DOI: 10.11817/j.issn.1672-7207.2016.01.009

柴油机水冷中冷器冷却性能仿真与试验

张钦国1,秦四成1,刘宇飞2,马润达1,李武1

(1. 吉林大学 机械科学与工程学院,吉林 长春,130022;

2. 吉林大学 汽车工程学院,吉林 长春,130022)

摘要:为了研究增压空气和冷却液对中冷器散热性能的影响及阻力特性,采用流-固耦合传热模型和换热器模型,对重型柴油机水冷中冷器内部流场和温度场进行三维数值模拟,分析中冷器内部流动阻力损失和传热性能,并通过台架试验对仿真结果进行验证。研究结果表明:进气口处空气回流较大,增加了空气流动的阻力和流动不均匀性;增压空气流量越大,冷却效率越高;空气出口温度控制在30~40 ℃,散热效果较好,满足使用要求;冷却液温度对中冷器冷却性能影响较大,温度每升高10 ℃,换热效率降低5%~10%。

关键词:水冷中冷器;波纹翅片;流-固耦合;换热器模型

中图分类号:U415.52+1 文献标志码:A 文章编号:1672-7207(2016)01-0054-08

Numerical simulation and experiment on cooling performance of water-air intercooler of diesel engine

ZHANG Qinguo1, QIN Sicheng1, LIU Yufei2, MA Runda1, LI Wu1

(1. College of Mechanical Science and Engineering, Jilin University, Changchun 130022, China;

2. College of Automotive Engineering, Jilin University, Changchun 130022, China)

Abstract: In order to study the influence of the charge air and the coolant on the intercooler heat dissipation performance and the resistance properties, fluid-solid coupling heat transfer model and heat exchanger model were used. Three-dimensional numerical simulation was carried out in order to obtain the water-cooled intercooler internal flow field and temperature field of a heavy diesel engine. The simulation results were verified through the bench test. The results show that return air flow is larger at the inlet and air flow resistance and flow nonuniformity increase. The heat dissipation performance is better with greater charge air flow rate. Outlet temperature is controlled at 30-40 ℃. The cooling effect is better, and meets the requirement. The different cooling water temperature has a greater influence on the cooling performance of the intercooler. The power conversion efficiency can be reduced by 5%-10% with coolant temperature raised 10 ℃.

Key words: water-air intercooler; wavy fin; fluid-solid couple; heat exchanger model

随着新排放法规的实施,国家对车辆排放的要求也越来越高。目前,发动机普遍采用涡轮增压技术提高进气密度,使燃烧更加充分,从而降低氮氧化物的排放。空气被增压后密度增大,温度升高,从而影响发动机的充气效率。未经冷却的增压空气进入燃烧室,容易导致发动机燃烧温度过高,造成爆震等故障,同时还会增加发动机废气中氮氧化物的含量,造成空气污染。所以,中冷器的冷却效率对保证车辆工作性能的稳定具有重要的作用。随着发动机功率的增加,为了降低进气温度,空冷中冷器已经不能满足冷却的需求,冷却效率更高的水冷中冷器得到越来越多的应用。水冷中冷器结构紧凑,内部流动比较复杂,如果进行试验研究不但周期长,而且费用高,采用计算流体动力学(CFD)技术进行仿真研究、优化结构方案,不但速度快,而且节约成本,在散热器性能的研究中起着越来越重要的作用[1]。国内外学者对中冷器内部不同翅片结构的传热性能进行了仿真研究,并对不同参数下翅片的传热性能进行了评价[2-5],而对水冷型中冷器的研究较少。李志刚[6]采用CFD方法对空冷型中冷器进行了流-固耦合传热仿真分析,并进行了匹配设计。王晶等[7]将中冷器简化为RADIAROR模型对发动机舱散热进行了仿真,但不能得到中冷器内部的换热情况。颜卫国等[8]对热管中冷器的传热与阻力特性进行了研究。朱振华等[9]对冷却液温度对发动机性能的影响进行了仿真研究。研究表明采用CFD技术进行流-固耦合传热仿真分析是研究中冷器内部复杂流动传热问题的有效途径。为研究水冷中冷器内部流场和热交换情况,本文作者应用fluent软件中的换热器模块,对某款柴油机用水冷中冷器进行传热性能数值模拟,并在发动机台架上进行整机试验,通过对比试验数据和仿真结果,证明此研究方法的可行性和准确性,为水冷中冷器的设计和优化提供理论依据。

1 几何模型和网格划分

1.1 物理模型

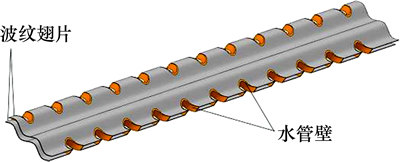

图1所示为系统结构示意图。水冷中冷器工作原理如图1(a)所示,过滤后的空气被涡轮增压器加压后温度急剧升高,经过中冷器冷却后温度降低,最后通过进气歧管进入燃烧室。冷却液经过水泵加压后,通过进水口进入中冷器内部的管道,在中冷器内部与空气进行热交换后从出水口流回水箱。本文选用的中冷器有效冷却长度为300 mm,高度为400 mm,宽度为250 mm,内部采用波纹翅片,具体结构如图1(b)所示。

图1 系统结构示意图

Fig. 1 System structure diagram

本文主要研究发动机不同工况下进气流量和冷却液温度、流量对中冷器冷却性能的影响,故只对中冷器部分进行模拟。由于整体对中冷器进行仿真,结构复杂,网格数量太多,在现有计算机上无法模拟,故选取单元体周期模型进行研究[10]。同时,由于存在气体和液体两股流体交叉流动,用多孔介质模型无法模拟,本文使用fluent软件中的换热器模块对整体进行模拟。进行整体仿真需要先求出摩擦因数与雷诺数的关联方程,为此建立如图2所示的单元体仿真模型,模型有效冷却长度为300 mm;翅片间距为2 mm;翅片厚度为0.25 mm;铜管直径为10 mm和铜管壁厚为1 mm。

图2 单元体结构

Fig. 2 Unit structure diagram

1.2 控制方程

中冷器内部流体的流动和换热遵循质量守恒、动量守恒、能量守恒三大定律,固体的稳态温度场导热遵循拉普拉斯方程,基本控制方程如下[1]:

(1)

(1)

(2)

(2)

式中:s为动量方程源相; 广义扩散系数;u为速度矢量;

广义扩散系数;u为速度矢量; 为流体密度;T 为固体的温度。

为流体密度;T 为固体的温度。

换热器模型控制方程如下[10]:

(3)

(3)

(4)

(4)

其中: 为沿程阻力损失;F为压力损失系数;kc和ke分别为入口和出口的压力损失因数;

为沿程阻力损失;F为压力损失系数;kc和ke分别为入口和出口的压力损失因数; 为空气密度;UAmin为最小流通面积的气体速度;a为摩擦因数;b为摩擦指数;A为散热面积;Ac为最小流通面的面积;

为空气密度;UAmin为最小流通面积的气体速度;a为摩擦因数;b为摩擦指数;A为散热面积;Ac为最小流通面的面积; 为最小流通率;Re为雷诺数;vi和ve为冷流体入口和出口的速度;

为最小流通率;Re为雷诺数;vi和ve为冷流体入口和出口的速度; 为冷流体的平均速度。

为冷流体的平均速度。

中冷器的冷却性能和阻力性能是评价其性能最重要的2个指标,采用Colburn传热性能因子j和Fanning摩擦因数f表征中冷器的冷却性能和流动阻力,采用j/f作为综合评价因子[11]:

(5)

(5)

(6)

(6)

式中:Pr为普朗特数;L为翅片的长度;Dh为水力直径;v为平均流速;k为导热系数;ρ为空气的密度。

1.3 网格划分和边界条件

图3所示为计算网格。在进行网格划分时,为了减少网格数量,节约计算时间,对计算模型进行了简化,单元体模型采用六面体结构网格,对流-固耦合面划分边界层,如图3(a)所示;对整体模型进行分块,中间形状规则区域划分为六面体网格,其他区域由于结构不规则采用四面体和混合网格划分,对流场和温度场变化较大的区域进行了网格细化,充分发展区域用核心六面体网格划分以减少网格数量,如图3(b)所示。为了保证计算精度,进行了网格的无关性检验,经过多次划分网格,最后单元体选取445 623个网格数目作为研究对象,整体网格数量为1 154 534个。为了提高计算的精度,方程的离散采用有限体积法,选用标准k-ε湍流模型,内部为不可压缩稳态求解,选择二阶迎风差分格式和SIMPLE求解算法[10]。

空气采用流量入口和压力出口边界;冷却液采用流量入口和压力出口边界;壁面为无滑移边界;管壁材料为铜,翅片材料为铝合金。

图3 计算网格

Fig. 3 Computational mesh

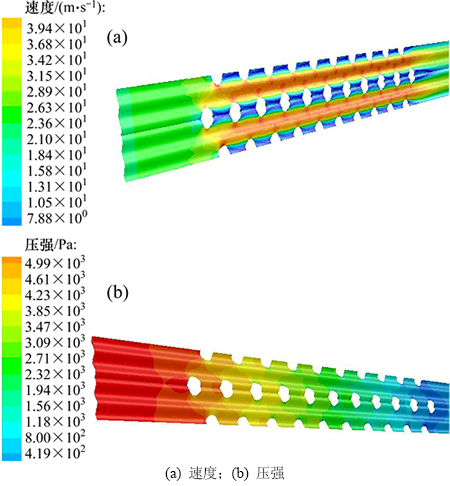

2 单元体仿真结果分析

图4所示为速度和压强云图。由图4(a)可知:空气沿着翅片表面流动,由于冷却管的扰流作用流动轨迹呈波浪形。由场协同理论可知,冷却管对温度场梯度和速度矢量的协同起到促进的作用,增强了换热效率。此外,由于管壁对空气的流动阻力作用,空气在流道中间流速较高,在管壁后面速度较低。中冷器进口和出口之间的沿程阻力损失有着严格的限制,阻力过大会对发动机性能产生不良影响,从图4(b)可知:在该工况下,进口处压强约为4.9 kPa,由于冷却管的阻力作用使得压强沿流动方向越来越低,在入口处形成局部高压区,在冷却管壁前后产生了低压区,在出口处压强降为419 Pa,压降在工作允许的范围内。

图4 速度和压强云图

Fig. 4 Speed and pressure contours

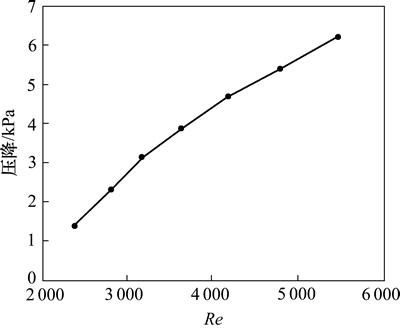

为了能够对散热器整体进行仿真,对不同速度下的内部压强变化进行仿真,得到雷诺数与压降的关系,如图5所示,对其进行数据拟合即得到式(4)中的摩擦因数a为12.66和摩擦指数b为0.99。

图5 雷诺数对压降的影响

Fig. 5 Influence of Re on pressure drop

将仿真结果代入式(5)和式(6)计算不同工况下波纹翅片的性能评价因子随空气入口流速的变化规律,并与董军启[11]中平直翅片的评价因子进行比较,对比结果如图6所示。由图6可知:2种翅片的评价因子均随空气流速的增加而增大,增长速率越来越小,这是由于流速越大,对流换热系数的增长速率越小,而翅片压力损失的速率却增加的缘故。相同流速下,波纹翅片评价因子大于平直翅片的评价因子,表明波纹翅片的散热效率要比平直翅片高,空气流速越大,波纹翅片优势越明显。

图6 不同翅片评价因子的比较

Fig. 6 Comparison of different finned evaluation factor

3 整体仿真结果分析

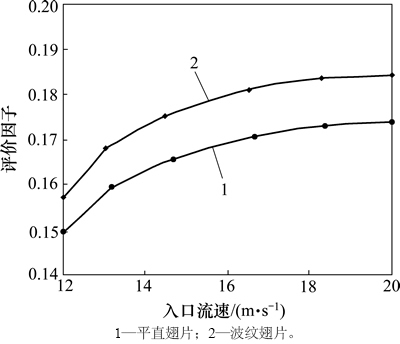

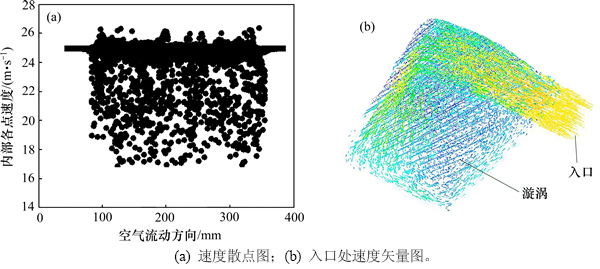

3.1 流动均匀性分析

增压空气在中冷器内部的流动均匀性对冷却效率有着重要的影响,不均匀流动会使换热效率降低,流动阻力加大[12-15]。流动的均匀性主要与入口的结构有关,合理的入口结构能够使中冷器达到最佳冷却效果。中冷器内部速度场仿真结果如图7所示。由图7(a)可知:中冷器上部散点密度明显大于下部散点密度,所以大部分空气从上部流过,上部气流速度明显大于下部气流速度,这是由于入口和出口同时在上部,上部气体流过的距离较短,而且出口压强较低使得气体能够容易通过,速度变化较小。当入口速度为25 m/s时,最下部速度最小为17 m/s,流动过程中,速度变化较大,表明中冷器内部空气流动不均匀。同时,从图7(b)可知:空气在入口处有较大的回流旋涡,造成入口处的流动阻力加大,仿真结果表明入口结构设计不合理,有待改进。

3.2 沿程阻力损失分析

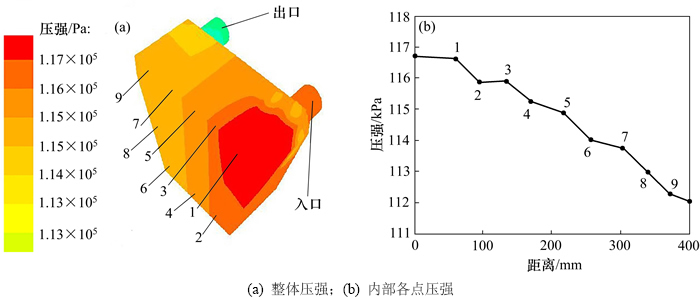

图8所示为整体压强仿真结果。从图8(a)可知:入口处压强较高达到了117 kPa,这是由于空气经过涡轮增压器后压强急剧增大,同时中冷器入口处空气大量回流造成的。中冷器内部从上到下和从左到右压强明显呈梯度降低,出口处压强降到113 kPa,整体压降在中冷器允许的使用范围内。为了能够了解中冷器内

图7 速度分布

Fig. 7 Velocity distribution

图8 整体压强仿真结果

Fig. 8 Overall pressure simulation results

部不同部位的阻力情况,选取图8(a)所示的9个点,各点的压强如图8(b)所示,各点的压强变化反映了中冷器内部各处的流动阻力变化,入口和出口处压强变化较小,表明此处流动阻力较小;随着流动的深入,受到冷却管和翅片的阻挡,压强降低的速率逐渐增大,入口和出口的压力差为4.5 kPa。

3.3 温度场仿真结果

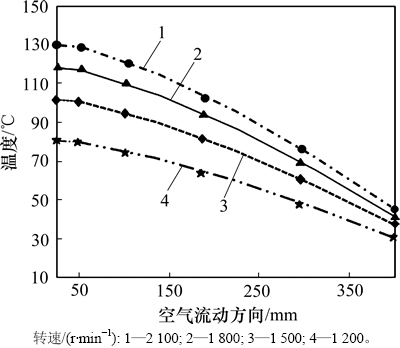

发动机不同转速下中冷器内部轴向截面加权平均温度变化仿真结果如图9所示。从图9可以看出:从入口到出口温度逐渐降低,在入口处即50 mm以内温度变化较小,这是由于入口处并没有翅片和冷却管。50 mm以后,空气与低温翅片和冷却管壁开始接触,温度明显降低。随着流动速度的降低,越靠近出口处冷却液温度越低,空气温度降低的梯度逐渐变大,冷却效果非常明显。发动机转速越高,增压空气的入口温度越高,当转速为2 100 r/min时入口温度达到了130 ℃,出口温度降为50 ℃,温差为80 ℃;当转速为1 200 r/min时入口温度为80 ℃,出口温度为33 ℃,温差为47 ℃,仿真结果表明尽管不同转速下入口处空气温度差别较大,但出口处空气温度差别较小,空气流量对中冷器的冷却效率影响较大,空气流量越大冷却效率越高,反之则越低。

图9 中冷器内部温度分布曲线

Fig. 9 Intercooler internal temperature distribution curves

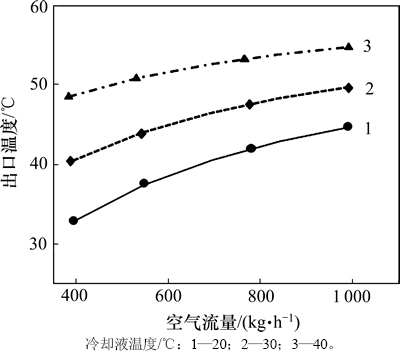

冷却液温度对冷却性能的影响仿真结果如图10所示。从图10可知:当冷却液温度为20 ℃、发动机转速为1 200 r/min时,中冷器出口处增压空气温度为33 ℃,随着转速的增加,空气流量逐渐增大,出口处空气温度越来越高,但增加的速率逐渐减小,当转速达到2 100 r/min时,出口温度为42 ℃。在相同转速下,冷却液温度越高,换热效率越低;空气流量越大,冷却液温度对换热效率的影响越小;冷却液温度每升高10 ℃,换热效率降低5%~10%,为了保证中冷器的冷却性能,冷却液温度控制在40 ℃以下。

图10 冷却液温度对冷却性能的影响

Fig. 10 Effects of coolant temperature on cooling performance

3.4 散热量仿真结果

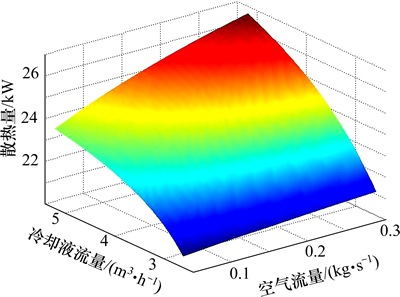

为了对中冷器的整体冷却性能进行评价,保持冷却液温度为30 ℃,对不同冷却液流量、不同转速下的换热量进行仿真,仿真结果如图11所示。由图11可知:散热量随着空气流量和冷却液流量的增大而增加,在相同的冷却液流量下,散热量与空气流量呈正比,这是由于发动机转速越高,空气流量越大,翅片的传热系数越大,散热效率也就越高。当冷却液流量为3 m3/h,空气质量流量从0.1 kg/s增加到0.3 kg/s时,散热量增加了1倍多;空气流量不变时,散热量与冷却液流量呈二次函数关系,冷却液流量每增加1 m3/h,热工转换效率提高3%~5%;当冷却液流量在4 m3/h以下时,对散热量的影响较大,超过5 m3/h后,对冷却效率影响较小,这是由于受冷、热流体的耦合散热面积的限制,要想继续提高散热效率只有对翅片结构进行改进。

图11 散热量仿真结果

Fig. 11 Simulation results of heat dissipating capacity

4 试验验证

为了验证仿真结果的准确性,在发动机试验台架上测试水冷中冷器的冷却性能,主要测量中冷器入口和出口的温度和压强。其中,发动机主要参数如下:增压中冷,六缸,缸径均为108 mm,行程为130 mm;排量为7.14 L;额定功率为220 kW;额定转速为2 300 r/min;最大扭矩为1 160 N·m。试验中的部分仪器为:Y380水力测功机、FC2000发动机测控系统、Pt100铂电阻温度传感器、CYZ103高温压力传感器、插入式气体质量流量计。环境温度为30 ℃,油门开度固定为78%,扭矩控制在700 N·m,采集中冷器入口和出口气体特性相关数据,计算分析后与仿真结果进行对比。

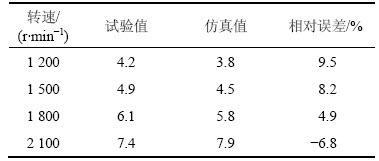

通过试验测得转速分别为1 200,1 500,1 800和2 100 r/m时增压空气压强变化和出口的温度,并与仿真结果进行比较,对比结果如表1和表2所示。由表1可知:随着转速的增加,压强损失越来越大,损失的速率逐渐增大;转速为1 200 r/min时压强损失的仿真值与试验值相对误差最大为9.5%,转速越高相对误差越小。由表2可知:转速越高,中冷器出口温度越高,升高的速率却越来越小,试验结果与仿真结果变化趋势一致;转速为1 200 r/min时相对误差最大约为7.0%,相对误差随转速的变化较小。对比结果表明:利用本文基于CFD的三维流固耦合传热模拟值与试验值相对误差在10%以内,由于仿真过程中影响因素较多,所以该相对误差在允许的范围内;采用本文的研究方法可信,能够较好地对中冷器内部流体流动传热性能进行模拟,此仿真方法可以缩短设计周期和降低试验成本[16-17],同时克服了试验的局限性。

表1 空气沿程阻力仿真值与试验值的对比

Table 1 Comparison between simulation results and experimental results of air frictional resistance kPa

表2 中冷器出口空气温度仿真值与试验值的对比

Table 2 Comparison between simulation results and experimental results of air temperature at the exit ℃

5 结论

1) 基于三维流场理论,采用流-固耦合传热模型能够较好地模拟入口雷诺数对阻力损失的影响趋势;最大沿程阻力损失不超过8 kPa,满足使用要求;通过性能评价因子的比较,表明该型号中冷器内部采用的波纹翅片的传热性能优于平直翅片的传热性能。

2) 中冷器的传热性能入口结构设计不合理,导致空气回流较大,增加了空气流动的不均匀性;空气流量越大中冷器冷却效率越高,越接近中冷器出口位置冷却效率越高;冷却液温度越低,中冷器冷却性能越好,冷却液温度每升高10 ℃,换热效率降低5%~10%,为了保证中冷器的冷却性能,冷却液温度控制在40 ℃以下。

3) 仿真值与试验值吻合较好,相对误差在10%以内,验证了仿真模型的准确性;本文采用的研究方法能够较好地反映不同工况下增压空气的流量和冷却液温度对中冷器散热量的影响,为中冷器的设计和优化提供了指导,有利于缩短研发周期和降低设计成本。

参考文献:

[1] JEONG C H, KIM H R, HA M Y, et al. Numerical investigation of thermal enhancement of plate fin type heat exchanger with creases and holes in construction machinery[J]. Applied Thermal Engineering, 2014, 62(2): 529-544.

[2] 肖宝兰, 俞小莉, 韩松, 等. 翅片参数对车用中冷器流动传热性能的影响[J]. 浙江大学学报(工学版), 2010, 44(11): 2164-2168.

XIAO Baolan, YU Xiaoli, HAN Song, et al. The study of effects of fin parameters on thermal hydraulic performance of a vehicular charged air cooler[J]. Journal of Zhejiang University (Engineering Science), 2011, 44(11): 2164-2168.

[3] 董军启, 陈江平, 袁庆丰, 等. 板翅换热器平直翅片的传热与阻力性能试验[J]. 农业机械学报, 2007, 38(8): 53-56.

DONG Junqi, CHEN Jiangping, YUAN Qingfeng, et al. Flow and heat transfer on compact smooth fin surfaces[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007, 38(8): 53-56.

[4] 李红智, 罗毓珊, 王海军, 等. 增压空冷器用开缝翅片的结构优化设计[J]. 西安交通大学学报, 2008, 42(11): 1356-1360.

LI Hongzhi, LUO Yushan, WANG Haijun, et al. Configuration optimization design for slotted fin surface in pressurized air cooler[J]. Journal of Xi’an Jiaotong University, 2008, 42(11): 1356-1360.

[5] 徐振元. 工程车辆波纹翅片散热器特性分析与应用研究[D]. 长春: 吉林大学机械科学与工程学院, 2012: 30-35.

XU Zhenyuan. Research on characteristics and application of wave fin radiator in engineering vehicle[D]. Changchun: Jilin University. College of Mechanical Science and Engineering, 2012: 30-35.

[6] 李志刚. 基于CFD技术的柴油机中冷器的优化设计与匹配研究[D]. 天津: 天津大学机械学院, 2007: 4-5.

LI Zhigang. The research on optimizing design and matching for the intercooler of diesel engine based on CFD [D]. Tianjin: Tianjin University. College of Mechanical Engineering, 2007: 2-5.

[7] 王晶, 张成春, 张春艳, 等. 客车后舱门开口对发动机舱体散热的影响[J]. 农业机械学报, 2012, 43(9): 31-36.

WANG Jing, ZHANG Chengchun, ZHANG Chunyan, et al. Effect of back door opening of bus engine cabin on underhood heat dissipation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(9): 31-36.

[8] 颜卫国, 俞小莉, 陆国栋, 等. 热管中冷器的传热与阻力特性[J]. 浙江大学学报(工学版), 2011, 45(1): 132-135.

YAN Weiguo, YU Xiaoli, LU Guodong, et al. Experimental study on flow and heat transfer of heat pipe heat exchanger[J]. Journal of Zhejiang University (Engineering Science), 2011, 45(1): 132-135.

[9] 朱振华, 朱敬安, 沈天宇, 等. 冷却液温度对发动机性能和传热的影响研究[J]. 拖拉机与农用运输车, 2011, 38(4): 28-30.

ZHU Zhenhua, ZHU Jing’an, SHEN Tianyu, et al. Influence of coolant temperature on engine performance and heat transmission[J]. Tractor and Farm Transporter, 2007, 19(6): 1390-1396.

[10] 刘佳鑫. 工程机械散热模块传热性能研究[D]. 长春: 吉林大学机械科学与工程学院, 2013: 58-66.

LIU Jiaxin. Research on heat transfer performance of heat-dissipation module for construction machinery[D]. Changchun: Jilin University. College of Mechanical Science and Engineering, 2013: 58-66.

[11] 董军启. 车辆冷却系统空气侧特性研究[D]. 上海: 上海交通大学机械与动力工程学院, 2007: 50-60.

DONG Junqi. Research of air side flow and heat transfer character of vehicle cooling systems[D]. Shanghai: Shanghai Jiaotong University. College of Mechanical Dynamic and Engineering, 2007: 50-60.

[12] 王福军. 计算流体力学分析-CFD软件原理与应用[M]. 北京: 清华大学出版社, 2004: 7-20.

WANG Fujun. Computation fluid dynamics-theory and application of CFD program[M]. Beijing: Tsinghua University Press, 2004: 7-20.

[13] 李杰, 王耘, 宋晓文, 等. 板翅式机油冷却器内部压力分布研究[J]. 轻工机械, 2010, 28(5): 19-23.

LI Jie, WANG Yun, SONG Xiaowen, et al. Study on inner pressure distribution in offset strip-fin oil cooer[J]. Light Industry Machinery, 2010, 28(5): 19-23.

[14] 王峰, 闫清东, 马越, 等. 基于CFD技术的液力减速器性能预测研究[J]. 系统仿真学报, 2007, 19(6): 1390-1396.

WANG Feng, YAN Qingdong, MA Yue, et al. Prediction and analysis on hydraulic retarder performance based on CFD[J]. Journal of System Simulation, 2007, 19(6): 1390-1396.

[15] 焦安军, 厉彦忠, 张瑞, 等. 板翅式换热器不同结构导流片导流性能的研究[J]. 西安交通大学学报, 2001, 35(11): 1113-1117.

JIAO Anjun, LI Yanzhong, ZHANG Rui, et al. Flow distribution performance of different distributor’s configuration in plate-fin heat exchanger[J]. Journal of Xi’an Jiaotong University, 2001, 35(11): 1113-1117.

[16] 傅立敏, 贺宝琴, 吴允柱, 等. 汽车超车过程的空气动力特性研究[J]. 空气动力学学报, 2007, 25(3): 351-356.

FU Limin, HE Baoqin, WU Yunzhu, et al. Research on aerodynamic characteristics during the vehicle overtaking process[J]. Acta Aerodynamica Sinica, 2007, 25(3): 351-356.

[17] 傅立敏, 扶原放. 轿车并列行驶湍流特性的数值模拟[J]. 吉林大学学报(工学版), 2005, 35(4): 358-362.

FU Limin, FU Yuanfang. Numerical simulation on characteristics of turbulent flow around two cars driving side-by-side[J]. Journal of Jilin University (Engineering and Technology Edition), 2005, 35(4): 358-362.

(编辑 罗金花)

收稿日期:2014-12-10;修回日期:2015-02-08

基金项目(Foundation item):国家自然科学基金资助项目(50775096);国家“十二五”科技支撑计划项目(2013BAF07B04) (Project(50775096) supported by the National Natural Science Foundation of China; Project(2013BAF07B04) supported by the National Science and Technology Pillar Program during the 12th “Five-year” Plan Period)

通信作者:秦四成,教授,博士生导师,从事工程车辆节能与控制研究;E-mail: qsc925@hotmail.com