网络首发时间: 2015-10-27 13:39

Sn对Mg-Al-Ca系合金热裂敏感性的影响

沈阳工业大学材料科学与工程学院

摘 要:

为了研究Sn对Mg-Al-Ca系合金热裂敏感性的影响,通过Clyne-Davies模型对MgAl7Ca1Snx(x=0,0.5,1,2)系合金的热裂敏感性进行预测。采用“T”型热裂模具,对MgAl7Ca1Snx系合金凝固过程中的温度、收缩应力信号数据进行采集,研究热裂纹萌生和扩展的相关信息。利用X射线衍射(XRD)和扫描电子显微镜(SEM)分别对MgAl7Ca1Snx系合金显微组织和热裂断口区域形貌进行观察。揭示合金的凝固最后阶段剩余液相分数,脆弱区域的凝固温度变化,第二相种类等因素对Mg Al7Ca1Snx系合金热裂倾向的影响;合金热裂倾向从大到小顺序为MgAl7Ca1Sn1>MgAl7Ca1Sn2>MgAl7Ca1Sn0.5>MgAl7Ca1。其中,由于Mg Al7Ca1Sn1合金凝固温度区间最宽,脆弱区域的凝固温度变化最大,凝固最后阶段形成液膜最少,枝晶干涉点后析出的第二相阻碍枝晶间的补缩等多种原因使之热裂倾向最大。

关键词:

Mg-Al-Ca-Sn合金;热裂敏感性;收缩应力;凝固曲线;

中图分类号: TG146.22

作者简介:王博(1992-),男,辽宁铁岭人,硕士研究生,研究方向:镁合金材料及应用;E-mail:1372185963@qq.com;;刘正,教授;电话:13940138906;E-mail:zliu4321@vip.sina.com;

收稿日期:2015-08-31

基金:国家科技部“973”计划项目(2013CB632203);国家自然科学基金项目(51571145);辽宁省创新团队项目(LT2013004);辽宁省科技攻关计划项目(2013979)资助;

Hot Tearing Susceptibility of Mg-Al-Ca Alloy with Different Sn Additions

Wang Bo Liu Zheng Mao Pingli Wang Zhi Wang Feng

School of Materials Science and Engineering,Shenyang University of Technology

Abstract:

In order to clarify the effect of Sn element on the hot tearing susceptibility of Mg-Al-Ca alloy,the hot tearing susceptibility of Mg Al7Ca1Snx( x = 0,0. 5,1,2) alloys was evaluated by thermodynamic calculations based on Clyne Davies model. The solidification temperature and shrinkage stress during the solidification of MgAl7Ca1Snx alloys in the“T”type hot tearing permanent-mold were acquired with the attached computer. The microstructure and morphology of hot tearing regions of the alloys were observed by X-ray diffraction( XRD) and scanning electron microscopy( SEM). The affecting factors of hot tearing susceptibility of MgAl7Ca1Snx alloys,such as the variation of solid fraction in vulnerable region,the residual liquid fraction in the final stage,the type of the second phase of the alloys were discussed based on the above calculation and observation. The results demonstrated that the hot tearing susceptibility in the investigated alloys was found as follows: Mg Al7Ca1Sn1>MgAl7Ca1Sn2> MgAl7Ca1Sn0.5> MgAl7Ca1. The highest hot tearing susceptibility of MgAl7Ca1Sn1 alloy resulted from the following factors: the largest freezing range,the biggest changing of the variation of solid fraction in vulnerable region,the least liquid film in the final stage of solidification,the formation of the second phase which worsenedthe liquid flow and interdendritic feeding after dendrite coherency.

Keyword:

Mg-Al-Ca-Sn alloys; hot tearing susceptibility; shrinkage stress; solidification curve;

Received: 2015-08-31

镁及镁合金被誉为“21世纪绿色工程材料”

近年来的研究表明,Ca,Sn元素加入到Mg-Al系合金中可明显改善其组织及性能

1 实验

本次试验采用Mg Al7Ca1Snx(x=0~2)合金作为试验材料,其中合金的主要原料是Mg锭(99.95%)、Al锭(99.98%)、Sn粒(99.98%)、Ca以Mg-30%Ca中间合金的方式加入。所设计的合金名义成分如表1所示。

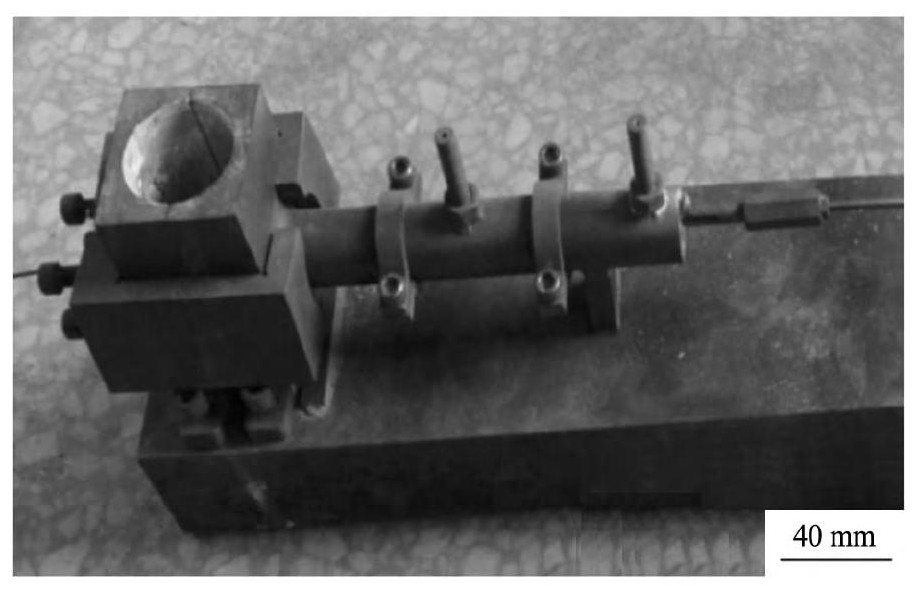

为研究不同Sn含量对Mg-Al-Ca系合金热裂敏感性的影响,采用井式坩埚电阻炉制备了不同Sn含量的Mg-7Al-1Ca-x Sn(x=0,0.5,1,2;%,质量分数)合金。合金熔炼采用浓度99.8%氮气和浓度为0.2%六氟化硫作为保护气体,以1.6L·min-1的气体流速不断通入井式坩埚炉中。实验采用“T型”模具。模具采用H13钢制成,几何形状如图1所示,模具左半部分由左右两半模块组成,并在外围用两个金属套加固,以防止实验时在高温金属液浇入直浇道时金属液从模具缝隙流出。

本实验所采用的热裂检测装置利用模拟信号与数字信号的转换,用计算机对被测合金的凝固温度和时间、凝固收缩应力等数据进行实时测量收集,如图2。实验中采用Lab View软件对采集数据进行显示。

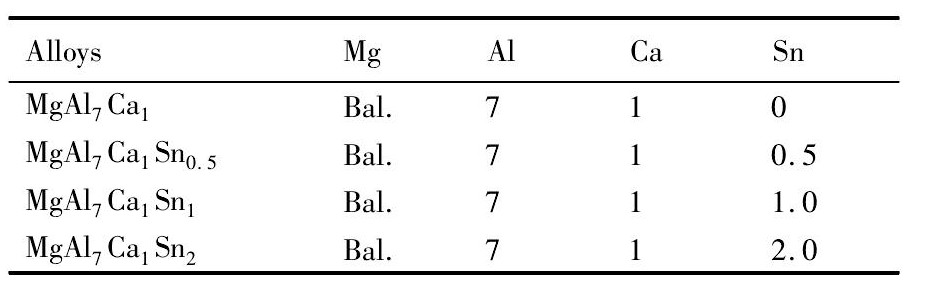

表1 试验合金的化学成分Table 1 Chemical compositions of tested alloys(%,mass fraction) 下载原图

表1 试验合金的化学成分Table 1 Chemical compositions of tested alloys(%,mass fraction)

图1 实验所用到的热裂模具Fig.1 Schematic of mold for hot tearing

基于Clyne-Davies模型

式中,tV为应力释放过程易脆弱阶段的时间;tR为应力释放过程应力松弛阶段的时间。

图2 镁合金热裂测试系统示意图Fig.2 Schematic of experimental setup

1-Alloy temperature feedback;2-Mold temperature feedback at centre;3-Mold temperature feedback at back;4-Solidification shrinkage stress feedback;5-Stress Test rod;6-Stress Sensor;7-Digital to analog converter

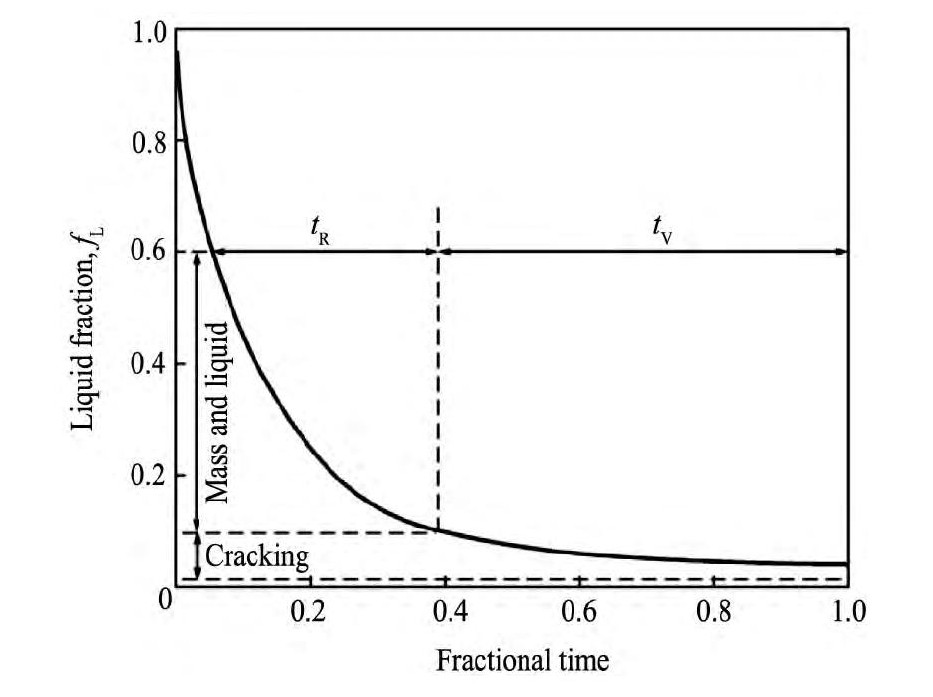

如图3所示,应力松弛阶段时间tR与易脆弱阶段时间tV的关系和计算方法是由实验测得的合金凝固冷却曲线换算而成的液相分数与凝固时间关系曲线确定的。具体计算方法如图3所示。

2 结果与讨论

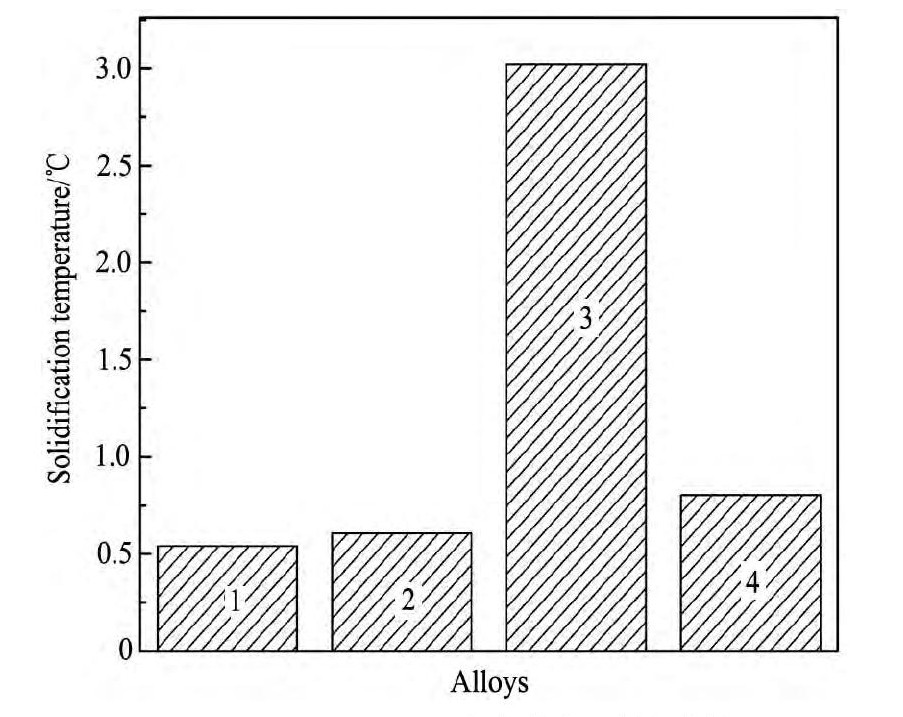

图4所示是以CSC参数评定的Mg Al7Ca1Snx系合金的热裂敏感性,通过图4可以发现Mg Al7Ca1Snx系合金的CSC参数从大到小的顺序为:CSC(Mg Al7Ca1Sn1)>CSC(Mg Al7Ca1Sn2)>CSC(Mg Al7Ca1Sn0.5)>CSC(Mg Al7Ca1)。即,Mg Al7Ca1Sn1合金热裂倾向最大,Mg Al7Ca1合金热裂倾向最小。

图3 应力松弛阶段时间tR与易脆弱阶段时间tV的测量方法示意图Fig.3 Method of determination of stress relaxation time tRand vulnerable time tVfrom plot of variation of liquid frac-tion with fractional time

图4 MgA l7Ca1Snx合金的热裂敏感性Fig.4 Hot tearing susceptibility of MgA l7Ca1Snxalloys

1-MgA l7Ca1;2-MgA l7Ca1Sn0.5;3-MgA l7Ca1Sn1;4-MgA l7Ca1Sn2

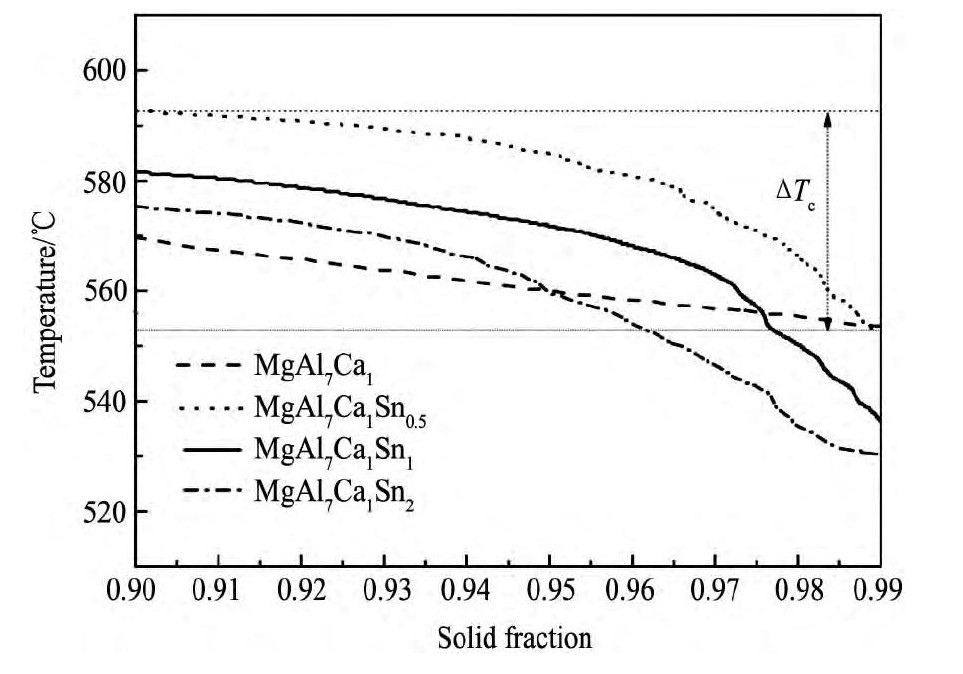

图5所示的是在Clyne和Davies定义的合金脆弱区域内凝固温度区间ΔTc与合金固相分数变化的关系曲线图。在此阶段残余液相所占比例极小,枝晶分离得到的补缩量会很低,所以ΔTc温度区间越大,越容易形成热裂。从图5中可以看出,Mg Al7Ca1和Mg Al7Ca1Sn0.5的ΔTc相对较小,分别为20和39℃,Mg Al7Ca1Sn2的ΔTc值为46℃,而Mg Al7Ca1Sn1的ΔTc值最大为48℃,这表明其在枝晶分离阶段中得到收缩量最大,热裂纹非常易于形成。一般而言,热裂倾向与凝固温度区间成正比关系,而与凝固最后阶段剩余液相分数成反比,即较小的凝固温度区间,较高的剩余液相分数,凝固收缩过程中液膜补缩越大,会使得合金的热裂倾向越小

Mg Al7Ca1Snx合金断口的X射线衍射(XRD)图谱见图6,从图6中谱线可以看出,Mg Al7Ca1Snx合金除了都含α-Mg相外,主要由Mg17Al12相组成,Mg Al7Ca1合金中还含(Mg,Al)2Ca相[20]。合金中Sn含量为0.5%时,Ca Mg Sn相的衍射峰被检测到,而(Mg,Al)2Ca相衍射峰消失。由此可以推断出在Mg-Al-Ca合金中加入0.5%的Sn可以抑制(Mg,Al)2Ca的立即产生,转而生成三元Ca Mg Sn相。当Sn的加入量提高至1%和2%时,在合金Mg Al7Ca1Sn1和合金MgA l7Ca1Sn2中检测到了Mg2Sn衍射峰,而且第二相的数量逐渐增多。

图5 脆弱区域的凝固温度变化ΔTc随固相分数变化曲线Fig.5 Relationship between solidification temperature and sol-id fraction in vulnerable region

图6 MgA l7Ca1Snx合金的XRD图谱Fig.6 XRD patterns of MgA l7Ca1Snxalloys

(1)MgA l7Ca1;(2)MgA l7Ca1Sn0.5;(3)MgA l7Ca1Sn1;(4)MgA l7Ca1Sn2

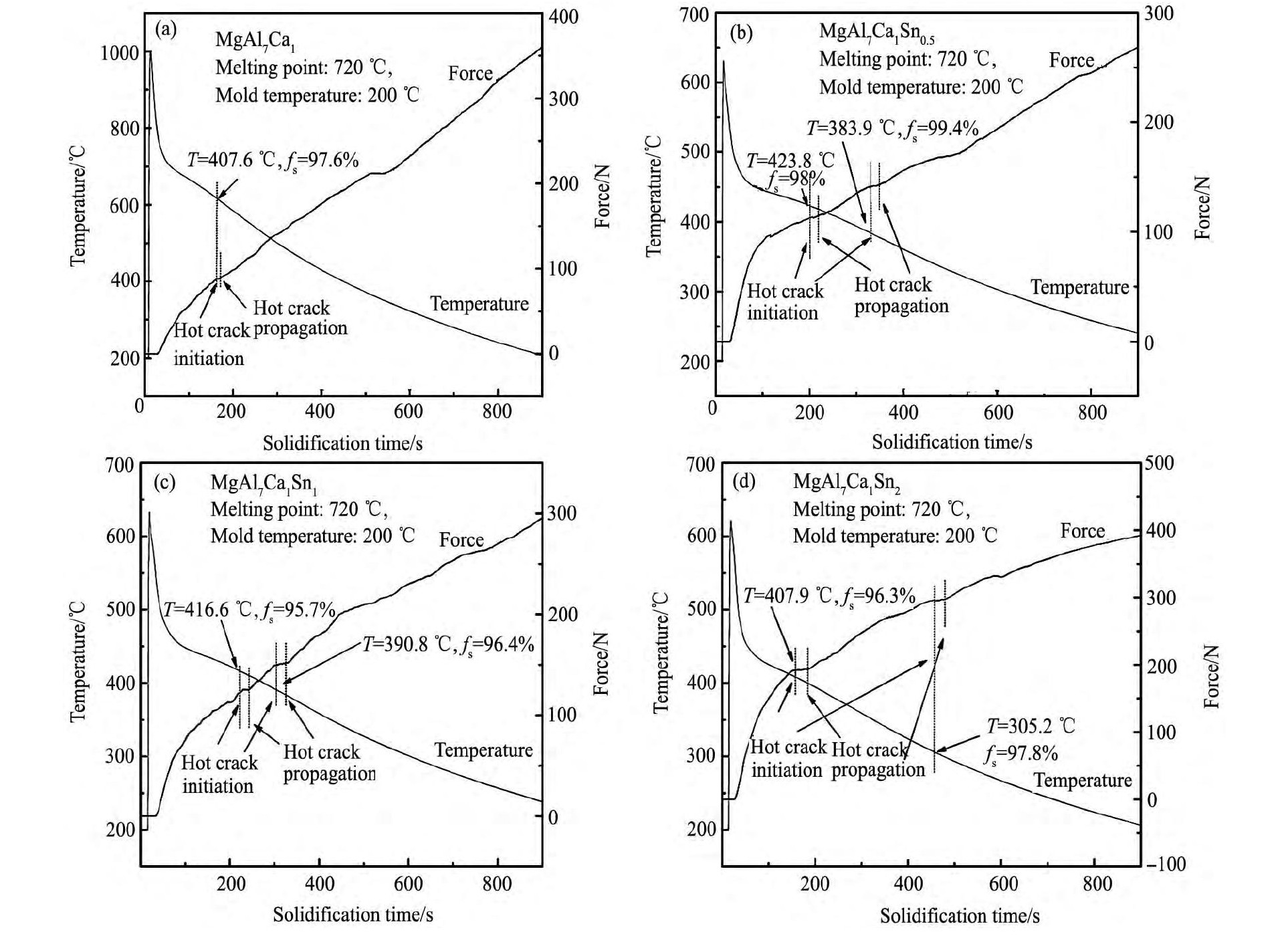

在凝固过程中,由液相转变为固相时,必然产生体积收缩,形成了收缩应力导致合金出现热裂现象。通过测量合金凝固收缩过程中形成的应力释放的大小来定性和定量地分析成分不同的合金的热裂行为。图7(a)为Mg Al7Ca1合金的凝固收缩应力与凝固温度的关系曲线,如图7(a)所示在407.6℃、固相分数(fs)97.6%时出现了应力下降的情况,产生裂纹,但凝固收缩应力的松弛情况较为平缓,而且没有出现二次裂纹,该合金在凝固最后阶段残留液相对分离枝晶的填充和愈合比较充分,合金的热裂倾向较小。如图7(b)为Mg Al7Ca1Sn0.5合金的凝固收缩应力与凝固温度的关系曲线。如图7(b)所示,凝固开始阶段,应力上升速度很快,在423.8℃、固相分数96.8%时应力出现急剧的减小,此时裂纹开始生成,形成一次裂纹,而在温度383.9℃、固相分数99.4%时凝固应力又出现了快速减小,形成了二次裂纹。初始裂纹生成时,液相成分是相对比较高,所以裂纹可以得到补缩;随着凝固的进行,由三元共晶相组成的液膜较薄,能够承受的凝固收缩应力较小,因此,产生第二次微裂纹。如图7(c),在416.6℃、固相分数95.7%时Mg Al7Ca1Sn1合金的凝固收缩应力曲线发生急剧上升,并且一直处于高收缩应力状态。这是因为在凝固过程中析出的第二相成网格状分布,降低了枝晶间残余液相的流动性,使得枝晶间的补缩比较困难,使得在液相剩余较多的情况下出现热裂纹。在390.8℃、固相分数96.4%时合金发生第二次热裂行为。图7(d)是Mg Al7Ca1Sn2合金的凝固收缩应力与凝固温度的关系曲线。如图7所示,凝固开始阶段,凝固时间和收缩应力曲线同时增大,在407.9℃、固相分数96.3%以及305.2℃、固相分数97.8%时应力出现下降,但是应力松弛程度低,幅度较小。这是由于随着Sn含量的增加,各元素组成的共晶相的含量增加,使得形成的液膜抵抗收缩应力的能力提高,使得凝固收缩应力曲线应力松弛的幅度明显减小。

图7 MgA l7Ca1Snx合金凝固收缩应力与凝固温度关系曲线Fig.7 Contraction force and temperature as function of time for MgA l7Ca1Snxalloys

(a)MgA l7Ca1;(b)MgA l7Ca1Sn0.5;(c)MgA l7Ca1Sn1;(d)MgA l7Ca1Sn2

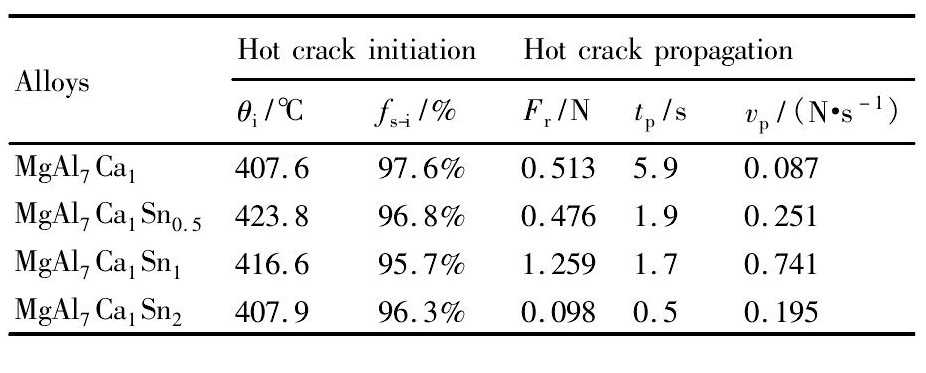

在合金凝固的过程中,如果残余液相不能及时将已经分离的枝晶进行弥合,则分离枝晶形成了微裂纹便会在凝固收缩应力的作用下开始扩展。在凝固收缩应力的持续作用下,当合金由于枝晶分离而得不到有效液体补缩,已经形成的热裂纹便开始扩展。因此通过分析测得的凝固收缩应力随时间的变化曲线也可以得到裂纹的扩展情况。表2给出了Mg Al7Ca1Snx系合金热裂的起始和扩展阶段的实验分析数据。从表2中的实验数据可以得出热裂从开始到终止详细情况,如,热裂产生的起始温度、固相分数、应力松弛情况及持续时间和速率。因为凝固收缩应力决定了裂纹的形成及扩展,所以用凝固收缩应力的变化率反应裂纹的扩展速率,其单位为N·s-1。对于Mg Al7Ca1和Mg Al7Ca1Sn0.5来说,裂纹在较高的固相分数下开始形成,枝晶已经完成相互连接,合金内部已经形成一个具有较高的抵抗凝固收缩应力的整体结构,使得刚刚萌生的裂纹扩展速度明显降低,随着Sn含量的增加,Mg Al7Ca1Sn1合金中第二相粒子不断析出并以网格状形式生长,其结构明显降低了枝晶间残余液相的流动性,使得枝晶间补缩非常困难,所以在较低的固相分数下初始裂纹就产生了。θi表示裂纹开始形成的温度;fs-i是裂纹开始时形成的固相分数;Fr是在裂纹扩展过程中应力松弛;tp是裂纹扩展时间;vp是裂纹扩展速率。虽然有较多液相对其进行补缩,但其糊状区的强度远低于收缩应力,于是使得裂纹扩展较快。而对于Mg Al7Ca1Sn2,随着Sn含量的逐渐增大,有大量的Mg2Sn颗粒相析出,由于Mg2Sn颗粒相显微硬度和熔点高,热稳定性好,因而对基体具有有效的弥散强化作用,能够降低该区域α-Mg相的晶粒尺寸,使得残余液相的畅通的补缩通道持续时间延长,进而提高了合金晶间的补缩能力,所以初始裂纹产生后会很好地进行补缩,使得裂纹的扩展速度大大降低。

表2 MgA l7Ca1Snx系合金热裂的形成及扩展情况分析Table 2Information about initiation and propagation of hot tearing for MgA l7Ca1Snxalloys 下载原图

表2 MgA l7Ca1Snx系合金热裂的形成及扩展情况分析Table 2Information about initiation and propagation of hot tearing for MgA l7Ca1Snxalloys

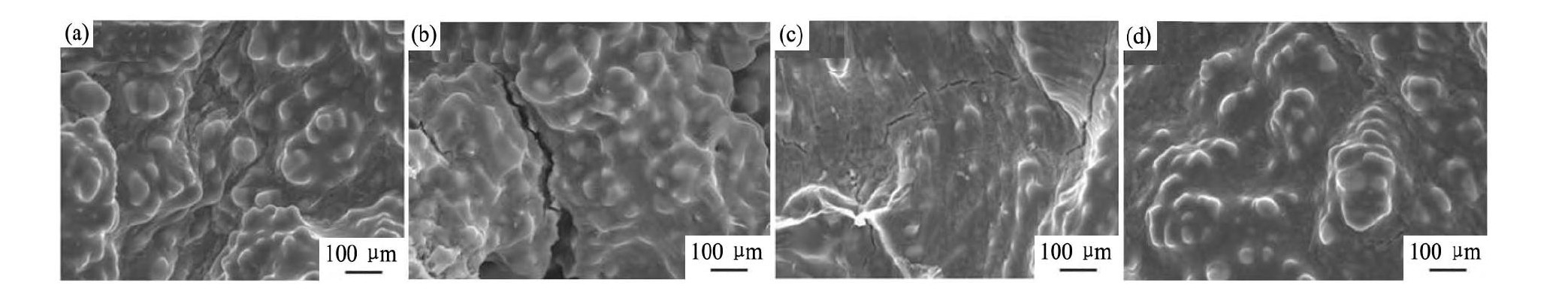

图8所示为Mg Al7Ca1Snx系合金裂纹表面液膜-枝晶分离的扫描电镜(SEM)形貌,从图8中可见,在裂纹表面上附着有一层液膜,这是由于在枝晶的分离阶段,低熔点相在枝晶表面形成液膜,而液膜又在凝固过程中最后凝固,所以会在裂纹表面发现液膜的存在。图8(a)为Mg Al7Ca1合金的热裂纹表面形貌,可以在裂纹表面观察到液膜的存在,但是液膜的厚度很薄,这是由于合金中的Ca元素的质量分数较小导致在近固相线时形成的低熔点共晶相较少,最终导致裂纹的生成。图8(b)为Mg Al7Ca1Sn0.5合金的热裂纹表面形貌,由于该合金Sn含量较少,所以低熔点的共晶相的析出量较少,致使在晶界偏聚形成的液膜较薄。液膜的强度远低于凝固收缩应力的强度,所以仅观察到有少量的液膜被拉伸痕迹。图8(c)为Mg Al7Ca1Sn1合金的热裂纹表面形貌,因为合金的枝晶干涉点温度较高,所以阻碍了液相在枝晶间的流动。虽然可以明显观察到低熔点共晶相在晶界偏聚的数量明显增多,并且从液膜形成的褶皱程度看其厚度也明显增加,但是得不到及时补缩的分离的枝晶无法抵抗凝固收缩应力对其的拉扯,所以留下了许多没有得到填充的微裂纹,使得合金热裂倾向较大。图8(d)为Mg Al7Ca1Sn2合金的热裂纹表面形貌,此时Sn含量增多,有大量的Mg2Sn析出,较好地抑制了α-Mg的过分长大,晶粒也明显减小,使得合金的热裂倾向性明显降低。

图8 MgA l7Ca1Snx合金裂纹表面液膜-枝晶分离形貌Fig.8 SEM images of dendrite and liquid film separation for MgA l7Ca1Snxalloys

(a)MgA l7Ca1;(b)MgA l7Ca1Sn0.5;(c)MgA l7Ca1Sn1;(d)MgA l7Ca1Sn2

3 结论

1.以CSC参数评定的Mg Al7Ca1Snx系合金的热裂敏感性,从大到小的顺序为:CSC(Mg Al7Ca1Sn1)>CSC(Mg Al7Ca1Sn2)>CSC(Mg Al7Ca1Sn0.5)>CSC(Mg Al7Ca1),即Mg Al7Ca1Sn1合金热裂倾向最大,Mg Al7Ca1合金热裂倾向最小。

2.Sn含量对Mg Al7Ca1Snx系合金的热裂敏感性有显著的影响,Sn含量较少时最后凝固阶段枝晶间剩余液相形成的第二相阻碍枝晶间残余液相的流动,增大了合金的热裂倾向。当合金中的Sn含量较多时,会析出大量的Mg2Sn颗粒相,Mg2Sn颗粒相抑制α-Mg的枝晶生长,使晶粒得到细化,增大液膜抵凝固抗收缩应力的能力;使得残余液相畅通补缩的通道的持续时间延长,降低了合金的热裂倾向。

3.凝固路径的特征对Mg Al7Ca1Snx合金的热裂敏感性大小有着重要的作用。Mg Al7Ca1Sn1的凝固温度区间在四种合金中最长,凝固最后阶段剩余液相最少,脆弱区域的凝固温度变化ΔTc最大,所以该合金的热裂倾向在4种合金中最大。

参考文献