J. Cent. South Univ. (2019) 26: 2845-2853

DOI: https://doi.org/10.1007/s11771-019-4218-0

Two-stage optimization model for renewing warranty considering warranty deadline

SU Chun(苏春), YANG Xiao-tian(杨小天)

School of Mechanical Engineering, Southeast University, Nanjing 211189, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract:

Renewing warranty can provide customers with better service, and thus help manufacturers to gain market opportunities. In engineering practice, the cost for replacement is usually higher than the cost for maintenance, hence manufacturers often face huge challenge to reduce the warranty service cost. With consideration of the warranty deadline, we propose a two-stage optimization model for renewing warranty. In the first stage, a renewing warranty with deadline (RWD) policy is implemented, where the deadline represents the cumulative uptime threshold. When the cumulative uptime exceeds the deadline, the product will be minimally repaired and kept to the residual warranty period. When RWD is expired, the replacement warranty with limited repairs (RWLR) policy is applied. Under the free replacement and pro-rata warranty policy, the corresponding two-stage cost optimization model is established from the manufacturer’s perspective, the aim is to minimize the cost rate and obtain the optimal warranty period. A numerical example is provided to illustrate the validity of the proposed model, and the sensitivity analysis is also carried out.

Key words:

renewing warranty with deadline; limited repairs; minimal repair; warranty cost rate;

Cite this article as:

SU Chun, YANG Xiao-tian. Two-stage optimization model for renewing warranty considering warranty deadline [J]. Journal of Central South University, 2019, 26(10): 2845-2853.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-019-4218-01 Introduction

Warranty is a contractual obligation between the manufacturer and the consumers [1]. It can act as a protection for the consumers against defective items as well as against consumers’ excessive claims for the manufacturer [2]. Thus, warranty is of great importance for both of them [3, 4]. Furthermore, due to fierce competition, attractive warranty policy has become an effective way to promote products for the manufacturer.

A detailed review of warranty policies was done by CHEN et al [5] and PARK et al [6]. Among them, one-dimensional warranty policy is defined in terms of product’s age or usage, while two- dimensional policy considers both of them as well as the potential interaction between them. Meanwhile, in the free replacement warranty (FRW) policy, manufacturer agrees to repair or provide replacement for failed items free of charge for the consumer under certain conditions; while in the pro-rata replacement warranty (PRW) policy, the manufacturer agrees to refund a fraction of the purchase price when the item fails during the warranty period. Additionally, in the renewing warranty (RW) policy, the failed item will be replaced by a new one and with a new warranty period; while in a non-renewing warranty (NRW) policy, the replacement of a failed item does not alter the original warranty period.

RW is a common-used warranty policy especially for high-quality electromechanical products [7]. For instance, Intel Inc. offers a three- year warranty for its CPUs including a one-year limited renewable warranty; and Apple Inc.provides a two-year renewable warranty policy for the key components of its laptops. Meanwhile, RW is also desirable for consumers, since they can receive better warranty service compared to NRW [8, 9].

However, most existing warranty policies focus on NRW, only a few studies pay attention to RW [10, 11]. MONDAL et al [8] proposed a cost model as well as the mathematical formulation for RW. SAHIN and POLATOGLU [12] considered the optimal maintenance strategy following the expiration of renewing warranty. On that basis, the influence of RW on original optimal replacement strategy was analyzed. JUNG and PARK [13] extended SAHIN and POLATOGLU’s model by incorporating preventive maintenance activity into the policy. Considering the maintenance cost and downtime loss, JUNG et al [14] proposed an optimal replacement policy when RW is expired. YEH et al [15] analyzed the effects of renewing free replacement warranty (RFRW) on age- replacement policy for non-repairable products. CHIEN [16] extended YEH’s model in Ref. [15] to a general repairable case. JUNG et al [17] defined the life cycle from customer’s perspective, and proposed an optimal maintenance policy under RW.

Simple RW policy may put heavy cost pressure on the manufacturers, especially when the product’s reliability is not so high. To reduce the manufacturer’s cost pressure and optimize the warranty policy, a variety of combined RW policies have been put forward. Combining the free and pro-rata replacement policy with RW policy, WU et al [18] proposed a cost model to optimize the burn-in time and the length of warranty period for non-repairable products. CHIEN [19] presented a new warranty servicing strategy for repairable systems, where RFRW was combined with a rebate policy. To optimize the preventive replacement age for non-repairable products, CHIEN [20] developed a renewable free replacement with a pro-rata warranty policy. Compared with RW policy, the combined RW can not only reduce the warranty cost, but also help manufacturers to promote the sales at lower prices.

RW policy is effective under certain situations, especially for non-repairable products. While for most repairable products, the maintenance cost is usually lower than the replacement. Therefore, it is more realistic to restore the product through suitable maintenance actions. The maintenance policies for repairable systems have been studied extensively [21]. In recent years, combining the maintenance threshold with replacement strategy has received some attention. PARK et al [22-24] proposed a renewable minimal repair-replacement warranty policy, where the repair time threshold was adopted. TANG et al [25] determined the best maintenance time by evaluating the failure threshold. With a threshold point on the number of repairs, BAI et al [26] proposed a repair-limit risk-free replacement warranty policy. However, up to now, study on RW by considering the repair limitation is still insufficient.

Nowadays, most manufacturers provide minimal repair (MR) for their products during the warranty period. MR can restore the failed item to an operational state and keep its failure rate the same as that just before failure. Compared with the direct replacement, MR can lower the manufacturer’s cost, however it is not effective for promoting sales and improving customer’s satisfaction. Conversely, RW can compensate the above shortages of MR.

By integrating the merits of MR with RW, the novel warranty policy may be attractive for both the manufacturer and customers. In fact, manufacturer can promote its sales and improve customer’s satisfaction by providing a short-term replacement service in the initial stage of warranty. In this study, we propose a two-stage renewing warranty, where the warranty deadline is also considered. In the first stage, the renewing warranty with a deadline (RWD) is carried out, where the deadline represents the cumulative uptime threshold. When RWD is expired, the replacement warranty with limited repairs (RWLR) will be implemented in the second stage. The purpose is to establish a two-stage warranty cost model and optimize the warranty period.

The remainder of this study is organized as follows. Section 2 describes the two-stage warranty strategy, including RWD and RWLR. Section 3 develops the cost model under the two-stage warranty and within the expected length of life cycle. The mathematical formulas are derived to compute the expected cost rate per unit time under different warranty policies accordingly. In Section 4, a numerical example is provided to illustrate the effectiveness of the proposed warranty policies. Conclusions and some future research directions are drawn in Section 5.

2 Description of two-stage warranty

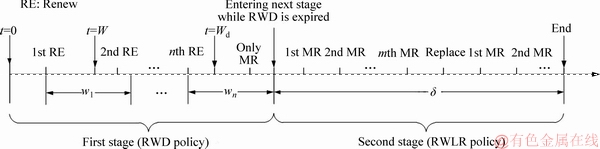

It is assumed that the repairable product has a pre-specified length of warranty period, denoted by W. In the proposed strategy, two kinds of warranty policies will be implemented in sequence. In the first stage, RWD with the parameter of (W, Wd) is implemented, where W denotes the pre-specified warranty and Wd denotes the warranty deadline. When a failure occurs, the product will be replaced by a new one and the warranty period is renewed after that, and wi denotes the ith renewed warranty. When the cumulative uptime exceeds the deadline, the product will be minimally repaired during the residual renewed warranty period.

When RWD is expired, the RWLR policy with the parameter of (δ, m) will be started, where δ represents the warranty period of the second stage and m is the number of minimal repairs. That is to say, this policy has a threshold of m. When the number of failures reaches m within δ, the failed product will be replaced with a new one. In the second stage, if a failure occurs, the product will be minimally repaired or replaced until the end of the warranty period.

The proposed warranty policy is shown in Figure 1.

3 Model formulation

3.1 Expected length of life cycle

In this study, the warranty period is divided into two stages, i.e., renewing stage and minimal repair stage. If a failure occurs in the renewing stage, the failed products will be replaced and the warranty is renewed. Therefore, the renewing period is an independent random variable.

The lifetime of a product, i.e., X, is an independent random variable. It can be defined with probability density function (PDF) f(t) and cumulative distribution function (CDF) F(x). Let N(W, Wd) denote the number of renewal during the first stage, Ti (i=1, 2, 3, …) denote the time to the product’s failure, which is renewed at ith failure during the RWD period. T0 is the time that the product is sold, τi is the interval between (i-1)th and ith failure, and τi=Ti-Ti-1. In this study, the life cycle is defined to start when the new product is sold and to end when the warranty of the second stage is expired. Given N(W, Wd)=n, the product’s lifetime can be expressed as

Therefore, to obtain the expectation of the life cycle, it is necessary to analyze the distribution of N(W, Wd).

Under the RWD strategy, the condition for the number of renewal being n is τi≤W∩Tn≤Wd and τn+1>W∪Tn+1>Wd. Thus, the number of renewal can be obtained as:

(1)

(1)

According to Eq. (1), for τi∈[0, Wd], the conditional probability that τi is less than W can be obtained as:

(2)

(2)

It is assumed that the failure interval τi is independent and identically distributed, thus  is an independent random variable. According to the conclusion in Ref. [27], the probability that Tn is less than Wd can be expressed as:

is an independent random variable. According to the conclusion in Ref. [27], the probability that Tn is less than Wd can be expressed as:

(3)

(3)

where Fn(Wd) is the n-fold convolution of F(Wd). The detailed derivation formula is as follows:

Figure 1 Sketch map of proposed warranty policy

(4)

(4)

(5)

(5)

The probability function of N(W, Wd) can be calculated as follows:

(6)

(6)

By taking the expectation on conditioned on N(W, Wd)=n, the length of expected life cycle can be obtained as follows:

(7)

(7)

where  .

.

By integrating Eqs. (6) and (7), we can obtain the total expected cycle length with:

(8)

(8)

When Wd=W, Eq. (8) is turned into Eq. (9), which is similar to the replacement model of SAHIN et al [12].

(9)

(9)

3.2 Expected cost rate

Under PRW strategy, the consumer is responsible for the pro-rated replacement cost. Therefore, for the consumer, the total replacement cost Cc, r is derived by:

(10)

(10)

where NR is the number of renewal during the first stage, and cr is the replacement cost per unit.

The manufacturer’s replacement cost Cm, r is calculated as:

(11)

(11)

In addition, when the cumulative uptime exceeds the deadline and it is still within the first stage, the product will be minimally repaired, and kept to the last renewed warranty period. Thus, the expected number of failures during the last renewed warranty E(Nl) can be obtained as:

(12)

(12)

where h(t) is the failure rate.

Given N(W, Wd)=n, for the manufacturer the total conditional expected cost during the first stage can be evaluated as:

(13)

(13)

where cm is the minimal repair cost per unit.

By taking the expectation on E[C(W, Wd)|N(W, Wd)=n] of Eq. (13) with respect to N(W, Wd), the manufacturer’s expected cost under the pro-rata RWD, denoted by ECP(W, Wd), can be obtained as:

(14)

(14)

According to Eq. (14), the manufacturer will share the replacement cost with the proportion of 1-I(W)/(WF(W)). When the proportion equals 1, the cost under free replacement RWD ECF(W, Wd) can be derived as:

(15)

(15)

Thus, the expected number of renewals can be obtained as:

(16)

(16)

When RWD policy is expired, RWLR policy will be put into effect with the parameter of (δ, m). During this warranty period, the replacement will be implemented after every m times of minimal repair. Assuming that the product’s failure follows exponential distribution, and the failure rate remains unchanged when the product is minimally repaired or replaced. Therefore, the failure process obeys homogeneous Poisson distribution, and the failure rate h(t)=λ. Let Nδ denote the number of failures within the maintenance interval, then the probability density function of Nδ is:

(17)

(17)

(18)

(18)

Under RWLR policy, the product needs to be replaced after the mth minimal repair. Nδ, r and Nδ, a are the corresponding number of replacements and minimal repairs respectively.

(19)

(19)

Apparently, E(Nδ)=E(Nδ, a)+E(Nδ, r). Therefore, the expected number of minimal repairs can be obtained as:

(20)

(20)

Let ca be the cost of minimal repair per failure, and EC(δ, m) represent the expected warranty cost that the manufacturer needs to pay during the second stage. Then, we have:

(21)

(21)

Now, we discuss the expected warranty cost rate during the life cycle from the manufacturer’s perspective. During the first stage, the manufacturer needs to pay the replacement cost with a certain proportion and the minimal repair. Let ECRP(W, Wd, δ) and ECRF(W, Wd, δ) denote the manufacturer’s total expected cost rate of warranty under PRW and FRW respectively. Then, we have:

(22)

(22)

(23)

(23)

3.3 Model optimization

To sum up, the proposed optimization model is as follows: with the deadline Wd and the number of limited repairs m, to minimize the total expected warranty cost rate (ECR) and obtain the optimal value of δ for a given warranty period W.

In this study, the downhill simplex method is applied to obtain the optimal solution. This method does not require calculating the derivatives, and it is widely used in nonlinear optimization problems [28]. The corresponding program for solving the model is established on the platform of Matlab .

.

4 Numerical example

In this section, a numerical example is given to illustrate the effectiveness of the proposed model. Considering that the life distribution of most electronic products obeys exponential distribution, here it is assumed that the failure time follows exponential distribution with the parameter of λ=0.25. It means that the first average failure time of the product is 4 years. Thus, its PDF is f(t)=0.25e-0.25t, and the CDF is F(t)=1-e-0.25t.

It is assumed that the product will be provided with a free replacement RWD by the manufacturer, and the warranty period in the first stage is 0.5 year. When the product fails in the first stage, it will be replaced by the manufacturer. When the RWD is expired, minimal repair or replacement will be implemented for the failed product according to the product’s state. The unit of money is US dollar ($), and the unit of time is year. The deadline Wd is 2, the warranty period of the second stage δ is 2, the number of limited repairs m is 2, the cost for per replacement (cr) is $5000, and the cost for per minimal repair (cm) is $300.

4.1 Analysis of deadline

In this study, we will analyze the influence of the warranty deadline on the RW policy, and the effect of the deadline on the renewal’s number and warranty cost rate is also illustrated.

4.1.1 Number of renewal

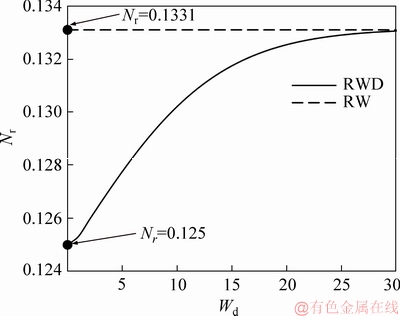

According to the research by CHEN [29], for a given warranty period W, the expected number of renewals can be obtained as F(W)/(1-F(W)). To investigate the difference between RWD and other basic warranty policies, the expected number of renewals under two different warranty policies is calculated. With the increase of the deadline Wd, the expected number of renewals for different warranty policies is shown in Figure 2.

Figure 2 Expected number of renewals under different policies

Obviously, the cost of RW policy is closely related to the number of renewals. The larger the number of renewals is, the replacement will occur more frequently. From Figure 2, it is also found that for RW policy, the expected number of renewals Nr is constantly equal to 0.1331; while for RWD policy, when Wd=0.5, Nr equals 0.125, which is the same as the number of replacements in the non-renewing warranty; meanwhile, with the increase of the deadline, Nr for RWD policy shows an upward trend, and then it becomes flat gradually. Furthermore, when Wd→+∞, the curve of RWD will overlap with that of RW.

4.1.2 Effect of deadline on cost rate

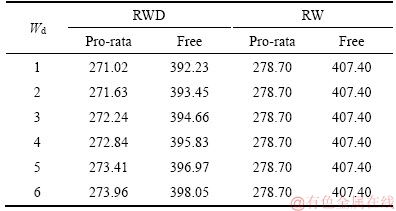

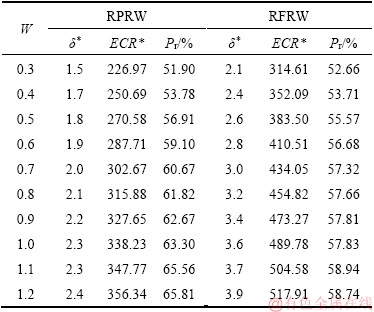

Table 1 shows the effect of deadline Wd on the expected cost rate under different warranty policies. Obviously, Wd has a direct impact on the number of renewals, and therefore it has a significant impact on product’s warranty cost.

Table 1 Effect of Wd on expected cost rate under different policies

From Table 1, it can also be found that in both pro-rata warranty policy and free replacement warranty policy, the expected cost rate of RWD is always lower than that of RW. It shows that RWD policy can reduce the warranty cost obviously. With the increase of the deadline Wd, the expected cost rate of RW remains constant, while the expected cost rate of RWD increases slowly. The result is consistent with the tendency in Figure 2.

4.2 Optimal warranty period

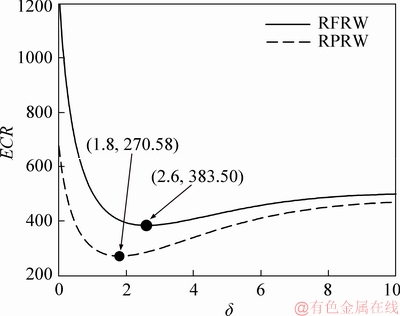

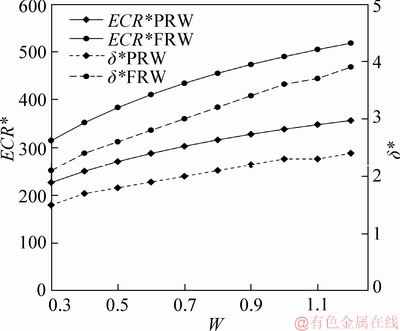

Based on the initial parameters, various warranty policies and different lengths of maintenance period are considered to obtain the optimal warranty period for the second stage. When δ increases from 0 to 10 in steps of 0.1, the expected cost rate under RFRW and RPRW is shown in Figure 3.

From Figure 3, under RPRW policy, the optimal warranty period of the second stage δ* is 1.8 years and the manufacturer’s ECR* is $270.58; while under RFRW policy, the δ* is 2.6 years and the ECR* is $383.50. Obviously, both the optimal warranty period and corresponding expected cost rate under RFRW policy are higher than those under RPRW policy. The intuitive reason is that when implementing PRW policy, consumers will share some replacement cost, and therefore it can help the manufacturer to reduce the cost pressure.

Figure 3 Relationship between warranty cost rate and warranty period in second stage

4.2.1 Effect of W on optimal solutions

When the length of warranty period W increases from 0.3 to 1.2 in steps of 0.1, we calculate the optimal maintenance interval and expected cost rate. In order to analyze the impact of the cost under the first stage on the on the optimal solution, a percentage denoted by Pr= or

or  is introduced, where Pr represents the proportion of the cost under the first phase in the total cost. The results are shown in Table 2 and Figure 4 respectively.

is introduced, where Pr represents the proportion of the cost under the first phase in the total cost. The results are shown in Table 2 and Figure 4 respectively.

Table 2 Effect of W on optimal policies

From Table 2 and Figure 4, it is found that δ* and ECR* tend to increase with the increase of warranty period. In addition, when W≥1.0, the growth of δ* tends to slow down. For the manufacturer, products’ failure in the first stage means the corresponding replacement, and it also indicates high replacement cost. The cost percentage, i.e., Pr, increases with the increase of W, which will lead to an increase of the expected life-cycle cost rate. The basic warranty period, i.e., W, is another a key factor. It has a significant impact on the optimal warranty period of the second stage, i.e., δ*, and it has also influence on the optimal expected warranty cost rate, i.e., ECR*.

Figure 4 Effect of W on optimal policies

4.2.2 Effect of m on optimal solutions

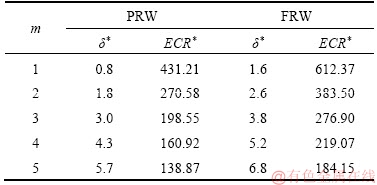

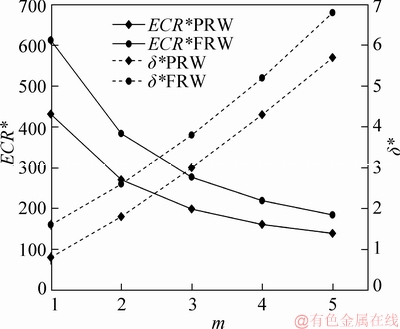

According to the definition of RWLR, when the number of limited repairs m is 0, the product will be replaced immediately once it fails in the second stage; when m→+∞, it means that no matter how many times of failures have occurred, the product will only be minimally repaired. Considering that m increases from 1 to 5, the optimal warranty period of the second stage, i.e., δ*, and the expected warranty cost, i.e., ECR*, are calculated accordingly, the corresponding results are showed in Table 3 and Figure 5, respectively.

As can be seen, with the increase of m, the optimal length of the maintenance warranty period, i.e., δ*, will also increase, while the life cycle cost rate, i.e., ECR*, shows a downward trend. This is consistent with the actual situation. That is, the higher the m is, the greater the possibility of a minimal repair after the product’s failure will be. Actually, the cost of minimal repair is usually far lower than that of the replacement.

Table 3 Effect of m on optimal policies

Figure 5 Effect of m on optimal policies

Based on the above analysis, it is found that under the two-stage warranty, the optimal warranty period and expected cost rate depend on a variety of factors, including the length of basic warranty period, the deadline, the number of minimal repairs as well as the repair cost, etc.

5 Conclusions

In this study, we put forward a two-stage warranty strategy, i.e., the first stage of RWD and the second stage of RWLR. Under the proposed two-stage warranty policy, the failed products will be replaced, renewed, or minimally repaired according to their actual states. A numerical example is provided to verify the effectiveness of the proposed policy. Some conclusions are obtained as follows:

1) The RWD proposed in this study is an extension of RW. As the deadline approaches infinity, the number of the renewals under RWD policy will equal the number of the renewals under RW policy.

2) By reducing the warranty cost invested in the first stage, it can help to reduce the life-cycle warranty cost rate. Additionally, the threshold of limited repairs’ number has also a significant impact on the expected warranty cost rate. Therefore, for the manufacturers, these factors should be taken into consideration to gain a more scientific warranty period.

In this study, the failure process is assumed to follow the exponential distribution. In fact, it is more practical to consider the Weibull distribution. To further reduce the cost of RWD, the other kinds of maintenance methods, such as preventive maintenance, opportunistic maintenance etc., can also be integrated into the warranty optimization model.

References

[1] ZHAO Xiu-jie, XIE Min. Using accelerated life tests data to predict warranty cost under imperfect repair [J]. Computers & Industrial Engineering, 2017, 107: 223-234. DOI: 10.1016/j.cie.2017.03.021.

[2] MO Si-min, ZENG Jian-chao, XU Wei-bin. A new warranty policy based on a buyer’s preventive maintenance investment [J]. Computers & Industrial Engineering, 2017, 111: 433- 444. DOI: 10.1016/ j.cie.2017.07.036.

[3] SU Chun, WANG Xiao-lin. Modeling flexible two- dimensional warranty contracts for used products considering reliability improvement actions [J]. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, 2016, 230(2): 237-247. DOI: 10.1177/ 1748006X15627395.

[4] YANG Duo, HE Zhen, HE Shu-guang. Warranty claims forecasting based on a general imperfect repair model considering usage rate [J]. Reliability Engineering & System Safety, 2016, 145: 147-154. DOI: 10.1016/j.ress.2015.09. 012.

[5] CHEN C K, LO C C, WENG T C. Optimal production run length and warranty period for an imperfect production system under selling price dependent on warranty period [J]. European Journal of Operational Research, 2017, 259(2): 401-412. DOI: 10.1016/j.ejor.2016.10.038.

[6] PARK M, JUNG K M, PARK D H. Optimization of periodic preventive maintenance policy following the expiration of two-dimensional warranty [J]. Reliability Engineering & System Safety, 2018, 170: 1-9. DOI: 10.1016/j.ress.2017.10. 009.

[7] VAHDANI H, MAHLOOJI H, JAHROMI A E. Warranty servicing for discretely degrading items with non-zero repair time under renewing warranty [J]. Computers & Industrial Engineering, 2013, 65(1): 176-185. DOI: 10.1016/j.cie.2011. 08.012.

[8] MONDAL S, PAL S, MANNA D K. Cost estimation under renewing warranty policy―An application [J]. Quality Engineering, 2003, 16(1): 93-98. DOI: 10.1081/QEN- 120020775.

[9] LI Xin-yue, JIA Yun-xian, WANG Peng, XIE Jian, GAO Qin-he, SI Xiao-sheng. Renewable warranty policy for multiple-failure-mode product considering different maintenance options [J]. Eksploatacja i Niezawodnosc- Maintenance and Reliability, 2015, 17(4): 551-560. DOI: 10.17531/ein.2015.4.10.

[10] SHAFIEE M, CHUKOVA S. Maintenance models in warranty: A literature review [J]. European Journal of Operational Research, 2013, 229(3): 561-572. DOI: 10.1016/j.ejor.2013.01.017.

[11] SHANG Li-jun, CAI Zhi-qiang. Optimal replacement policy of products with repair-cost threshold after the extended warranty [J]. Journal of Systems Engineering and Electronics, 2017, 28(4): 725-731. DOI: 10.21629/ JSEE.2017.04.12.

[12] SAHIN I, POLATOGLU H. Maintenance strategies following the expiration of warranty [J]. IEEE Transactions on Reliability, 1996, 45(2): 220-228. DOI: 10.1109/24. 510805.

[13] JUNG G M, PARK D H. Optimal maintenance policies during the post-warranty period [J]. Reliability Engineering & System Safety, 2003, 82(2): 173-185. DOI: 10.1016/ S0951-8320(03)00144-3.

[14] JUNG K M, HAN S S, PARK D H. Optimization of cost and downtime for replacement model following the expiration of warranty [J]. Reliability Engineering & System Safety, 2008, 93(7): 995-1003. DOI: 10.1016/ j.ress.2007.05.005.

[15] YEH R H, CHEN G C, CHEN M Y. Optimal age- replacement policy for nonrepairable products under renewing free-replacement warranty [J]. IEEE transactions on reliability, 2005, 54(1): 92-97. DOI: 10.1109/TR. 2004.841723.

[16] CHIEN Y H. A general age-replacement model with minimal repair under renewing free-replacement warranty [J]. European Journal of Operational Research, 2008, 186(3): 1046-1058. DOI: 10.1016/j.ejor. 2007.02.030.

[17] JUNG K M, PARK M, PARK D H. System maintenance cost dependent on life cycle under renewing warranty policy [J]. Reliability Engineering & System Safety, 2010, 95(7): 816-821. DOI: 10.1016/j.ress.2010.02.010.

[18] WU C C, CHOU C Y, HUANG C. Optimal burn-in time and warranty length under fully renewing combination free replacement and pro-rata warranty [J]. Reliability Engineering & System Safety, 2007, 92(7): 914-920. DOI: 10.1016/j.ress.2006.05.017.

[19] CHIEN Y H. A new warranty strategy: Combining a renewing free-replacement warranty with a rebate policy [J]. Quality and Reliability Engineering International, 2008, 24(7): 807-815. DOI: 10.1002/ qre.930.

[20] CHIEN Y H. Optimal age for preventive replacement under a combined fully renewable free replacement with a pro-rata warranty [J]. International Journal of Production Economics, 2010, 124(1): 198-205. DOI: 10.1016/j.ijpe. 2009.10.025.

[21] LIU Fan-mao, ZHU Hai-ping, LIU Bo-xing. Maintenance decision-making method for manufacturing system based on cost and arithmetic reduction of intensity model [J]. Journal of Central South University, 2013, 20(6): 1559-1571. DOI: 10.1007/s11771-013-1648-y.

[22] PARK M, JUNG K M, PARK D H. Optimal post-warranty maintenance policy with repair time threshold for minimal repair [J]. Reliability Engineering & System Safety, 2013, 111: 147-153. DOI: 10.1016/j.ress.2012.10.017.

[23] PARK M, JUNG K M, PARK D H. A generalized age replacement policy for systems under renewing repair- replacement warranty [J]. IEEE Transactions on Reliability, 2016, 65(2): 604-612. DOI: 10.1109/ TR.2015.2500358.

[24] PARK M, JUNG K M, PARK D H. Optimal maintenance strategy under renewable warranty with repair time threshold [J]. Applied Mathematical Modelling, 2017, 43: 498-508. DOI: 10.1016/j.apm.2016.11.015.

[25] TANG Sheng-jin, YU Chuan-qiang, FENG Yong-bao, XIE Jian, GAO Qin-he, SI Xiao-sheng. Remaining useful life estimation based on wiener degradation processes with random failure threshold [J]. Journal of Central South University, 2016, 23(9): 2230-2241. DOI: 10.1007/s11771-016-3281-z.

[26] BAI J, PHAM H. Repair-limit risk-free warranty policies with imperfect repair[J]. IEEE Transactions on Systems, Man, and Cybernetics-Part A: Systems and Humans, 2005, 35(6): 765-772. DOI: 10.1109/TSMCA.2005.851343.

[27] SAMATLI-PAC G, TANER M R. The role of repair strategy in warranty cost minimization: An investigation via quasi-renewal processes [J]. European Journal of Operational Research, 2009, 197(2): 632-641. DOI: 10.1016/j.ejor.2008. 06.034.

[28] LI Wen-jian, PHAM H. An inspection-maintenance model for systems with multiple competing processes [J]. IEEE Transactions on Reliability, 2005, 54(2): 318-327. DOI: 10.1109/TR.2005.847264.

[29] CHEN J A, CHIEN Y H. Renewing warranty and preventive maintenance for products with failure penalty post-warranty [J]. Quality and Reliability Engineering International, 2007, 23(1): 107-121. DOI: 10.1002/ qre.824.

(Edited by HE Yun-bin)

中文导读

考虑质保截止期的两阶段更新质保优化模型

摘要:更新质保可以为顾客提供更优质的服务,帮助企业赢得市场机会。但是,在工程实际中替换成本通常高于维修成本,制造商将面临如何降低质保服务成本的严峻挑战。本文提出一种考虑质保截止期的两阶段更新质保优化模型。在第一阶段,制造商提供带有截止期的更新质保(RWD),其中截止期表示累计运行时间阈值,当产品累积运行时间超出截止期时,在余下的质保期内制造商将会对产品采取最小维修。当第一段质保期满结束,制造商将提供具有有限维修次数限制的替换质保(RWLR)。文中以成本率最小为优化目标,从制造商的视角分别建立基于免费替换、按比例分摊质保的两阶段成本优化模型,通过求解模型得到最优质保期。文中通过案例验证所提出模型的有效性,并完成参数灵敏度分析。

关键词:截止更新质保;有限维修次数;最小维修;质保成本率

Foundation item: Project(71671035) supported by the National Natural Science Foundation of China

Received date: 2018-04-14; Accepted date: 2019-03-04

Corresponding author: SU Chun, PhD, Professor; Tel: +86-13851875437; E-mail: suchun@seu.edu.cn; ORCID: 0000-0002-5523-1469

Abstract: Renewing warranty can provide customers with better service, and thus help manufacturers to gain market opportunities. In engineering practice, the cost for replacement is usually higher than the cost for maintenance, hence manufacturers often face huge challenge to reduce the warranty service cost. With consideration of the warranty deadline, we propose a two-stage optimization model for renewing warranty. In the first stage, a renewing warranty with deadline (RWD) policy is implemented, where the deadline represents the cumulative uptime threshold. When the cumulative uptime exceeds the deadline, the product will be minimally repaired and kept to the residual warranty period. When RWD is expired, the replacement warranty with limited repairs (RWLR) policy is applied. Under the free replacement and pro-rata warranty policy, the corresponding two-stage cost optimization model is established from the manufacturer’s perspective, the aim is to minimize the cost rate and obtain the optimal warranty period. A numerical example is provided to illustrate the validity of the proposed model, and the sensitivity analysis is also carried out.