DOI: 10.11817/j.issn.1672-7207.2020.11.015

凝胶注模成型氧化锆陶瓷盖板工艺研究

李奔可1,陈茵芝1,李小兰1,王晨扬1,黄国基2,谢睿1,王小峰1

(1. 南华大学 化学化工学院,湖南 衡阳,421001;

2. 中国运载火箭技术研究院,北京,100076)

摘 要:

因环氧树脂体系的氧化锆凝胶注模成型技术进行改进和发展,研究固相体积分数对浆料流变性能、凝胶过程、生坯和烧结坯力学性能的影响规律,并研究高性能氧化锆陶瓷盖板制备方法。研究结果表明:浆料黏度随固相体积分数增加而增大,但即使固相体积分数高达55.0 %,浆料黏度也仅为0.606 Pa·s,能够满足浇注成型的要求;当固相体积分数为52.5%时,烧结坯强度的Weibull模量达到最大值13.38,即微观结构均匀性最佳,采用该固相体积分数的浆料成功地制备了表面光滑、厚度仅为0.4 mm氧化锆陶瓷盖板。

关键词:

凝胶注模成型;氧化锆;海因环氧树脂;流变性能;Weibull分析;

中图分类号:TB34 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3128-08

Study on gelcasting of zirconia ceramic cover plate

LI Benke1, CHEN Yinzhi1, LI Xiaolan1, WANG Chenyang1, HUANG Guoji2, XIE Rui1,WANG Xiaofeng1

(1. School of Chemistry and Chemical Engineering, University of South China, Hengyang 421001, China;

2. China Academy of Launch Vehicle Technology, Beijing 100076, China)

Abstract: A low-toxicity gelling system based on hydantoin epoxy resin was developed for gelcasting of zirconia ceramic to fabricate the high-performance cover plate. The effects of the solid loadings on the rheological properties, gelation behaviors, mechanical properties of the green and sintered bodies were investigated. The results show that the viscosities of zirconia suspensions increase with the increase of the solid loadings. However, the suspension even with a high solid volume fraction of 55.0% still displays a moderate viscosity of 0.606 Pa·s, which is suitable for the gelcasting process. The sintered body with a more homogenous microstructure is obtained after derived from the 52.5% zirconia suspension, where the Weibull modulus reaches the maximum value of 13.38. The zirconia ceramic cover plate with the thickness of 0.4 mm and smooth surface is successfully fabricated.

Key words: gelcasting; zirconia; hydantoin epoxy resin; rheology; Weibull analysis

指纹识别技术因其具有安全、便捷、准确及易操作等优点已广泛应用于智能便携设备如笔记本电脑、智能手机等中。为保护指纹识别传感器在复杂环境下使用时免受磨损及汗水侵蚀,并保持高信号识别灵敏度,指纹盖板材料的性能尤为重要。常用盖板材料主要包括蓝宝石、钢化玻璃以及氧化锆陶瓷等,其中氧化锆陶瓷(ZrO2)因其具有耐磨性好、强度高、断裂韧性高、介电常数高以及无信号屏蔽等优点,被视为指纹识别盖板的理想材料[1]。然而,传统ZrO2薄板制备方法如干压成型、注射成型以及流延成型等均难以制备高性能ZrO2陶瓷盖板[2],例如干压成型法难以制备厚度在1 mm以下的盖板;注射成型中大量有机添加物易导致盖板内残留大量孔洞等缺陷;流延成型虽作为工业化薄板制备常用技术,但成型过程中使用了大量有机溶剂而对环境造成污染。凝胶注模成型是20世纪90年代由YOUNG等[3-5]提出的一种新型陶瓷胶态成型技术,其基本过程是将陶瓷粉体、有机单体、交联剂以及分散剂通过球磨混合制备高固相体积分数、低黏度的陶瓷浆料,在催化剂和引发剂作用下,有机单体与交联剂聚合,形成三维网络结构,使陶瓷颗粒原位固化成型,获得高强度的陶瓷生坯。TAN等[6]采用丙烯酰胺为凝胶体系制备了无缺陷的ZrO2薄板,但该体系具有神经毒性且聚合反应容易受到空气中氧气的抑制作用,难以满足工业化应用需求。SNIJKERS等[7]采用低毒性的明胶为凝胶体系,实现了厚度为50~400 μm的ZrO2薄板成型,但其生坯强度低,难以满足后续生坯加工。海因环氧树脂作为一种新型的凝胶体系,具有成本低、毒性小及水溶性好等优点,基于锆钛酸铅陶瓷的凝胶注模成型前期研究表明,采用该体系可获得强度高达30.16 MPa的陶瓷生坯[8]。为此,本文基于海因环氧树脂为凝胶体系的ZrO2陶瓷凝胶注模成型,系统研究固相体积分数对浆料流变性能、凝胶过程以及生坯和烧结坯性能的影响,在优化参数条件下最终获得厚度仅为0.4 mm的ZrO2陶瓷盖板。

1 实验

1.1 实验原料

采用商用的ZrO2粉体(中值粒径D50=1.43 μm,江西赛瓷材料有限公司生产)作为原料,海因环氧树脂(MHR-045,湖北锡太化工股份有限公司生产)及其固化剂3, 3'-二氨基二丙胺(梯希爱(上海)化成工业发展有限公司生产)作为凝胶体系,聚丙烯酸铵(Disper AG 165,深圳海润化工有限公司生产)作为分散剂。

1.2 实验过程

将质量分数为15.0%的海因环氧树脂与去离子水混合均匀得到预混液,加入质量分数为1.0%的聚丙烯酸铵和一定质量的ZrO2粉体,并滴入1~2滴消泡剂正辛醇;球磨24 h后,加入质量分数为14.8%的固化剂3, 3′-二氨基二丙胺(DPTA)搅拌均匀后真空除泡,浇注于聚二甲基硅氧烷(PDMS)模具中,待固化后脱模;再经80 ℃干燥处理得到陶瓷生坯,最后在1 550 ℃条件下烧结2 h得到陶瓷样品。

1.3 性能测试

采用直径为40 mm的平板旋转流变仪(AR 2000EX,美国TA公司生产)对浆料流变性能进行表征。测试前在剪切速率为100 s-1时对浆料进行预处理30 s,在剪切速率变化范围为1~1 000 s-1时测定浆料黏度,在剪切速率为0.1 s-1时测试浆料黏度随时间的变化,以表征浆料凝胶过程。采用电子万能试验机(CMT 6203,深圳新三思材料检测有限公司制造)测量陶瓷生坯及烧结坯的强度,其中,跨距设定为30.0 mm,加载速度为0.5 mm/min。采用扫描电子显微镜(MIRA3 LMH,捷克TESCAN公司)观察生坯断面形貌。

2 结果与讨论

2.1 浆料流变性能

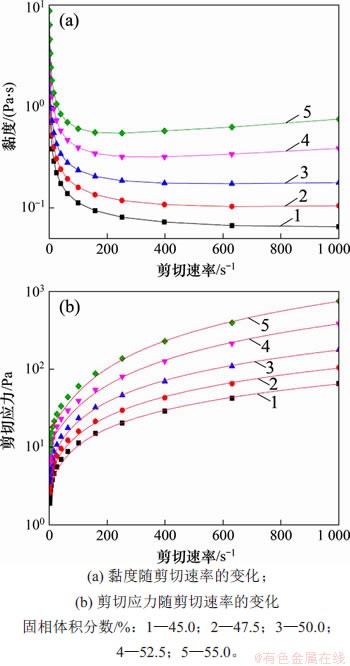

图1所示为固相体积分数对ZrO2浆料流变性能的影响。由图1可知:随着固相体积分数增加,浆料流变特性由剪切变稀逐渐转变为剪切变稠。采用Herschel-Bulkley模型[9]对浆料流变特性随固相体积分数变化进行定量描述,其表达式如下:

式中:τ为剪切应力;τ0为屈服应力;η为塑性黏度系数;γ为剪切速率;n为流变指数。拟合参数如表1所示。

、

图1 固相体积分数对ZrO2浆料流变性能的影响

Fig. 1 Effect of solid volume fraction on rheological behaviors of ZrO2 suspensions

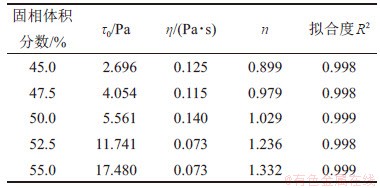

表1 基于Herschel-Bulkley模型拟合得到的流变参数

Table 1 Rheological parameters of ZrO2 suspensions fitted by Herschel-Bulkley model

由表1可知:随着固相体积分数增加,屈服应力τ0增大。在高固相体积分数陶瓷浆料中,粒子因相互吸引力作用而形成空间网状结构;随着固相体积分数增加,颗粒间距减小吸引力增加,网络结构强度提高,浆料流动即破坏该空间网络结构所需剪切应力(屈服应力)随之增加[10];此外,浆料的流变指数n也随着固相体积分数增加而增大,当浆料固相体积分数低于50.0%时,流变指数n小于1,浆料呈剪切变稀特性,即浆料黏度随剪切速率增加而降低;随着固相体积分数继续增加,流变指数n大于1,表明浆料流变特性向剪切变稠转变[11]。虽然在凝胶注模成型过程中,浆料剪切变稠特性不利于模具充分填充,但即使固相体积分数高达55.0%,其剪切变稠程度依然较小;当剪切速率从100 s-1增加至1 000 s-1时,浆料黏度仅从0.606 Pa·s增加至0.751 Pa·s,该黏度依然能够满足浇注成型要求。

由图1可知:随着固相体积分数从45.0 %增加至55.0 %,浆料黏度由0.113 Pa·s增加至0.606 Pa·s(剪切速率为100 s-1)。浆料黏度随着固相体积分数增加而急剧上升的主要原因是:固相体积分数增加导致颗粒间距减小,颗粒间相互作用力增强使得团聚体数量增加,浆料黏度随之增加;当固相体积分数增加至某一临界值时,颗粒之间彼此接触而形成致密且强度高的空间网状结构,浆料黏度将增大至无限大,该固相临界体积分数即为陶瓷浆料的最大固相体积分数[12]。采用文献[13]中模型可对ZrO2浆料最大固相体积分数进行推算,其表达式为

式中:ηr为相对黏度,即剪切速率为100 s-1时浆料黏度ηs与溶剂水黏度η0(0.89 mPa·s,25 ℃时)的比值;a和b为常数;φ为固相体积分数;m为相关系数,一般取值为2[14]。

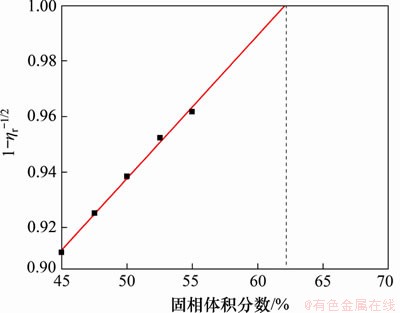

图2所示为(1-ηr-1/2)随固相体积分数φ的变化曲线。由图2可知:当拟合直线外推至(1-ηr-1/2)等于1时,ZrO2浆料相对黏度为无限大,经计算,采用该ZrO2浆料最大固相体积分数可高达62.2%,该值略小于等径球密堆积所获得理论最大固相体积分数(64.0%),其原因可能是初始ZrO2陶瓷粉体中存在一定程度团聚,部分团聚体即使在球磨过程中依然无法破碎,导致颗粒难以形成致密堆积[15]。

图2 根据(1-ηr-1/2)-φ线性关系推导得到的陶瓷浆料最大固相体积分数

Fig. 2 The maximum solid volume fraction obtained by relationship between (1-ηr-1/2) and φ

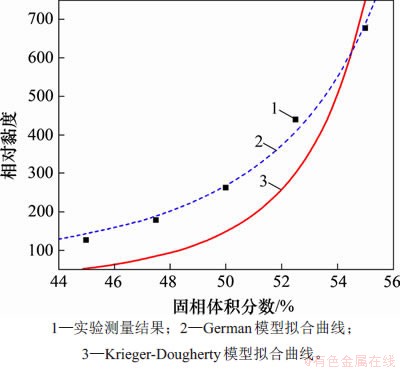

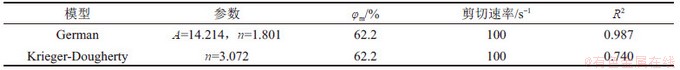

对于凝胶注模成型而言,陶瓷浆料固相体积分数增加有利于提高生坯和烧结坯致密度,降低干燥和烧结收缩率,但同时会造成浆料黏度上升,不利于浆料气泡排除以及模具充分填充,因此,明确固相体积分数与浆料黏度之间定量关系对于指导高固相体积分数陶瓷浆料的制备具有重要意义。基于上述计算得到的浆料最大固相体积分数,采用German模型[16]和Krieger-Dougherty模型[17]对黏度随固相体积分数变化进行定量分析,其表达式分别如下:

式中:A为幂律指数;φm为最大固相体积分数。

图3所示为采用German和Krieger-Dougherty模型拟合得到的浆料黏度随固相体积分数变化曲线,拟合参数如表2所示。由图3可知:采用German模型比Krieger-Dougherty模型拟合度更高,但仍与实验测量结果存在一定偏差。其主要原因是:理论模型简单地假定浆料固相体积分数仅取决于颗粒粒径,但在实际浆料体系中,ZrO2颗粒表面通过吸附一定量的聚丙烯酸根离子形成静电空间位阻,而稳定分散在水溶液中,因此,浆料有效固相体积分数取决于颗粒粒径和吸附层厚度,然而,吸附层厚度不仅与聚丙烯酸根离子的相对分子质量有关,而且与其在水溶液中的伸展程度密切相关,随着固相体积分数增加,颗粒间距减小,吸附层被压缩而使得厚度减小,因此,在实际过程中难以准确得到吸附层厚度,致使模型采用的固相体积分数与有效固相体积分数存在偏差[15]。

图3 采用2种流变模型拟合得到的浆料黏度随固相体积分数变化曲线

Fig. 3 Fitted curves of viscosities with solid loadings of ZrO2 suspensions using flow models

表2 German和Krieger-Dougherty模型拟合参数

Table 2 Fitting parameters of German and Krieger-Dougherty models

2.2 浆料凝胶过程

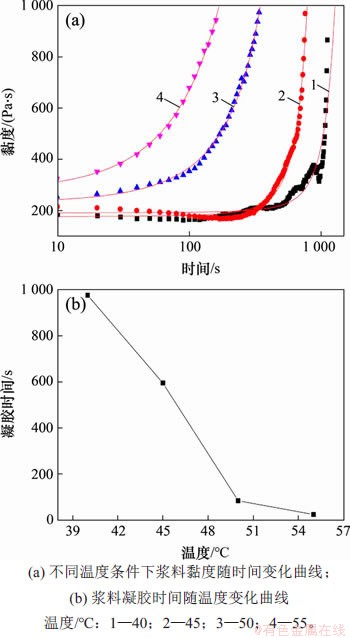

图4所示为温度对固相体积分数为52.5%的ZrO2浆料凝胶反应过程的影响。由图4(a)可知:在反应初期,浆料处于诱导期,其黏度较稳定地维持在较低值;随着时间延长,海因环氧树脂与3, 3′-二氨基二丙胺交联形成三维聚合物网络,浆料黏度急剧增加,并由液态转变为凝胶态而失去流动性。由图4(b)可知:随着温度从40 ℃上升至55 ℃,ZrO2陶瓷浆料凝胶时间从975.7 s降低至23.6 s。浆料凝胶反应速率随着温度升高而加快的原因主要是海因环氧树脂和3, 3′-二氨基二丙胺分子运动速率随着温度升高而增加,分子间有效碰撞次数增加,凝胶反应速率加快,致使浆料凝胶时间减少。凝胶反应速率随温度变化曲线可采用阿伦尼乌斯方程[18-19]进行定量描述,其表达式如下:

图4 温度对ZrO2浆料凝胶反应过程的影响

Fig. 4 Effect of temperature on gelation process of ZrO2 suspensions

式中:t为反应时间;r为反应速率;R为气体常数,取为8.314 J/(mol·K);Ea为反应活化能;T为热力学温度;A为指前因子。

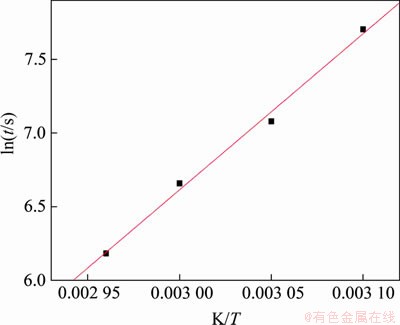

图5所示为ZrO2浆料凝胶反应的阿伦尼乌斯曲线。由图5可知:ZrO2浆料凝胶时间对数与温度倒数呈线性关系(R2 =0.992)。基于拟合直线的斜率(Ea/R)可计算得到浆体凝胶反应活化能Ea为88.03 kJ/mol,远高于文献报道的其他凝胶体系的值[20],表明采用海因环氧树脂体系的ZrO2陶瓷浆料凝胶反应速度较慢,这将为后续浆料处理如固化剂添加、真空除泡以及浇注成型提供充足的操作时间。

图5 氧化锆浆料凝胶反应的阿伦尼乌斯曲线

Fig. 5 Arrhenius curve of gelation process of zirconia suspension

2.3 凝胶注模成型生坯性能

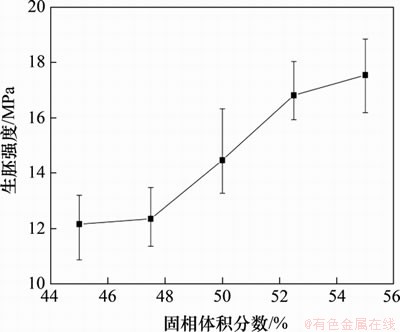

图6所示为ZrO2陶瓷生坯强度随固相体积分数变化曲线。由图6可知:随着固相体积分数从45.0%增加至55.0%。ZrO2陶瓷生坯平均强度从12.16 MPa增加至17.54 MPa。产生该现象的主要原因是固相体积分数增加将提高颗粒堆积密度,降低固化干燥后生坯的孔洞等缺陷数量,进而提高陶瓷生坯强度。

图6 固相体积分数对ZrO2陶瓷生坯强度的影响

Fig. 6 Green strengths of dried ZrO2 green bodies with different volume fractions

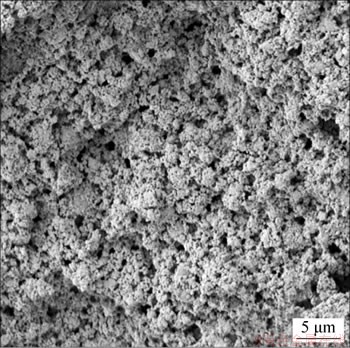

图7所示为固相体积分数为52.5%的ZrO2陶瓷生坯断面SEM图。由图7可知:ZrO2陶瓷生坯结构均匀,颗粒堆积紧密,致密度高,无明显气孔及团聚体等缺陷存在。

图7 ZrO2陶瓷生坯断面的SEM图

Fig. 7 SEM image of fracture surface of ZrO2 green body

2.4 凝胶注模成型烧结坯性能

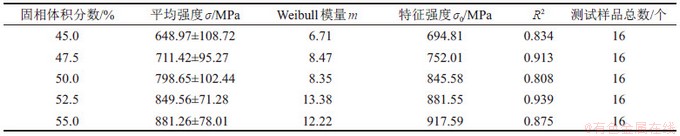

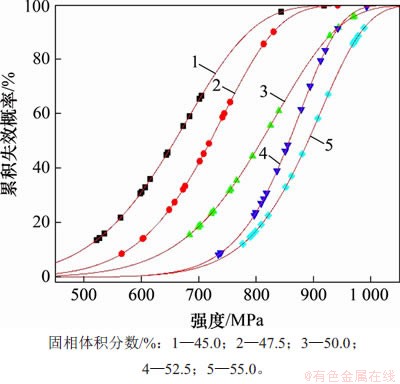

图8所示为不同固相体积分数的ZrO2陶瓷烧结坯强度Weibull分布曲线,其中Weibull统计分析拟合参数如表3所示。由表3可知:随着固相体积分数从45.0%增加至52.5%,ZrO2陶瓷烧结坯的平均强度和Weibull模量分别从(648.97±108.72) MPa 和6.71增加至(849.56±71.28) MPa和13.38。其主要原因是随着固相体积分数增加,浆料中颗粒堆积密度增加,经原位固化成型得到的生坯致密度高,孔洞等缺陷较少,使得高温烧结后陶瓷坯体内保留的缺陷较少,因此,烧结强度和Weibull模量随之增加。但当固相体积分数继续增加至55.0%时,Weibull模量随之减小至12.22。这可能是因为浆料黏度随固相体积分数增加而增大,导致陶瓷浆料气泡排除难度增加,生坯内气孔分布不均匀,并且浆料中团聚体等缺陷数量也随固相体积分数的增加而增多,这些缺陷被保存在烧结坯内,使得其强度分布分散度增大[21]。

表3 不同固相体积分数的ZrO2烧结坯平均抗弯强度以及拟合获得的Weibull统计分析参数

Table 3 The mean flexural strength(σ) and Weibull data for the ZrO2 sintered bodies containing different solid volume fractions

图8 不同固相体积分数的ZrO2烧结坯抗弯强度Weibull分布曲线

Fig. 8 Weibull plots of three-point bending strength for ZrO2 sintered bodies with different volume fractions

2.5 凝胶注模成型制备的氧化锆陶瓷盖板

图9所示为采用固相体积分数为52.5%陶瓷浆料浇注得到的ZrO2盖板。由图9可知:得到的ZrO2陶瓷盖板厚度仅为0.4 mm且均匀一致,表面光滑无明显缺陷。

图9 凝胶注模成型制备得到的ZrO2盖板照片

Fig. 9 Photographs of ZrO2 cover plate fabricated by gelcasting

3 结论

1) ZrO2陶瓷固相体积分数对其流变特性影响显著,随着固相体积分数由45.0%增加至55.0%,浆料黏度由0.113 Pa·s增加至0.606 Pa·s,且其流变特性由剪切变稀转变为剪切变稠。

2) ZrO2陶瓷浆料凝胶过程与温度密切相关,随着温度上升,浆料凝胶反应速率增加,凝胶时间减少。当固相体积分数为52.5%时,ZrO2陶瓷浆料的反应活化能为88.03 kJ/mol。

3) 固相体积分数对凝胶注模成型烧结坯强度及稳定性产生较大影响。随着固相体积分数增加,烧结坯平均强度随之增加,但Weibull模量则呈现先增加后降低的变化趋势。当ZrO2固相体积分数为52.5%时,Weibull模量达到最大值88.03 kJ/mol。

4) 采用低毒性的海因环氧树脂为凝胶体系,实现了表面光滑无缺陷且厚度仅为0.4 mm的ZrO2陶瓷盖板的制备成型。

参考文献:

[1] 孙亚光, 金昊, 杨文龙, 等. 氧化锆陶瓷的制备与应用[J]. 中国陶瓷工业, 2016, 23(6): 24-29.

SUN Yaguang, JIN Hao, YANG Wenlong, et al. Preparation and application of zirconia ceramics[J]. China Ceramic Industry, 2016, 23(6): 24-29.

[2] DONG Qizheng, ZHU Tianbin, XIE Zhipeng, et al. Optimization of the tape casting slurries for high-quality zirconia substrates[J]. Ceramics International, 2017, 43(18): 16943-16949.

[3] YOUNG A C, OMATETE O O, JANNEY M A, et al. Gelcasting of alumina[J]. Journal of the American Ceramic Society, 1991, 74(3): 612-618.

[4] OMATETE O O, JANNEY M A, NUNN S D. Gelcasting: from laboratory development toward industrial production[J]. Journal of the European Ceramic Society, 1997, 17(2/3): 407-413.

[5] JANNEY M A, OMATETE O O, WALLS C A, et al. Development of low-toxicity gelcasting systems[J]. Journal of the American Ceramic Society, 1998, 81(3): 581-591.

[6] TAN Qiangqiang, ZHANG Zhongtai, TANG Zilong, et al. Rheological properties of nanometer tetragonal polycrystal zirconia slurries for aqueous gel tape casting process[J]. Materials Letters, 2003, 57(16/17): 2375-2381.

[7] SNIJKERS F, DE WILDE A, MULLENS S, et al. Aqueous tape casting of yttria stabilized zirconia using natural product binder[J]. Journal of the European Ceramic Society, 2004, 24(6): 1107-1110.

[8] XIE Rui, WANG Xiaofeng, PENG Guowen, et al. A modified gelcasting approach to fabricate microscale randomized 1-3 piezoelectric arrays[J]. Ceramics International, 2017, 43(1): 144-148.

[9] RUESCHHOFF L, COSTAKIS W, MICHIE M, et al. Additive manufacturing of dense ceramic parts via direct ink writing of aqueous alumina suspensions[J]. International Journal of Applied Ceramic Technology, 2016, 13(5): 821-830.

[10] ZHANG Shuai, SHA Na, ZHAO Zhe. Surface modification of α-Al2O3 with dicarboxylic acids for the preparation of UV-curable ceramic suspensions[J]. Journal of the European Ceramic Society, 2017, 37(4): 1607-1616.

[11] RENGER C, KUSCHEL P, KRISTOFFERSSON A, et al. Rheology studies on highly filled nano-zirconia suspensions[J]. Journal of the European Ceramic Society, 2007, 27(6): 2361-2367.

[12] TSENG W J, LIN K C. Rheology and colloidal structure of aqueous TiO2 nanoparticle suspensions[J]. Materials Science and Engineering: A, 2003, 355(1/2): 186-192.

[13] LIU D M, TSENG W J. Rheology of injection-molded zirconia-wax mixtures[J]. Journal of Materials Science, 2000, 35(4): 1009-1016.

[14] SONG Yuanling, LIU Xiaolin, CHEN Jianfeng. The maximum solid loading and viscosity estimation of ultra-fine BaTiO3 aqueous suspensions[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2004, 247(1/2/3): 27-34.

[15] TSENG W J, LI S Y. Rheology of colloidal BaTiO3 suspension with ammonium polyacrylate as a dispersant[J]. Materials Science and Engineering A, 2002, 333(1/2): 314-319.

[16] GARCIA-FRANCO C A, CHRISTENSEN R M. Non-Newtonian behavior of suspensions[J]. Acta Mechanica, 1980, 37(1/2): 85-97.

[17] LI Xingbang, ZHONG He, ZHANG Jingxian, et al. Powder characteristics on the rheological performance of resin-based zirconia suspension for stereolithography[J]. Journal of Inorganic Materials, 2020, 35(2): 231-235.

[18] CHAIGNE S, BOEUF-MURAILLE G, BOULESTEIX R, et al. Aqueous gelcasting of CeO2 ceramics using water-soluble epoxide[J]. Ceramics International, 2019, 45(18): 23964-23966.

[19] WANG Xiaofeng, PENG Chaoqun, WANG Richu, et al. Polymerization and rheological behavior of the thermoresponsive gelcasting system based on N-isopropylacrylamide[J]. International Journal of Applied Ceramic Technology, 2016, 13(5): 966-972.

[20] XU Xiaogang, WEN Zhaoyin, WU Xiangwei, et al. Rheology and chemorheology of aqueous γ-LiAlO2 slurries for gel-casting[J]. Ceramics International, 2009, 35(6): 2191-2195.

[21] LI Hua, FAN Huiqing, WANG Baisong, et al. Mechanical and electrical properties of lithium stabilized sodium beta alumina solid electrolyte shaping by non-aqueous gelcasting[J]. Journal of the European Ceramic Society, 2020, 40(8): 3072-3079.

(编辑 陈灿华)

收稿日期: 2020 -09 -21; 修回日期: 2020 -10 -23

基金项目(Foundation item):国家自然科学基金资助项目(51802147);国家级大学生创新创业训练计划项目(201710555007);湖南省大学生创新创业训练计划项目(20191055509) (Project(51802147) supported by the National Natural Science Foundation of China; Project(201710555007) supported by the National Undergraduate Training Programs for Innovation and Entrepreneurship; Project(20191055509) supported by the Undergraduate Training Programs for Innovation and Entrepreneurship of Hunan Province)

通信作者:谢睿,博士,讲师,从事陶瓷湿法成型研究;E-mail:xierui145@163.com

摘要:对基于低毒性海因环氧树脂体系的氧化锆凝胶注模成型技术进行改进和发展,研究固相体积分数对浆料流变性能、凝胶过程、生坯和烧结坯力学性能的影响规律,并研究高性能氧化锆陶瓷盖板制备方法。研究结果表明:浆料黏度随固相体积分数增加而增大,但即使固相体积分数高达55.0 %,浆料黏度也仅为0.606 Pa·s,能够满足浇注成型的要求;当固相体积分数为52.5%时,烧结坯强度的Weibull模量达到最大值13.38,即微观结构均匀性最佳,采用该固相体积分数的浆料成功地制备了表面光滑、厚度仅为0.4 mm氧化锆陶瓷盖板。