Treatment of bauxite residue dust pollution by improving structural stability via application of synthetic and natural polymers

来源期刊:中南大学学报(英文版)2019年第2期

论文作者:徐光 丁旭涵 周伟 Biswas WAHIDUL 郭幸运

文章页码:440 - 448

Key words:unconfined compressive strength; experimental design; polyacrylamide; Guar gum; combined application

Abstract: The residue drying area (RDA) is the major source of fugitive red sand (RS) dust emissions in the bauxite mining industry and causes serious environmental and safety detriments. Polymer stabilizer (PS) is one of the promising non-traditional stabilizers to mitigate such issues. This research investigated the unconfined compressive strength (UCS) of RS using synthetic polymer stabilizer (SPS) and natural polymer stabilizer (NPS), and to determine the optimum application concentration and mixing ratio of the PAM and Guar gum mixture. Results illustrated that PAM apparently outperform Guar gum in stabilizing sand particles. The mixture of PAM and Guar gum is more effective than individual use. The optimum polymer concentration and the mixing ratio are 0.94 wt.% and 0.6 (PAM : total (PAM + Guar gum)), respectively. A rigorous regression model was developed to predict the UCS value based on application concentration and mixing ratio for the purpose of cost and time efficiency.

Cite this article as: DING Xu-han, XU Guang, ZHOU Wei, Biswas WAHIDUL, GUO Xing-yun. Treatment of bauxite residue dust pollution by improving structural stability via application of synthetic and natural polymers [J]. Journal of Central South University, 2019, 26(2): 440–448. DOI: https://doi.org/10.1007/s11771-019-4016-8.

ARTICLE

J. Cent. South Univ. (2019) 26: 440-448

DOI: https://doi.org/10.1007/s11771-019-4016-8

DING Xu-han(丁旭涵)1, XU Guang(徐光)1, 2, ZHOU Wei(周伟)2,Biswas WAHIDUL3, GUO Xing-yun(郭幸运)1

1. Department of Mining Engineering and Metallurgical Engineering, Western Australian School of Mines, Curtin University, Kalgoorlie, Australia;

2. State Key Laboratory of Coal Resources and Safe Mining, China University of Mining and Technology, Xuzhou 221116, China;

3. Sustainable Engineering Group, School of Civil and Mechanical Engineering, Curtin University, Australia

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract: The residue drying area (RDA) is the major source of fugitive red sand (RS) dust emissions in the bauxite mining industry and causes serious environmental and safety detriments. Polymer stabilizer (PS) is one of the promising non-traditional stabilizers to mitigate such issues. This research investigated the unconfined compressive strength (UCS) of RS using synthetic polymer stabilizer (SPS) and natural polymer stabilizer (NPS), and to determine the optimum application concentration and mixing ratio of the PAM and Guar gum mixture. Results illustrated that PAM apparently outperform Guar gum in stabilizing sand particles. The mixture of PAM and Guar gum is more effective than individual use. The optimum polymer concentration and the mixing ratio are 0.94 wt.% and 0.6 (PAM : total (PAM + Guar gum)), respectively. A rigorous regression model was developed to predict the UCS value based on application concentration and mixing ratio for the purpose of cost and time efficiency.

Key words: unconfined compressive strength; experimental design; polyacrylamide; Guar gum; combined application

Cite this article as: DING Xu-han, XU Guang, ZHOU Wei, Biswas WAHIDUL, GUO Xing-yun. Treatment of bauxite residue dust pollution by improving structural stability via application of synthetic and natural polymers [J]. Journal of Central South University, 2019, 26(2): 440–448. DOI: https://doi.org/10.1007/s11771-019-4016-8.

1 Introduction

The production and disposal of bauxite residue (red sand, RS) poses acute environmental impacts to both mine sites and the surrounding regions [1–4]. It does not only cause health issues, including upper respiratory tract, lung and eye irritation, wheezing and rhinitis, due to the emitted RS dust [5], but also has adverse impacts on the ecosystem, such as salinity problem, and water pH alteration [6–10]. Therefore, fugitive RS dust management is a major concern which requires long-lasting, fast-acting and effective solutions [11].

Bauxite residue is one of the primary by-products of the aluminum refinery process with the global production of 1.2 Mt/a [12, 13]. It is mainly constituted by the undissolved alumina and heaps of metallic oxide [14, 15]. Bauxite residue is separated into coarse fraction named RS with a particle size larger than 150 μm (i.e. 60% of the residue), and fine fraction named red mud with the particle size finer than 150 μm (i.e. 40%) [16–18]. The mass fraction of the metallic oxide and the phase of the residue vary with refinery sites and plants due to different levels of process techniques and geological characteristics. The major treatment of bauxite residue is the “dry stacking” disposal method [19–21], where RS is used to construct the dike walls for the storage and drying of red mud [22]. However, this method in fact causes the generation and emission of RS dust from the dike wall due to its poor aggregate stability, the breakdown of the internal bonding between surface particles after capillary salt transportation, surface efflorescence, and the reduction of sodium molar volume when exposed to dry conditions [23–25].

One effective way to mitigate dust emission is the chemical stabilization of RS via the application of polymer stabilizer (PS). Studies revealed that a positive improvement on unconfined compressive strength (UCS) correlates to increases in other mechanical properties, such as the shear strength, crust surface hardness, and the final dust erosion resistance [26, 27]. Thus, UCS can be used as an index to predict its effectiveness of dust control [28]. The UCS improving mechanism depends on various PS types. Cationic PS tends to react with the negatively charged particle surface of clay fraction of sand through the neutralization process [29]. However, anionic PS attracts particles with multivalent cations such as Na+, K+, Ca2+ and Mg2+, while non-ionic PS mainly adsorb particles via the van der Waals (VDW) force [29]. Normally, ionic or covalent bonds provide the highest bonding energy with short lasting time, while bonds caused by VDW force offer weak bond energy over a long period [30].

Polymer stabilizer is generally classified into synthetic PS and natural PS. Synthetic polymers are manually extracted from petroleum oil while natural polymers only occur in nature environment and the majority of them are water-based. Previous studies emphasize the utilization of SPS only to enhance the structural strength and dust control of treated materials, but no research has been done on NPS and the combined effect of different types of stabilizers on RS. For example, for SPS studies, one research [31] analyzed the effectiveness on improving compressive strength of poly methyl mehta acryl (PMMA) and polyvinyl acetate when applied to soil. When the concentrations of stabilizers are within the range of 0.4 wt% to 3.7 wt%, an approximately linear improvement of UCS of RS with the increase of stabilizer concentration was observed. This finding was confirmed by another study on the investigation of sandy soil structure strength improvement by acrylic emulsion PS for a concentration range between 0.5 wt% and 2 wt% [32]. However, different conclusions were made when considering a wider concentration range of stabilizers. For example, one PS named “STW stabilizer”, when used in a concentration range of 0 to 10 wt%, showed a fast improvement on UCS at the initial stage, but it leveled off when further increasing the concentration [27, 33]. Other studies also confirmed this finding [27, 34, 35]. However, although many studies have been carried out on NPS for the dust control performance improvement, very few of them showed the correlation between this performance and the UCS. CHEN et al [36] and CHANG [37, 38] assessed the UCS of materials treated by single PS. CHEN et al [36] found that the UCS increases linearly when the stabilizer concentration increases from 0 to 0.5 wt%. CHANG et al [37, 38] employed a wider stabilizer concentration range and further illustrated that the UCS increases with higher NPS concentration and this improvement is much more obvious when continuously increasing the NPS amount. However, no research has been done on the combined effect of different types of PS on red sand. Study in this paper is necessary for a better strategy of applying stabilizer for RS dust control.

This study aims at the investigation on the combined effect of SPS and NPS on the UCS of RS, and determines the optimum mixing ratio of the two stabilizers to achieve the best result for a cost effective manner. Whether the stabilizer concentration has significant effect on the UCS was investigated. After that, the combined effect of the two stabilizers is investigated via the 2k experimental design. Finally, an optimum application scheme including combined application mixing ratio and total application concentration was determined by using the response surface experimental design method.

2 Materials and methods

2.1 Sands

The red loam sand was purchased and used as the substitute for test samples due to restricted availability of RS materials. It has a particle size distribution mainly ranging from 0.04 mm to 0.7 mm, which is similar with the RS. Particles size distribution test was performed by following the standard AS 1289.3.6.1 [39]. The sand was classified as poorly graded sand (SP) (based on the Unified Soil Classification System raised by American Society for Testing and Materials in 1985). The sand constituents were identified to be similar with red sand. Sand was dried in an oven at 75 °C, and sieved to the diameter <1.18 mm. The processed sand has an optimum moisture content (OMC) of 5% and a maximum dry density (MDD) of 2.16 g/cm3 by following the standard AS 1289.5.2.1 [40]. As shown in Table 1, the direct shear strength test following AS 1289.6.2.2 [41] showed that the friction angle of tested sand is 38.27° and the cohesion is 0.26 kPa, which are similar with those of red sand [42, 43].

Table 1 Direct shear strength test data

2.2 Stabilizers

One synthetic polymer named “polyacrylamide (PAM)” and one natural polymer named “Guar Gum” were applied in this study. They were purchased from Sigma Aldrich (Australia) as powders. PAM was a water-soluble linear polymer formed by the free radical polymerization of the acrylamide monomer. It was formed by acrylate-based transparent particles with a molecular weight of 3–25 million daltons [44]. PAM can be used in agricultural field to control soil erosion during irrigation [45–48], to reduce dust emission in arid and semi-arid areas [49, 50], and for the rapid building of helicopter landing pad [44, 51]. Guar gum was isolated from the endosperm of the lobus seed of the Cyamopsis Tetragonoloba [52]. It was a natural cationic polymer with the most effective water solubility. It had a molecular weight of 2.2×105 daltons. Guar gum is normally produced in white powder state and can form transparent solution with high viscosity which exhibits non- Newtonian rheological properties.

2.3 UCS test

The UCS mainly represents the change of structural strength of the treated sand. In this study, sand was adequately mixed with deionized water first to achieve its optimum moisture content which is identified in Section 2.1, and then thoroughly mixed with the polymer powder. This method can greatly simplify the preparation procedure with lower requirements of the preparation apparatus. High-speed blender ensures uniform mixing of stabilizer powder and wet sand. The mixture was sealed for 2 h to allow adequate interaction between the stabilizer powder and the moisture. After that, the mixture was then compacted into a 4 cm×8 cm (diameter×height) cylindrical mould as it was reported by DING et al [53]. During the compaction, a 2.5 kg top load was slightly applied onto the surface of the specimen and a vibration table was employed for uniform compaction. All samples were air dried under ambient temperature and humidity until the mass change per day was below 0.2 g. The STX-100 soil test equipment was used at a loading rate of 1 mm/min by following the standard ASTM D2166/D2166M [54]. The prepared sample and the cylindrical mold are described in Figure 1.

Figure 1 Cylindrical mould and sample:

Firstly, one test based on the simple comparative design was conducted firstly to determine whether the stabilizer concentration has significant effect on the UCS of the treated sand. Two stabilizer concentrations (0.2 wt% and 1 wt%) were selected according to CHEN et al [36]. Five replicates were prepared for this test to achieve more reliable data. Secondly, two stabilizers were applied simultaneously in different mixing ratios for their concentrations between 0.2 wt% and 1 wt% in the specimens, to assess their structural performance in terms of UCS via a 2k design. 2k design is one of the experimental design methods which is extremely useful by providing the smallest number of runs when studying k factors at two levels [55]. Five different PAM to Total mixing ratios were selected (0, 0.25, 0.5, 0.75 and 1) and 3 replicates were prepared for each combination as shown in Table 2. Lastly, the response surface design was used to determine the optimum concentration and mixing ratio. As the maximum stabilizer concentration is 1 wt% due to the limited water solubility of these polymers, the experimental region is confined. Thus, the optimal designs for response surface experimental method is used, and the details are shown in Table 3.

Table 2 Sample preparation for 2k design in mass ratio

Table 3 UCS test experimental design

2.4 Statistical analysis methods

Both t-test and ANOVA are employed in this study to statistically evaluate the experimental data for a more reliable and accurate manner. t-test refers to a method that analyzes a normal distribution where the sample content is small (normally less than 30) and the standard deviation is unknown. T-test can effectively predict the probability of the occurrence of a difference and evaluate whether the difference between two averages is significant or due to human errors based on t-distribution theory. ANOVA is short for analysis of variance, which determines the difference of the means of two or more samples is significant or not.

3 Results and discussion

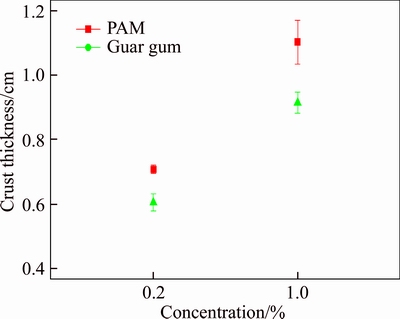

The performance of non-traditional stabilizers to improve the UCS of red send dust has been investigated. As confirmed by Figure 2, PAM performed better than Guar Gum in strengthening the UCS of RS. As the concentration of the stabilizer increased from 0.2 wt.% to 1 wt.%, the UCS of PAM treated sample increased from 0.708 MPa to 1.102 MPa, and Guar gum treated sample increased from 0.605 MPa to 0.915 MPa. t-test was performed to evaluate the significance of the mean difference of the UCS data. The assessment of t-test is achieved by comparing the calculated t-value with the p-value in t-table which corresponds to the significance level. If the calculated t-value is less than the t-table value, there is significant difference between means. In this study, the t0 of both PAM and Guar Gum treated sand is much lower than t0.025,8. Thus, the mean difference of the UCS is significant which is due to the change of concentrations rather than test errors. Results is consistent with the study by IYENGAR et al [29] and KHATAMI et al [30] who illustrated an obvious improvement on UCS after the individual application of acrylate-based SPS and NPS.

Figure 2 UCS simple comparative test results

In order to evaluate the performance of PAM and Guar gum mixture on the UCS of tested sand, tests based on the 2k design have been performed (Figure 3). As 1 wt.% stabilizer can achieve better UCS, the total stabilizer concentration was fixed at 1 wt% in this test, but different combination ratios of the two stabilizers were used to strengthen structural stability of samples. The combination ratio denotes the fraction of PAM in the amount of total applied stabilizers. The combined use of two stabilizers resulted in higher UCS of RS than being used individually. The UCS with 0.75 wt% PAM and 0.25 wt% Guar gum achieved the maximum UCS of 1.385 MPa, which is 1.5 times that treated by only Guar gum and 1.23 times that treated by only PAM.

Figure 3 UCS of samples treated by polymers in different mixing ratios

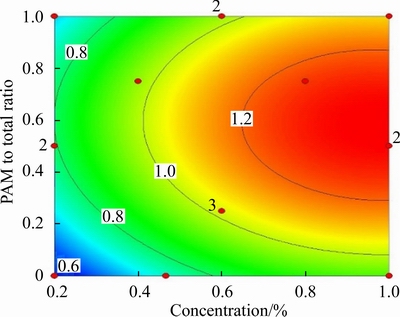

Based on the above 2k design experiments, it is confirmed that an optimum combination ratio exists when the overall application concentration is 1 wt%. Test based on the response surface design has been conducted to further investigate how UCS changes with combination ratios and the concentrations of PS in treated sand. 16 runs were performed based on the optimal design for response surface, as shown in Table 3.

The ANOVA results presented in Table 4 suggested that both stabilizer concentration and mixing ratio have significant effects on the UCS. It shows from Figures 4 and 5 that generally, UCS increases with stabilizer concentration, and a plateau is reached at concentrations around 1 wt%.

Table 4 ANOVA of UCS test

Figure 4 Contour plot of UCS test (MPa)

Figure 5 Perspective 3D plot of UCS test

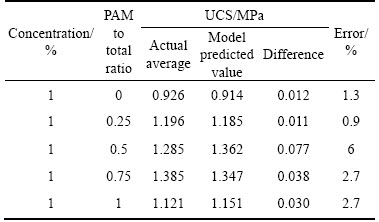

The optimum UCS occurs at the PAM to total ratio of 0.6 and the concentration of 0.94 wt%. A quadratic empirical equation, Eq. (1), has been generated based on these results to determine an optimum UCS for different levels of concentration and mixing ratio of PS in this test. In Eq. (1), x is the stabilizer concentration and y is the ratio of PAM to total. Figure 6 shows the scatter plot of actual vs predicted value, indicating the differences between the predicted value and observed records with the R2 equal to 0.9775. It shows that all the predicted values well agree with the actual. To further validate the model accuracy, the independent data sets from the 2k design experiments are used to calculate the prediction error. As can be seen in Table 5, the predicted errors are all below 6%, indicating an acceptable model reliability.

where x and y stand for the stabilizer concentration and the mass ratio of PAM to total, respectively.

Figure 6 Predicted vs actual UCS plot of constructed model

It is noted that the values of UCS obtained in this study are lower than other studies. The maximum UCS in this study is 1.317 MPa, but in other studies it is improved up to 3.2 MPa when the NPS concentration is about 0.5 wt% [37]. This is mainly because of the difference in the mixing method used in sample preparation. Although the preparation method used in the current study required the mixtures of the sand and stabilizers to be sealed for 2 h for improved interaction of the stabilizer-sand-water, compared to the wet mix mentioned in Section 2.3, the current preparation method may not offer complete mixing and interaction, which may result in a reduction on the UCS of treated samples.

Table 5 Assessment of model accuracy

4 Conclusions

It is noted that both PAM and Guar gum provide improved UCS with higher concentration, and PAM apparently outperform Guar gum. The mixture of PAM and Guar Gum could improve the UCS performance better than being used individually in RS. Response surface test further illustrates that the optimum combination of polymer concentration and mixing ratio is 0.94 wt.% and 0.6 (PAM to total ratio), respectively. A regression model was developed to determine UCS for different concentration and mixing ratio of the two investigated stabilizers in RS.

This study is one of the tasks aiming at developing more effective dust control solutions by using chemical stabilizers. Most notably, this is one of the few studies to our knowledge to investigate the use of both synthetic and natural polymers for enhancing the structure strength of RS for reducing dust pollution potentials. It is noted that the combination of PAM and Guar gum improved the UCS of treated sand up to 1.5 times that by each single stabilizer treatment. Results provide significant evidence that even though the single application of polymer can improve the UCS of treated sand, the combination usage of non-ionic and cationic polymer may result in an advanced enhancement. With the identification of the optimal mix ratio, more economical dust control strategy can be achieved.

References

[1] ZHU F, CHENG Q Y, XUE S G, LI C X, HARTLEY W, WU C, TIAN T. Influence of natural regeneration on fractal features of residue microaggregates in bauxite residue disposal areas [J]. Land Degradation & Development, 2018, 29: 138–149. DOI: 10.1002/ ldr.2848.

[2] XUE S G, YE Y Z, ZHU F, WANG Q L, JIANG J, HARTLEY W. Changes in distribution and microstructure of bauxite residue aggregates following amendments addition [J]. Journal of Environmental Sciences, 2019, 78: 276–286. DOI: 10.1016/j.jes.2018. 10.010.

[3] LIU Z W, LI W X, MA W H, YIN Z L, WU G B. Comparison of deep desulfurization methods in alumina production process [J]. Journal of Central South University, 2015, 22: 3745–3750.

[4] LIAO J X, JIANG J, XUE S G, CHENG Q Y, WU H, MANIKANDAN R, HARTLEY W, HUANG L. A novel acid-producing fungus isolated from bauxite residue: The potential to reduce the alkalinity [J]. Geomicrobiology Journal, 2018, 35: 840–847. DOI: 10.1080/01490451. 2018.1479807.

[5] IAI. Background information on typical bauxite residue [M]. European Aluminum Association, 2013.

[6] MAYES W, BURKE I, GOMES H, ANTON  , MOLN

, MOLN R M, FEIGL V, UJACZKI

R M, FEIGL V, UJACZKI  . Advances in understanding environmental risks of red mud after the Ajka spill, Hungary [J]. Journal of Sustainable Metallurgy, 2016, 2: 332–343.

. Advances in understanding environmental risks of red mud after the Ajka spill, Hungary [J]. Journal of Sustainable Metallurgy, 2016, 2: 332–343.

[7] GELENCS R A S, KOV

R A S, KOV TS N R, TUR

TS N R, TUR CZI B, ROST

CZI B, ROST SI A G, HOFFER A S, IMRE K L, NYIR

SI A G, HOFFER A S, IMRE K L, NYIR ′-K

′-K SA I, CS

SA I, CS KBER

KBER NYI-MALASICS D, T

NYI-MALASICS D, T TH A D M, CZITROVSZKY A R. The red mud accident in Ajka (Hungary): Characterization and potential health effects of fugitive dust [J]. Environmental Science & Technology, 2011, 45: 1608–1615.

TH A D M, CZITROVSZKY A R. The red mud accident in Ajka (Hungary): Characterization and potential health effects of fugitive dust [J]. Environmental Science & Technology, 2011, 45: 1608–1615.

[8] DAUVIN J C. Towards an impact assessment of bauxite red mud waste on the knowledge of the structure and functions of bathyal ecosystems: The example of the Cassidaigne canyon (north-western Mediterranean Sea) [J]. Marine Pollution Bulletin, 2010, 60: 197–206.

[9] KONG X F, JIANG X X, XUE S G, HUANG L, HARTLEY W, WU C, LI X F. Migration and distribution of saline ions in bauxite residue during water leaching [J]. Trans Nonferrous Met Soc China, 2018, 28: 534–541. DOI: 10.1016/S1003- 6326(18)64686-2.

[10] KONG X F, TIAN T, XUE S G, HARTLEY W, HUANG L, WU C, LI C X. Development of alkaline electrochemical characteristics demonstrates soil formation in bauxite residue undergoing natural rehabilitation [J]. Land Degradation & Development, 2018, 29: 58–67. DOI: 10.1002/ldr.2836.

[11] XUE S G, KONG X F, ZHU F, HARTLEY W, LI X F, LI Y W. Proposal for management and alkalinity transformation of bauxite residue in China [J]. Environmental Science and Pollution Research, 2016, 23: 12822–12834. DOI: 10.1007/ s11356-016-6478-7.

[12] ZHU F, HOU J T, XUE S G, WU C, WANG Q L, HARTLEY W. Vermicompost and gypsum amendments improve aggregate formation in bauxite residue [J]. Land Degradation & Development, 2017, 28: 2109–2120. DOI: 10.1002/ ldr.2737.

[13] YANG H B, PAN X L, YU H Y, TU G F, SUN J M. Effect of ferrite content on dissolution kinetics of gibbsitic bauxite under atmospheric pressure in NaOH solution [J]. Journal of Central South University, 2017, 24: 489–495.

[14] EVANS K, NORDHEIM E, TSESMELIS K. Bauxite residue management [J]. Light Metals, 2012: 63–66.

[15] GR FE M, POWER G, KLAUBER C. Bauxite residue issues: III alkalinity and associated chemistry [J]. Hydrometallurgy, 2011, 108: 60–79.

FE M, POWER G, KLAUBER C. Bauxite residue issues: III alkalinity and associated chemistry [J]. Hydrometallurgy, 2011, 108: 60–79.

[16] Alcoa. Dust management plan for the Alcoa Pinjarra bauxite residue disposal area [R]. 2007.

[17] HOWE P L, CLARK M W, REICHELT-BRUSHETT A, JOHNSTON M. Toxicity of raw and neutralized bauxite refinery residue liquors to the freshwater cladoceran Ceriodaphnia dubia and the marine amphipod Paracalliope australis [J]. Environmental Toxicology and Chemistry, 2011, 30: 2817–2824.

[18] LI Y, HAYNES R, ZHOU Y F, CHANDRAWANA I. Chemical and physical properties of seawater-neutralized bauxite residue mud and sand and the effects of leaching [J]. International Journal of Environmental Science and Development, 2016, 7: 273–277.

[19] POWER G, GRAFE M, KLAUBER C. Bauxite residue issues: I. current management, disposal and storage practices [J]. Hydrometallurgy, 2011, 108: 33–45.

[20] XUE S G, ZHU F, KONG X F, WU C, HUANG L, HUANG N, HARTLEY W. A review of the characterization and revegetation of bauxite residues (red mud) [J]. Environmental Science and Pollution Research, 2016, 23: 1120–1132. 10.1007/s11356-015-4558-8.

[21] XUE S G, LI M, JIANG J, MILLAR G J, LI C X, KONG X F. Phosphogypsum stabilization of bauxite residue: Conversion of its alkaline characteristics [J]. Journal of Environmental Sciences, 2018, 77: 1–10. DOI: 10.1016/j.jes.2018.05.016.

[22] LI Y W, JIANG J, XUE S G, MILLAR G J, KONG X F, LI X F, LI M, LI C X. Effect of ammonium chloride on leaching behavior of alkaline anion and sodium ion in bauxite residue [J]. Transactions of Nonferrous Metals Society of China, 2018, 28: 2125–2134. DOI: 10.1016/S1003-6326(18)64857-5.

[23] KLAUBER C, HARWOOD N, HOCKRIDGE R, MIDDLETON C. Proposed mechanism for the formation of dust horizons on bauxite residue disposal areas [J]. Light Metals, 2016: 951–956.

[24] ZHU F, ZHOU J Y, XUE S G, HARTLEY W, WU C, GUO Y. Aging of bauxite residue in association of regeneration: A comparison of methods to determine aggregate stability & erosion resistance [J]. Ecological Engineering, 2016, 92: 47–54. DOI: 10.1016/j.ecoleng.2016.03.025.

[25] ZHU F, LIAO J X, XUE S G, HARTLEY W, ZOU Q, WU H. Evaluation of aggregate microstructures following natural regeneration in bauxite residue as characterized by synchrotron-based X-ray micro-computed tomography [J]. Science of the Total Environment, 2016, 573: 155–163. DOI: 10.1016/j.scitotenv. 2016.08.108.

[26] GAO W, WU Z, WU Z. Study of mechanism of the W-OH sand fixation [J]. Journal of Environmental Protection, 2012, 3: 1025–1033.

[27] LIU J, SHI B, JIANG H T, HUANG H, WANG G H, KAMAI T. Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer [J]. Engineering Geology 2011, 117: 114–120.

[28] XU G, DING X H, KURUPPU M, ZHOU W, BISWAS W. Research and application of non-traditional chemical stabilizers on bauxite residue (red sand) dust control, a review [J]. Science of the Total Environment, 2017, 616: 1552–1565.

[29] IYENGAR S R, MASAD E, RODRIGUEZ A K, BAZZI H S, LITTLE D, HANLEY H J M. Pavement subgrade stabilization using polymers: Characterization and performance [J]. Journal of Material in Civil Engineering, 2013, 25: 472–483.

[30] KHATAMI H R, O’KELLY B C. Improving mechanical properties of sand using biopolymers [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2012, 139: 1402–1406.

[31] ZANDIEH A R, YASROBI S S. Study of factors affecting the compressive strength of sandy soil stabilized with polymer [J]. Geotechnical and Geological Engineering, 2010, 28: 139–145.

[32] AL-KHANBASHI A, EL-GAMAL M. Modification of sandy soil using water-borne polymer [J]. Journal of Applied Polymer Science, 2002, 88: 2484–2491.

[33] HUANG H, SHI B, LIU J, GAO W, JIANG H T. Experimental study on the strength of soil modified by STW ecotypic soil stabilizer [J]. Journal of Disaster Prevention and Mitigation Engineering, 2008, 28: 87–97.

[34] JIANG C, SHI B, LIU F, LIU J, HUANG H. Study on soil improvement of expansive soil slope with ecotypic soil stabilizer in Ning-Huai Expressway [J]. Journal of Disaster Prevention and Mitigation Engineering, 2009, 29: 507–512.

[35] AL-KHANBASHI A, ABDALLA S W. Evaluation of three waterborne polymers as stabilizers for sandy soil [J]. Geotechnical & Geological Engineering, 2006, 24: 1603–1625.

[36] CHEN R, RAMEY D, WEILAND E, LEE I, ZHANG L. Experimental investigation on biopolymer strengthening of mine tailings [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2016, 142: 06016017.

[37] CHANG I, CHO G C. Strengthening of Korean residual soil with β-1, 3/1, 6-glucan biopolymer [J]. Construction and Building Materials, 2012, 30: 30–35.

[38] CHANG I, IM J, CHO G C. Geotechnical engineering behaviors of gellan gum biopolymer treated sand [J]. Canadian Geotechnical Journal, 2016, 53: 1658–1670.

[39] Australian Standard. AS1289.3.6.1. Standard method of analysis by sieving in Methods of testing soils for engineering purposes—Soil classification tests— Determination of the particle size distribution of a soil [S]. 2009.

[40] Australian Standard. AS1289.5 Methods of testing soils for engineering purposes, Method 51 1: Soil compaction and density tests—Determination of the dry density/moisture content relation of a soil using standard compactive effort [S]. 2003.

[41] Australian Standard. AS1289.6.2.2. Soil strength and consolidation tests—Determination of the shear strength of a soil—Direct shear test using a shear box: Methods of testing soils for engineering purposes [S]. 1998.

[42] JITSANGIAM P, NIKRAZ H, JAMIESON E. Sustainable use of a bauxite residue (red sand) in terms of roadway materials [C]// Proceedings of the 2nd International Conference on Sustainable Engineering and Science. Auckland, New Zealand, 2007: 20–23.

[43] NEWSON T, DYER T, ADAM C, SHARP S. Effect of structure on the geotechnical properties of bauxite residue [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2006, 132: 143–151.

[44] ORTS W J, ROA-ESPINOSA A, SOJKA R E, GLENN G M, IMAM S H, ERLACHER K, PEDERSEN J S. Use of synthetic polymers and biopolymers for soil stabilization in agricultural, construction, and military applications [J]. Journal of Materials in Civil Engineering, 2007, 19: 58–66.

[45] DOU Chao-yin, LI Fa-hu, WU L S. Soil erosion as affected by polyacrylamide application under simulated furrow irrigation with saline water [J]. Pedosphere, 2012, 22: 681–688.

[46] LENTZ R D, SOJKA R E. Applying polymers to irrigation water: Evaluating strategies for furrow erosion control [J]. Transactions of the ASAE, 2000, 43: 1561–1568.

[47] BJORNEBERG D L, AASE J K. Multiple polyacrylamide applications for controlling sprinkler irrigation runoff and erosion [J]. Applied Engineering in Agriculture, 2000, 16: 501–504.

[48] AASE J K, BJORNEBERG D L, SOJKA R E. Sprinkler irrigation runoff and erosion control with polyacrylamide- laboratory tests [J]. Soil Science Society of America Journal, 1998, 62: 1681–1687.

[49] HE J J, CAI Q G, TANG Z J. Wind tunnel experimental study on the effect of PAM on soil wind erosion control [J]. Environmental Monitoring and Assessment, 2008, 145: 185–193.

[50] ARTHUR G, LEONID V, JIFTAH B A. Combating wind erosion of sandy soils and crop damage in the coastal deserts: Wind tunnel experiments [J]. Aeolian Research, 2013, 9: 69–73.

[51] ROA-ESPINOSA A, BUBENZER G, MIYASHITA E. Sediment and runoff control on construction sites using four application methods of polyacrylamide mix [C]// Proceedings of the National Conference on Tools for Urban Water Resource Management and Protection. USEPA Office of Research and Development EPA/625/R-00/001, 2000: 278–283.

[52] CASAS J A, MOHEDANO A F, GARC A-OCHOA F. Viscosity of guar gum and xanthan/guar gum mixture solutions [J]. Journal of the Science of Food and Agriculture, 2000, 80: 1722–1727.

A-OCHOA F. Viscosity of guar gum and xanthan/guar gum mixture solutions [J]. Journal of the Science of Food and Agriculture, 2000, 80: 1722–1727.

[53] DING X H, XU G. Innovative sample preparation apparatus and method to construct cylindrical specimen for mechanical properties test of sandy materials [M]// Office TAP, ed. Vol 2016102039. Australia, 2016.

[54] ASTM. D2166/D2166M-16. Standard test method for unconfined compressive strength of cohesive soil [S]. American Society for Testing and Materials International, 2006.

[55] MONTGOMERY D C. Design and analysis of experiments [M]. John Wiley & Sons, 2017.

(Edited by YANG Hua)

中文导读

人工合成及天然高分子材料在铝土矿尾矿粉尘污染防治中的

沙土结构稳定性优化研究

摘要:在铝土矿产业中,尾矿库作为主要尘源会导致严重的环境及安全问题。使用高分子固沙剂降低尾矿库扬尘是较有潜力的治理方案。本文深入研究了人工合成高分子材料聚丙烯酰胺及天然高分子材料瓜尔胶对铝土矿尾矿砂单轴抗压强度的影响并得出了两种固沙剂的最优配比。结果表明,聚丙烯酰胺在固沙效能上高于瓜尔胶且两者混合使用的效果优于单一使用。聚丙烯酰胺及瓜尔胶在0.94 wt. % 浓度及3:2混合时达到最优固沙效果。本文同时提出了基于两种固沙剂不同浓度及配比条件下的有效快速预测单轴抗压强度的数学模型。

关键词:单轴抗压强度;实验设计方法;聚丙烯酰胺;瓜尔胶;混合使用

Foundation item: Project(2016YFC0501103) supported by the National Key Research and Development Program of China; Project(51574222) supported by the General Program of National Science Foundation of China; Project(SKLCRSM15KF01) supported by Independent Research Projects of State Key Laboratory of Coal Resources and Safe Mining, CUMT, China; Project(2015) supported by the Mining Education Australia Collaborative Research Grant Scheme

Received date: 2018-10-25; Accepted date: 2018-12-08

Corresponding author: XU Guang, PhD; E-mail: xuguang@vt.edu; ORCID: 0000-0002-4923-1702