J. Cent. South Univ. (2017) 24: 2134-2144

DOI: https://doi.org/10.1007/s11771-017-3622-6

Determination of microscopic waterflooding characteristics and influence factors in ultra-low permeability sandstone reservoir

REN Da-zhong(任大忠)1, 2, SUN Wei(孙卫)1, HUANG Hai(黄海)2, NAN Jun-xiang(南珺祥)3, CHEN Bin(陈斌)1

1. State Key Laboratory of Continental Dynamics, Northwest University, Xi’an 710069, China;

2. Department of Petroleum Engineering, Xi’an Shiyou University, Xi’an 710065, China;

3. National Engineering Laboratory of Low Permeability Oilfield Exploration and Development, Xi’an 710018, China

Central South University Press and Springer-Verlag GmbH Germany 2017

Central South University Press and Springer-Verlag GmbH Germany 2017

Abstract:

Actual sandstone micromodel was used in this work to conduct the microscopic waterflooding experiment of ultra-low sandstone reservoir, since the inside seepage characteristics of microscopic waterflooding process of Chang 8 ultra-low permeability sandstone reservoir of Upper Triassic Yanchang formation in Huaqing region of the Ordos Basin, China is difficult to observe directly. Combined with physical property, casting thin sections, constant-rate mercury injection capillary pressure and nuclear magnetic resonance, the influence of reservoir property on the waterflooding characteristics in pores were analyzed and evaluated. Seepage paths of waterflooding characteristics were divided into four types: homogeneous seepage, reticular-homogeneous seepage, finger-reticular seepage and finger-like seepage, the waterflooding efficiency of which decreases in turn. More than 70% of residual oil occurs as flowing-around seepage and oil film. Physical property, pore structure and movable fluid characteristics are all controlled by digenesis and their impacts on waterflooding efficiency are in accordance. Generally, the pore throat radius size and distribution and movable fluid percentage are closely related to waterflooding law.

Key words:

1 Introduction

Microscopic waterflooding characteristic is important in the process of oilfield development, as the complex microscopic geological factors can determine the quality of reservoirs and therefore will influence the displacement efficiency [1-5]. Ultra-low permeability sandstone reservoirs show characteristics of poor physical properties, strong pore structures heterogeneity, low saturation of movable fluid and a high degree of digenesis. As a result, the seepage characteristic of ultra-low permeability sandstone reservoirs is quite different from that of normal reservoirs [5-8].

Three types of common methods are usually used in the study of ultra-low permeability sandstone reservoirs microscopic waterflooding:

1) Conventional core(CC) displacement experiment. This method shows waterflooding characteristics by analyzing oil displacement efficiency which changes under different injection parameters. However, the range of corresponding movable throat radius cannot be acquired using this method [5, 7, 9, 10]; 2) X-ray computer tomography (CT) displacement experiment [6, 11]. Waterflooding characteristics has been studied using this method based on the image of oil-water distribution in the full core derived from CT scan image of different water displacing oil effects. The disadvantage is that this method is similar to that of the previous method; 3) Nuclear magnetic resonance (NMR) waterflooding technology. The advantages of this method are that it can quantify the changes on oil displacement efficiency, and provide the range of movable throat radiuses through T2 spectrum distribution [12, 13]. However, the movement of oil and water and the distribution of the residual oil are difficult to observe.

Based on the advantages and disadvantages of the methods used currently, a new method using actual sandstone micromodels (ASM) in waterflooding seepage experiment thus has been developed to solve the problems mentioned above [8, 14-16]. The occurrence of the oil in pores under the original saturated condition, the movement of oil and water in the process of the displacement and the occurrence state of residual oil in pores can be observed initially under the microscope scale. Besides, the sweep area of water and the oil displacement efficiency can be quantitatively measured by volume calculation and image analysis.Currently, the analysis of the influence factors of water displacement efficiency still mainly focuses on the physical properties, high-pressure mercury injection (HPMI) and the casting thin sections (CTS) test data [8, 16-18], which has led to a similar result for conventional reservoirs. Further researches are needed to deepen the understanding of the throat characteristics, movable fluid parameters and the influence of experimental conditions on the water displacement efficiency.

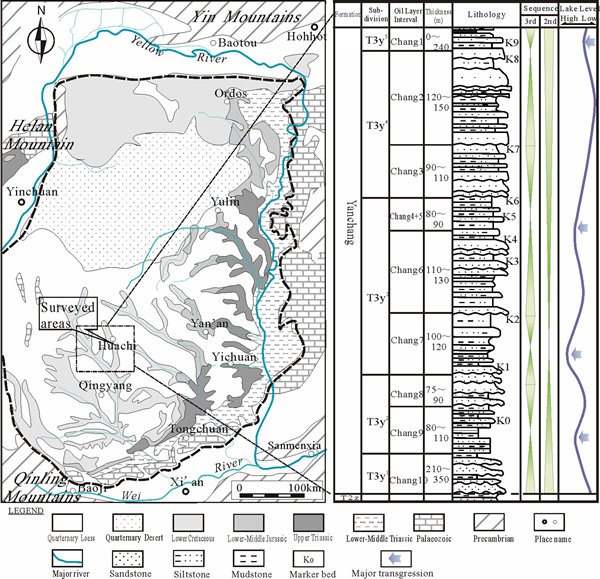

In this work, core samples from Chang 8 reservoir of Upper Triassic Yanchang Formation in Huaqing region of the Ordos basin, China are used in the waterflooding seepage experiment. The actual sandstone micromodels and its test data are used (Fig. 1), together with physical properties, CRMI, NMR and CTS analysis, the microscopic waterflooding characteristics and the influence factors in ultra-low permeability sandstone reservoirs have been studied comprehensively. Therefore the experiment results can be used to evaluate the potential development of reservoirs in actual practice.

2 Samples and actual sandstone micromodels

Fourteen groups of core plug samples were collected from Chang 8 sandstone reservoirs of Upper Triassic Yanchang formation in Huaqing region of the Ordos Basin, China. Experiment cylindrical core plugs (40 mm or 50 mm in length and 25 mm in diameter) were drilled parallel to bedding from each cired interval. The residual crude oil of every core plug was removed and the cores were vacuumed at 110 °C for 10 h in order to remove the residual water and immobile water before tests. For effective protection of the original petrophysical properties and pore structure of cores, porosity and permeability tests were conducted first, followed by casting thin sections (CTS) where core plugs were cut into four parts. The experiments of actual sandstone micromodel (RSM), constant-rate mercury injection capillary pressure (CRMICP) and nuclear magnetic resonance (NMR) were done at last.

2.1 Samples

The Ordor Basin is the second largest sedimentary basin, which lies in the Yellow River basin, China, as shown in Fig. 1. The Upper Triassic Yanchang formation is an important oil-bearing reservoir in Huaqing region (Ordos Basin), which can be subdivided into five segments, and they are T3y1 to T3y5 from the bottom to the top which is about 1000 m thick. It can be subdivided into 10 oil-layer-intervals, and they are Chang1 to Chang 10 from the top to the bottom. The Chang 8 is the expansion period of the lake, where the delta front underwater distributary channel sand bodies develop. The Chang 8 crude oil from Chang 7 has been formed into a hydrocarbon bearing place [9, 19] (Fig. 1(b)). The reservoir rocks are mainly grey medium to fine grained arkose and feldspathic litharenite. The average oil saturation of massive sandstone (>2.0m) is 45.7%; the average porosity and permeability are 11.02% and 1.26 mD respectively; the average actual porosity is 3.22%; the main pore types of the reservoir are intergranular pores (46.27%) and feldspar solution pores (42.96%); the average throat radius is 0.53 μm; the average throat sorting coefficient is 0.17.

2.2 Actual sandstone micromodels

In order to effectively preserve the original physical properties and pore structure of the cores, the microscopic models are made from the following steps: slicing the cores—cleaning oil—drying—polishing— cementing, etc. The experimental conditions are controlled as follows: the size of the cores is 2.5 cm×2.5 cm×0.7 cm; the pressure-bearing capacity is 0.2- 0.35 MPa; the temperature tolerance is around 70 °C; the viscosity of the experimental oil is 1.45 mPa·s; and it turns into red after contacting oil-soluble red dye. The compound “formation-water” can be dyed into blue with methylene blue.

3 Instruments and procedures

3.1 Instruments

Water flooding experiment of the core samples was accomplished using the real sandstone micro-model water flooding experimental facility which was developed by SUN [6], as shown in Figs. 2 and 3. The introduction of the facility can be seen in Refs. [8, 14, 15]. The physical property, casting thin sections and the image are acquired with the porosity-permeability equipment of State Key Laboratory of Continental Dynamics of Northwest University, China and the core debris image collection and analysis system (research facilities by the laboratory). The pore and throat parameters of core samples are obtained on the basis of constant-rate mercury injection capillary pressure (CRMICP) test with the experimental setup (ASPE-730, Coretest Systems, USA) in Langfang Research Institute of Petroleum Exploration and Development, China. The NMR apparatus is supplied by Niumag Corporation (Shanghai, China). The introduction of the CRMICP and NMR can be seen in Ref. [7].

Fig. 1 Location and sedimentary facies of surveyed area

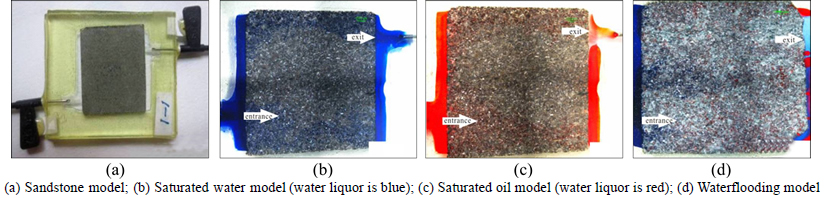

Fig. 2 Flow chart of experiment

3.2 Experimental procedure

The main procedure of the experiment is to stimulate the mechanism of seepage and the original water saturation of reservoir. The aim of this experiment is to discover the impact of water injection on the oil recovery and residual oil. The key steps of the experiment are demonstrated as: 1) cores samples are put into the drying oven at 50 °C for 10 h in order to remove the movable water and capillary water in the samples; 2) The property of the sample is analyzed using gas logging and the pore volume of the model is calculated; 3) The model is vacuumized, the formation saturated water is self-absorbed and the permeability of the model is measured. And then calculate the original water saturation and observe the characteristic of the saturated water (Figs. 2 and 3); 4) The water flooding experiment is carried out until the residual oil state is stable and the oil driving water pressure is recorded. The initial oil saturation is calculated and the oil flooding water seepage characteristics are observed (Figs. 2 and 3(c)); 5) The water flooding experiment is conducted using one time pore volume till the residual oil state is stable, and the breakout pressure of the water flooding is determined. The water flooding seepage characteristics, residual oil saturation and types during the each stage of the water flooding are counted. In the end, water oil displacement efficiency and residual oil saturation in no water stage are calculated (Figs. 2 and 3(d)); 6) The integrated interpretation analysis of water flooding experiment is made according to the measurement data and the observed experimental phenomena.

Fig. 3 Photos of water-displacement core experiment with sandstone micromodels:

4 Experiment results

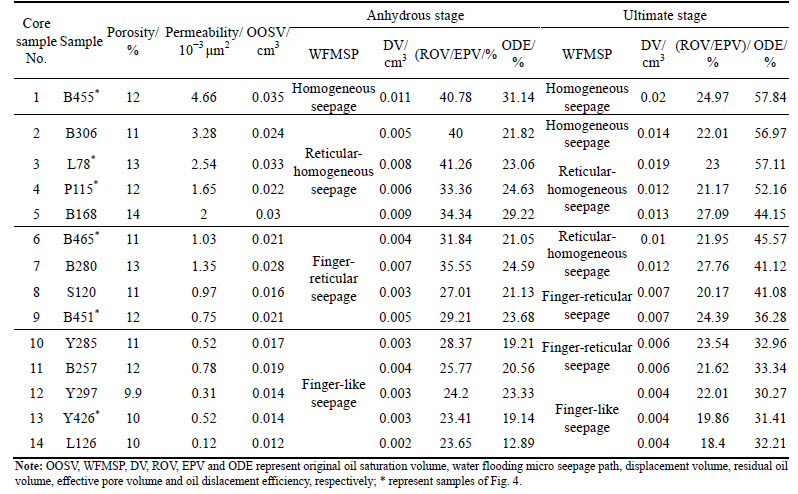

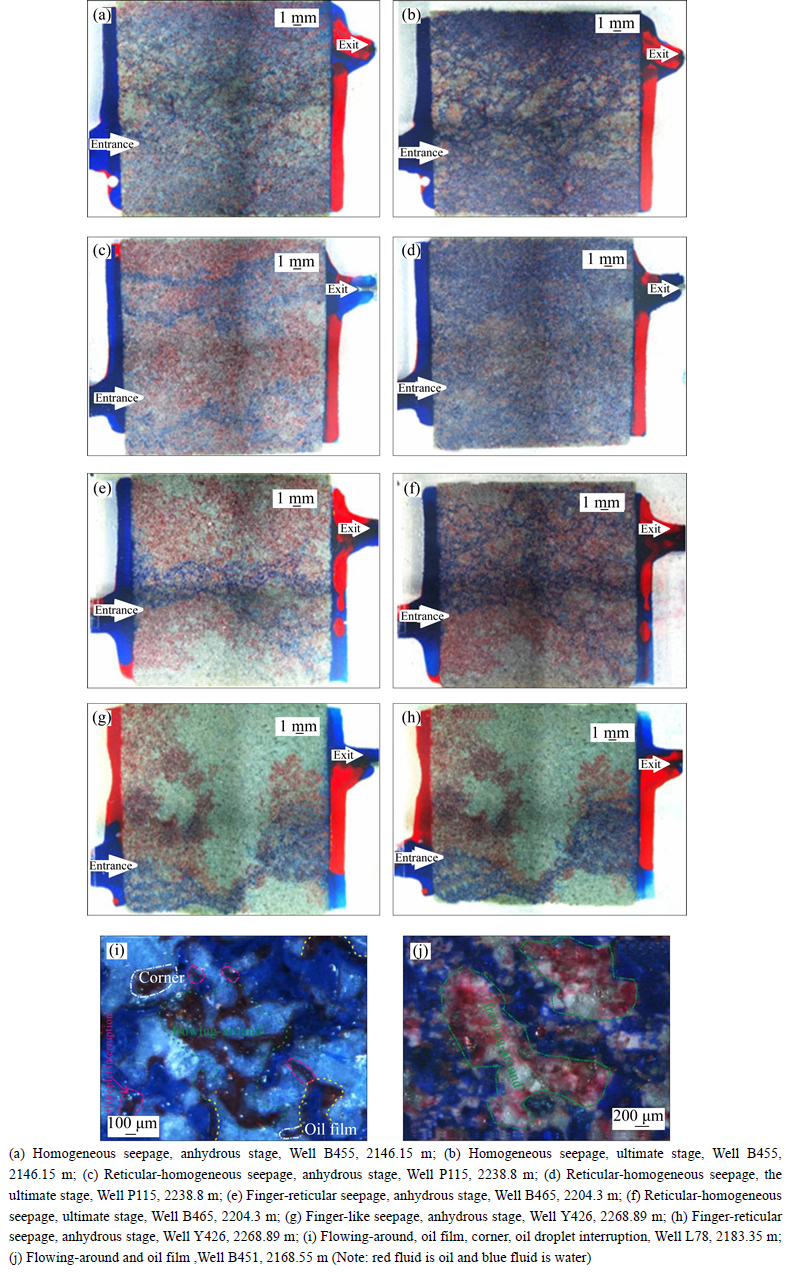

Fourteen core samples used in the experiment are from wells with different reservoir properties and pore structures. Results of the experiment have been demonstrated in Table 1 and Fig. 4. Due to the physical properties of tight sandstone and the medium to poor pore throat heterogeneity of the samples, the main types of seepage paths are combined-types. Based on the whole horizon observed under microscope and image acquisition system (Fig. 3), which is the observation of the water flooding characteristic under centimeter-scale, the seepage path of the model can be divided into four types: homogeneous seepage (Model I), reticular- homogeneous seepage (Model II), finger-reticular seepage (Model III) and finger-like seepage (Model IV).

4.1 Homogeneous seepage

As shown in Figs. 4 (a) and (b) and Table 1, after the water is injected into the oil saturation model, several displacement paths sweep evenly and the front of the flooding water moves parallelly. As the displacement time passes by and the pressure increases, a part of the area (Model I) will form reticular seepage flows with a few being finger-like; in the mid-high water-cut stage, the seepage paths grow in both number and width, and the whole area presents homogeneous and homogeneous- reticular seepage flows. The results suggest that the effective porosity of this model has well developed and the connectivity is fair. It is known that the original oil saturation volume is 0.035 cm3; the oil displacement efficiency in the water-free stage is 31.14% with a displacement volume of 0.011 cm3; the oil displacement efficiency in the final stage is 57.84% with a displacement volume of 0.020 cm3.

4.2 Reticular-homogeneous seepage

As shown in Figs. 4 (c) and (d) and Table 1, when the pressure keeps increasing, the part of the model area (Model II) will form homogeneous seepage flows with a few showing finger-like; in mid-high water-cut stage, the seepage paths will grow in number and width, and the model presents reticular-homogeneous seepage and homogeneous seepage flows appear locally. The finger- like seepage area is relatively small. The results show that the effective porosity in Model II has been well developed and pore throat connectivity is good. The original oil saturation volume is 0.027 cm3; the average oil displacement efficiency in the water-free stage is 24.68% and the corresponding average displacement volume is 0.007 cm3; the average oil displacement efficiency of the ultimate stage is 52.6% with a corresponding average displacement volume of 0.014 cm3.

4.3 Finger-reticular seepage

As shown in Figs. 4(e), (f), and Table 1, after water is injected into the saturated oil model, the main displacement path presents the finger–reticular sweeps and the front of the flooding water shows finger–reticular shape and finger-like shape appears in a few parts. As the time passes by and pressure increases, part of the area (Model III) will form reticular seepage flows with a few becoming homogeneous flow; in mid-high water-cut stage, the number and size of seepage paths increase, and the model presents finger–reticular seepage flows with reticular-homo the generous seepage flows appear locally. The finger-like seepage flows area of circle flows increases apparently. The results suggest that Model III has a relatively poor development of effective porosity and pore connectivity. The original oil saturation volume is 0.022 cm3; the average oil displacement efficiency in the water-free stage is 22.61% with a corresponding average displacement volume of 0.005 cm3; the average oil displacement efficiency in the ultimate stage is 41.01% with a corresponding average displacement volume of 0.009 cm3.

Table 1 Testing results of waterflooding seepage experiments with real sandstone micromodels

4.4 Finger-like seepage

As shown in Figs. 4(g) and (h) and Table 1, after water is injected into the saturated oil model, the single displacement path presents finger-like sweeps shape and the front of the fluid moves ahead as a finger shape. As the time passes by and pressure increases, parts of the area (Model IV) form finger-reticular seepage flows; in the mid-high water-cut stage, the number and size of seepage paths increase; the model presents finger-like seepage flows with finger-reticular seepage flows appears locally. Then it develops into a large rounded flowing area. The results demonstrate that the effective porosity in Model IV and its pore connectivity are poor. The original oil saturation volume is 0.015 cm3; the average oil displacement efficiency in the water-free stage is 19.03% with a corresponding average displacement volume of 0.003 cm3; the average oil displacement efficiency in the ultimate stage is 26.04% with a corresponding average displacement volume of 0.005 cm3.

In summary, under the specific displacement pressure, seepage paths are controlled by the effective pore throat. The average oil displacement efficiency of homogeneous seepage, reticular-homogeneous seepage, finger-reticular seepage and finger-like seepage decreases systematically.

4.5 Characteristics of residual oil

It is known that the residual oil characteristics are mainly controlled by reservoir physical properties, pore structure, interstitial material, wettability, the seepage path, displacement pressure and the properties of oil and water [8, 14-16, 19].

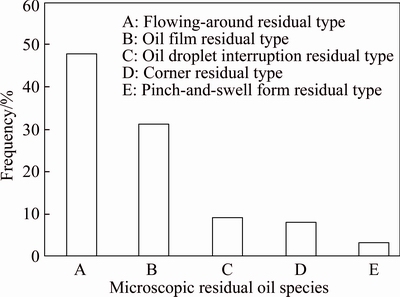

According to the observation from microscope, there are mainly five main types of the residual oil forms, which are flowing-around, oil film, oil in the corner (sealed pore), oil droplet interruption, and pinch-and- swell form. Flowing-around and oil film account for over 70% of the total residual oil; the main residual oil types are that homogeneous seepage and reticular- homogeneous seepage correspond to flowing-around (16.7%-41.2%), oil film (10.7%-31.6%), a small portion of corner oil (3.6%-11.4%) and oil droplet interruption (3.9%-11.8%), while finger-reticular and finger-like seepages present flowing-around (21.4%-51.2%) and oil film dominantly (8.7%-27.8%) (Figs. 4 and 5).

Table 1 shows that the residual oil volume to effective pore volume ratios in the water-free stage of homogeneous displacement, reticular-homogeneous displacement, finger-reticular displacement, and finger- like displacement are 40.78%, 7.27%, 0.90% and 25.08%, respectively. The corresponding residual oil volume to effective pore volume ratios of the ultimate stage of the four types are 24.97%, 23.32%, 23.57% and 21.09%, respectively.

Fig. 4 Microscopic characteristics of oil displacement in waterflooding seepage experiments with real sandstone micromodels:

Fig. 5 Distribution frequency of different microscopic residual oil types

At the water-free stage, the ratio of residual oil volume to effective pore volume decreases from the homogeneous displacement to reticular displacement to finger-like displacement. At the ultimate stage, the ratios of residual oil volume to the effective pore volume of the four different displacement types are close to each other. All these show that residual oil is mainly distributed in the space with effective pore development and good pore connectivity.

5 Discussion

This part mainly analyzes the factors influencing water displacement efficiency. There are 5 aspects: 1) reservoir physical property, 2) diagenetic evolution parameters, 3) pore structure, 4) movable fluid percentage and 5) seepage path.

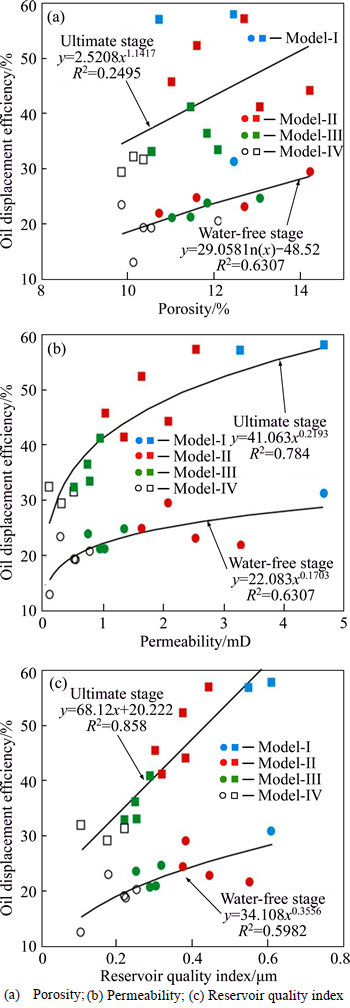

5.1 Physical properties

As shown in Fig. 6, the correlation between the sample’s oil displacement efficiency and its physical property are positive. Data in Table 1 supports that among all these parameters, heterogeneity is more dominant than porosity, but less dominant than permeability.

Figure 6(a) illustrates that the correlation coefficient between porosity and oil displacement efficiency is higher in the water-free stage than that in the ultimate stage, while Fig. 6(b) shows that the correlation between the water displacing oil efficiency and permeability is better in the ultimate stage than that in the water-free stage. All these shows that reservoirs with a relatively higher connected porosity in water-free stage tend to form waterflood channeling paths which shows a characteristic of high porosity and small sweeping area. Companied with the forming of water driving oil channels, the permeability of the effective throat network is enhanced so that the seepage paths get to grow in both number and width and the sweeping area also increases. In return, oil displacement efficiency increases with the enhancement of permeability, but when permeability is greater than 1.5 mD, the trend of this kind slows down. Relatively speaking, among samples having close porosity while big differences in permeability, those with higher permeability and with relatively uniform seepage paths tend to have higher oil displacement efficiency under the same experimental conditions.

Fig. 6 Scattered plots of oil displacement efficiency vs petrophysical parameters for core samples:

Reservoir quality index is a function of porosity and permeability, and its correlation coefficient with oil displacement efficiency is higher than that of pore permeability, as seen in Fig. 6(c). It demonstrates that a single physical parameter cannot truly reflect seepage properties [16-18], and explains that oil displacement efficiency is not completely controlled by a single reservoir parameter. Instead, it is independent at an extent.

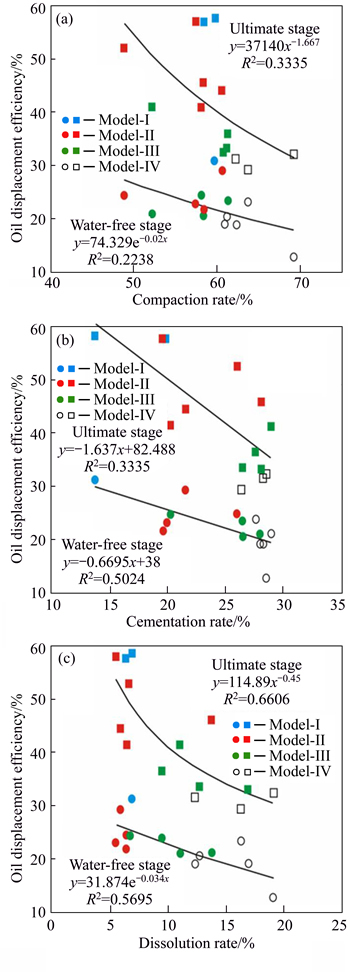

5.2 Diagenetic evolution parameters

As for different diagenetic evolution characteristics of reservoirs, their physical property, pore structure and seepage characteristics can be classified by obvious time intervals [6-11, 18]. Based on the above analysis, the diagenetic evolution characteristics parameters of the experimental samples, such as the rates of compaction, cementation, and dissolution all have negative correlation with oil displacement efficiency, and the correlation coefficients increase in turn. The correlations of the three parameters are all better in the ultimate stage than the water-free stage (Fig. 7).

The correlation between the compaction rate of oil displacement efficiency is weak, especially when the compaction rate is at about 60%, the correlation between the two is weaker (Fig. 7(a)). The influence of the cementation rate on oil displacement efficiency is stronger than that on compaction rate (Fig. 7(b)). When cementation rate is less than 25%, the oil displacement efficiency decreases significantly with the increase of cementation rate (Fig. 7(b)). The effects of the dissolution rate on oil displacement efficiency are stronger than that of the former two parameters(Fig. 7(c)). When the dissolution rate is less than 8%, there is almost no correlation between the dissolution rate and oil displacement efficiency (Fig. 7(c)). Due to the fact that dissolution holes enhance the heterogeneity of pore structure, fluid in corrosion holes with small capillary resistance rapidly advances so that the Jamin effect of water drive oil is strengthened, and residual oil is returned in the channel, which causes the reduction of oil displacement efficiency. This shows that the heterogeneity of pore structure has closer relationship with oil displacement efficiency.

Fig. 7 Scattered plots of oil displacement efficiency vs diagenetic evolution parameters for core samples

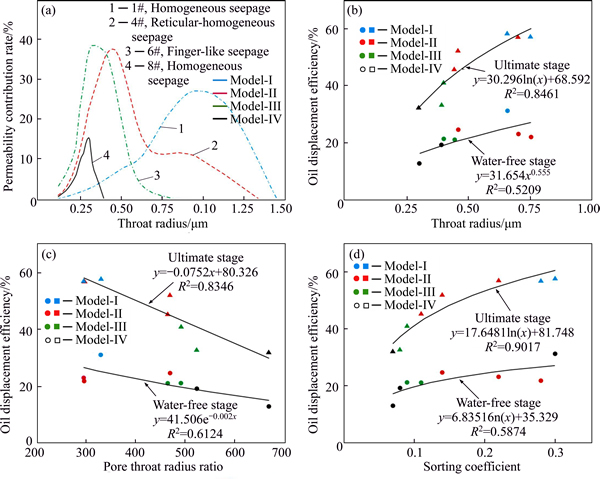

5.3 Pore structure

5.3.1 Throat radius

Homogeneous displacement (1#), reticular- homogeneous displacement (4#), finger-reticular displacement (6#), finger-like displacement (8#) are selected as representative samples. The corresponding average throat radiuses are 0.657 μm, 0.456 μm,0.402 μm and 0.302 μm, as shown in Table1. The throat radiuses corresponding to the scope and peak of the curve function of permeability contribution rate get smaller in turn, as shown in Fig. 8(a). Average throat radius is positively correlated with the oil displacement efficiency at both the water-free and ultimate stages. The corresponding coefficient R2 is 0.5209 and 0.8461, which can be seen in Fig. 8(b). When throat radius is less than 0.5 μm, a terraced increase is shown in the scatter plots of throat radius versus oil displacement efficiency. When throat radius is greater than 0.5 μm, the fitting curve becomes gentler (Fig. 8(b)).

All the above shows that the water displacement efficiency is influenced by both the throat size and the shape of the throat permeability contribution rate curve. Under the same experimental conditions, when the average throat radius is close or equal to each other, the oil displacement efficiency will be higher with more homogenous seepage paths and larger sweeping area if the throat radius is wide with even distribution.

5.3.2 Pore throat radius ratio

It can be seen from Fig. 8(c) that the negative correlation between pore throat radius ratio and oil displacement efficiency is medium good (R2=0.6124) at the water-free stage and is better at the ultimate stage (R2=0.8346). This suggests that the throat radius ratio is higher, the core is more compact. Especially when the throat radius is less than 0.5 μm, the pore connectivity becomes poorer and displacement resistance increases as the effect of capillary force would be enhanced. Under the same experimental conditions, the relatively high permeability zone will form flowing-around residual oil with small sweeping area and low oil displacement efficiency. Hence, it is concluded that pore throat radius ratio is one of the most important parameters charactering reservoir compact degree, heterogeneity and seepage mechanism.

5.3.3 Sorting coefficient

Along with the increase of sorting coefficient, throat distribution range gets wider and the oil displacement efficiency increases significantly. The correlation coefficient R2 between sorting coefficient and oil displacement efficiency in the water-free stage and the ultimate stage are 0.5874 and 0.9017 respectively as shown in Fig. 8(d). In Fig. 8, the response relationship between the sorting coefficient and water flooding efficiency of the ultimate stage is the strongest among all the coefficients. When sorting coefficient is less than 0.15, a terraced increase is shown in the scatter plots of sorting coefficient and oil displacement efficiency. In Fig. 8(d), when sorting coefficient is greater than 0.15, the fitting curve becomes gentler.

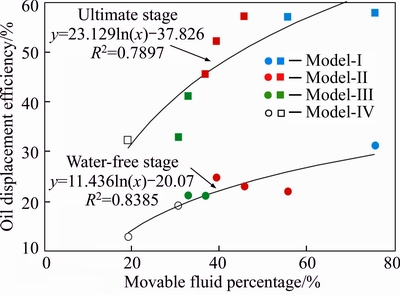

5.4 Movable fluid percentage

Studies on movable fluid percentage have been widely applied in reservoir percolation mechanism and productivity estimation [12, 13]. As shown in Fig. 9, there are positive correlations between movable fluid percentage and oil displacement efficiency in the water- free stage and the ultimate stage. The corresponding correlation coefficient R2 is 0.8385 and 0.7897, respectively. When the movable fluid percentage is less than 40%, oil displacement efficiency increases in a terraced way with the increase of movable fluid percentage. When the movable fluid percentage is larger than 40%, the fitting curve becomes gentler. All these show that the movable fluid percentage has stronger influence on productivity than any other parameters, such as porosity, permeability and digenesis parameters. Its influence is close to that of throat radius and reservoir quality index on productivity, but it can directly characterize the relationship between the fluid characteristics and the oil displacement efficiency.

Fig. 8 Scattered plots of effective pore throat parameters vs oil displacement efficiency for core samples

Fig. 9 Scattered plots of movable fluid percentage vs oil displacement efficiency for core samples

5.5 Seepage path

Table1 and Fig. 4 together can make a comparative study that oil displacement efficiencies of the four types of seepage paths are different from each other. For homogeneous displacement, reticular-homogeneous displacement, finger-reticular displacement and finger- like displacement, their corresponding average oil displacement efficiency at the water-free stage are 31.14%, 24.68%, 22.61% and 19.03% respectively, while at the ultimate stage the numbers are 57.84%, 52.60%, 41.01% and 32.04%, respectively. This may help to conclude that by using fracturing, profile modification, acidification and other technical skills to improve the heterogeneity of reservoir, water flooding seepage paths and oil displacement efficiency.

6 Conclusions

1) The ultimate oil displacement efficiency of Chang 8 ultra-low permeability sandstone reservoir in Huaqing oilfield is low; the microscopic seepage paths of Chang 8 reservoir are homogeneous displacement, reticular-homogeneous displacement and finger-like displacement. The corresponding oil displacement efficiency reduces in turn under the same experimental conditions. Over 70% of residual oil is the flowing- around form and oil film, and the residual oil is mainly distributed in high quality reservoir with effective pore development and good pore connectivity.

2) Research results show that the size and distribution of throat radius are also found closely related to the waterflooding seepage characteristics. Physical property, pore structure and movable fluid percentage are controlled by digenesis, which are found illustrating consistent impact on the waterflooding mechanism. Generally, when the permeability is greater than 1.5 mD, the throat radius is greater than 0.5 μm, the sorting coefficient is greater than 0.15, the saturation of movable fluid is greater than 40%, and the increasing trend of oil displacement efficiency will be obviously weakened.

3) The size and distribution of throat radius and movable fluid percentage are closely related to the microscopic waterflooding mechanism. Therefore, in the development process, high permeability zones of the ultra-low permeability sandstone reservoirs should be optimized. Besides, the high-permeability zone and the heterogeneity of pore structure should be paid special attention to.

References

[1] NELSON R A. Geologic analysis of naturally fractured reservoirs [M]. Second Ed. Houston: Gulf Publishing, 2001.

[2] SHALABI E W A, SEPEHRNOORI K, POPE G. New mobility ratio definition for estimating volumetric sweep efficiency of low salinity water injection [J]. Fuel, 2015, 158: 664-671.

[3] AGBALAKA C C, DANDEKAR A Y, PATIL S L. Coreflooding studies to evaluate the impact of salinity and wettability on oil recovery efficiency [J]. Transport in Porous Media, 2009, 76(1): 77–94.

[4] TAN Chao, WANG Na-na, DONG Feng. Oil–water two-phase flow pattern analysis with ERT based measurement and multivariate maximum Lyapunov exponent [J]. Journal of Central South University, 2016, 23(1): 240-248.

[5] LI Dao-pin. Low permeable sandstone oilfield development [M]. Beijing: Petroleum industry press, 1997. (in Chinese )

[6] SUN Wei, SHI Cheng-en, ZHAO Jing-zhe, ZHAO Lei. Application of X-CT scanned image technique in the research of micro-pore texture and percolation mechanism in ultra-permeable oilfield: Taking an example from Chang 82 formation in the Xifeng oil field [J]. Acta Geology Sinica, 2006, 80(5): 775-779. (in Chinese)

[7] GAO H. Research on micro-pore structure and micro-flow mechanism of Ultra low permeability sandstone reservoir [D]. Xi’an: Northwest University, 2009. (in Chinese)

[8] QUAN Hong-hui, ZHU Yu-shuang, ZHANG Hong-jun, LI Li, SHAO Fei, ZHANG Zhang. Reservoir pore structure and micro-flow characteristics of waterflooding: A case study from Chang-6 reservoir of Wangyao block in Ansai oilfield [J]. Oil Gas Geology, 2011, 32(54): 952-959. (in Chinese)

[9] REN Da-zhong, SUN Wei, WEI Hu, ZHOU Shu-xun, ZHANG Yi-guo, ZHANG Xi. Types of sandstone reservoir diagenetic facies and microscopic pore structure characteristics of chang-81 reservoir in Huaqing oilfield [J]. Geoscience, 2014, 28(2): 379-387. (in Chinese)

[10] NGUYEN V H, SHEPPARD A P, KNACKSTEDT M A,PINCZEWSKI W V. The effect of displacement rate on imbibition relative permeability and residual saturation [J]. Journal of Petroleum Science and Engineering, 2006, 52: 54-70.

[11] SCHEMBRE J M, KOVSCEK A R. A technique for measuring two-phase relative permeability in porous media via X-ray CT measurements [J]. Journal of Petroleum Science and Engineering, 2003, 39: 159-174.

[12] AL-M AHROOQI S H, GRATTONI C A, MUGGERIDGE A H. Pore-scale modelling of NMR relaxation for the characterization of wettability [J]. Journal of Petroleum Science and Engineering, 2006, 52: 172-186.

[13] ZHAO Y, SONG Y, LIU Y, JIANG L, ZHU N. Visualization of CO2 and oil immiscible and miscible flow processes in porous media using NMR micro-imaging [J]. Petroleum Science, 2011, 8(2): 183-193.

[14] SUN W, TANG G Q. Visual study of water injection in low permeable sandstone [J]. Journal of Canadian Petroleum Technology, 2006, 11(45): 21-26.

[15] SUN W, QU Z, TANG G. Characterization of water injection in low permeability rock using sandstone micromobles [J]. Journal of Petroleum Technology, 2004, 56(5): 71-72.

[16] LI Zhen-quan, HOU Jian, CAO Xu-long, CHAO Yue-ming, SONG Xin-wang, WANG Ke-wen. Microscopic simulation for influence of microscopic reservoir parameters on remaining oil distribution [J]. Acta Petrolei Sinica, 2005, 26(6): 69-73. (in Chinese)

[17] WANG Rui-fei, SUN Wei. Main controls for water displacing oil efficiency by the micromodel water flooding experiment in ultra-low permeability sandstone reservoir [J]. Petroleum Geology & Experiment, 2010, 32(1): 93-97. (in Chinese)

[18] ZHANG Xi, REN Da-zhong, REN Qiang-yan, HUANG Hai, LIU Deng-ke, QU Xue-feng. The feature of the microscopic pore structure and its influence on oil displacement efficiency in Chang 6 Reservoir in Jiyuan Oilfield of Ordos Basin [J]. Journal of Northwest University: Natural Science Edition, 2015, 45(2): 283-290. (in Chinese)

[19] CHEN Lin, LU Yong-chao, WU Ji-yuan, XING Feng-cun, LIU Lu, MA Yi-quan, RAO Dan, PENG Li. Sedimentary facies and depositional model of shallow water delta dominated by fluvial for Chang 8 oil-bearing group of Yanchang Formation in southwestern Ordos Basin, China [J]. Journal of Central South University, 2015, 22(12): 4749-4763.

(Edited by FANG Jing-hua)

Cite this article as:

REN Da-zhong, SUN Wei, HUANG Hai, NAN Jun-xiang, CHEN Bin. Determination of microscopic waterflooding characteristics and influence factors in ultra-low permeability sandstone reservoir [J]. Journal of Central South University, 2017, 24(9): 2134–2144.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-017-3622-6Foundation item: Project(2015KTCL01-09) supported by the Innovation Project of Science and Technology of Shaanxi Province, China; Project(2015M582699) supported by the China Postdoctoral Science Foundation; Project(2016JQ4022) supported by the Natural Science Foundation Research Project of Shaanxi Province, China; Project(41702146) supported by the National Natural Science Foundation of China

Received date: 2016-01-13; Accepted date: 2016-05-31

Corresponding author: REN Da-zhong, PhD, Lecturer; Tel/Fax: +86–29–88303489; E-mail: rendazhong123@163.com

Abstract: Actual sandstone micromodel was used in this work to conduct the microscopic waterflooding experiment of ultra-low sandstone reservoir, since the inside seepage characteristics of microscopic waterflooding process of Chang 8 ultra-low permeability sandstone reservoir of Upper Triassic Yanchang formation in Huaqing region of the Ordos Basin, China is difficult to observe directly. Combined with physical property, casting thin sections, constant-rate mercury injection capillary pressure and nuclear magnetic resonance, the influence of reservoir property on the waterflooding characteristics in pores were analyzed and evaluated. Seepage paths of waterflooding characteristics were divided into four types: homogeneous seepage, reticular-homogeneous seepage, finger-reticular seepage and finger-like seepage, the waterflooding efficiency of which decreases in turn. More than 70% of residual oil occurs as flowing-around seepage and oil film. Physical property, pore structure and movable fluid characteristics are all controlled by digenesis and their impacts on waterflooding efficiency are in accordance. Generally, the pore throat radius size and distribution and movable fluid percentage are closely related to waterflooding law.