能。鉴于此,从理论上研究复合材料的导热特征,具有极为重要的理论价值。

国内外学者提出过一些预测导热系数的数学模型,如Baschirow-Selenew模型、Maxwell-Eucken模型、Bruggeman模型、Agari模型等[14-19]。这些研究主要集中在以下两个方面:一是借助相关的数学方法推导精确或近似的解析表达式;二是研究几何因子如形状、大小、排列方式等对热导率的影响,对初始方程添加相关的参数以扩大方程的适用范围,提高预测精度。然而,传统模型都是在忽略界面热阻和孔隙的理想情况下建立的,因此上述模型仅能对复合材料的导热系数进行估算,其理论值与实验值存在较大的误差。目前,研究表明界面热阻是影响复合材料等效导热系数的关键因素。特别是弥散相粒径较小时,对复合材料的导热系数存在显著影响。在不考虑孔隙的前提下,GEIGER等[20]和HASSELMAN等[21]在Maxwell模型的基础上进行了修正,利用有效当量法思想,提出了含界面热阻的复合材料有效介质理论EMT (Effective medium theory)模型,并探讨了界面热阻的影响。然而,材料实际制备过程中,复合材料内部存在孔隙且含量不同。根据文献报道,仅有关于描述含孔隙的单相材料导热系数的理论研究[22]。目前,综合考虑孔隙和界面热阻影响的复合材料传热模型尚未见报道。 然而,关于含气孔的单相材料导热性能研究中,当量法也是其基本方法之一。由于含界面热阻复合材料及含气孔单相材料导热性能都可用当量法的思想建模,这为问题的解决找到了突破口。利用两步当量法思想,基于最小热阻力法则和等效导热系数法则,可建立含孔隙和界面热阻的复合材料导热模型并计算其等效导热系数。

1 理论推导

1.1 含界面热阻复合材料有效热导率

1.1.1 数学模型的建立

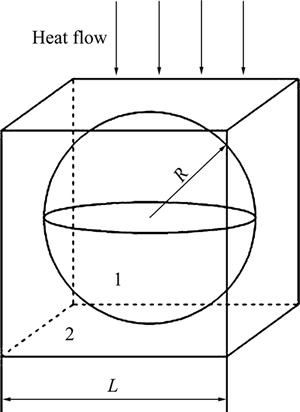

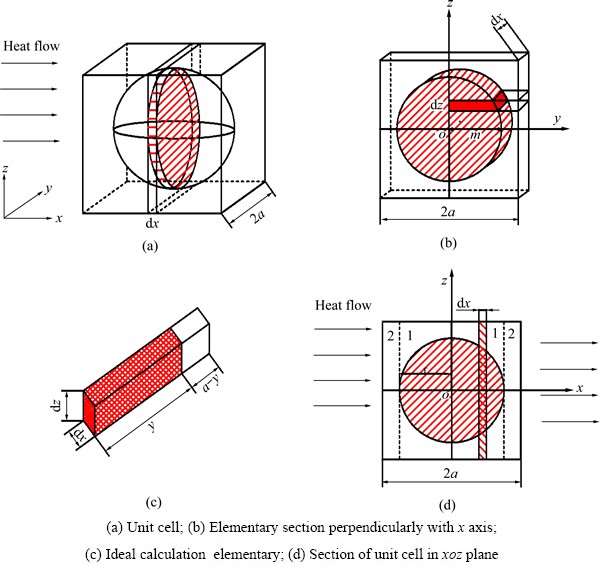

根据最小热阻力法则及比等效导热系数相等法则可知,当颗粒状弥散相复合材料的单元体与总体有相等的比等效热阻时,则不论单元体的尺度大小,在只考虑热传导时,可用单元体的热导率表示整个材料的热导率。因此,研究复合材料等效热导率,归结为研究具有相同比等效热阻的单元体的等效热导率。将整体复合材料视为由大量心部包含一个弥散颗粒的立方单元体组成的密堆体,热流从立方体顶面进入(见图1)。

图1 复合材料单元体模型

Fig. 1 Unit cell of composites

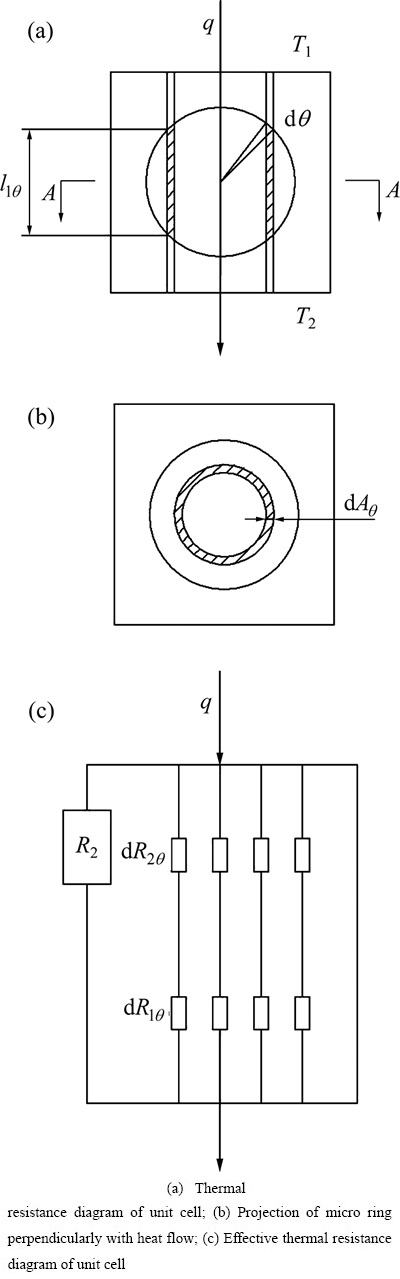

对于金属基复合材料,通过计算各热流通道的串联热阻,再将其各通道的热阻并联,即可求得单元体的等效热阻,即串-并联模型(见图2)。

1.1.2 含界面热阻复合材料有效热导率的推导

基于串-并联模型,对其进行修正,将界面热阻引入该模型,推导含界面热阻的复合材料等效导热系数表达式。

假设球心位于立方体中心,球体弥散颗粒半径为R,立方体边长为L,则填充相体积分数:

,且

,且 ≤

≤ (1)

(1)

图2 串-并联模型

Fig. 2 Series-parallel connection models

将热流通道分为两大系统:一个是在热流方向上只有连续相的简单通道;另一个是在热流方向上要遇到球体弥散相的通道,在该通道系统内,根据热阻率相等的原则,以过球心的热流线为轴,取微元环通道,如图2(a)所示。进而球半径R与轴线夹角θ处则有增量dθ所形成的与轴线平行的圆筒环,该微环在热流方向上的投影面积dAθ (见图2(b)):

(2)

(2)

在微环通道内分散相的长度:

(3)

(3)

连续相的长度:

(4)

(4)

此外,假设界面热阻的面积热阻为RB,则在热流方向含弥散相的微环通道的热阻dRθ由弥散相和分散相串联而得(见图2(c));

(5)

(5)

由上式可知,当夹角θ自0变至π/2时,含有弥散相的热流通道即由多个增量为dθ的微元环通道并联所构成。根据图2(c),则该通道的总热阻由各微元环通道的热阻与单一连续相通道的热阻R2并联而得,其中热阻R2由式(6)所示。

(6)

(6)

因此,可得总热阻Rt-b的表达式:

(7)

(7)

进而求得单元体的有效热导率λt-b:

(8)

(8)

式中: ,

, 。

。

1.2 含气孔和界面热阻复合材料有效热导率

显然,固相/固相(金属/陶瓷)复合材料可转换成有效导热系数为λt-b的单相固体材料,则含气孔的复合材料的导热系数可用含气孔的单相材料的导热模型进一步求出,其单元体模型如图3(a)所示。

图3 含气孔材料的单元体结构

Fig. 3 Structures of unit cell containing void

对含孔隙复合材料作如下假设:1) 气孔相为球形且弥散分布;2) 热流沿x轴方向传递;3) 不考虑对流换热。由假设1)可知,可以用单元体的热导率表示整个材料的热导率,选边长为2a且内部含有球的立方体作单元体,球心在立方体的中心且半径设为r,以球心为坐标原点,则此单元体可被垂直于x轴的平面截成许多薄片,如图3(a)所示。考虑如下一个薄片,它由垂直于x轴且距离为dx的两个平面截得,如图3(b)所示,其中m=(r2-x2)0.5。将图3(b)右上角的部分用垂直于z轴且距离为dz的两个平行平面继续将其分割并用平面近似代替两相材料交界处的曲面,得到如图3(c)所示的计算微元。

图3(c)的微元中气孔相与固体相所占的体积分数分别为y/a和(a-y)/a,当热流为x轴方向时,固相与气相的热阻为并联,利用热阻的定义及热阻并联的性质可得微元的热导率为

(9)

(9)

式中:λd与λc分别为气相与固相的热导率。

同理可推得图3(b)中右上角长方体的热导率为

(10)

(10)

将式(9)代入式(10)并写成积分形式得:

(11)

(11)

由于图3(b)中4个长方体是对称的且在热流方向上并联,所以图3(b)中整个微元体的热导率也为λquarter。整个单元体可以分成图3(d)中所示的4部分,其中部分1为气相与固相的混合体,部分2为固相。利用积分平均方法,对λquarter在x轴方向上积分即可得到部分1的热导率λ1为

(12)

(12)

图3(d)中部分1与部分2在热流方向上是串联的,由热阻的定义及串联热阻的性质推得仅考虑导热时整个单元体的有效热导率λec满足:

(13)

(13)

显然,其气孔相在单元体所占比例即为孔隙率ξ=πr3/(6a3)。结合式(8),固体复合材料等效导热系数λb-t即为固相导热系数λc,将其代入式(13),则推导出含孔隙和界面热阻的复合材料等效导热系数为

(14)

(14)

2 实验及结果分析

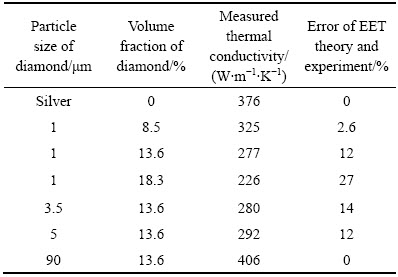

杨广等[23]研究了金刚石/Ag复合材料的导热性能,对其导热系数进行了测试,利用有效介质理论EMT讨论了复合材料晶粒尺寸和体积分数对其导热性能的影响。表1所列为复合材料导热系数的实验值及与理论值的误差。

表1 金刚石/银复合材料导热性能

Table 1 Effective thermal conductivity of diamond/silver

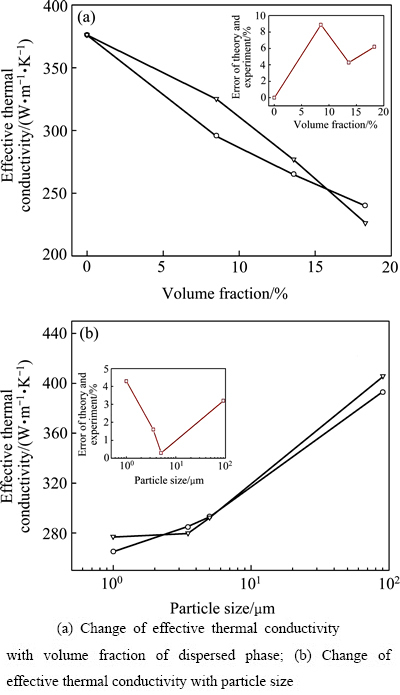

根据文献[24]提供的相关参数,利用式(14)计算复合材料等效导热系数。图4所示为金刚石/银复合材料导热性能测试与模型计算结果。由图4可知,等效导热系数理论值与实验值非常吻合,模型计算结果明显优于EMT理论。研究发现,随着金刚石体积分数的增加,复合材料的导热系数逐渐降低。这是由于体积分数的增加使陶瓷/金属的界面热阻增加,当热流穿过金属-非金属界面时,界面热阻对界面处电子-声子热传递的阻碍作用增加,进而导热系数逐渐降低(见图4(a))。根据图4(b)所示,当金刚石的体积分数不变时,界面热阻随晶粒尺寸的增加而减小,进而导致复合材料有效导热系数逐渐增大。这表明晶粒大小对材料热导率有显著的影响。

图4 金刚石/银的导热性能实验与模型计算结果

Fig. 4 Result of experiment and calculation values of diamond/silver

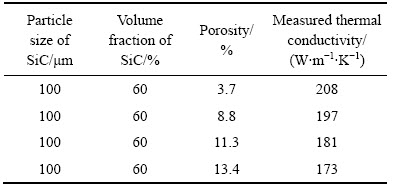

文献[25]报道了SiC/Al复合材料的导热系数,其相关参数如表2所列。将其代入含孔隙及界面热阻理论模型,即可得到理论值。

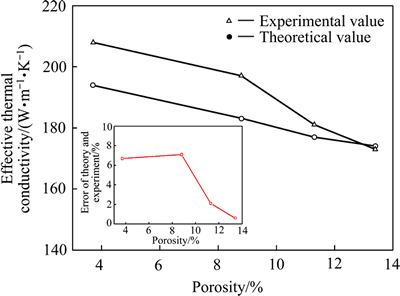

图5所示为SiC/Al复合材料导热系数理论与实验结果。研究发现,理论值与实验值符合的较好,其误差较小。如图5可知,气孔对复合材料导热系数有较大影响。等效导热系数随着孔隙度的提高,呈下降的趋势。这主要是由于空气的热导率远小于固体材料的,随着孔隙率的增加,气孔导热所占比重增加,但空气的热导率远小于固相材料的,因此随着孔隙率增加使整个复合材料的等效导热系数逐渐降低。

表2 SiC/Al复合材料参数

Table 2 Parameters of silicon carbide/aluminum composite material

图5 SiC/Al导热性能实验与模型计算结果

Fig. 5 Results of experiment and calculation values of SiC/Al

3 结论

1) 对最小热阻力法则及比等效导热系数法进行修正,首次推导含孔隙及界面热阻的复合材料的有效导热系数表达式。

2) 理论数据与实验数据误差较小,该模型可以精确计算金属基复合材料的导热系数。

3) 当界面热阻对复合材料导热系数存在较大影响时,颗粒体积分数的增加,使复合材料内界面增多,界面热阻引起导热系数的下降;而界面热阻随颗粒尺寸的增加而减小,所以导致热导率随粒径增大而提高。

4) 孔隙对复合材料有效导热系数存在显著影响,有效热导率随孔隙率增加而减小。这主要是因为空气的热导率远低于固相的,气孔比重的增加使复合材料的导热系数降低。

REFERENCES

[1] BAI Peng-fei, YI Zi-chuan, TANG Biao, ZHOU Guo-fu. Solid- phase sintering process and forced convective heat transfer performance of porous-structured micro-channels[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3): 900-906.

[2] GUO Hong, HAN Yuan-yuan, ZHANG Xi-min, JIA Cheng-chang, XU Jun. Microstructure and thermophysical properties of SiC/Al composites mixed with diamond[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 170-174.

[3] XIU Zi-yang, WANG Xu, HUSSAIN M, FENG Chao, JIANG Long-tao. Effect of heat treatment on microstructure and thermophysical properties of diamond/2024 Al composites[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3584-3591.

[4] 陈代刚, 于家康, 于 威, 袁 曼. 镀层厚度对镀钛金刚石/铝复合材料热导率的影响[J]. 中国有色金属学报, 2013, 23(1): 802-808.

CHEN Dai-gang, YU Jia-kang, YU Wei, YUAN Man. Effect of coating thickness on thermal conductivity of Ti-coated diamond/ Al composites[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 802-808.

[5] 袁 曼, 于家康, 陈代刚, 于 威, 李华伦, 曹禄华. SiCp/ZL101基复合材料的界面与性能[J]. 中国有色金属学报, 2013, 23(3): 779-785.

YUAN Man, YU Jia-kang, CHEN Dai-gang, YU Wei, LI Hua-lun, CAO Lu-hua. Interface and properties of SiCp/ZL101 matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 779-785.

[6] WU Chuan-song, ZHANG Wen-bin, SHI Lei, CHEN Mao-ai. Visualization and simulation of plastic material flow in friction stir welding of 2024 aluminium alloy plates[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1145-1451.

[7] 刘 奇, 程树森, 牛建平, 刘东东. 铜钢复合冷却壁传热及热应力分析[J]. 中国有色金属学报, 2015, 25(2): 523-533.

LIU Qi, CHENG Shu-sen, NIU Jian-ping, LIU Dong-dong. Heat transfer and thermal stress analysis of copper steel composite stave[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 523-533.

[8] 李俊文, 赵海东, 吴朝忠, 李元元. 铝合金挤压铸造过程界面的传热行为[J]. 中国有色金属学报, 2014, 24(11): 2727-2734.

LI Jun-wen , ZHAO Hai-dong, WU Chao-zhong, LI Yuan-yuan. Interfacial heat transfer behavior of aluminum alloy during squeeze casting[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2727-2734.

[9] MOLINA J M, RHEME M, CARRON J. Thermal conductivity of aluminum matrix composites reinforced with mixtures of diamond and SiC particles[J]. Scripta Materialia, 2008, 58(5): 393-396.

[10] HARDING G L, YIN Z Q, MACKEY D W. Heat extraction efficiency of a concentric glass tubular evacuated collector[J]. Solar Energy, 1985, 35(1): 71-79.

[11] DUFFIE J A, BECKMAN W A. Solar engineering of thermal processes[M]. New York: John Wiley & Sons INC, 1991: 41-230.

[12] 文玉良, 丁 静, 杨建平, 陆建峰. 聚光太阳能热发电中吸热器吸收涂层的选择[J]. 太阳能学报, 2009, 30(6): 764-768.

WEN Yu-liang, DING Jian, YANG Jian-ping, LU Jian-feng. Selection of solar coatings in concentrating solar power[J]. Acta Energiae Solaris Sinica, 2009, 30(6): 764-768.

[13] 周圣丰, 戴晓琴, 熊 征, 张天佑. 激光感应复合快速熔覆功能梯度YSZ/NiCrAlY涂层的研究[J]. 中国激光, 2013, 40(4): 0403004-1-0403004-6.

ZHOU Sheng-feng, DAI Xiao-qin, XIONG Zheng, ZHANG Tian-you. Functionally graded YSZ/NiCrAlY coating prepared by laser induction hybrid rapid cladding[J]. Chinene Journal of Lasers, 2013, 40(4): 0403004-1-0403004-6.

[14] AGARI Y, UNO T. Estimation on thermal-conductivities of filled polymers[J]. Journal of Applied Polymer Science, 1986, 32(7): 5705-5712.

[15] AGARI Y, UEDA A, NAGAI S. Thermal-conductivity of a polymer composite[J]. Journal of Applied Polymer Science, 1993, 49(9): 1625-1634.

[16] AGARI Y, UEDA A, NAGAI S. Thermal-conductivities of composites in several types of dispersion-systems[J]. Journal of Applied Polymer Science, 1991, 42(6): 1665-1669.

[17] AGARI Y, UEDA A, NAGAI S. Thermal-conductivity of a polyethylene filled with disoriented short-cut carbon-fibers[J]. Journal of Applied Polymer Science, 1991, 42(6): 1117-1124.

[18] GU G Q. Calculation method for effective constants of periodic composite media[J]. Journal of Physics D: Applied Physics, 1993, 26(9): 1371-1377.

[19] LIANG X G, QU W. Effective thermal conductivity of gas-solid composite materials and the temperature difference effect at high temperature[J]. International Journal of Heat and Mass Transfer, 1999, 42(10): 1885-1893.

[20] GEIGER A L, HASSELMAN D P H, DONALDSON K Y. Effect of reinforcement particle-size on the thermal-conductivity of a particulate silicon carbide-reinforced aluminum-matrix composite[J]. Journal of Materials Science Letter, 1993, 12(6): 420-423.

[21] HASSELMAN D P H, JOHNSON L F. Effective thermal-conductivity of composites with interfacial thermal barrier resistance[J]. Journal of Composite Materials, 1987, 21(6): 508-515.

[22] 万 宾, 乐 恺, 郑连存, 张欣欣, 于 帆. 两相复合材料有效热导率的理论推导[J]. 工程热物理学报, 2008, 29(12): 2071-2074.

WAN Bin, YUE Kai, ZHENG Lian-cun, ZHANG Xin-xin, YU Fan. Theoretical derivation of effective thermal conductivity for two-phase composite materials[J]. Journal of Engineering Thermophysics, 2008, 29(12): 2071-2074.

[23] 杨 广, 堵永国, 白书欣, 龙 雁, 胡君遂, 张家春. 界面热阻对金刚石/银复合材料导热率的影响[J]. 国防科技大学学报, 1998, 20(6): 119-122.

YANG Guang, DU Yong-guo, BAI Shu-xin, LONG Yan, HU Jun-sui, ZHANG Jia-chun. Effect of thermal boundary resistance on the thermal conductivity of diamond/ag metal matrix composites[J]. Journal of National University of Defense Technology, 1998, 20(6): 119-122.

[24] STONER R J, MARIS H J. Kapitza conductance and heat-flow between solids at temperatures from 50 to 300 K[J]. Physical Review B, 1993, 48(22): 16373-16387.

[25] 褚 克, 贾成厂, 梁雪冰, 陈 惠. SiCp/Al复合材料中孔隙影响热导率的模型[C]// 中国金属学会. 第七届(2009)中国钢铁年会论文集. 北京: 冶金工业出版社, 2009: 25-31.

CHU Ke, JIA Cheng-chang, LIANG Xue-Bing, CHEN Hui. Numerical study of the effect of porosity on the thermal conductivity of spark plasma sintered (SPS) consolidated SiCp/Al composites[C]// The Chinese Society for Metals. 2009 CSM Annual Meeting Plenary Sessions. Beijing: Metallurgical Industry Press, 2009: 25-31.

Effective thermal conductivity of composite materials containing pore and interface thermal resistance

PANG Xu-ming1, ZHOU Jian-qiu1, YANG Jing-xin2, LIAO Ming-hong2

(1. School of Mechanical and Power Engineering, Nanjing Technology University, Nanjing 211816, China;

2. College of Energy Engineering, Nanjing Technology University, Nanjing 211816, China)

Abstract: Based on the laws of the minimal thermal resistance and the specific effective thermal conductivity, the effective thermal conductivity of solid-solid phase composite material containing interface thermal was established by the modifying the series-parallel connection model. Thus the solid-solid phase composite material was viewed as the single phase solid material that the thermal conductivity is equal to the effective thermal conductivity. Then, the thermal conductivity of the composite material containing pore was derived by the heat transfer model of a single phase material containing pore. The effective thermal conductivity of composite materials containing pore and interface thermal resistance was deduced. And the effects, such as pores, particle size and volume fraction of dispersed phase on thermal conductivity were investigated. The calculation values agree well with the experimental results obtained from the other literature which show the method is effective.

Key words: composite material; effective thermal conductivity; interface thermal resistance; pore

Foundation item: Project(51502133) supported by the National Natural Science Foundation of China; Project (BK20140945) supported by the Natural Science Foundation of Jiangsu Province, China

Received date: 2015-05-29; Accepted date: 2015-12-23

Corresponding author: PANG Xu-ming; Tel: +86-25-58139953; E-mail: pxmkf@njtech.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51502133);江苏省自然科学基金资助项目(BK20140945)

收稿日期:2015-05-29;修订日期:2015-12-23

通信作者:庞旭明,讲师,博士;电话:025-58139953;E-mail: pxmkf@njtech.edu.cn

摘 要:以最小热阻力法则及比等效导热系数法,通过修正串-并联模型,建立含界面热阻的固-固相复合材料等效导热模型,将固-固相复合材料转换为导热系数为等效热导率的单相固体材料,再利用含孔隙的单相材料导热系数模型推导含孔隙和界面热阻的复合材料有效导热系数。计算含孔隙及界面热阻的复合材料的有效导热系数并讨论气孔、分散相的含量及颗粒尺寸对其有效热导率的影响。将有效导热系数的理论值与相关实验数据进行比较。结果表明两者吻合较好,证明公式的准确性。

[4] 陈代刚, 于家康, 于 威, 袁 曼. 镀层厚度对镀钛金刚石/铝复合材料热导率的影响[J]. 中国有色金属学报, 2013, 23(1): 802-808.

[5] 袁 曼, 于家康, 陈代刚, 于 威, 李华伦, 曹禄华. SiCp/ZL101基复合材料的界面与性能[J]. 中国有色金属学报, 2013, 23(3): 779-785.

[7] 刘 奇, 程树森, 牛建平, 刘东东. 铜钢复合冷却壁传热及热应力分析[J]. 中国有色金属学报, 2015, 25(2): 523-533.

[8] 李俊文, 赵海东, 吴朝忠, 李元元. 铝合金挤压铸造过程界面的传热行为[J]. 中国有色金属学报, 2014, 24(11): 2727-2734.

[12] 文玉良, 丁 静, 杨建平, 陆建峰. 聚光太阳能热发电中吸热器吸收涂层的选择[J]. 太阳能学报, 2009, 30(6): 764-768.

[13] 周圣丰, 戴晓琴, 熊 征, 张天佑. 激光感应复合快速熔覆功能梯度YSZ/NiCrAlY涂层的研究[J]. 中国激光, 2013, 40(4): 0403004-1-0403004-6.

[22] 万 宾, 乐 恺, 郑连存, 张欣欣, 于 帆. 两相复合材料有效热导率的理论推导[J]. 工程热物理学报, 2008, 29(12): 2071-2074.

[23] 杨 广, 堵永国, 白书欣, 龙 雁, 胡君遂, 张家春. 界面热阻对金刚石/银复合材料导热率的影响[J]. 国防科技大学学报, 1998, 20(6): 119-122.