文章编号:1004-0609(2011)05-0975-06

7039铝合金靶板侵彻过程中的组织特征及数值模拟

蔡一鸣1, 李慧中2, 梁霄鹏2, 汤国建1

(1. 国防科学技术大学 航天与材料工程学院, 长沙 410073;2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要: 采用光学显微镜(OM)分析子弹斜侵彻7039铝合金后弹坑周围的组织特征,并对侵彻过程进行数值模拟。结果表明:子弹侵彻7039铝合金靶材后,弹坑周围的显微组织呈现有规律的特征;当绝热软化作用较弱时,弹坑周围出现绝热剪切带和裂纹;且随着热软化的加强,绝热剪切带聚合成较宽的层叠剪切变形带,紧邻的晶粒严重变形产生扭曲带,侵彻末期组织中形成大量的变形显微带。采用Largrange描述的Johnson-Cook本构模型能够有效地模拟子弹斜冲击侵彻7039铝合金靶材的过程。

关键词:7039铝合金;侵彻;Johnson-Cook本构模型;显微组织

中图分类号: TG146.2 文献标志码:A

Microstructure character and numerical modeling of

7039 aluminum alloy target during impact penetration

CAI Yi-ming1, LI Hui-zhong2, LIANG Xiao-peng2, TANG Guo-jian1

(1. School of Aerospace and Materials Engineering,

National University of Defense Technology, Changsha 410073, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: 7039 aluminum alloy target was obliquely penetrated. The microstructure character around the crater was investigated by optical microscopy (OM). A numerical modeling during the impact penetration was established. The results show that, with the bullet penetrating into the 7039 aluminum alloy, the microstructure character around the crater is regular. When the adiabatic softening is insignificant, the adiabatic shear bands (ASB) and cracks around the crater are found. When the adiabatic softening is increased, the adiabatic shear bands coalesce into a wider overlapping shear deformation band, and the adjacent grains are deformed seriously, resulting in a lot of contorted bands. At the end of the penetration process, there are a lot of microbands. The process of bullet oblique impact penetration into the 7039 aluminum alloy can be simulated effectively using Johnson-Cook constitutive model described by Largrane.

Key words: 7039 aluminum alloy; penetration; Johnson-Cook constitutive model; microstructure

7039铝合金是一种具有优良的焊接性能、抗弹性能和加工性能的中高强Al-Zn-Mg系合金,被广泛应用于装甲结构材料[1-3]。作为装甲材料通常要承受高应变速率的加载变形,而在高应变率加载条件下,材料的动态反应非常复杂,不同的学者从各个方面展开了研究,如MURR等[4]发现6061-T6铝合金弹坑周围出现了显微带。KUMAR等[5]报道了7017铝靶板受变形弹和刚性弹垂直侵彻后微观组织及硬度的变化情况。LI和GOLDSMITH等[6]研究了中厚铝靶板(6061-T6)受侵彻后的速度和子弹偏航情况。张新明等[7]研究了2519A铝合金板材受侵彻后材料的微观组织,发现当侵彻不同深度时,弹坑微观组织呈现不同特征,靶板主要发生塑性扩孔破坏。FORRESTAL等[8-9]假定弹体侵彻贯穿靶材的过程为延性扩孔过程,应用圆柱形空腔膨胀理论研究了刚性尖头弹侵彻贯穿铝合金靶材问题,并建立了估测剩余速度和弹道极限的方程。B?RVIK等[10-11]发现采用Johnsen-Cook模型模拟合金弹道极限与残余速度的准确度更高。本文作者对子弹侵彻7039铝合金后,弹坑周围的组织特征进行研究,并对侵彻过程进行数值模拟,为该合金抗弹性能的研究提供依据。

1 实验

打靶试验用板材为T6态7039铝合金板,化学成分(质量分数,%)为0.30 Si、0.40 Fe、4.50 Zn、3.30 Mg、0.15 Cu、0.25 Mn、0.20 Zr、0.10 Ti,余量为Al。T6处理工艺为(470 ℃,1 h)固溶+(120 ℃,24 h)时效,板厚为20 mm,用7.62 mm口径弹道枪,弹体为53式WO-109C穿甲燃烧弹,在距靶板100 m处以42°倾角入射靶板测得弹速为816 m/s,发射子弹16发,击中靶板不同部位,选取其中一个弹坑沿中线剖开,在沿弹丸侵彻方向的不同位置取金相试样在XJP-6A金相显微镜下观察,观察位置为沿侵彻方向靠近弹坑的边缘,金相腐蚀剂为Kellor试剂(1.0%HF+1.5%HCl+ 2.5%HNO4+95%H2O)。数值模拟采用ANSYS/LS- DYNA软件Lagrange方法描述,材料本构模型为Johnson-Cook模型。

2 结果及分析

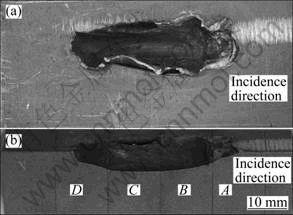

图1所示为弹丸斜侵7039-T6铝合金靶板后形成的弹坑正面和剖面的宏观形貌。在弹丸的侵彻下,靶材发生塑性流动并被压挤至四周,最终形成一个由侵彻变形产生的宏观坑(见图1(a))。穿燃弹射入靶板,靶板未形成通孔,背部未见隆起(见图1(b)),表明该厚度板材的安全角小于42°。由于7039-T6铝合金靶板的屈服强度低于弹头,易于塑性流动,使铝靶板呈延性扩孔破坏。

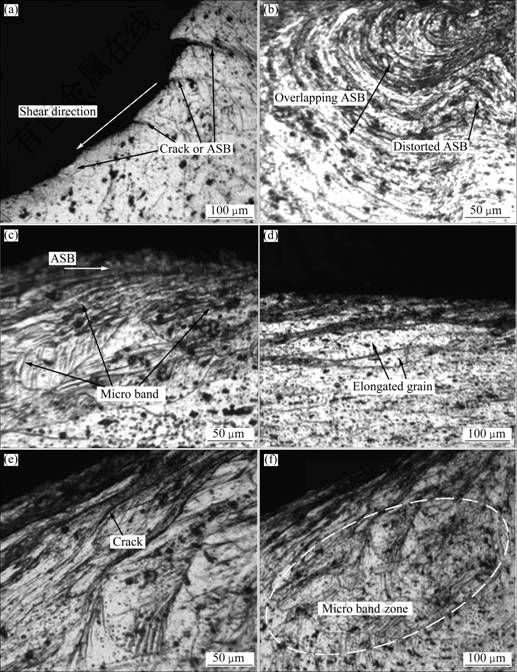

图2所示为图1(b)中所标明的弹坑周围A、B、C 和D 4个位置靠近弹坑边缘的金相组织。子弹开坑阶段,靶材受到加工硬化作用,坑壁形成绝热剪切带,并且形成与坑壁成角度的裂纹,如图2(a)所示。随着侵彻的深入,绝热失稳部位在热软化的作用下剪切变形扩张,形成层叠剪切带,如图2(b)所示。当侵彻继续深入时,较宽层叠剪切带的外层出现晶粒拉长变形现象,或出现变形微带,如图2(c)和(d)所示。继续侵彻时,绝热剪切带层叠宽度增加,裂纹增多,如图2(e)所示。在绝热剪切带和裂纹旁边,出现以晶粒扭曲较小且含有高密度显微带为特征的区域,如图2(f)所示。

图1 弹坑的宏观照片

Fig.1 Macroscopical photographs of craters of 7039 Al target: (a) Obverse; (b) Section

已有研究表明,在绝热剪切带中发生的绝热剪切、剪切失稳和剪切局域化等现象出现在许多极端变形或严重塑性变形的情形,如子弹的冲塞和冲击成坑、弹靶的侵彻贯穿,机械加工中的冲剪和冲孔、等通道角加工,各种动态加工包括搅拌摩擦焊接和电磁加工 等[12-13]。绝热剪切带内的剪切变形非常大,其应变机制包括动态再结晶(DRX)、亚微米级的再结晶晶粒滑移的“超塑性”流动[14]。在子弹开坑阶段,靶材受到的剪切应变最大,最容易导致动态再结晶,由局部强烈的动态再结晶而产生绝热剪切带,绝热剪切带高度局域化而形成裂纹,如图2(a)所示。当子弹侵入后,动能转化热能,靶材中动态回复发挥作用[6]。剪切失稳的形核和发展表现为剪切带出现频率增大和间隔空间减小,当剪切带群体出现时,则形成一定厚度的“层叠剪切带”,如图2(b)和(c)所示。由于加工硬化、应变率敏感性和温度敏感性对剪切局域化与剪切“流动”起关键作用,剪切带内绝热剪切温度的上升一般由剪切应变和剪切应变率控制[15],所以,局部热软化是剪切带形成的主要驱动力。在子弹侵彻末期,子弹的动能和转化的热能均减少,从而形成更多的变形显微带,如图2(e)和(f)所示。由以上分析可知,7039铝合金在高速冲击侵彻作用下,当热软化作用较弱时,显微组织表现为绝热剪切带和裂纹;随着热软化作用的加强,显微组织表现为层叠变形带、晶粒严重变形带和变形显微带。

图2 弹坑边缘不同部位的金相组织

Fig.2 Optic photographs from different portables of crater wall region: (a) Section A; (b) Section B; (c), (d) Section C; (e), (f) Section D

2.3 卵形杆弹对7039铝合金靶板的斜侵彻模拟

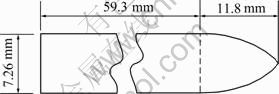

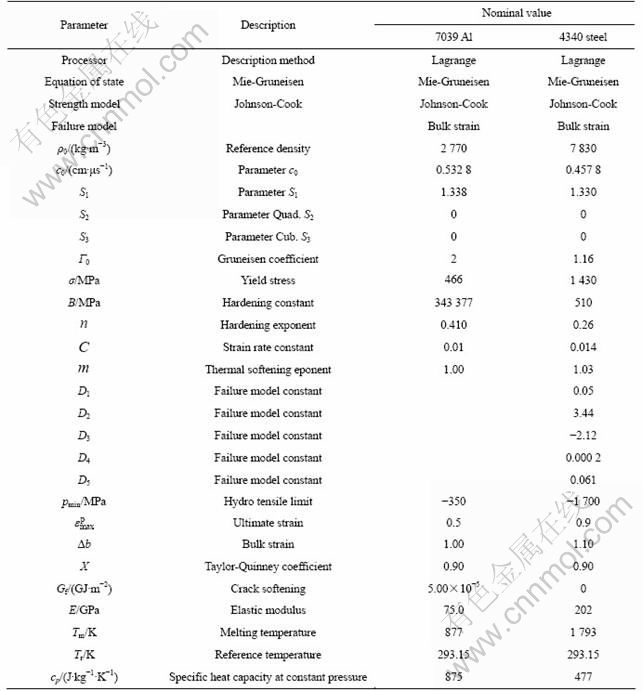

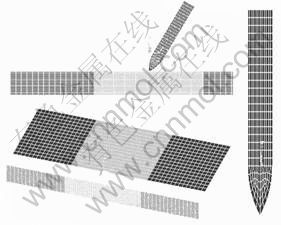

在对子弹侵彻靶材的过程进行模拟时,杆弹模型选用杆径为7.26 mm的4340钢卵形杆弹,如图3所示。子弹入射初速度v0=802 m/s,入射倾角q=45°,不考虑偏航角,靶板视为厚板,数学模型参数如表1所列。弹靶的网格划分如图4所示。

图3 卵形杆弹的尺寸示意图

Fig.3 Geometry for ogive-nose rod with 3.0 mm caliber- radius-head (CRH)

图5所示为模拟子弹侵彻靶材后弹坑的正面和剖面形貌。由图5可见,子弹侵彻靶材后,随着子弹的侵入,弹坑逐渐变深,侵彻一段后,子弹发生偏转,最后沿靶面飞出,在靶面上形成凹坑。与图1中实际打靶形成的弹坑形貌相比发现,模拟结果与实际打靶形成的弹坑形貌吻合较好,说明采用该数值模拟模型能够真实地反映子弹侵彻靶面的过程。

表1 4340钢和7039铝合金用于穿透模拟的材料参数

Table 1 Materials parameters for simulation of 4340 steel and 7039 Al alloy

图4 45°倾角斜贯穿时弹靶的网格分布

Fig.4 Mesh distribution of target under oblique impact with obliquity of 45°

图5 速度为802 m/s、倾斜角为45°斜侵彻7039-T6Al靶的模拟结果

Fig.5 Simulation results of 7039-T6 Al target at velocity of 802 m/s and obliquity of 45°: (a) Obverse; (b) Section

3 结论

1) 7039铝合金靶材受到子弹侵彻作用后,当热软化作用较弱时,弹坑周围出现绝热剪切带和裂纹;随着热软化作用加强,绝热剪切带聚合成较宽的层叠剪切变形带,相邻发生晶粒严重变形,产生扭曲带;子弹侵彻的末期组织中形成大量的显微变形带。

2) 采用Largrange描述和Johnson-Cook本构模型能够有效地模拟7039铝合金靶材受到子弹侵彻的 过程。

REFERENCES

[1] LEECH P W. Observations of adiabatic shear band formation in 7039 aluminum alloy[J]. Metallurgical and Materials Transactions A, 1985, 16(10): 1900-1903.

[2] 黄兰萍, 陈康华, 李 松, 刘红卫. 高温预析出对Al-Zn-Mg铝合金组织, 力学性能和应力腐蚀性能的影响[J]. 中国有色金属学报, 2005, 15(5): 727-733.

HUANG Lan-ping, CHEN Kang-hua, LI Song, LIU Hong-wei. Effect of high-temperature pre-precipitation on micro-structure, mechanical property and stress corrosion cracking of Al-Zn-Mg aluminum alloy[J]. The Chinese Journal of Nonferrous metals, 2005, 15(5): 727-733.

[3] 黄继武, 尹志民, 聂 波, 陈继强, 何振波. 7A52铝合金原位加热过程中的物相转变与热膨胀系数测量[J]. 兵器材料科学与工程, 2007, 30(4): 9-12.

HUANG Ji-wu, YIN Zhi-min, NIE Bo, CHEN Ji-qiang, HE Zhen-bo. Investigation of phases and thermal expansivity of 7A52 alloy in in-site heating[J]. Ordnance Material Science and Engineering, 2007, 30(4): 9-12.

[4] MURR L E, ALICIA A, NIOU C S. Microbands and shear-related microstructural phenomena associated with impact craters in 6061-T6 aluminum[J]. Materials Science and Engineering A, 1996, 216(1/2): 69-79.

[5] KUMAR K S, SINGH D, BHAT T B. Studies on aluminum armour plates impacted by deformable and non-deformable projectiles[J]. Materials Science Fourm, 2004, 465/466: 79-84.

[6] LI K, GOLDSMITH W. Impact on aluminum plates by tumbling projectiles experimental study[J]. International Journal of Impact Engineering, 1996, 18(1): 23-43.

[7] 张新明, 高 慧, 李慧中, 刘 瑛, 冀东晟. 一种高铜铝合金板侵彻后的显微组织分析[J]. 兵器材料科学与工程, 2007, 30(3): 14-17.

ZHANG Xin-ming, GAO Hui, LI Hui-zhong, LIU Ying, JI Dong-sheng. Microstructure analysis of the penetrated aluminum plate with high copper content[J]. Ordnance Material Science and Engineering, 2007, 30(3): 14-17.

[8] FORRESTAL M J, PIEKUTOWSKI A J. Penetration experiments with 6061-T6511 aluminum targets and spherical- nose steel at striking velocities between 0.5 and 3.0 km/s[J]. International Journal of Impact Engineering, 2000, 24(1): 57-67.

[9] FORRESTAL M J, WARREN T L. Perforation equations for conical and ogival nose rigid projectiles into aluminum target plates[J]. International Journal of Impact Engineering, 2009, 36(2): 220-225.

[10] B?RVIK T, CLAUSEN A H, HOPPERSTAD O S, LANGSETH M. Perforation of AA5083-H116 aluminum plates with conical-nose steel projectiles-experimental study[J]. International Journal of Impact Engineering, 2004, 30(4): 367-384.

[11] B?RVIK T, FORRESTAL M J, HOPPERSTAD O S, WARREN T L, LANGSETH M. Perforation of AA5083-H116 aluminum plates with conical-nose steel projectiles: Calculation [J]. International Journal of Impact Engineering, 2009, 36(3): 426-437.

[12] 时 捷, 董 瀚, 王 琪, 田 亮. 装甲钢板中绝热剪切带的特征[J]. 金属学报, 2000, 36(10): 1045-1049.

SHI Jie, DONG Han, WANG Qi, TIAN Liang. Characteristics of the adiabatic shear band in the armor sheet plate[J]. Acta Metallurgica Sinica, 2000, 36(10): 1045-1049.

[13] SEMIATIN S L, LAHOTI G D, OH S I. Material behavior under high stress and ultrahigh loading rates[C]//Proceedings of Sagamore Army Materials Research Conference. New York: Plenum Press, 1983: 119-160.

[14] 王礼立. 爆炸与冲击载荷下结构和材料动态响应研究的新进展[J]. 爆炸与冲击, 2001, 21(2): 81-83.

WANG Li-li. Progress in studies on dynamic response of structures and materials under explosive loading[J]. Explosion and Shock Waves, 2001, 21(2): 81-83.

[15] MURR L E, ESQUIVEL E V. Observations of common microstructural issues associated with dynamic deformation phenomena: Twins, microbands, grain size effects, shear bands, and dynamic recrystallization[J]. Journal of Materials Science, 2004, 39: 1153-1168.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(50671121); 湖南省科技计划项目(2009GK3038)

收稿日期:2010-04-11;修订日期:2011-03-07

通信作者:李慧中,教授,博士; 电话: 0731-88830377; E-mail: lhz606@mail.csu.edu.cn