网络首发时间: 2017-03-29 13:53

析出相对GH141宏观残余应力的影响

北京科技大学材料科学与工程学院

摘 要:

通过小孔法和场发射扫描电镜 (FE-SEM) 分别测试观察了GH141高温合金在不同过时效温度下残余应力的变化和γ'析出相形态的演变, 研究了微观析出相的改变对宏观残余应力的影响。结果表明, 只有一次过时效处理时, 选择10个温度实验点, 随着温度从1000℃降低到810℃, 残余应力数值从54 MPa逐渐增大到98 MPa, 增加了81%, 且增长速度总体呈现先快后慢的趋势。微观统计分析表明, γ'析出相数量及体积分数这两者变化趋势与残余应力变化趋势相一致;在有多次时效工艺处理时, 第一次时效温度越低, γ'相体积变小且数量增多, 第二次时效温度越低, γ'相体积不变而数量增多。残余应力的测试结果表明, 只有γ'相体积分数与残余应力变化趋势一致。经对比分析得出结论, 在析出应力占主导的情况下, γ'析出相体积分数是影响GH141宏观残余应力变化的唯一微观因素。

关键词:

中图分类号: TG132.3

作者简介:刘谨 (1989-) , 男, 湖北仙桃人, 博士研究生, 研究方向:金属材料残余应力及微观表征研究;E-mail:liujin19890214@si-na.com;;赵志毅, 教授;电话:13311019097;E-mail:zhaozhiyi@263.net;

收稿日期:2016-12-12

基金:“十三五”国家重点研发计划项目 (2016YFB0300200) 资助;

Effect of Precipitates on Macroscopic Residual Stress of GH141

Liu Jin Zhao Zhiyi Xue Rundong

School of Materials Science and Engineering, University of Science and Technology Beijing

Abstract:

Evolution of residual stress and precipitate pattern of GH141 superalloy under overaging treatments at different temperatures were tested by hole drilling method and field emission scanning electron microscopy ( FE-SEM) . Effect of microscopic precipitates on macroscopic residual stress of GH141 was studied. The results indicated that under once overaging treatments, as the ten temperature points reduced from 1000 to 810 ℃, residual stress value increased gradually from 54 to 98 MPa, increased by 81% and the tendency of increase hurry first then slow. Microscopic statistical analysis showed that the variation of the particle number and volume fraction of γ' precipitates was consistent with residual stress. Under multiple overaging treatments, the low first aging temperature made theγ' grain minify and quantity increased, whereas the low second aging temperature raised the particle number but volume invariant. The variation of the volume fraction of γ' precipitates was the only one consistent with residual stress. Come to the conclusion by contrast analysis, in the case of precipitation stress hold a dominant position, the variation of the volume fraction of γ' precipitates was the one and the only one microscopic factor consistent with residual stress.

Keyword:

GH141; aging; stress; precipitate;

Received: 2016-12-12

GH141高温合金是一种沉淀强化型高温高强度合金[1], 具有良好的时效强化作用[2]。现阶段对其研究主要集中在高温性能及组织控制上[3,4,5,6]。它作为焊接材料在焊接完成后需要进行热处理, γ'相作为强化相在析出时消耗了γ基体中的Al和Ti导致点阵常数的减小而出现净收缩, 这种收缩会导致高应力的出现, 加剧了材料应力应变集中, 其粗化行为能显著影响镍基高温合金的高温性能[7], 它是镍基高温合金中的研究重点[8,9]。若应变集中在过热区的晶粒边界上, 当晶界的变形能力不足以承受金属内部产生的应变时, 就会产生应变时效裂纹[10,11]。研究者们对焊接裂纹做了相应研究[12,13,14], 但鲜有提及残余应力这个关键的因素。有研究指出焊接前对GH141进行过时效是减少应变时效裂纹行之有效的方法[15]。为研究其原因, 本文在前人研究基础上, 设计一次过时效及多次时效工艺, 研究两种工艺下宏观残余应力的变化趋势以及微观γ'相的形态演变, 并将这两者进行关联分析, 为焊前过时效工艺的设计提供进一步的理论基础。

1实验

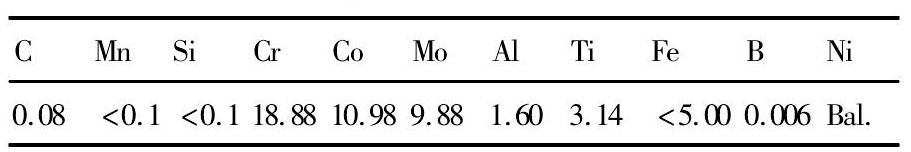

实验用材料为GH141高温合金, 化学成分如表1所示。

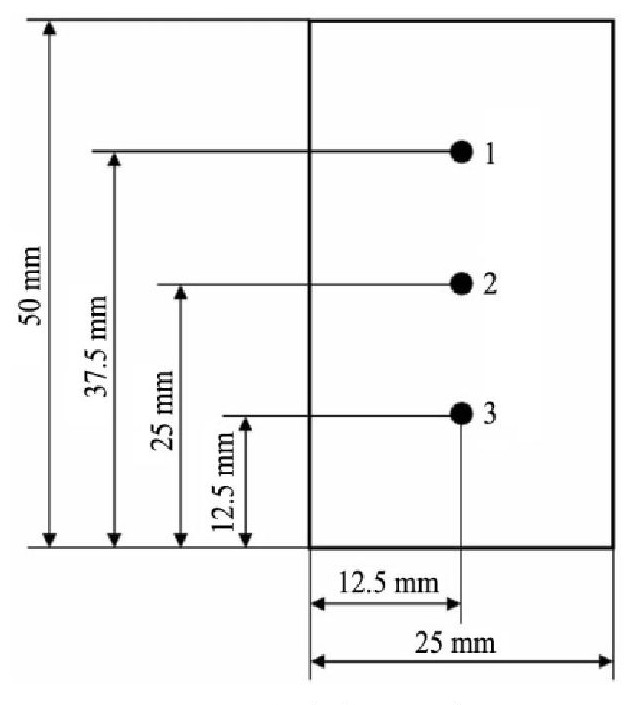

将试样线切割成50 mm×25 mm×10 mm大小。分别进行对应热处理, 热处理完成后用小孔法进行残余应力测试, 每个试样测试3个点, 具体测试位置如图1所示。

应力测试过程:工件表面打磨清洗处理, 粘贴应变片, 导线连接, 仪器调试, 钻孔, 测试并读出释放应变, 代入公式计算残余应力。金相试样经过磨样、电解侵蚀后, 用场发射扫描电镜 (FE-SEM) 观察微观组织形貌。

2结果与讨论

2.1一次时效处理时温度的影响

参考实际过时效参数, 在固溶温度1080℃以下, 标准时效温度760℃以上为温度区间, 以20℃为温度梯度, 设置10组过时效温度参数来进行研究。具体热处理参数为:1080℃固溶0.5 h, 设定过时效温度处理4 h。10组过时效温度从编号1-10分别为1000, 980, 960, 930, 910, 890, 870, 850, 830, 810℃。

表1 GH141合金化学成分Table 1 Chemical compositions of GH141 (%, mass fraction) 下载原图

表1 GH141合金化学成分Table 1 Chemical compositions of GH141 (%, mass fraction)

图1 测试点位置示意图Fig.1 Schematic diagram of test points

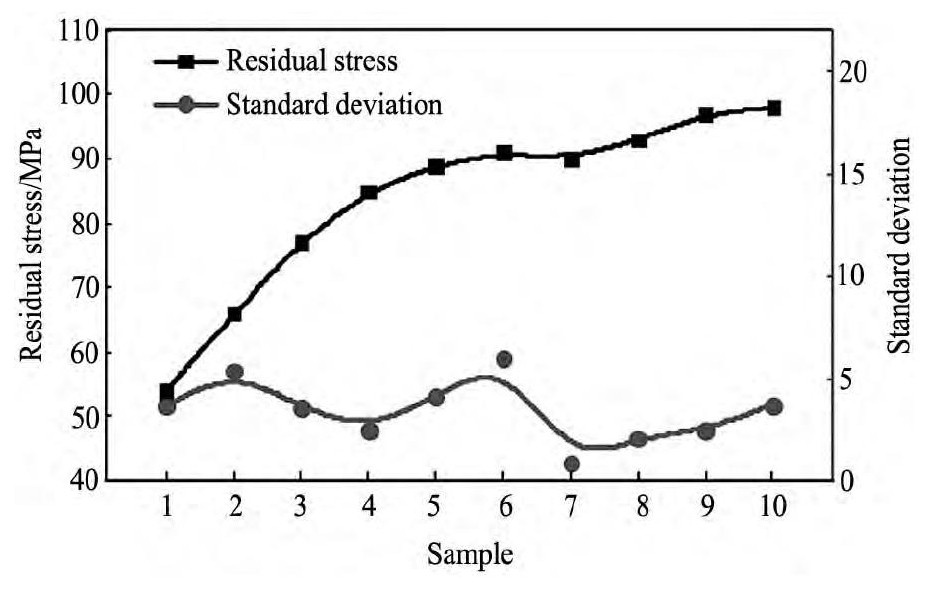

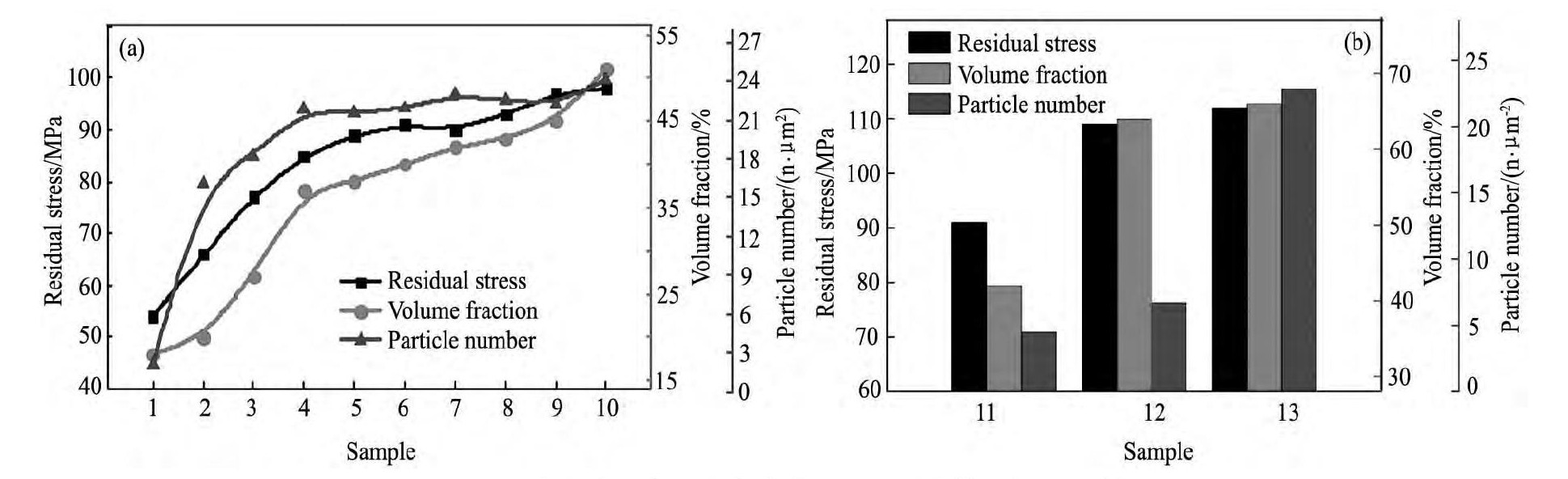

10组不同过时效温度试样, 每个试样选择3个点进行测试, 测试结果如表2所示。将平均值及标准差绘制成二维图, 如图3所示。

分析表2及图2, 从标准差数值可以看出, 测试结果的数据波动较小, 在可接受范围之内, 测试数据可靠。随着过时效温度的降低, 残余应力呈现出逐渐增加的趋势。试样1应力最小, 为54 MPa, 试样1到试样5增加幅度较大, 增加了35 MPa。试样5到试样10增加幅度较小, 仅增加了9 MPa。这说明过时效温度与残余应力大小之间存在对应关系, 且过时效温度越低, 残余应力数值越大, 增长速度总体呈现先快后慢的趋势。

表2 一次过时效不同温度下残余应力测试结果Table 2 Test results of residual stress under once overag-ing treatments at different temperatures 下载原图

表2 一次过时效不同温度下残余应力测试结果Table 2 Test results of residual stress under once overag-ing treatments at different temperatures

图2 一次过时效不同温度下残余应力测试结果Fig.2Test results of residual stress under once overaging treatments at different temperatures

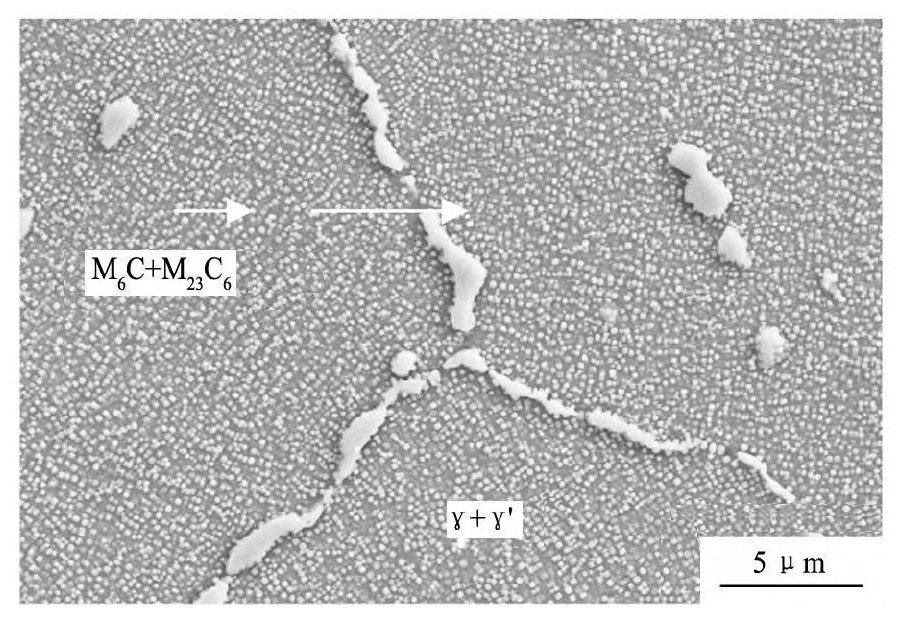

图3 典型GH141扫描电镜微观组织Fig.3 SEM image of representative microstructure of GH141

过时效处理后, 经过磨样、电解侵蚀, 用电镜观察微观组织形貌。典型的GH141高温合金组织如图3所示, 基体为面心立方的γ相, 主要强化相有γ'以及MC, M6C, M23C6型碳化物。其中γ'析出相较小, 经固溶时效之后在基体上密布, 从照片形貌上可以较容易辨认出γ'相。不同过时效温度处理下碳化物形态分布相似, 本文重点观察γ'析出相形态的演变。

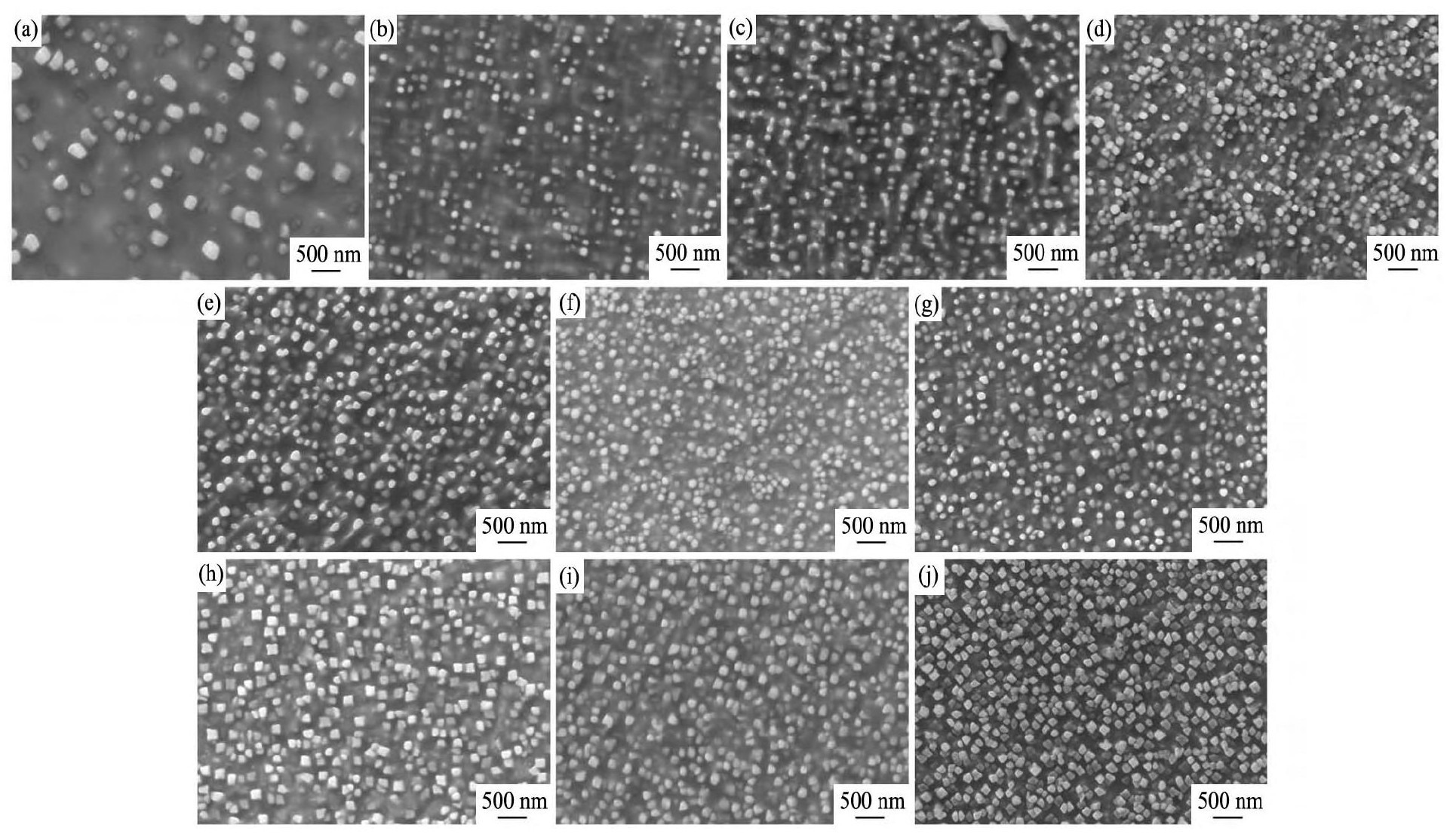

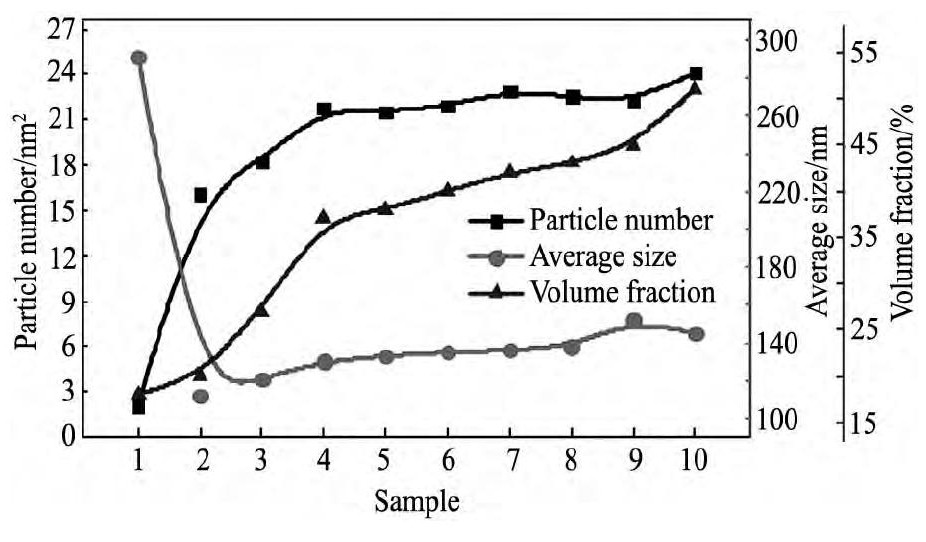

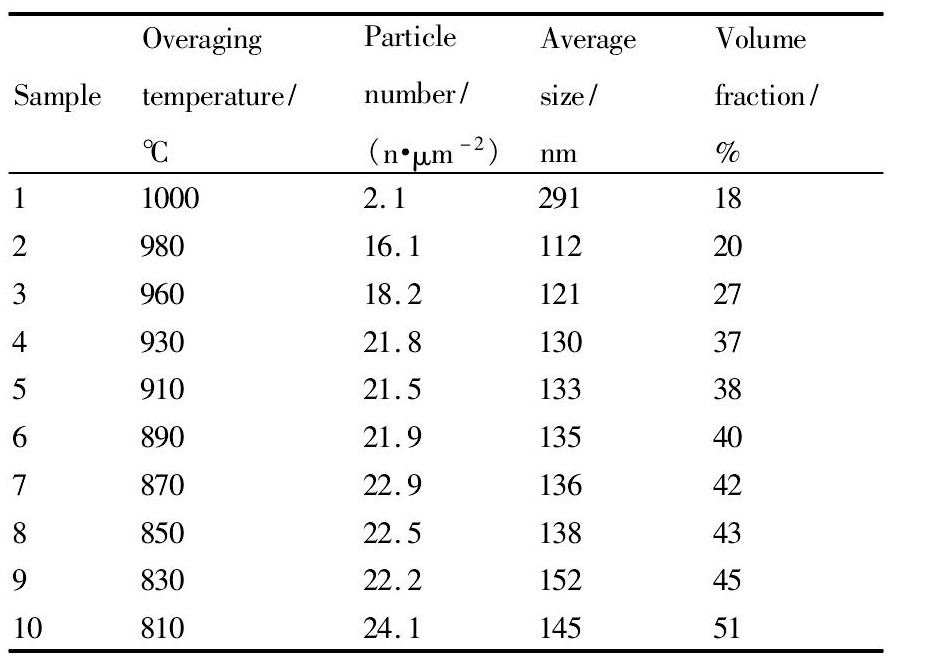

图4为一次过时效不同温度下γ'析出相形貌, 为对γ'析出相进行进一步的分析, 将其进行定量处理, 选取了四倍于金相图片尺寸大小区域先用Photoshop软件进行处理, 再用Image J软件对γ'相的颗粒数、平均晶粒尺寸及体积分数进行了测定。分析测试结果如表3所示, 将其绘制成二维图如图5所示。

表3 一次过时效不同温度下GH141高温合金γ'析出相定量分析Table 3 Quantitative analysis ofγ'phases in GH141 under once overaging treatments at different temperatures 下载原图

表3 一次过时效不同温度下GH141高温合金γ'析出相定量分析Table 3 Quantitative analysis ofγ'phases in GH141 under once overaging treatments at different temperatures

图4 一次过时效不同温度下GH141高温合金γ'析出相扫描电镜形貌Fig.4 SEM images ofγ'phases in GH141 superalloy under once overaging treatments at different temperatures

(a) Sample 1, 1000℃; (b) Sample 2, 980℃; (c) Sample 3, 960℃; (d) Sample 4, 930℃; (e) Sample 5, 910℃; (f) Sample 6, 890℃; (g) Sample 7, 870℃; (h) Sample 8, 850℃; (i) Sample 9, 830℃; (j) Sample 10, 810℃

图5 一次过时效不同温度下GH141高温合金γ'析出相定量分析Fig.5 Quantitative analysis ofγ'phases in GH141 under once overaging treatments at different temperatures

由表3及图4, 5可知, 在1000℃时效时, γ'相非常粗大, 而且数量很少。在温度从1000℃降至810℃的过程中, γ'相颗粒数开始时急剧上升, 到达930℃后上升趋势减缓, 然后缓慢平稳的上升。在颗粒数增加的同时, γ'相尺寸也在发生变化, 在1000℃时, γ'相尺寸为291 nm, 到980℃时, γ'相尺寸就降至112 nm, 然后随着温度的降低, 平均尺寸开始缓慢增大。γ'相体积分数受颗粒数和平均尺寸两者共同作用, 代表了γ'相在整个微观组织中所占比例, 它随着时效温度的下降稳定上升。

2.2多次时效处理时温度的影响

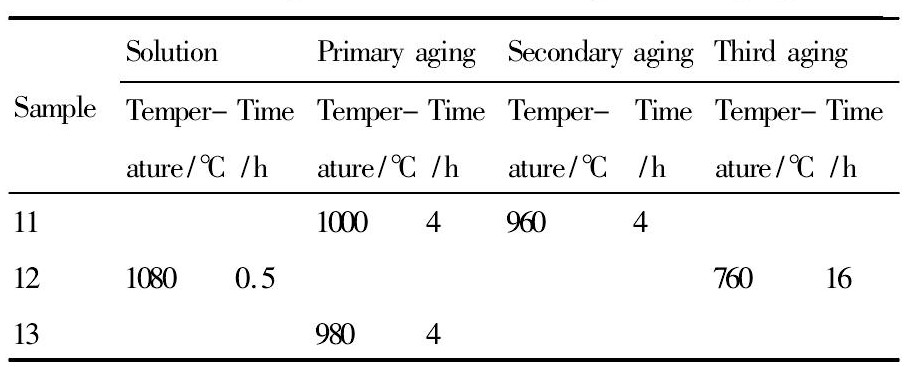

实际生产工艺中, 多采用多次时效工艺, 现参考实际生产工艺和以上研究, 选取了3种不同多次时效工艺来进行分析, 具体参数如表4所示。

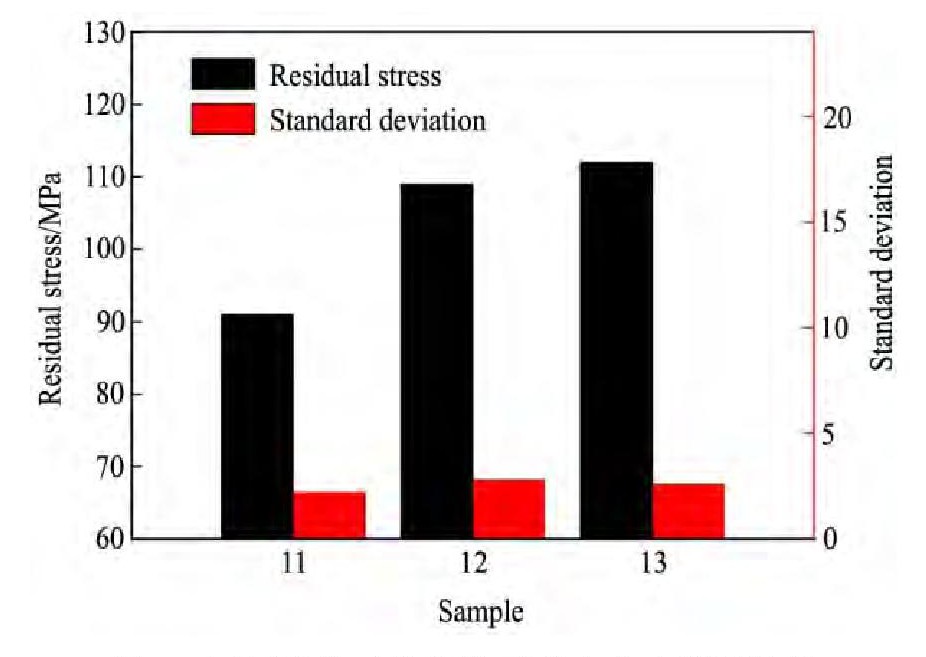

残余应力测试平均值及标准差如图6所示。

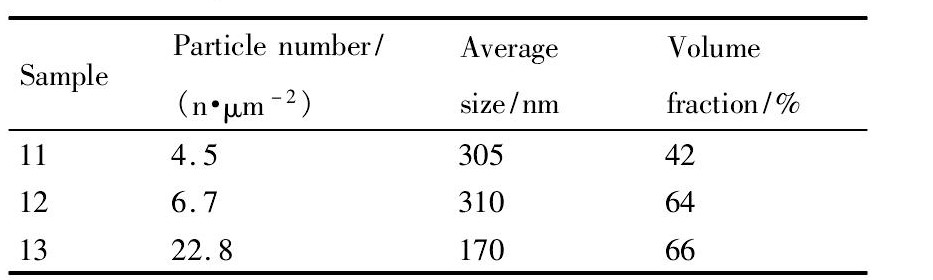

通过图6观察残余应力随着时效温度的变化, 首先对比时效温度的差别, 3者的3次时效温度都相同, 为760℃。试样11与12的一次时效温度相同而二次时效温度不同, 后者二次时效温度较低。试样12与13的二次时效温度相同而一次时效温度不同, 后者一次时效温度较低。试样11残余应力为91 MPa, 试样12比试样11残余应力高出18MPa, 试样13比试样12残余应力高3 MPa。对比分析可以得出结论:在其他工艺相同时, 时效温度越低, 残余应力越高。图7为γ'析出相形貌, 同样, 对γ'析出相进行定量分析, 分析测试结果如表5所示, 将其绘制成二维图如图8所示。

表4 多次过时效工艺参数Table 4 Process parameters of multiple overaging 下载原图

表4 多次过时效工艺参数Table 4 Process parameters of multiple overaging

图6 不同多次时效参数下残余应力测试结果Fig.6Test results of residual stress under multiple overaging treatments at different temperatures

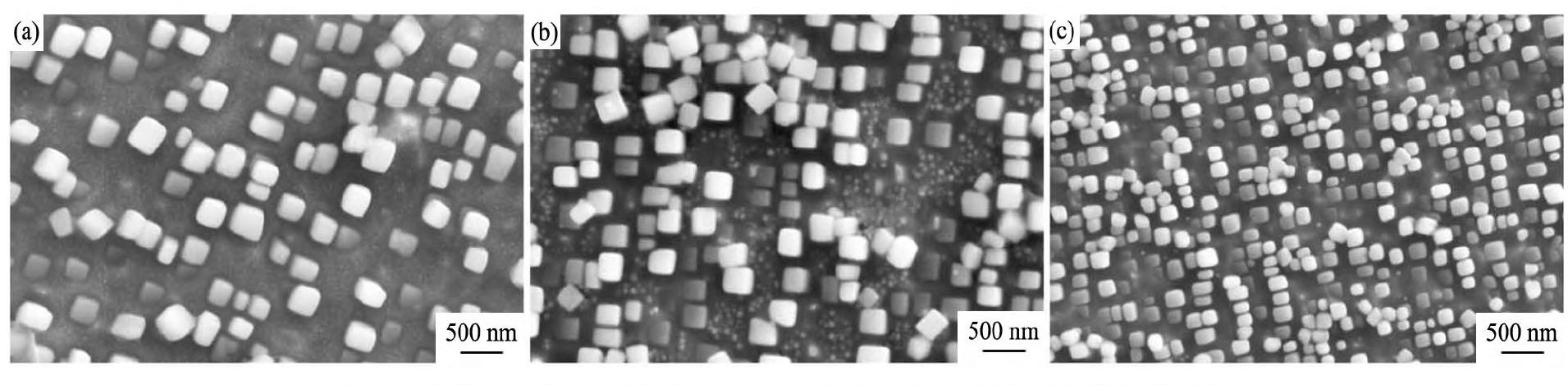

图7 多次过时效不同温度下GH141高温合金γ'析出相扫描电镜形貌Fig.7 SEM images ofγ'phases in GH141 superalloy under multiple overaging treatments at different temperatures

(a) Sample 11; (b) Sample 12; (c) Sample 13

表5 多次过时效不同温度下GH141高温合金γ'析出相定量分析Table 5Quantitative analysis ofγ'phases in GH141 un-der multiple overaging treatments at different temperatures 下载原图

表5 多次过时效不同温度下GH141高温合金γ'析出相定量分析Table 5Quantitative analysis ofγ'phases in GH141 un-der multiple overaging treatments at different temperatures

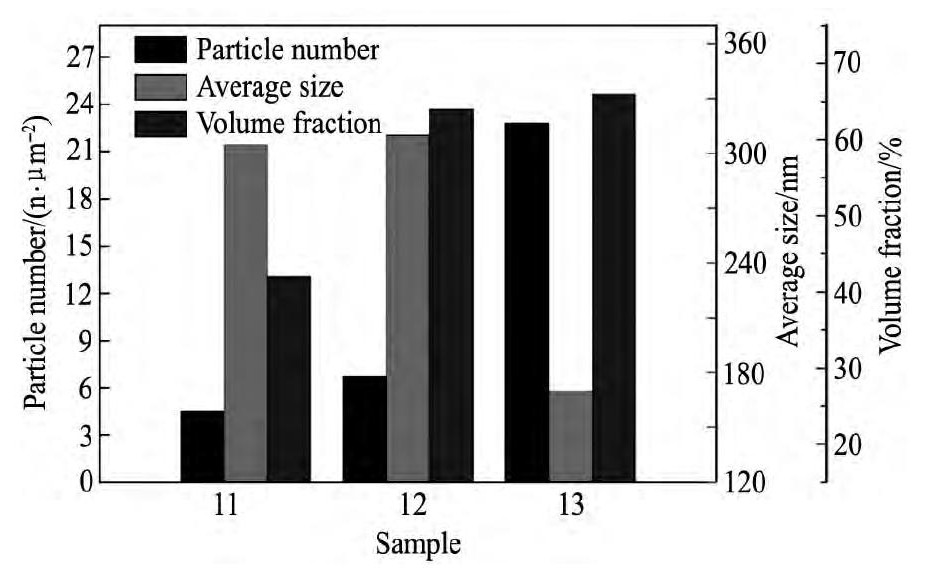

图8 多次过时效不同温度下GH141高温合金γ'析出相定量分析Fig.8 Quantitative analysis ofγ'phases in GH141 under mul-tiple overaging treatments at different temperatures

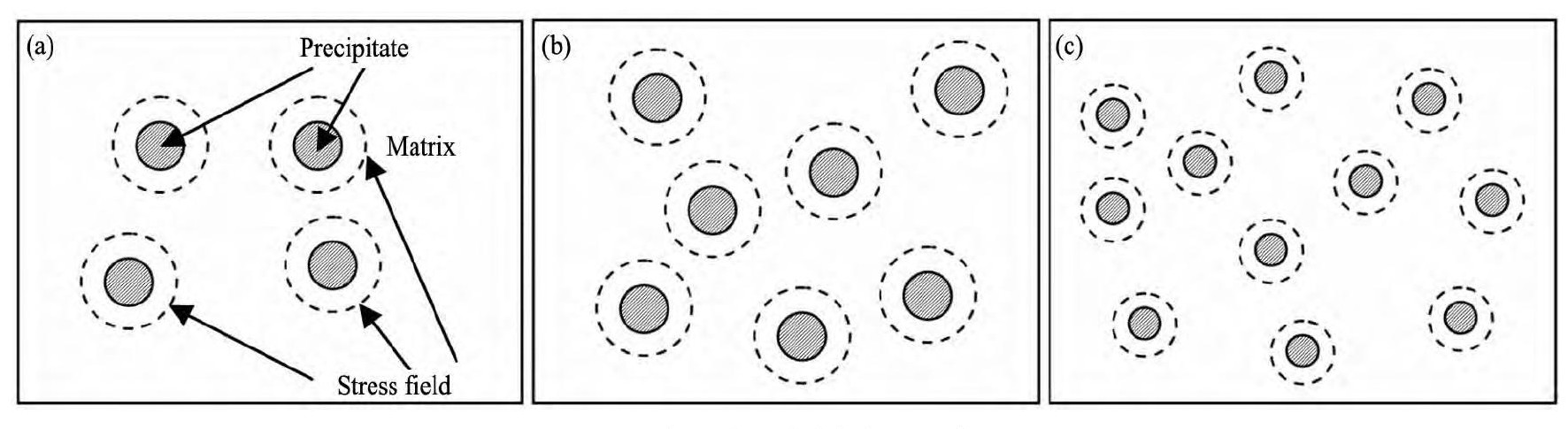

由图7观察γ'析出相可以明显看出3组试样的不同, 经过整个过时效工艺, 形成了两种形态的γ'相, 一种比较粗大, 一种细小, 弥散分布在粗大γ'相之间。一次时效为1000℃时效, 形成很大的立方形γ'相, 而一次时效为980℃时效形成的γ'相尺寸较小, 且数量更多。二次时效为960℃时效时, γ'相数量较少, 而二次时效为870℃时形成的γ'相数量较多。

2.3讨论

首先分析一次过时效处理过程。对比随着过时效温度的降低残余应力的变化 (图2) 以及γ'析出相3种参数的变化 (图5) , 可以发现残余应力的变化趋势与γ'相颗粒数以及体积分数的变化趋势相似。将三者放在同一张图里进行对比, 如图9 (a) 所示。残余应力与γ'相数量及体积分数都呈正相关关系。其次, 在多次时效处理时, 残余应力、γ'相颗粒数及γ'相体积分数三者之间的对比关系如图9 (b) 所示, 其中残余应力仍然与γ'相体积分数保持正相关关系, 却与γ'相颗粒数失去正相关关系。分析其原因, 不同温度下一次过时效处理时, γ'相平均尺寸差别较小, 而不同温度下多次时效处理时, 试样13γ'相平均尺寸与试样11和12差别较大。前一组尺寸相似时三者的变化趋势相似, 后一组尺寸不同时γ'相数量的变化趋势与其它两者不同。表明与宏观残余应力值呈正相关关系的实际上是γ'相体积分数而不是γ'相颗粒数, 前一组γ'相颗粒数表现出来与残余应力的正相关关系是因为其尺寸相似而出现的伪正相关。

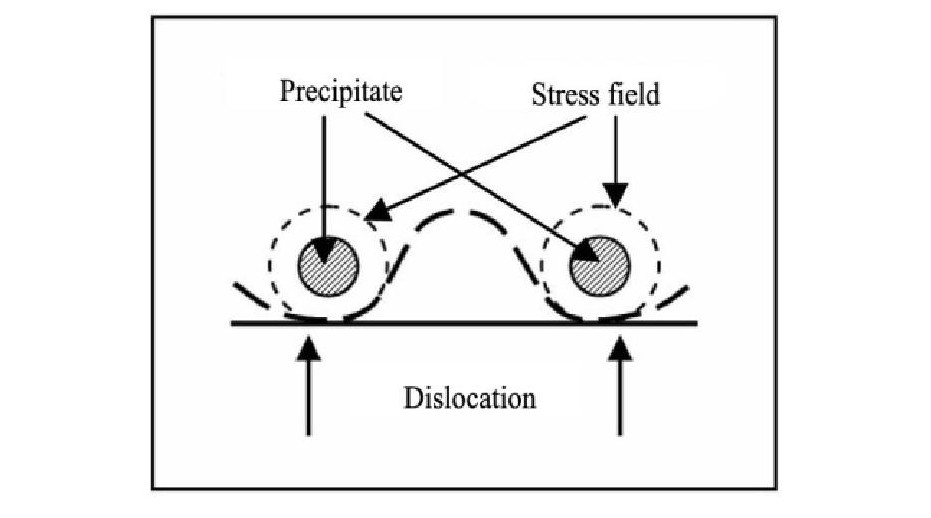

残余应力是由于材料内部宏观或微观的组织发生了不均匀的体积变化而产生, 它主要是由不均匀变形应力、热应力、相变应力和析出应力所构成。实验中各组实验条件几乎不存在前3种应力上的差别, 它们之间残余应力的区别主要是由不同析出应力造成。这种情况下, γ'相与基体γ相之间的关系对镍基合金的各项性能起到决定性的作用[16,17]。γ'相和基体γ相虽然呈共格关系, 但二者晶格常数存在微小的差异, 在两相界面上产生的错配应力场可对基体中运动位错产生阻碍作用。且γ'析出相的阻碍作用中其中主要的一项就是应力场的阻碍。位错通过析出相所造成的应力场障碍表现如图10所示, 应力场越大, 对位错运动的阻碍也就越大。对以γ'相为强化相的时效析出型铁、镍基高温合金来说, 会采用增加析出物所造成的应力场来增强强化效果[18]。

图9 不同过时效温度下残余应力、γ'相颗粒数及体积分数对比Fig.9 Comparison of residual stress, particle number and volume fraction ofγ'precipitates under overaging treatments at different temperatures

(a) Once aging; (b) Multiple aging

图1 0 析出相应力场对位错运动的阻碍Fig.10 Hinder of precipitate stress field to movement of dislo-cations

图11为多次时效处理时析出相周围应力场示意图, 图11 (a~c) 分别对应试样11、试样12和试样13的γ'相及其周围应力场情况。γ'析出相在试样12中比试样11产生的应力场多, 故最后试样12的应力大。在试样13中比试样12中产生的应力场多, 但单个应力值变小, 导致最后两者应力相差不大。在这个过程中, 最重要的因素就是γ'析出相体积分数, 这就是在析出应力占主导的情况下, 它能够直接影响宏观残余应力的原因。

图1 1 析出相周围应力场示意图Fig.11 Schematic diagram of stress field around precipitates

(a) Sample 11; (b) Sample 12; (c) Sample 13

3结论

1.对于GH141高温合金, 在只有一次过时效处理时, 随着温度的降低, 残余应力数值逐渐增大, 增长速度总体呈现先快后慢的趋势。

2.对于GH141高温合金, 在多次时效工艺处理时, 第一次时效温度越低, γ'相体积变小且数量增多;第二次时效温度越低, γ'相体积不变而数量增多。

3.在析出应力占主导的情况下, 宏观残余应力的变化趋势与γ'析出相所占体积分数变化趋势相一致, γ'析出相体积分数是影响宏观残余应力变化的唯一微观因素。

参考文献