文章编号:1004-0609(2013)08-2156-07

挤压比对Mg-6Zn-1Y-1Ce合金组织和力学性能的影响

杨文朋1,郭学锋1,任 昉2

(1. 河南理工大学 材料科学与工程学院,焦作 454000;

2. 河南理工大学 经济管理学院,焦作 454000)

摘 要:在300 ℃将d 50 mm的铸态Mg-6Zn-1Y-1Ce合金挤压成d 14 mm、d 12 mm和d 10 mm的棒材,使用X射线衍射、光学显微镜、扫描电镜和透射电镜分析合金组织,测试其室温拉伸性能。结果表明:合金再结晶组织与挤压比相关,挤压比越大,再结晶越充分;d 14 mm、d 12 mm和d 10 mm试样的再结晶面积分数分别为69.0%、85.8%和99.1%,平均晶粒尺寸分别为2.7、2.9和5.9 μm,屈服强度分别为327.4、286.5和237.5 MPa。合金的高强度归因于合金化和细晶强化的综合作用。

关键词:镁合金;挤压比;组织;拉伸性能

中图分类号:TG146.2 文献标志码:A

Effects of extrusion ratio on microstructure and mechanical properties of Mg-6Zn-1Y-1Ce alloy

YANG Wen-peng1, GUO Xue-feng1, REN Fang2

(1. School of Materials Science and Engineering, Henan Polytechnic University, Jiaozuo 454000, China;

2. School of Economic and Management, Henan Polytechnic University, Jiaozuo 454000, China)

Abstract: Mg-6Zn-1Y-1Ce alloy bars with diameters of 14 mm, 12 mm and 10 mm were prepared by extrusion from as-cast ingots with diameter of 50 mm at 300 ℃. The microstructures were examined by XRD, OM, SEM and TEM, and the tensile properties were tested at room temperature. The results show that the recrystallization microstructure of as-extruded alloys correlates to the extrusion ratio. The recrystallized area fractions for bars of d 14 mm, d 12 mm and d 10 mm are 69.0%, 85.8% and 99.1%, respectively. The mean grain sizes are 2.7, 2.9 and 5.9 μm, respectively. The yield strengths are 327.4, 286.5 and 237.5 MPa, respectively. The high strengths are attributed to the combined action of alloying and fine-grain strengthening mechanism.

Key words: magnesium alloy; extrusion ratio; microstructure; tensile properties

近年来,汽车行业的节能减排已成为社会各方关注的焦点,而利用已有资源制备高强度、低密度的高性能材料是最有效的解决方案之一。镁具有密度低、资源充足、且易回收再利用等优点而受到广泛关注。目前,镁合金已经可以替代部分钢铁零件用于汽车和航空、航天等领域[1-2]。研究表明,添加少量稀土的镁合金会形成高温强化相,使合金具有优异的室、高温力学性能[3-4]。GUO等[5-6]通过向Mg-6Zn合金中添加少量Y和Ce元素开发高强韧Mg-Zn-Y-Ce合金,该系合金最高强度达520 MPa,最大伸长率达27%。然而,目前关于Mg-Zn-Y-Ce系合金的报道主要是快速凝固薄带经过(往复)挤压成形的产品,而其铸态合金方面仅报道了挤压丝材的组织和性能[7]。挤压是铸态合金最常用的塑性加工工艺之一,合金组织细化程度与挤压温度和挤压比密切相关。挤压温度较低时,再结晶晶粒细小,但合金中会存在未再结晶区域,提高温度组织中未再结晶区域会减少,但晶粒会长大[8]。挤压比的变化实质上是应变量的变化,通常认为挤压比越大,组织越均匀、细小[9]。然而,在挤压力相同时,增大挤压比必然使挤压速度降低,而目前大部分研究未探讨挤压应变速率对组织和性能的影响。对于高强度Mg-6Zn-1Y-1Ce合金,本文作者之前研究了挤压温度对其组织和性能影响,发现300 ℃是比较合理的挤压温度[8],但挤压比对组织和性能的影响尚未报道。因此,本文作者在300 ℃研究挤压比对Mg-6Zn-1Y-1Ce合金组织和性能的影响,探讨挤压应变速率对其影响机制,为镁合金深加工的优化提供参考。

1 实验

1.1 材料制备

铸态Mg-6Zn-1Y-1Ce合金在Ar + SF6气体保护环境中熔炼。首先熔化纯Mg(纯度>99.9%),720 ℃加入纯Zn(纯度>99.9%)、Mg-47%Y和Mg-90%Ce中间合金颗粒。熔炼过程中不断搅拌,保温20 min后将熔体浇铸到d 52 mm的石墨模具中获得铸锭。将铸锭加工成d 50 mm的坯料用以挤压。

挤压前将坯料和挤压模具在300 ℃保温1 h,使材料整体温度均匀。挤压时使用MoS2作为润滑剂,挤压力恒定,约为6.28×105 N,挤压凹模直径分别为d 14 mm、d 12 mm和d 10 mm,对应的挤压比分别为12.8、17.4和25。各挤压比下挤压轴线线速度为分别18、12和5 mm/min,挤压过程中温度波动±2 ℃。

1.2 组织分析

使用RigakuD/max-3C型X射线衍射(XRD)分析相组成,辐射源为Cu Kα,扫描步进0.033°,扫描范围20°~80°。金相试样经过打磨、抛光和腐蚀后,使用Nikon Epiphot型光学显微镜(OM)和JEM-6700F扫描电镜(SEM)观察组织。组织照片使用图像软件分析,平均晶粒度使用截线法测量。透射电镜(TEM)样品平行于挤压方向截取,手工减薄至80 μm,-30 ℃在 (11.2 g Mg(ClO4)2+5.3 g LiCl+500 mL CH3OH+100 mL CH2H5OH)溶液中双喷减薄至穿孔,最后使用离子减薄仪在4.0 keV加速电压下除氧化膜,使用JEM-3010型TEM分析沉淀相特征和位错组态,操作电压300 keV。

1.3 拉伸性能测试

圆棒型拉伸试样沿挤压方向截取,标距30 mm,直径6 mm (按GB/T 228—2002执行)。室温拉伸在HT2800机上测试,在1×10-4 s-1恒定应变速率下拉伸。拉伸断口使用JSM-6700F型SEM观察。

2 结果与分析

2.1 显微组织

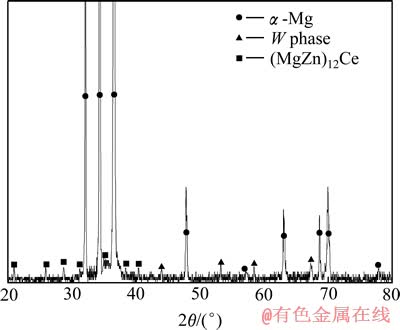

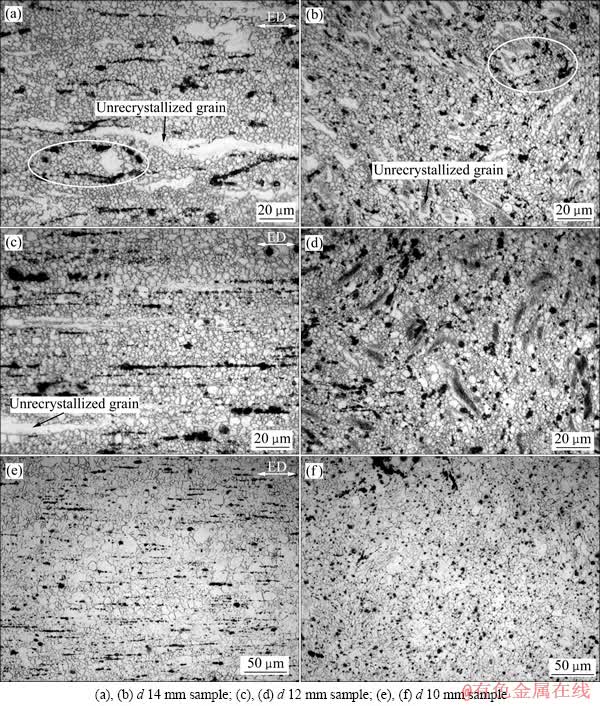

Mg-6Zn-1Y-1Ce合金XRD分析结果如图1所示。由图1可知,合金中主要化合物是W相和(MgZn)12Ce相。挤压态合金组织(图2)由细小的等轴晶和不规则 的粗大晶粒组成,等轴晶为动态再结晶晶粒,粗大晶粒是未发生再结晶的晶粒。d 14 mm挤压试样纵截面组织(见图2(a))中部分未发生再结晶的晶粒沿挤压方向被拉长,具有较大的纵横比,且晶粒边界均呈锯齿状,说明动态再结晶时,新晶粒形成于原始晶粒的晶界上。横截面组织(见图2(b))中未再结晶晶粒形状不规则,边界仍呈锯齿状。与d 14 mm试样相比,d 12 mm试样纵截面组织中沿挤压方向被拉长的未再结晶晶粒尺寸变小(见图2(c)),纵横比仍很大,边界仍呈锯齿状;横截面组织(见图2(d))由等轴晶组成,基本观察不到未再结晶晶粒。d 10 mm试样发生了充分的再结晶,纵、横截面(见图2(e)和2(f))组织均由等轴晶组成,很难观察到沿挤压方向被拉长的晶粒。

图1 铸态Mg-6Zn-1Y-1Ce合金的XRD谱

Fig. 1 XRD pattern of as-cast Mg-6Zn-1Y-1Ce alloy

图2 挤压态Mg-6Zn-1Y-1Ce合金纵横截面组织

Fig. 2 Microstructures of cross ((a), (c), (e)) and longitudinal ((b), (d), (f)) sections of as-extruded Mg-6Zn-1Y-1Ce alloy

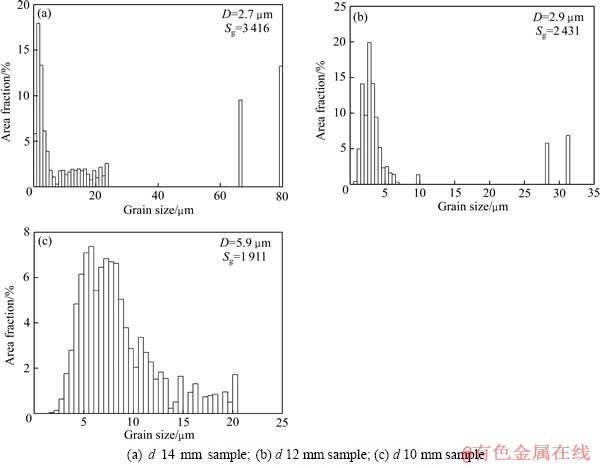

由晶粒尺寸分布统计图(见图3(a),图中Sg为晶粒统计数量)可知,d 14 mm试样具有双峰晶粒分布特征,这种组织特征在挤压镁合金中经常被观察到[10-11]。试样平均晶粒尺寸约为2.7 μm,其中约有98.8%的晶粒尺寸小于10 μm,面积分数为54.0%。未再结晶区域面积分数约为31.0%。与d 14 mm试样对比,随着挤压比的提高,合金中未再结晶区域面积分数减小,d 12 mm试样中约为14.2%(见图3(b)),而d 10 mm试样为0.9%(见图3(c))。然而,随着挤压比增加平均晶粒尺寸增大,d 10 mm试样晶粒平均尺寸约为5.9 μm。

图2中灰黑色质点为第二相颗粒,是铸态合金中晶界上的网状金属间化合物经挤压破碎后形成的细小颗粒,平行于挤压方向分布。然而,对于挤压比较小的d 14 mm试样,部分颗粒的分布仍呈网状,典型区域如图2(a)和2(b)中椭圆区域所示。在d 12 mm和d 10 mm试样组织中没有发现网状分布特征的化合物,说明提高挤压比会改善第二相的均匀度。

SEM组织中第二相颗粒呈亮白色(图4),从图4(a)中可以看出,纵截面第二相颗粒分布不均匀,局部区域有聚集现象,如平行四边形区域所示。从高倍组织照片(图4(a)中插图)中可以看出,许多小于500 nm的不规则颗粒堆积在一起,这些颗粒具有尖锐的棱角。仔细观察发现,部分相邻颗粒的边界相吻合,而且有些颗粒之间有粘接(图4(a)中箭头所示),可以推测大 颗粒破碎成小颗粒后没有分散开,并平行于挤压流变方向呈线性分布。在纵截面组织(图4(b))中也可以观察到少许聚集颗粒,但没有纵截面明显。

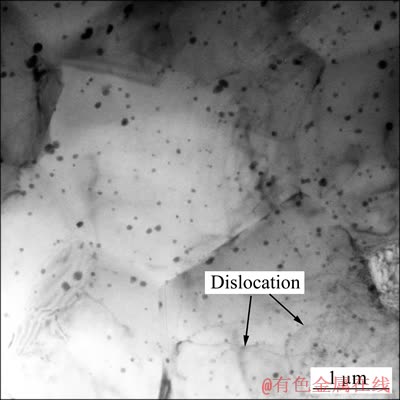

图5所示为d 14 mm试样的TEM像。由图5可知,合金经再结晶后大部分晶粒内部无位错,个别晶粒内部存在少量位错。另外,在晶内和晶界上分布着大量沉淀相颗粒,平均尺寸约为110 nm。

图3 挤压态Mg-6Zn-1Y-1Ce合金晶粒尺寸分布

Fig. 3 Grain size distributions of as-extruded Mg-6Zn-1Y-1Ce alloy

图4 d 12 mm挤压态Mg-6Zn-1Y-1Ce合金试样的SEM像

Fig. 4 SEM images of as-extruded Mg-6Zn-1Y-1Ce alloy with diameter of d 12 mm

2.2 拉伸性能

表1所列为挤压合金的拉伸性能。由表1可知,随着挤压比增加,合金强度降低。d 14 mm试样综合力学性能最优,其屈服强度比d 12 mm和d 10 mm试样分别高约40 MPa和90 MPa。虽然d 10 mm试样组织相对均匀,但晶粒相对粗大,伸长率仅有9.5%,略低于d 14 mm和d 12 mm试样的。

观察试样断口形貌(图6)发现,d 14 mm挤压试样由许多细小等轴韧窝和一些解理台阶组成(图6(a)),结合金相组织可以推测出在拉伸变形初期主要是细晶的塑性变形,随着变形量增加,细晶不能满足进一步塑形变形的需求,开始转变为以未再结晶的大晶粒变形为主的变形模式。由于室温下大晶粒的塑性变形能力较差,晶粒主要以穿晶脆断为主,之后裂纹向细晶组织扩展,并最终导致材料断裂。因此,韧窝为动态再结晶晶粒断面,而解理面为未再结晶晶粒断面。

图5 d 14 mm挤压态Mg-6Zn-1Y-1Ce合金试样的TEM像

Fig. 5 TEM image of as-extruded Mg-6Zn-1Y-1Ce alloy with diameter of 14 mm

表1 挤压态Mg-6Zn-1Y-1Ce合金的拉伸性能

Table 1 Tensile properties of as-extruded Mg-6Zn-1Y-1Ce alloy

d 12 mm和d 10 mm试样(图6(b)和(c))断口形貌相似,均由大小不等的韧窝组成,韧窝周围有尖锐的撕裂棱,底部有细小的强化相颗粒,为典型的韧性断口。在拉伸过程中,裂纹起源于二次相颗粒和基体的界面处,之后裂纹向基体扩展,并导致材料断裂。

3 讨论

3.1 显微组织

合金在300 ℃挤压后发生动态再结晶,平均晶粒细化至6 μm以下。然而,挤压比相对较小的d 14 mm和d 12 mm试样并未发生充分的再结晶,未再结晶晶粒被细小的再结晶晶粒包围,且其晶界呈锯齿状,这种组织特征归因于非连续动态再结晶机制[12]。在以滑移为主导的晶粒中,大量位错将在晶界处塞积,并使晶界局部区域发生扭曲,而扭曲区域晶格点阵严重畸变,当位错密度超过其吸收能力或当吸收位错所需的时间不充足时,晶格畸变最严重区域会成为动态再结晶优先形核之处。再结晶晶粒在原始晶粒边界以弓出方式形核,新晶粒围绕着原始粗大晶粒边界呈环状分布,并且与原始晶粒不同的晶粒取向特征。随着变形量增大,未再结晶晶粒一方面在应力作用下发生塑性变形,另一方面位错不断向晶界运动,促使新的晶粒不断形成。再结晶晶粒越来越多,并不断向原始晶粒内部扩展。如果挤压完成时,组织没有完全再结晶,则未再结晶区域集中在原始晶粒中心区域,并沿挤压方向被拉长。所以,在非连续动态再结晶机制下,未再结晶区域面积分数的减小与合金的真应变有关,合金获得的真应变越大,贮能越高,其动态再结晶越充分。坯料由d 50 mm挤压为d 14 mm、d 12 mm和d 10 mm试样,试样的真应变分别为2.55、2.85和3.22,真应变较大的d 10 mm试样基本完全发生了再结晶,而真应变较小的d 14 mm和d 12 mm试样再结晶不充分,组织中仍存在31.0%和14.2%的未再结晶区域。

图6 不同直径挤压态Mg-6Zn-1Y-1Ce合金试样断口形貌

Fig. 6 Fractographs of as-extruded Mg-6Zn-1Y-1Ce alloy with different diameters

通常认为,在一定挤压温度下,挤压比越大,再结晶晶粒越细小。然而,d 10 mm试样晶粒比d 14 mm和d 12 mm试样粗大。考虑到挤压时压力和温度相同,随着挤压比增加,挤压速度降低。因此,d 10 mm试样中晶粒粗化与挤压时应变速率有关。挤压过程中合金的应变速率可用下式进行计算[13]:

(1)

(1)

式中:v为挤压杆运动速度(mm/min);φ为凹模半角;d0和dm分别为坯料和挤出棒材直径。根据式(1)可计算出d 14 mm、d 12 mm和d 10 mm试样的应变速率分别为0.16 s-1、0.12 s-1和0.06 s-1。可见,d 10 mm试样挤压过程中应变速率最小。

Zener-Hollomon参数综合了温度和应变速率的影响,因此可引入Z参数来分析应变速率对镁合金的晶粒尺寸的影响。Z值与变形温度(T)和应变速率( )的关系为[14]

)的关系为[14]

(2)

(2)

(3)

(3)

式中:Q为激活能;R为摩尔气体常数;k和b均为常数。由式(2)和(3)可知,当温度一定时,如果应变速率较慢,则再结晶晶粒受高温影响越大,晶粒容易长大。d 10 mm试样挤压时应变速率过小,再结晶晶粒在挤压过程中长大而粗化。然而,其晶粒长大并不显著,平均尺寸小于6 μm,这主要是由于在热挤压过程中从基体析出了大量纳米级的沉淀相(见图5),这些沉淀颗粒对晶界有较强的钉扎作用,可以有效阻碍晶界移动,抑制晶粒长大。总之,若要获得均匀的细晶组织,挤压应该在相对较高的应变速率下进行。

3.2 拉伸性能

晶粒尺寸为1~2 μm的挤压态纯镁屈服强度约为150~160 MPa[15],晶粒度与其接近的d 14 mm试样屈服强度是其2倍多。所以,Mg-6Zn-1Y-1Ce合金表现出的高强度除了晶粒细化效果外,还与合金化有关。通常,多晶合金的屈服强度sYS遵循Hall-Petch公式[16]:

sYS=s0+kD-1/2 (4)

式中:s0为单晶的屈服强度;D为晶粒平均尺寸;k为表征晶界对强度影响程度的常数,可以用式(5)表 示[16]:

k=M 2τcr1/2 (5)

式中:M是Taylor因子,与激活滑移系数量相关;r是临近晶粒内部位错塞积和位错源之间最近距离( );τc是滑移系开动所需的剪切应力(MPa),可以表示为

);τc是滑移系开动所需的剪切应力(MPa),可以表示为

tc=s0cos f cos l (6)

式中:cos f cos l为Schmid因子。添加合金化元素后,会引入固溶强化和颗粒强化。Ce在Mg基体固溶度极低,虽然Y固溶度较大,但在Mg-Zn合金中,Y的固溶度会降低到较低水平[17],Y和Ce元素几乎全部在凝固过程中形成了三元(MgZn)12Ce相和W相,固溶强化主要是Zn元素的贡献。强化相颗粒包括破碎的第二相颗粒和沉淀相颗粒的作用,主要强化相为W相和(MgZn)12Ce相。W相为面心立方结构,与基体的取向关系为[001] ||  、(110) ||

、(110) ||  [18],为高温稳定的强化相,W相能显著提高合金强度,例如,W相增强的热挤压Mg-6Zn-4Y合金屈服强度高达350 MPa[19]。(MgZn)12Ce相是Mg12Ce相中部分Zn替代Mg形成的固溶体,与基体取向关系<100> ||

[18],为高温稳定的强化相,W相能显著提高合金强度,例如,W相增强的热挤压Mg-6Zn-4Y合金屈服强度高达350 MPa[19]。(MgZn)12Ce相是Mg12Ce相中部分Zn替代Mg形成的固溶体,与基体取向关系<100> ||  ,<010> ||

,<010> ||  ,<001> || <0001>[20],对基体有明显的增强作用。例如,挤压态ZK60-1.5Ce合金抗拉强度达340.6 MPa[21]。所以,W相和(MgZn)12Ce相的强化效果能大幅提高合金强度,固溶强化和颗粒强化的综合作用结果会使屈服强度s0显著增大。由式(5)和(6)可知,s0值增大的同时会提高k值,即晶粒越细小,合金屈服强度提高幅度越大,因此,Mg-6Zn-1Y-1Ce合金的高强度是合金化和晶粒细化的综合效果。

,<001> || <0001>[20],对基体有明显的增强作用。例如,挤压态ZK60-1.5Ce合金抗拉强度达340.6 MPa[21]。所以,W相和(MgZn)12Ce相的强化效果能大幅提高合金强度,固溶强化和颗粒强化的综合作用结果会使屈服强度s0显著增大。由式(5)和(6)可知,s0值增大的同时会提高k值,即晶粒越细小,合金屈服强度提高幅度越大,因此,Mg-6Zn-1Y-1Ce合金的高强度是合金化和晶粒细化的综合效果。

然而,d 14 mm和d 12 mm试样晶粒平均尺寸仅差0.2 μm,但其屈服强度相差约40 MPa。因此,其强度差异除了晶粒强化因素外,还受其他因素的影响。从其组织特征可知,两者均由细小的等轴晶和未再结晶区域组成,d 14 mm试样中未再结晶区域面积分数高达31.0%,是d 12 mm试样的2倍。研究表明,未再结晶晶粒沿 晶体学方向放置,其c轴垂直于(偏差±5°)挤压方向[10]。根据Schmid准则,未再结晶晶粒在{0001}

晶体学方向放置,其c轴垂直于(偏差±5°)挤压方向[10]。根据Schmid准则,未再结晶晶粒在{0001} 的Schmid因子值很小[22],这些晶粒的基面滑移被抑制,当拉伸方向平行于基面时,最容易激活的

的Schmid因子值很小[22],这些晶粒的基面滑移被抑制,当拉伸方向平行于基面时,最容易激活的

孪生系也不活跃[23],所以,这些晶粒在拉伸时具有很强的抗屈服能力,能显著增加屈服强度,因此,d 14mm试样具有更高的强度。

孪生系也不活跃[23],所以,这些晶粒在拉伸时具有很强的抗屈服能力,能显著增加屈服强度,因此,d 14mm试样具有更高的强度。

4 结论

1) 在300 ℃、将d 50 mm的Mg-6Zn-1Y-1Ce合金坯料挤压为d 14 mm、d 12 mm和d 10 mm的试棒,挤压比越大,合金动态再结晶越充分,3种试样再结晶区域面积分数分别为69%、85.8%和99.1%。

2) 挤压力一定时,挤压比越大,挤压应变速率越小,再结晶晶粒受温度影响越大,晶粒长大越明显,d 14 mm、d 12 mm和d 10 mm试样平均晶粒尺寸分别为2.7、2.4和5.9 μm。

3) 挤压态Mg-6Zn-1Y-1Ce合金具有优异的力学性能,d 14 mm、d 12 mm和d 10 mm样品屈服强度分别为327.4、286.5和237.5 MPa,合金的高强度归因于合金化和细晶强化的综合作用。

REFERENCES

[1] ANYANWU IA, GOKAN Y, NOZAWA S, KAMADO S, KOJIMA Y TAKEDA S, ISHIDA T. Heat resistant magnesium alloys for automotive powertrain applications[J]. Materials Science Forum, 2003, 419/422(I): 445-450.

[2] FROES F. Advanced metals for aerospace and automotive use[J]. Materials Science and Engineering A, 1994, 184(2): 119-133.

[3] SMOLA B,  MORDIKE B L. Significance of stable and metastable phases in high temperature creep resistant magnesium-rare earth base alloys[J]. Journal of Alloys and Compounds, 2004, 378(1/2): 196-201.

MORDIKE B L. Significance of stable and metastable phases in high temperature creep resistant magnesium-rare earth base alloys[J]. Journal of Alloys and Compounds, 2004, 378(1/2): 196-201.

[4]  KLOC L, EVANGELISTA E. Threshold creep behavior of an Mg-Zn-Ca-Ce-La alloy processed by rapid solidification[J]. Materials Science and Engineering A, 1996, 215(1/2): 73-83.

KLOC L, EVANGELISTA E. Threshold creep behavior of an Mg-Zn-Ca-Ce-La alloy processed by rapid solidification[J]. Materials Science and Engineering A, 1996, 215(1/2): 73-83.

[5] GUO X, SHECHTMAN D. Extruded high-strength solid materials based on magnesium with zinc, yttrium, and cerium additives[J]. Glass Physics and Chemistry, 2005, 31(1): 44-52.

[6] GUO X, SHECHTMAN D. Reciprocating extrusion of rapidly solidified Mg-6Zn-1Y-0.6Ce-0.6Zr alloy[J]. Journal of Materials Processing Technology, 2007, 187/188: 640-644.

[7] 郭学锋, 任 昉. 高强度Mg-Zn-Y-Ce-Zr合金细丝的制备与表征[J]. 中国有色金属学报, 2011, 21(2): 290-295.

GUO Xue-feng, REN Fang. Preparation and characterization of high strength Mg-Zn-Y-Ce-Zr alloy wire[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 290-295.

[8] YANG Wen-peng, GUO Xue-feng. High strength Mg-6Zn-1Y-1Ce alloy prepared by hot extrusion[J]. Journal of Wuhan University of Technology, 2013, 28(2): 389-395.

[9] 李永军, 张 奎, 李兴刚, 马鸣龙, 王海珍, 何兰强. 挤压变形对Mg-5.0Y-7.0Gd-1.3Nd-0.5Zr合金组织和性能的影响[J]. 中国有色金属学报, 2010, 20(9): 1692-1697.

LI Yong-jun, ZHANG Kui, LI Xing-gang, MA Ming-long, WANG Hai-zhen, HE Lan-qiang. Influence of extrusion on microstructures and mechanical properties of Mg-5.0Y-7.0Gd- 1.3Nd-0.5Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1692-1697.

[10] AZEEM M A, TEWARI A, MISHRA S, GOLLAPUDI S, RAMAMURTY U. Development of novel grain morphology during hot extrusion of magnesium AZ21 alloy[J]. Acta Materialia, 2010, 58(5): 1495-1502.

[11] SASAKI T T, YAMAMOTO K, HONMA T, KAMADO S, HONO K. A high-strength Mg-Sn-Zn-Al alloy extruded at low temperature[J]. Scripta Materialia, 2008, 59(10): 1111-1114.

[12] AL-SAMMAN T, LI X, CHOWDHURY S G. Orientation dependent slip and twinning during compression and tension of strongly textured magnesium AZ31 alloy[J]. Materials Science and Engineering A, 2010, 527(15): 3450-3463.

[13] DIETER G E. Mechanical metallurgy[M]. Singapore: McGraw-Hill Book Company, 1988: 625-629.

[14] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[15] SOMEKAWA H, MUKAI T. Effect of grain refinement on fracture toughness in extruded pure magnesium[J]. Scripta Materialia, 2005, 53(9): 1059-1064.

[16] ONO N, NOWAK R, MIURA S. Effect of deformation temperature on Hall-Petch relationship registered for polycrystalline magnesium[J]. Materials Letters, 2003, 58(1/2): 39-43.

[17] SUZUKI M, KIMURA T, KOIKE J, MARUYAMA K. Effects of zinc on creep strength and deformation substructures in Mg-Y alloy[J]. Materials Science and Engineering A, 2004, 387/389(1/2): 706-709.

[18] SINGH A, WATANABE M, KATO A, TSAI A P. Crystallographic orientations and interfaces of icosahedral quasicrystalline phase growing on cubic W phase in Mg-Zn-Y alloys[J]. Materials Science and Engineering A, 2005, 397(1/2): 22-34.

[19] YANG Wen-peng, GUO Xue-feng. High strength magnesium alloy with α-Mg and W-phase processed by hot extrusion[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2358-2364.

[20] YANG Wen-peng, GUO Xue-feng, LU Zheng-xin. TEM microstructure of rapidly solidified Mg-6Zn-1Y-1Ce alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 786-792.

[21] WU A, XIA C, WANG J. Distribution, evolution and the effects of rare earths Ce and Y on the mechanical properties of ZK60 alloys[J]. Journal of University of Science and Technology Beijing: Mineral, Metallurgy, Materials, 2006, 13(5): 424-428.

[22] HOMMA T, MENDIS C, HONO K, KAMADO S. Effect of Zr addition on the mechanical properties of as-extruded Mg-Zn-Ca-Zr alloys[J]. Materials Science and Engineering A, 2010, 527(9): 2356-2362.

[23]  ADEVA P. Effect of forging on the microstructure and mechanical properties of Mg-Zn-Y alloy[J]. Journal of Materials Processing Technology, 2008, 206(1/3): 99-105.

ADEVA P. Effect of forging on the microstructure and mechanical properties of Mg-Zn-Y alloy[J]. Journal of Materials Processing Technology, 2008, 206(1/3): 99-105.

(编辑 李艳红)

基金项目:河南省科技公关项目(10212210031);河南省教育厅自然科学基金资助项目(2010A4300008);河南省高等学校矿业工程材料重点学科开放实验室开放基金(KLMEM2012)

收稿日期:2012-10-23;修订日期:2013-04-17

通信作者:杨文朋,讲师,博士;电话:0391-3986906;E-mail: wenpengy@gmail.com