文章编号:1004-0609(2017)-01-0051-06

超声功率-凝固压力协同作用对真空差压铸造铝合金二次枝晶间距的影响

严青松,芦 刚,李 成,沈加利

(南昌航空大学 航空制造工程学院,南昌 330063)

摘 要:

通过测试与分析不同超声功率与凝固压力下真空差压铸造ZL114A铝合金的二次枝晶间距,研究超声功率与凝固压力协同作用对真空差压铸造铝合金二次枝晶间距的影响,建立真空差压铸造ZL114A铝合金二次枝晶间距与超声功率及凝固压力的关系。结果表明:在超声功率和凝固压力协同作用下,超声效应与凝固压力挤渗效应共同影响真空差压铸造铝合金二次枝晶间距;在超声功率600 W与凝固压力350 kPa协同作用下,真空差压铸造铝合金二次枝晶间距最小;当凝固压力小于300 kPa时,超声功率对铝合金二次枝晶间距影响较大;当凝固压力大于300 kPa时,凝固压力对真空差压铸造ZL114A铝合金二次枝晶间距影响较大。

关键词:

中图分类号:TG249.2 文献标志码:A

铝合金铸件由于具有良好的力学性能、比强度和耐蚀性,且生产工艺简便,成本较低,因此,应用非常广泛[1-3]。但是采用传统的铸造工艺生产的铝合金铸 造组织的一次枝晶和二次枝晶间距都比较大,特别是二次枝晶臂间距大小直接影响着成分偏析、第二相及显微孔洞的分布,从而对铝合金铸件组织和性能产生影响。因此,要获得晶粒细小、组织致密的铝合金铸件必须控制和改善凝固过程。

在金属凝固过程中施加超声振动有利于细化晶粒。早在20世纪30年代,各国学者就开始从事超声振动在金属凝固领域的研究工作。RAMIREZ等[4]研 究了超声处理对镁合金熔体晶粒细化的影响,认为超声波会产生空化效应,形成很多空化泡及显微空穴,在空化泡的崩溃过程中,产生的强烈冲击波将会击碎初生晶核和正在长大的晶体,使之成为破碎的晶体质点弥散地分布于熔体中,提高形核率,同时抑制了晶体的生长,凝固后基体晶粒细小均匀。ESKIN[5-6]采用超声波对铝合金的凝固过程进行了较为深入的研究,试验结果表明超声产生的空化效应有利于形核增殖,导致晶粒细化,铝合金经过超声处理后,拉伸强度可以提高6%~10%。ATAMANENKO等[7-8] 采用超声熔体处理技术对铝合金的晶粒细化进行了研究,认为超声波晶粒细化效果与空化效应引起的过冷有关。李英龙等[9]研究了功率超声对Al-Si合金组织和性能的影响,认为功率超声通过热机制和机械机制能提高液相形核率,抑制Si相长大,同时,空化效应能使生长中的硅晶体破碎成颗粒,改变硅的形态和分布,减小其对基体的削弱作用,且能细化组织、提高合金的强度和塑性。李成等[10]研究超声功率对金属型铸造铝合金二次枝晶间距的影响,结果发现施加超声波后,铝合金二次枝晶间距减小,合金组织得到细化。蒋日鹏等[11]研究超声振动下铝合金凝固的晶粒细化机理,认为施加超声场可以改善温度场分布的均匀性,并且能够明显加快熔体的整体凝固进程,超声振动下铝合金的晶粒细化主要归功于超声空化促成的形核增殖与谐振效应抑制了晶体生长。同时,真空差压铸造作为一种先进的反重力铸造工艺,在整个凝固过程中金属熔体都受到压力场的作用,可以获得晶粒细小、组织致密的铸件。研究结果表明[12-13],在压力下凝固时,压力可以使铝合金熔体通过凝固枝晶间的狭窄通道向孔隙间流动,存在一种挤压驱动力。由于凝固区间的铝合金二次枝晶间距一般为10~100 μm,在压力作用下铝合金熔体在枝晶间流动的通道其实很狭窄,相当于渗流,可以认为是一种挤渗作用。从理论上讲,在凝固期间已形成一定骨架的枝晶都具有一定的强度,当产生的挤渗力大于枝晶的强度时,枝晶会发生显微塑性变形直至断裂,有利于细化晶粒。

目前,国内外专家对超声振动及压力凝固条件下晶粒细化进行了大量的研究,得到了很多有价值的结论。在真空差压铸造凝固过程中施加超声振动,将会使超声振动与凝固压力协同作用于铝合金熔体,必将会对铝合金熔体凝固过程的枝晶生长及补缩行为产生较大的影响。因此,本文作者系统研究超声功率与凝固压力协同作用对真空差压铸造铝合金二次枝晶间距的影响,建立铝合金二次枝晶间距与超声功率及凝固压力关系,为获得晶粒细小、组织致密复杂铝合金铸件提供理论指导。

1 实验

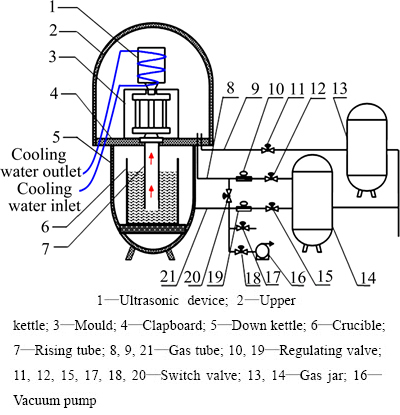

通过在自制的VCPC型真空差压铸造设备上引入超声振动装置进行实验,系统工作原理示意图如图1所示。当真空差压铸造抽真空阶段结束时,开始在充型、升压、凝固保压阶段施加超声振动直至泄压,实施超声功率-凝固压力协同作用,工艺曲线如图2所示。试样采用外形尺寸为d 12 mm×100 mm圆棒。铸型采用金属型,预热温度为270 ℃,合金为ZL114A(ZAlSi7Mg1A),浇注温度700 ℃左右,分别采用真空度20 kPa、充型压差35 kPa、保压时间80 s、不同超声功率(0、300、600和900 W)、不同的凝固压力(200、250、300、350 kPa)等工艺参数进行真空差压铸造铝合金试样。

为了测量二次枝晶间距的大小,在真空差压铸造的试样上的相同部位分别取样,利用XQ-1型金相镶嵌机对各试样进行镶嵌,经过粗磨、精磨、抛光,腐蚀。腐蚀液为0.5%HF(质量分数),腐蚀的时间为15~ 20 s。利用XJP-6A型金相显微镜对腐蚀后试样进行显微组织观察并拍取金相图片,并采用截线法和Image- Pro Plus金相分析软件对二次枝晶间距进行测量。

图1 超声振动下真空差压铸造工作原理图

Fig. 1 Working theory of vacuum counter-pressure casting under ultrasonic vibration

图2 超声功率-凝固压力协同作用工艺曲线

Fig. 2 Process graphs of synergistic action between ultrasonic power and solidification pressure

2 结果与分析

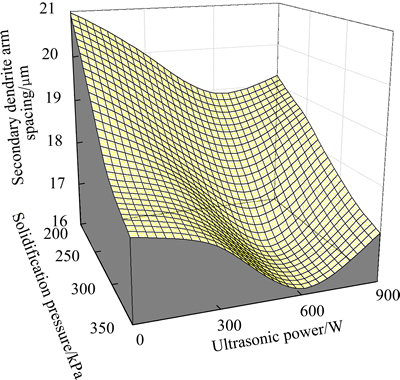

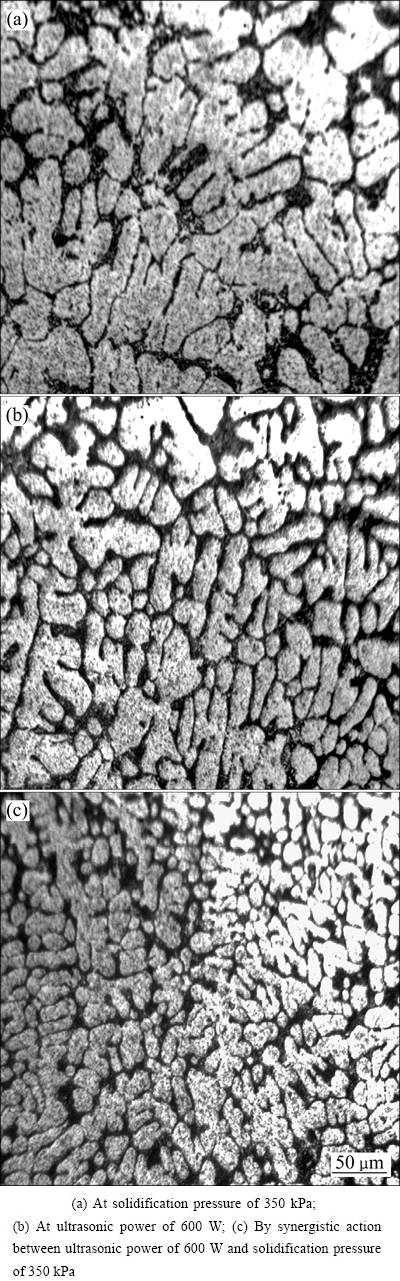

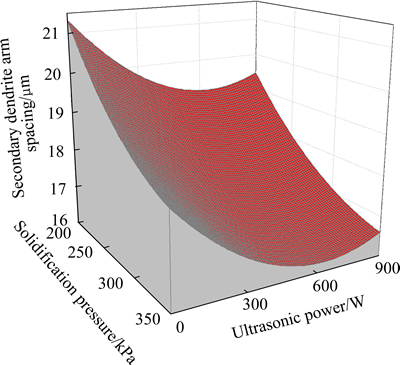

在超声功率-凝固压力协同作用下,真空差压铸造ZL114A合金试样的二次枝晶间距(Secondary dendrite arm spacing, SADS)的测试结果如表1所列。表1中,D1,D2和D3分别为测试1,2和3枝晶部位二次柱晶间距的大小。从表1可以得出,在超声功率-凝固压力协同作用下真空差压铸造ZL114A铝合金试样二次枝晶间距变化曲线,结果如图3所示。从图3可以看出,真空差压铸造ZL114A铝合金二次枝晶间距与超声功率及凝固压力都有一定的关系,超声功率及凝固压力共同影响二次枝晶间距大小。当超声功率600 W,凝固压力350 kPa时,真空差压铸造ZL114A铝合金二次枝晶间距λ2最小。当凝固压力小于300 kPa时,超声功率对真空差压铸造ZL114A铝合金二次枝晶间距影响较大;当凝固压力大于300 kPa时,凝固压力对真空差压铸造ZL114A铝合金二次枝晶间距影响较大。图4所示为不同条件下ZL114A铝合金显微组织;图4(a)所示为凝固压力350 kPa的铝合金显微组织;图4(b)所示为超声功率600 W的铝合金显微组织;图4(c)所示为超声功率600 W与凝固压力350 kPa协同作用的铝合金显微组织。从图4可以明显看出,超声功率600 W与凝固压力350 kPa协同作用下铝合金显微组织更加细小。

图3 超声功率-凝固压力协同作用下二次枝晶间距变化趋势图

Fig. 3 Variation trend of SADS with ultrasonic power and solidification pressure

表1 二次枝晶间距测试结果

Table 1 Testing results of secondary dendrite arm spacing

图4 不同条件下ZL114A铝合金的显微组织

Fig. 4 Microstructures of ZL114A aluminum alloy under different conditions

通过非线性最小二乘法拟合得到真空差压铸造ZL114A铝合金试样二次枝晶间距与超声功率及凝固压力的关系曲面,其结果如图5所示。从图5可以得出,真空差压铸造ZL114A铝合金二次枝晶间距λ2与超声功率U及凝固压力pc的关系如式(1)所示:

(1)

(1)

超声作用会使铝合金熔体中产生强烈的空化、声流、热效应等超声效应,空化与声流效应使铝合金的组织得到细化,达到了减小二次枝晶间距的效果[14-16]。但是超声功率越大,热效应效果越显著。当超声功率大于600 W时,其超声能量被熔体吸收更多,更容易造成熔体局部温度升高,延长了熔体中枝晶的长大时间,反而使组织变粗大,二次枝晶间距也增 大[17-18]。真空差压铸造在凝固压力的作用下会产生挤渗作用。挤渗作用的大小主要取决于凝固压力,凝固压力越大,挤渗作用就越强,金属液就能够更顺利的通过凝固枝晶间的狭窄通道向补缩区流动。而且,在挤渗过程中,即使枝晶连成骨架,只要其强度低于挤渗的压力,枝晶会发生塑性变形甚至会被液相流冲断,使游离晶粒增多,枝晶细小[19-20]。在超声功率-凝固压力协同作用下,铝合金熔体会同时受到超声作用及凝固压力的作用,超声功率-凝固压力协同作用示意图如图6所示。当超声振动空化效应产生的空化泡形成长大过程中,来自凝固压力挤渗效应产生的挤压会使空化泡更容易崩溃破灭,在周而复始的空化泡崩溃破灭过程中,产生的大量强烈的冲击波会击碎初生晶核和正在长大的枝晶,形成大量破碎的晶核质点,晶粒数量急剧增加,使铝合金的组织得到细化。同时,超声作用产生的声流等效力会与真空差压铸造凝固压力作用下产生挤渗力产生叠加,不仅加速了铝合金熔体中溶质的扩散,导致初生枝晶的二次枝晶壁根部容易产生溶质的富集,导致颈缩、熔断等现象,而且即使枝晶连成骨架,只要其强度低于超声功率-凝固压力协同产生的叠加力,枝晶会更容易被液相流冲断,使游离晶粒增多,进一步细化晶粒,减小二次枝晶间距。

图5 二次枝晶间距与超声功率和凝固压力关系拟合图

Fig. 5 Fitting relationship of SADS with ultrasonic power and solidification pressure

图6 超声功率-凝固压力协同作用示意图

Fig. 6 Sketch map of synergistic action between ultrasonic power and solidification pressure

3 结论

1) 超声功率和凝固压力协同作用对真空差压铸造铝合金二次枝晶间距影响明显。当超声功率600W、凝固压力350 kPa时,真空差压铸造铝合金二次枝晶间距最小。当凝固压力小于300 kPa时,超声功率对铝合金二次枝晶间距影响较大;当凝固压力大于300 kPa时,凝固压力对真空差压铸造ZL114A铝合金二次枝晶间距影响较大。

2) 建立了真空差压铸造ZL114A铝合金二次枝晶间距λ2与超声功率U及凝固压力pc的关系:

REFERENCES

[1] 蒋文明, 樊自田, 刘德均. 真空低压消失模壳型铸造和消失模铸造铝合金组织和性能对比[J]. 中国有色金属学报, 2013, 23(1): 22-28.

JIANG Wen-ming, FAN Zi-tian, LIU De-jun. Comparison of microstructures and properties of aluminum alloy between expendable pattern shell casting with vacuum and low-pressure and lost foam casting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 22-28.

[2] BAREKAR N S, DAS S, YANG X, HUANG Y, EL FAKIR O, BHAGURKAR A G, ZHOU L, FAN Z. The impact of melt conditioning on microstructure, texture and ductility of twin roll cast aluminium alloy strips [J]. Materials Science and Engineering A, 2016, 650(5): 365-373.

[3] SHIN J S, KO S H, KIM K T. Development and characterization of low-silicon cast aluminum alloys for thermal dissipation[J]. Journal of Alloys and Compounds, 2015, 644(25): 673-686.

[4] RAMIREZ A, QIAN M, DAVIS B. Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys[J]. Scripta Materialia, 2008, 59: 19-22.

[5] ESKIN C I. Broad prospects for commercial application of the ultrasonic (cavitation) melt treatment of light alloys[J]. Ultrasonics Sonochemistry, 2001, 8(3): 319-325.

[6] ESKIN C I. Improvement of the structure and properties of ingots and worked aluminum alloy semifinished products by melt ultrasonic treatment in a cavitation regime[J]. Metallurgist, 2010, 54(7): 505-513.

[7] ATAMANENKO T V,ESKIN D G, ZHANG L, KATGERMAN L. Criteria of grain refinement induced by ultrasonic melt treatment of aluminum alloys containing Zr and Ti[J]. Metallurgical and Materials Transactions A, 2010, 41(8): 2056-2066.

[8] ZHANG L,ESKIN D G, KATGERMAN L. Influence of ultrasonic melt treatment on the formation of primary intermetallics and related grain refinement in aluminum alloys[J]. Journal of Materials Science, 2011, 46(15): 5252-5259.

[9] 李英龙, 李宝绵, 刘永涛, 高彩茹, 戴恩泰. 功率超声对Al-Si合金组织和性能的影响[J]. 中国有色金属学报, 1999, 9(4): 719-722.

LI Ying-long, LI Bao-mian, LIU Yong-tao, GAO Cai-ru, DAI En-tai. Effect of high-intensity ultrasounic on structures and properties of Al-Si alloys [J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 719-722.

[10] 李成, 严青松, 芦刚, 沈加利. 超声功率对金属型铸造铝合金二次枝晶间距的影响[J]. 特种铸造及有色合金, 2015, 35(1): 103-105.

LI Cheng, YAN Qing-song, LU Gang, SHEN Jia-li. Effect of power ultrasonic on secondary dendrite arm spacing in metal permanent mould casting aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2015, 35(1): 103-105.

[11] JIANG R P,LI X Q, ZHANG M. Investigation on the mechanism of grain refinement in aluminum alloy solidified under ultrasonic vibration[J]. Metals and Materials International, 2015, 21(1): 104-108.

[12] 严青松, 余 欢, 魏伯康, 徐志峰, 蔡长春. 真空差压铸造工艺的凝固补缩特性与模型[J]. 中国有色金属学报, 2008, 18(6): 1051-1057.

YAN Qing-song, YU Huan, WEI Bo-kang, XU Zhi-feng, CAI Chang-chun. Solidification feeding behavior and model of vacuum counter-pressure casting technology[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1051-1057.

[13] YAN Qing-song, YU Huan, XU Zhi-feng, XIONG Bo-wen, CAI Chang-chun. Effect of holding pressure on the microstructure of vacuum counter-pressure casting aluminum alloy[J]. Journal of Alloys and Compounds, 2010, 501: 352-357.

[14] 丁莹莹. 铝合金凝固组织的超声细化机制研究[D]. 大连: 大连理工大学, 2010.

DING Ying-ying. Study on refinement mechanisms of aluminum alloy solidification treated by high intensity ultrasonic[D]. Dalian: Dalian University of Technology, 2010.

[15] ESKIN G I, MAKAROV G S. Effect of cavitation melt treatment on the structure refinement and property improvement in cast and deformed hypereutectic Al-Si alloys[J]. Materials Science Forum. 1997, 242: 65-70.

[16] 李开晔. 直入式超声波施振铸造试验及其凝固动力学机理研究[D]. 长沙: 中南大学, 2010.

LI Kai-ye. Study on Straight type ultrasonic vibration test and its solidification kinetics mechanism[D]. Changsha: Central South University, 2010.

[17] HUANG Hai-jun, XU Yi-fan, SHU Da, HAN Yan-feng, WANG Jun, SUN Bao-de. Effect of ultrasonic melt treatment on structure refinement of solidified high purity aluminum[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2414-2419.

[18] 何 迁. 功率超声对铝及铝合金凝固过程的影响[D]. 北京: 清华大学, 2008.

HE Qian. Effect of power ultrasonic treatment on solidification process of pure aluminum and aluminum alloy[D]. Beijing: Tsinghua University, 2008.

[19] 严青松, 余 欢, 芦 刚, 熊博文, 卢百平. 结晶压力对真空差压铸造铝合金二次枝晶间距的影响[J]. 中国有色金属学报, 2014, 24(5): 1194-1199.

YAN Qing-song, YU Huan, LU Gang, XIONG Bo-wen, LU Bai-ping, ZOU Xun. Effect of crystallization pressure on secondary dendrite arm spacing of vacuum counter-pressure casting aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1194-1199.

[20] KOVACHEVA R, BACHVAROV G, DAFINOVA R. Influence of the counter pressure casting conditions on the microstructural characteristics of AlSi7Mg castings[J]. Journal of Materials Science and Technology, 1996, 12(1): 42-56.

Effect of synergistic action between ultrasonic power and solidification pressure on secondary dendrite arm spacing of vacuum counter-pressure casting aluminum alloy

YAN Qing-song, LU Gang, LI Cheng, SHEN Jia-li

(School of Aeronautic Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The effect of synergistic action between ultrasonic power and solidification pressure on the secondary dendrite arm spacing of vacuum counter-pressure casting ZL114A aluminum alloy was studied through testing and analyzing the secondary dendrite arm spacing subjected to different ultrasonic power and solidification pressure. Meanwhile, the relationship of the secondary dendrite arm spacing of vacuum counter-pressure casting ZL114A aluminum alloy with ultrasonic power and solidification pressure was established. The results indicate that ultrasonic effect and extrusion and infiltration effect of solidification pressure affect the secondary dendrite arm spacing of vacuum counter-pressure casting aluminum alloy under synergistic action between ultrasonic power and solidification pressure, and the secondary dendrite arm spacing of aluminum alloy is the smallest under synergistic action of 600 W ultrasonic power and 350 kPa solidification pressure. When the solidification pressure is less than 300 kPa, the effect of ultrasonic power on secondary dendrite arm spacing is obvious, but when the solidification pressure is more than 300 kPa, the effect of solidification pressure on secondary dendrite arm spacing is greater.

Key words: aluminum alloy; secondary dendrite arm spacing; ultrasonic power; solidification pressure; vacuum counter-pressure casting

Foundation item: Project(51261025) supported by the National Natural Science Foundation of China

Received date: 2015-09-08; Accepted date: 2016-05-20

Corresponding author: YAN Qing-song; Tel: +86-791-83953326; E-mail: yanqs1973@126.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51261025)

收稿日期:2015-09-08;修订日期:2016-05-20

通信作者:严青松,教授,博士;电话:0791-83953326;E-mail: yanqs1973@126.com

摘 要:通过测试与分析不同超声功率与凝固压力下真空差压铸造ZL114A铝合金的二次枝晶间距,研究超声功率与凝固压力协同作用对真空差压铸造铝合金二次枝晶间距的影响,建立真空差压铸造ZL114A铝合金二次枝晶间距与超声功率及凝固压力的关系。结果表明:在超声功率和凝固压力协同作用下,超声效应与凝固压力挤渗效应共同影响真空差压铸造铝合金二次枝晶间距;在超声功率600 W与凝固压力350 kPa协同作用下,真空差压铸造铝合金二次枝晶间距最小;当凝固压力小于300 kPa时,超声功率对铝合金二次枝晶间距影响较大;当凝固压力大于300 kPa时,凝固压力对真空差压铸造ZL114A铝合金二次枝晶间距影响较大。

[1] 蒋文明, 樊自田, 刘德均. 真空低压消失模壳型铸造和消失模铸造铝合金组织和性能对比[J]. 中国有色金属学报, 2013, 23(1): 22-28.

[9] 李英龙, 李宝绵, 刘永涛, 高彩茹, 戴恩泰. 功率超声对Al-Si合金组织和性能的影响[J]. 中国有色金属学报, 1999, 9(4): 719-722.

[10] 李成, 严青松, 芦刚, 沈加利. 超声功率对金属型铸造铝合金二次枝晶间距的影响[J]. 特种铸造及有色合金, 2015, 35(1): 103-105.

[12] 严青松, 余 欢, 魏伯康, 徐志峰, 蔡长春. 真空差压铸造工艺的凝固补缩特性与模型[J]. 中国有色金属学报, 2008, 18(6): 1051-1057.

[14] 丁莹莹. 铝合金凝固组织的超声细化机制研究[D]. 大连: 大连理工大学, 2010.

[16] 李开晔. 直入式超声波施振铸造试验及其凝固动力学机理研究[D]. 长沙: 中南大学, 2010.

[18] 何 迁. 功率超声对铝及铝合金凝固过程的影响[D]. 北京: 清华大学, 2008.

[19] 严青松, 余 欢, 芦 刚, 熊博文, 卢百平. 结晶压力对真空差压铸造铝合金二次枝晶间距的影响[J]. 中国有色金属学报, 2014, 24(5): 1194-1199.