DOI: 10.11817/j.issn.1672-7207.2017.08.004

5083铝合金高温变形行为及加工图

戴青松1,刘栩2,付平3,张佳琪3,邓运来1, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 广西柳州银海铝业股份有限公司,广西 柳州,545006;

3. 中南大学 轻合金研究院,湖南 长沙,410083)

摘要:采用Gleeble-3800热模拟机对5083铝合金进行高温等温压缩实验,研究该合金在变形温度为300~500 ℃、应变速率为0.0l~10.0 s-1条件下的流变行为,建立合金高温变形的本构方程和加工图,采用电子背散射衍射(EBSD)分析变形过程中合金的组织特征。研究结果表明:流变应力随变形温度升高而降低,随应变速率增大而升高;当变形温度为400~500 ℃时,合金发生动态再结晶;5083铝合金的高温流变行为可用Zener-Hollomon参数描述,该合金在真应变为0.6时的加工图中存在2个失稳区域,其优选的加工条件是变形温度为420~500 ℃,应变速率为0.01~0.10 s-1。

关键词:5083铝合金;热变形;本构方程;热加工图

中图分类号:TG146.2 文献标志码:A 文章编号:1672-7207(2017)08-1988-07

High-temperature deformation behavior and processing map of 5083 aluminum alloy

DAI Qingsong1, LIU Xu2, FU Ping3, ZHANG Jiaqi3, DENG Yunlai1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Guangxi Liuzhou Yinhai Aluminum Co. Ltd., Liuzhou 545006, China;

3. Light Alloy Research Institute, Central South University, Changsha 410083, China)

Abstract: The flow stress features of 5083 aluminum alloy were studied by the isothermal compression of cylindrical specimen in temperature of 300-500 ℃ and strain rate of 0.01-10.0 s-1 with Gleeble-3800 simulated machine. The high temperature deformation constitutive equations and processing map were established, and furthermore, the microstructure characteristics were studied by electron back-scattered diffraction (EBSD) analysis. The results show that the flow stress increases with the increase of strain rate and decreases with the increase of deformation temperature. The dynamic recrystallization occurs at the strain rate of 10.0 s-1 and in temperature of 400-500 ℃. The flow stress of 5083 aluminum alloy can be represented by Zener-Hollomon parameter during high temperature deformation. There are two flow instability zones in the processing map when the true strain is 0.6, and the optimized deformation temperature and strain rate are 420-500 ℃ and 0.01-0.10 s-1, respectively.

Key words: 5083 aluminum alloy; hot deformation; constitutive equations; processing map

5083铝合金属Al-Mg系不可热处理强化型变形铝合金,具有中等强度、良好的成型性能、焊接性能、耐蚀性能等特点,广泛应用于车辆、船舶、航空航天等交通运输业及罐料制造业等领域[1-2]。合金在热变形过程中的流变应力是表征材料塑性的1个最基本量,在塑性变形过程中,材料的流变应力决定了加工时所需要施加的载荷及所需要消耗能量[3]。热加工图是基于动态材料模型的能量图和失稳图叠加,能够描述材料在不同变形温度和应变速率时组织变化机制,为材料变形时工艺制度的确定提供了参考依据[4]。热压缩实验可获得材料变形时的连续流变应力,通过流变应力计算材料的本构方程与加工图[5-6]。热变形行为与加工图往往是研究材料工艺与性能的前提,目前人们对铝合金的热变形行为与加工图进行了很多研究,如:刘欢等[7]利用热加工图研究了Mg-6.3Zn-0.7Zr- 0.9Y-0.3Nd合金的热变形行为及组织演变;LIN等[8]研究了Al-Zn-Mg-Cu-Cr合金的热变形行为,建立了合金的本构方程模型和加工图;JAQAN等[9]建立了Al-Li合金的加工图。目前,人们对5083铝合金热加工图及热变形过程中组织演化方面的研究较少。为此,本文作者对5083铝合金进行高温压缩变形,研究5083铝合金的高温热变形行为,建立本构方程模型和热加工图,探讨5083铝合金在不同变形条件时微观组织的变化,以便为该合金热加工工艺的制定提供依据。

1 实验材料与方法

实验用材料为已完全再结晶的5083铝合金热粗轧板材,其化学成分质量分数如表1所示。

表1 5083铝合金化学成分(质量分数)

Table 1 Chemical component mass fraction of 5083 aluminum alloy %

将热粗轧板材经机加工成直径×高为10 mm× 15 mm的圆柱体试样。在Gleeble-3800热模拟机上进行等温压缩实验,压缩温度分别为300,350,400,450和500 ℃,应变速率分别为0.01,0.1,1和10 s-1,变形量为50%,压缩时试样两端添加石墨片并均匀涂上润滑剂(75%石墨+20%机油+5%硝酸三甲苯脂,质量分数)以减小摩擦的影响。加热温度为5 ℃/s,保温2 min,变形后立即水淬,以保留其高温变形组织。采用双喷电解减薄法制备EBSD试样,在HELIOS NANOLAB 600i扫描电镜上利用背散射电子探头进行表征,采用HKL公司的Channel5EBSD系统进行标定,电压为20 kV,步长为0.5 μm,光学金相采用AXIO Scope A1型金相显微镜检测。

2 实验结果与分析

2.1 流变应力曲线特征

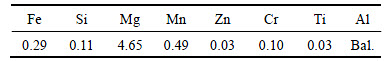

5083铝合金在不同变形条件下的流变应力曲线如图1所示。从图1可以看出:在一定变形温度和应变速率条件下,5083铝合金真应力随着真应变增大而增大;在变形初始阶段,流动应力迅速增大至峰值;当应力达到峰值后,真应力不再随真应变增大而增大,而是呈现出稳态流变特征或者下降趋势;合金在变形温度为300~500 ℃、应变速率为0.01~0.1 s-1的条件下,真应力达到峰值以后保持基本稳定,表明发生了典型的动态回复现象;在变形温度为400~500 ℃、应变速率为1 s-1及变形温度为300~500 ℃、应变速率为10 s-1的变形条件下,合金的应力-应变曲线出现了明显波浪峰,这是材料发生动态再结晶的表现,说明在该变形范围内合金发生了动态再结晶。从图1还可发现:在同一应变速率下,随变形温度升高,真应力水平明显下降;在同一变形温度下,随应变速率增大,真应力水平升高,说明5083铝合金在该试验条件下具有正的应变速率敏感性。

2.2 本构方程模型

材料高温变形过程中流变应力、变形速率、变形温度间的关系可用如下关系式进行描述[10-11]:

=Af(σ)exp[-Q/(RT)] (1)

=Af(σ)exp[-Q/(RT)] (1)

在低水平应力(ασ<0.8)下,

f(σ)=σn (2)

在高水平应力(ασ>1.2)下,

f(σ)=exp(βσ) (3)

在整个应力范围内,

f(σ)=[sinh(ασ)]n (4)

在所有应力状态下,式(1)可表示为

=A[sinh(ασ)]nexp[-Q/(RT)] (5)

=A[sinh(ασ)]nexp[-Q/(RT)] (5)

其中:f(σ)为应力水平有关的函数;σ为流变应力; 为应变速率;T为变形热力学温度;Q为热变形激活能;R为热力学常数;参数A,n,α,β均为常数,其中A为结构影响因子,n为应力指数,且α=β/n。流变应力与热变形条件的关系可用Zener-Holloman参数方程(Z参数)表示[10-11]。

为应变速率;T为变形热力学温度;Q为热变形激活能;R为热力学常数;参数A,n,α,β均为常数,其中A为结构影响因子,n为应力指数,且α=β/n。流变应力与热变形条件的关系可用Zener-Holloman参数方程(Z参数)表示[10-11]。

Z= exp[Q/(RT)]=A[sinh(ασ)]n (6)

exp[Q/(RT)]=A[sinh(ασ)]n (6)

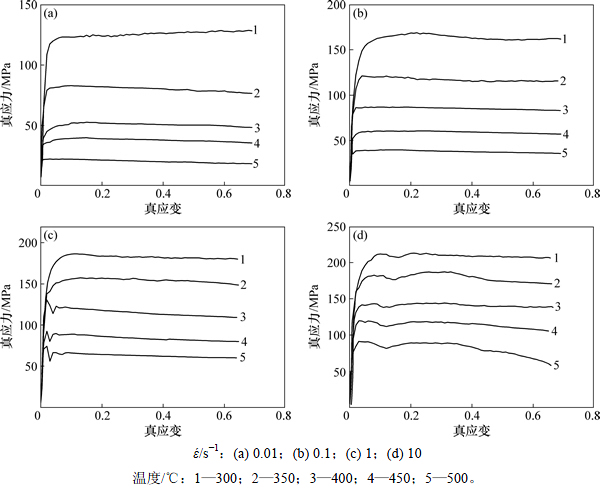

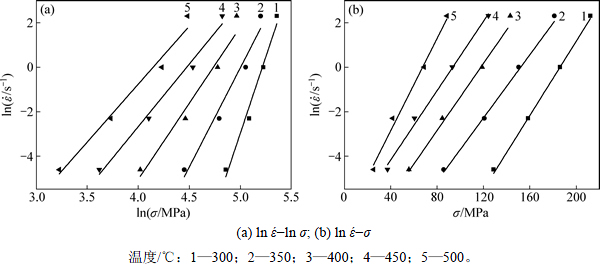

当变形温度T或应变速率 不变时,流变应力σ及其对数与应变速率

不变时,流变应力σ及其对数与应变速率 的对数(lnσ-ln

的对数(lnσ-ln ,σ-ln

,σ-ln ,ln[sinh(ασ)]-ln

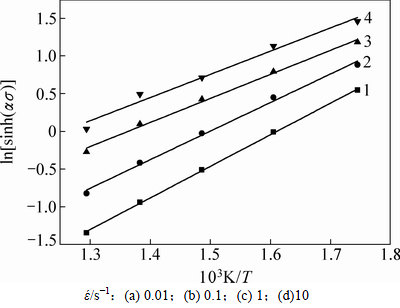

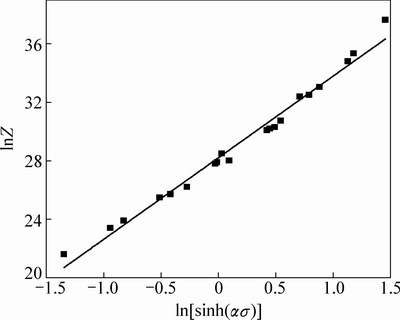

,ln[sinh(ασ)]-ln )、流变应力σ的对数与热力学温度T的倒数(ln[sinh(ασ)]-1/T)、流变应力σ的对数与Z的对数(ln[sinh(ασ)]-lnZ)之间均满足线性关系。图2~6所示为实验合金在不同变形条件下各关系的线性回归图,由各图中直线斜率的平均值可求得本构方程所需常数,计算得到A=1.77×1012 s-1,α=0.010 2 MPa-1,n=5.683,Q=168.336 kJ/mol。

)、流变应力σ的对数与热力学温度T的倒数(ln[sinh(ασ)]-1/T)、流变应力σ的对数与Z的对数(ln[sinh(ασ)]-lnZ)之间均满足线性关系。图2~6所示为实验合金在不同变形条件下各关系的线性回归图,由各图中直线斜率的平均值可求得本构方程所需常数,计算得到A=1.77×1012 s-1,α=0.010 2 MPa-1,n=5.683,Q=168.336 kJ/mol。

图1 5083铝合金不同变形条件下的真应力-真应变曲线

Fig. 1 True stress-true strain curves of 5083 aluminum alloy under different deformation conditions

图2 不同温度下5083铝合金的应变速率与流变应力的关系

Fig. 2 Relationship between strain rate and flow stress for 5083 alloy at different temperatures

将求得的A,α,n和Q等参数代入式(5),可得5083铝合金的流变应力本构方程为

=1.77×1012[sinh(0.010 2σ)]5.683×exp[-168 336/(RT)] (7)

=1.77×1012[sinh(0.010 2σ)]5.683×exp[-168 336/(RT)] (7)

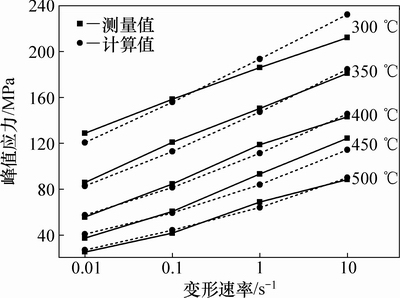

为检测上述本构方程的准确性,根据求得的5083铝合金峰值流变应力本构方程,计算不同变形条件下的峰值应力,并与实测值进行对比。由图6可以看出本构方程应力预测值与实测值较吻合,只有在变形温度为300 ℃、变形速率为10 s-1时,应力相对误差较大。造成该变形条件下应力相对误差较大的原因可能是:一方面,该条件应力较大,本文中虽然使用了适用于整个应力范围的本构模型,但并未考虑模型中参数与变形条件之间的动态关系,将A,n,α和β等参数看成常数处理,使得在高应力情况下误差较大;另一方面,试验过程并非绝热过程,在高速变形条件下试样产生的变形热来不及散失,使得温度瞬时升高,试样实际温度大于设定温度,导致材料应力降低,因而实际应力要小于预测值[12]。

图3 不同温度下5083铝合金流变应力与应变速率的关系

Fig. 3 Relationship between flow stress and rate of 5083 alloy at different temperatures

图4 5083铝合金流变应力与变形温度的关系

Fig. 4 Relationship between flow stress and deformation temperature of 5083 alloy

图5 5083铝合金流变应力与参数Z的关系

Fig. 5 Relationship between flow stress and Zener-Hollomon parameter

图6 5083铝合金峰值应力实测应力与计算应力的对比

Fig. 6 Peak stress comparison between measured and calculated value of 5083 aluminum alloy

为了更清晰地评价实测值与计算值之间的误差,可引入以下误差分析表达式:

(8)

(8)

(9)

(9)

式中:σE为流变应力实测值;σC为本构方程应力计算值;Rerr为相对误差;Rave为平均相对误差。根据式(8)和(9),本构方程的计算值与实测流变应力的平均相对误差仅为5.07%,且都在10.00%以内。

2.3 加工图

根据材料变形机制所绘制的加工图主要分为2类:一类是RAJ等[13]根据材料变形得出的试验数据和原子法建立的加工图;一类是PRASAD等[14]根据材料变形过程中得出的参数所绘制出的加工图。RAJ加工图具有较大局限性,其原因是:1) 它仅用于纯金属和简单合金,且只有在稳态下才有效,对一般的复杂合金不适用;2) 需要确定大量基本材料参数如激活能,扩散系数,结构参数和晶粒尺寸、分布等;3) 建立了几种典型过程的子模型,无法适用于各种变形机制[15]。为更加方便地绘制加工图,PRASAD等[14]提出基于动态材料模型(dynamic material model,DMM)的加工图。

根据动态材料模型的理论,材料在变形过程中作为一个功率耗散体,单位体积内所吸收的功率P可以表示成塑性变形消耗的功率G(耗散量)和组织变化所消耗的功率J(耗散协量),即[16]

(10)

(10)

式中:P为外界输入的功率。应变速率敏感指数m用于表征参数J与G的比值,

(11)

(11)

通过计算可得

(12)

(12)

当材料处于理想线性耗散状态时,m=1,此时J达到最大值,即

(13)

(13)

PRASAD等[14]引入功率耗散因子η:

(14)

(14)

通过合金在不同变形温度和应变速率条件下计算得m,然后通过式(14)求出不同变形条件时的耗散效率因子η,在T-lg 平面内绘制的等值线图即为功率耗散图。采用加工图对材料高温变形行为进行研究时,还需考虑材料的塑性失稳。PRASAD等[14-16]根据最大熵产生率原理,提出材料在高温变形时的失稳判据

平面内绘制的等值线图即为功率耗散图。采用加工图对材料高温变形行为进行研究时,还需考虑材料的塑性失稳。PRASAD等[14-16]根据最大熵产生率原理,提出材料在高温变形时的失稳判据 为

为

(15)

(15)

将不同变形条件时的m代入式(15),在T-lg 平面内绘制ξ(

平面内绘制ξ( )<0的区域,即得到失稳图。

)<0的区域,即得到失稳图。

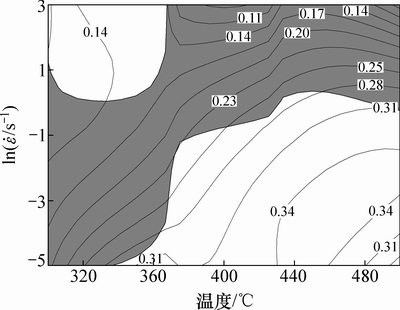

将功率耗散图和加工失稳图进行叠加可得到加工图。考虑到铝板材实际加工过程中单道次变形量一般不超过45%,因此,本文主要研究5083铝合金变形量为45%(真应变为0.6)的热加工图。图7所示为5083铝合金在真应变为0.6时的加工图,图中等值线上的数字表示功率耗散值,阴影部分为失稳区。

从图7可知:5083铝合金的加工失稳区范围较大,失稳区可划分为失稳Ⅰ区(温度为300~370 ℃,应变速率为0.01~1 s-1)与失稳Ⅱ区(温度为370~500 ℃,应变速率为1~10 s-1)。在失稳Ⅰ区、低温低应变速率时,η较小,在该区域内改变材料微观组织的能量较少,合金很可能发生热粘塑性失稳而产生绝热剪切。在失稳Ⅱ区、高温高应变速率时,大量塑性功转变成的热量及界面滑移产生的应力集中不能及时通过扩散等途径释放,极易引起局部流动而产生失稳[17]。

在应变速率为0.01 s-1的低应变速率区,温度为450 ℃时功率耗散值最大,达到0.34,同时,处于加工安全区,有利于加工;在应变速率为10 s-1高应变速率区,温度为400 ℃时功率耗散因子较小,只有0.09,同时处于加工失稳区,不利于加工。一般来说,材料失稳是由于材料在变形过程中发生了绝热剪切或局部流变失稳,失稳工艺区域不适合加工,在实际加工过程中应予以避免。安全加工区与流变失稳区域呈 X 形,表明温度和应变速率对5083铝合金的加工性能均有影响,整体上功率耗散因子随着应变速率增大而减小,随着变形温度增大而增大[18]。根据热加工图可知5083铝合金存在2个加工区:变形温度为300~370 ℃、应变速率为1~10 s-1区域及变形温度为360~500 ℃、应变速率为0.01~1 s-1区域,其中优选的加工区域条件如下:变形温度为420~500 ℃,应变速率为0.01~0.1 s-1。

图7 5083铝合金热加工图

Fig. 7 Processing map of 5083 aluminum alloy

3 讨论

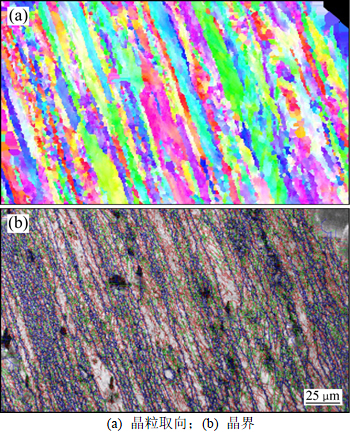

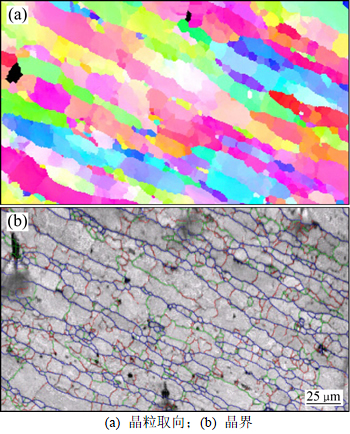

金属在热加工时,合金内位错密度急剧增加,而位错运动遇到晶界、杂质及第二相粒子的概率就会大大增加,使合金产生位错塞积,从而产生加工硬化,流变应力增大,使得金属的流变应力在热加工初始阶段迅速增大至峰值(见图1)。此后进入稳态变形阶段,流变应力基本保持不变。此时,合金变形时所产生的位错增殖和由位错的交滑移及攀移所产生的位错消失达到动态平衡,金属变形组织中以亚晶组织为主,并且亚晶界趋向二位晶界,亚晶间平均取向差较小,合金中发生亚晶的合并和多边形化,表现出强烈的动态回复行为[18]。在变形温度为300~500 ℃、应变速率为0.01~0.1 s-1时该合金均表现出上述特征。当变形温度为350 ℃、应变速率为0.1 s-1时合金的晶粒取向和晶界图见图8。从图8可见:合金的晶粒取向以小角度晶界为主,表现为动态回复特征。

图8 350 ℃和0.1 s-1条件下合金的晶粒取向及晶界图

Fig. 8 Grain orientation map and grain boundary map of alloy at 350 ℃ and 0.1 s-1

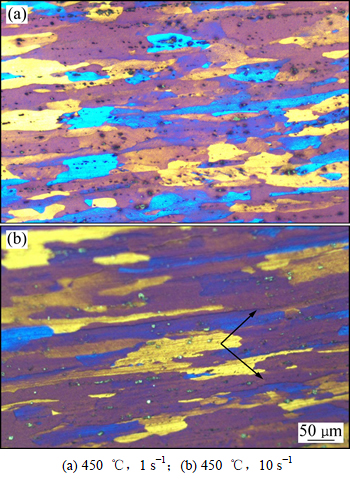

合金在高温变形时,位向差较小的亚晶间会合并成较大的亚晶。在亚晶合并过程中,亚晶粒必须转动导致合并后的大亚晶与其周围亚晶之间的位向差必然加大,形成大角度晶界。当温度进一步变高时,合并长大的亚晶就会成为再结晶的核心,表现出明显的动态再结晶行为[18]。合金在变形温度为450 ℃、应变速率为1 s-1变形条件下的晶粒取向和晶界图见图9。从图9可见:在该变形条件下,合金的晶粒取向以大角度晶界为主,明显发生了动态再结晶。

图10所示为不同变形条件下合金的金相组织。结合图7分析,其中图10(a)的变形参数优于加工图的安全区,可看出变形组织未出现裂纹、孔洞和剪切带等失稳现象;图10(b)的变形条件位于加工图的失稳区,可看出在晶界处产生了裂纹,说明该区域已经发生了流变失稳现象。

图9 450 ℃和1 s-1条件下合金的晶粒取向及晶界图

Fig. 9 Grain orientation map and grain boundary map of alloy at 450 ℃ and 1 s-1

图10 不同变形条件下合金的金相组织

Fig. 10 Optical microstructures at different conditions

4 结论

1) 5083铝合金高温变形时的峰值应力随变形温度升高而降低,随应变速率的增大而增大,合金在变形温度为300~500 ℃、应变速率为0.01~0.1 s-1的变形条件下发生动态回复;在变形温度为400~500 ℃、应变速率为1 s-1及变形温度为300~500 ℃、应变速率为10 s-1的变形条件下发生动态再结晶。

2) 5083铝合金高温变形下的本构方程可表示为: =1.77×1012[sinh(0.010 2σ)]5.683exp[-168 336/(RT)]。

=1.77×1012[sinh(0.010 2σ)]5.683exp[-168 336/(RT)]。

3) 5083铝合金真应变为0.6时的热加工图中存在2个失稳区,分别是变形温度为300~370 ℃、应变速率为0.01~1 s-1的区域以及变形温度为370~500 ℃、应变速率为1~10 s-1的区域。该合金优选加工区域如下:变形温度为420~500℃,应变速率为0.01~0.1 s-1。

参考文献:

[1] LIN Shuangping, NIE Zuoren, HUANG Hui, et al. Annealing behavior of a modified 5083 aluminum alloy[J]. Materials and Design, 2010, 31(3): 1607-1612.

[2] LEE Y B, DONG H S, PARK K T, et al. Effect of annealing temperature on microstructures and mechanical properties of a 5083 Al alloy deformed at cryogenic temperature[J]. Scripta Mteralia, 2004, 51(4): 355-359.

[3] 李惠中, 张新明, 陈明安, 等. 2519铝合金热变形行为[J]. 中国有色金属学报, 2005, 15(4): 621-625.

LI Huizhomg, ZHANG Xinming, CHEN Mingan, et al. Hot deformation behavior of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 621-625.

[4] 文智, 易丹青, 王斌, 等. Al-6Mg-0.4Mn-0.2Sc铝合金的高温变形行为及热加工图[J]. 中南大学学报(自然科学版), 2013, 44(3): 914-920.

WEN Zhi, YI Danqing, WANG Bin, et al. Hot deformation and processing maps of Al-6Mg-0.4Mn-0.2Sc aluminum alloy[J]. Journal of Central South University (Science and Technology), 2013, 44(3): 914-920.

[5] BOZZINI B, CERRI E. Numerical reliability of hot working processing maps[J]. Materials Science and Engineering A, 2002, 328(1/2): 344-347.

[6] CERRI E, SPIGARELLI S, EVANGELISTA S E, et al. Hot deformation and processing maps of a particulate reinforced 6061+20% Al2O3 composite[J]. Materials Science and Engineering A, 2002, 324(1/2): 157-161.

[7] 刘欢, 王琪, 易丹青, 等. Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd合金高温变形行为及加工图[J]. 中南大学学报(自然科学版), 2013, 44(1): 67-74.

LIU Huan, WANG Qi, YI Danqing, et al. High-temperature deformation behavior and processing map of Mg-6.3Zn-0.7Zr- 0.9Y-0.3Nd alloy[J]. Journal of Central South University (Science and Technology), 2013, 44(1): 67-74.

[8] LIN Gaoyong, ZHANG Zhenfeng, ZHANG Hui, et al. Study on the hot deformation behaviors of Al-Zn-Mg-Cu-Cr aluminum[J]. Acta Metallurgica Sinica, 2008, 21(2): 109-115.

[9] JAQAN R G, SRINIVASAN N, GOKHALE A A, et al. Processing map for hot working of spray formed and hot isostatically pressed Al-Li alloy (UL40)[J]. Journal of Materials Processing Technology, 2009, 209(18/19): 5964-5972.

[10] LI Yongying, WEI Dongdong, HU Jidong, et al. Constitutive modeling for hot deformation behavior of T24 ferritic steel[J]. Computational Materials Science, 2012, 53(1): 425-430.

[11] WU B, LI M Q, MA D W. The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy[J]. Materials Science and Engineering A, 2012, 542: 79-87.

[12] 肖罡, 李落星, 叶拓. 6013铝合金平面热压缩流变应力曲线修正与本构方程[J]. 中国有色金属学报, 2014, 24(5): 1268-1274.

XIAO Gang, LI Luoxing, YE Tuo. Modification of flow stress curves and constitutive equations during hot plane compression deformation of 6013 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1268-1274.

[13] RAJ R. Development of a processing map for use in warm-forming and hot-forming processes[J]. Metallurgical Transactions A, 1981, 12(6): 1089-1097.

[14] PARSAD Y, GEGEL H L, DORAIVELU S M, et al. Modeling of dynamic material behavior in hot deformation: forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15(10): 1883-1892.

[15] 曾卫东, 周义刚, 周军, 等. 加工图理论研究进展[J]. 稀有金属材料工程, 2006, 35(5): 673-677.

ZENG Weidong, ZHOU Yigang, ZHOU Jun, et al. The research process of processing maps theory[J]. Rave Metal Materials and Engineering, 2006, 35(5): 673-677.

[16] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, et al. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Materials Science and Engineering A, 2002, 325(1/2): 112-125.

[17] 傅高升, 陈贵清. 3003铝合金热变形机制及加工图[J]. 材料热处理学报, 2013, 34(2): 114-119.

FU Gaosheng, CHEN Guiqing. Hot deformation mechanism and processing maps of 3003 aluminum alloy[J]. Transactions of Materials and Heat Treatment, 2013, 34(2): 114-119.

[18] LIU Wenyi, ZHAO Huan, LI Dan, et al. Hot deformation behavior of AA7085 aluminum alloy during isothermal compression at elevated temperature[J]. Materials Science and Engineering A, 2014, 596: 176-182.

(编辑 陈灿华)

收稿日期:2016-09-10;修回日期:2016-11-15

基金项目(Foundation item):广西科学研究与技术开发计划课题(桂科重1598001-2)(Project(1598001-2)supported by the Scientific Research and Technology Development Program of Guangxi)

通信作者:邓运来,教授,博士生导师,从事有色金属材料加工工程研究 E-mail: luckdeng@csu.edu.cn