Heat transfer characteristics of lost foam casting process of magnesium alloy

Heat transfer characteristics of lost foam casting process of magnesium alloy

LIU Zi-li(刘子利)1, 2, PAN Qing-lin(潘青林)2,

CHEN Zhao-feng(陈照峰)1, LIU Xi-qin(刘希琴)1, TAO Jie(陶 杰)1

1. College of Materials Science and Engineering , Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China

Received 14 June 2005; accepted 20 March 2006

Abstract: Effects of vacuum, pouring temperature and pattern thickness on the heat transfer of magnesium alloy lost foam casting(LFC) process were explored. The results indicate that without vacuum a positive thermal gradient from the gate to the end of the casting was formed immediately after the mold filling. The average temperature of the casting, the temperature gradient and solidification times increase significantly with pouring temperature and pattern thickness. Vacuum plays a quite different role in the heat transfer during mould filling and solidification periods: it significantly increases the cooling rate of the filling melt, but decreases the cooling rate of the casting during solidification period. The temperature of the liquid metal drops sharply and varies greatly with no apparent mode in the casting after the mold filling. The amplitude of temperature fluctuations in the casting increases with vacuum, pouring temperature and pattern thickness. The average temperature increases with pouring temperature and pattern thickness, but less rapidly than that without vacuum. The effect of vacuum on the solidification times of castings is found to depend on pouring temperature, vacuum makes solidification times increase greatly at high pouring temperature, while decreases slightly at low pouring temperature.

Key words: magnesium alloy; lost foam casting; heat transfer

1 Introduction

The growing demand for mass reduction in aerospace and automotive industries has greatly increased the magnesium application. Currently, casting is the main industrial forming method for magnesium alloys, but the lag of research and development on casting technology has become a bottleneck for their further application[1-3]. Lost foam casting(LFC) has been regarded as a cost-effective, environment-friendly vital option to the conventional casting process for production of near-net shape castings with high quality, especially in forming components with thin-wall, complex-geometry, tight tolerances and smooth as-cast surface[3-5]. As the great advantages over the traditional casting process and the bright application future, increasing attentions have been paid to the research of LFC process of magnesium alloy in recent years[3, 6-11].

During the LFC mold filling processing, the endothermic degradation of the foam pattern from the moving metal-foam interface produces a chilling effect on the liquid metal. As a result, it influences the temperature field after mold filling and solidification modes of castings. Currently, the heat transfer and solidification characteristics in LFC process without vacuum had been investigated by many researchers, especially for aluminum alloys and cast iron[12-17], but little is known about the heat transfer characteristics in LFC process under vacuum, though it has been reported that vacuum can increase the fluidity and metal fill velocity for aluminum and ferrous alloys, and lessen the carbon defects in ferrous alloy[4,5]. Previous work on mold filling and microstructures suggested that vacuum played a vital role in the LFC process of magnesium alloy [3,6,7], and effects of vacuum on the heat transfer and solidification characteristics of the LFC process of magnesium alloy were investigated in this paper.

2 Experimental

2.1 Foam, molding, melting and pouring

A full factorial experiment was designed to evaluate the effects of three significant processing parameters, which are vacuum, pouring temperature and pattern thickness, on heat transfer characteristics in the LFC process of magnesium alloy. The experimental variables are listed in Table 1.

Table 1 Experimental variables for full factorial experiments

30/15 mm×30 mm×250mm patterns and a gate (30 mm×30 mm×200 mm) were hot-wire cut from EPS plates of nominal density 0.017 g/cm3, and assembled using commercially available glue. The ceramic coating was a low permeability coating provided by Ashland Chemical Company. The refractory slurry was brushed onto the patterns, and dried to a final thickness of about 0.3 mm. The coated pattern was placed in the 40 cm×40 cm×40 cm flask with plenum chamber in its base, and filled with washed silica sand of 40/70 screen mesh until it was completely embedded in it. Then, a plastic sheet was covered onto the flask, and a pouring cup of baked clay sand was placed on the position of the sprue. When no vacuum was applied, the pouring cup was put directly on the top of the sprue.

Commercial AZ91 ingot was melted in an electric resistance furnace. During melting and pouring of the magnesium alloy, a protective atmosphere of 0.1%SF6+CO2 was used to prevent its oxidation and burning. The metal was poured under vacuum varying from 0 to 0.05 MPa, and with pouring temperature of 700 and 750 ℃. If vacuum was applied, it was maintained throughout the whole pouring process and for another 5 min.

2.2 Data collection

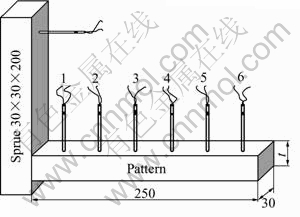

Six thermocouples were positioned at 2, 6, 10, 14, 18, 22 cm from the sprue along the length of the foam pattern, and their tips lay at sectional center of the locations, a thermocouple was also inserted into the top of sprue to monitor the heat transfer and solidification behavior there (Fig.1). To ensure good sensitivity and response time, the thermocouples were made up of the chromel-alumel wire of d 0.2 mm, shielded with ceramic protective tubes of d 1.5 mm. Data from the thermo- couples were collected and disposed by computerized data acquisition system. The process of the data collections was divided into 2 periods. For the first period, which was about 45 s from the beginning of pouring, the thermocouples were scanned every 0.02 s, in order to obtain the heat transfer characteristics during the pouring process. For the second period, the thermo- couples were scanned every 0.08 s so as record the heat transfer characteristic and solidification behaviors after the mold filling finished.

Fig.1 Schematic diagram of experimental setup(mm)(Six thermocouples were located at intervals of 40 mm along length foam pattern.)

3 Results 3.1 Cooling curve of LFC casting of magnesium alloy

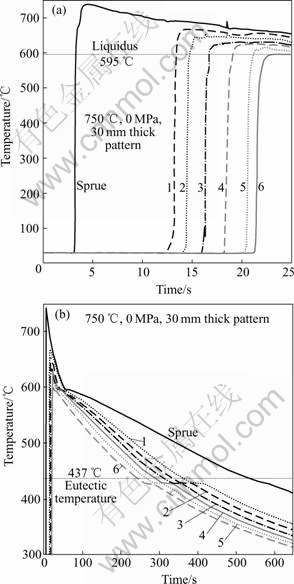

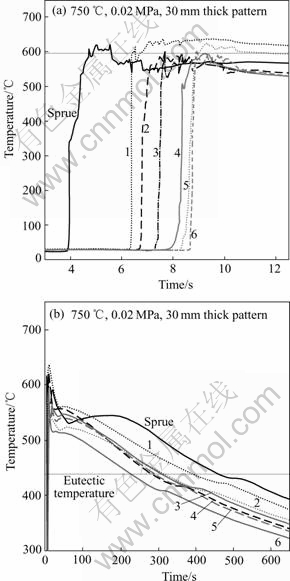

Figs.2 and 3 show the cooling curves for different locations in the castings of the LFC process of magnesium alloy without vacuum and under vacuum, respectively.

Without vacuum, the temperature loss about 70 ℃ was observed in the sprue for the magnesium alloy melt.As the mold filling continues, the temperature of the metal front keeps decreasing, and is close to the liquidus temperature when it reaches the position of the latest thermocouples. The average temperature decreasing rate of metal front is 3.6 ℃/cm during the mold filling, and a positive temperature gradient about 2.85 ℃/cm was established along the length of the casting immediately after mold filling had finished. The temperature gradient indicates directional solidification in the casting, solidification will start from the end of the casting to sprue as the melt cools down, and the start temperatures of solidification are nearly the same. The solidification time of the casting increases inversely with the distance from sprue. There exists no clear eutectic plateau in the cooling curve for the sprue, which indicates that it solidifies nearly in equilibrium mode.

Under vacuum, the temperature of the liquid metal decreases sharply when it enters the sprue, and even lowers than the liquidus temperature. Temperatures of the liquid metal in the mold cavity change greatly with no definite mode after mold filling, and the liquid metal at some positions is in the state of supercooling. The temperature of metal liquid in mold still varies greatly before solidification, and solidification start temperatures in the casting were far lower than that without vacuum, and the difference between them even reaches 45 ℃. A positive temperature gradient forms from the sprue to the casting end in the late solidification process, so local solidification times varies upon the location within the casting and is still inversely proportional to the distance from the sprue. Compared with the cases without vacuum, eutectic temperatures in the casting are lower, especially at the positions where the liquid melt temperature is lower after mold filling, but solidification times in the casting are much longer than that without vacuum, indicating the cooling rate of the casting under vacuum is definitely smaller during solidification period. From the above analysis, it can be concluded that applying vacuum significantly increases the cooling rate of the mold filling melt, but decreases the cooling rate of casting during solidification period.

Fig.2 Cooling curves for different locations in casting during LFC process of magnesium alloy without vacuum(30 mm thick pattern about 750 ℃ pouring temperature were used): (a) Mold filling period; (b) Whole casting period

Fig.3 Cooling curves for different positions in casting during LFC process of magnesium alloy under vacuum(30 mm thick pattern, 750 ℃ pouring temperature and 0.02 MPa vacuum are used): (a) Mold filling period; (b) Whole casting period

From analysis of the cooling curves of LFC processes of magnesium alloy, the temperature distributions in the casting after mold filling and the solidification times for different positions of the casting can be obtained, which reflects the heat transfer characteristics of LFC process of magnesium alloy during mold filling and solidification process.

3.2 Effects of processing parameters on heat transfer of LFC process of magnesium alloy

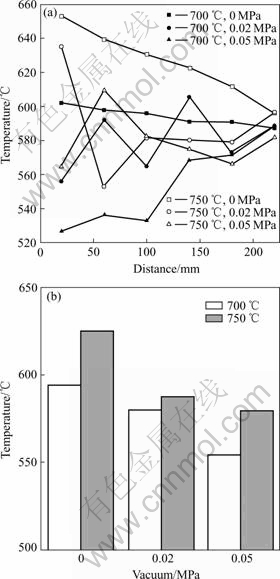

Effects of pouring temperatures and vacuums on the temperatures in the magnesium alloy castings are shown in Fig.4. Without vacuum, the temperatures in the castings after mold filling decrease with increasing distance from the sprue. As the pouring temperature increases, the average temperature and the temperature gradient in the casting increase, indicating high pouring temperature favors directional solidification. Under vacuum, the average temperature drops sharply, and temperatures in the casting vary greatly with no clear mode when the mold filling is completed. With vacuum increasing, the average temperature decreases further, and the temperature fluctuation in the casting increases. With the increasing pouring temperature, the average temperature and the temperature fluctuation in the casting increase, but the average temperature increases less rapidly than that without vacuum, indicating the cooling effect of vacuum on the filling melt increases with pouring temperature.

Fig.4 Temperature in magnesium alloy castings after mold filling at different pouring temperature and vacuums(30 mm thick patterns were used): (a) Temperature distributions in magnesium alloy castings; (b) Average temperatures of magnesium alloy castings

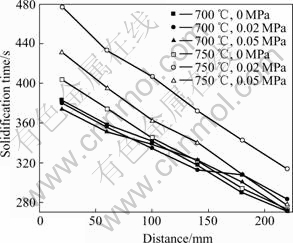

Fig.5 shows the solidification times along length of the magnesium alloy castings at different pouring temperatures and vacuum. Whether vacuum was adopted or not, the solidification time of the casting is an inverse measure of the distance from the sprue. The solidification times of the casting increase remarkably with pouring temperature, especially at the positions near the sprue. The effect of vacuum on the solidification time of castings was found depending on pouring temperature, solidification time increases greatly at high pouring temperature, while decreases slightly at low pouring temperature.

Fig.5 Solidification times along length of magnesium alloy castings at different pouring temperatures and vacuums(30 mm thick patterns were used)

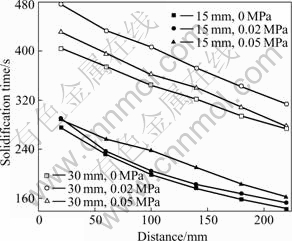

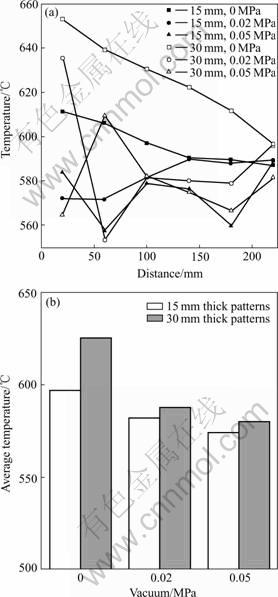

Effects of the pattern thickness on the temperature in the castings after the mold filling and solidification times of castings are just the same as that of pouring temperature (Figs.6 and 7). Without vacuum, the average temperature and the temperature gradient of the castings increases significantly with the pattern thickness. Under vacuum, the temperature fluctuations in the casting increases significantly with the pattern thickness, and the average temperature of the casting increases as well, though the increase of the average temperature is much smaller than that without vacuum. The solidification time of the casting increases remarkably with pattern thickness, especially at the positions near the sprue.

4 Discussion 4.1 Heat transfer during mold filling process 1) Heat transfer during mold filling process without vacuum

Without vacuum, the heat loss of the filling metal is mainly by the mode of heat radiation to the foam and of heat conduction to the surrounding coating and sand, and heat loss carried by the hot gaseous products within the metal-foam interface in the mode of heat convection is very small[13]. In the process of the metal filling, liquid metal fills ahead steadily with a slow and ever-decreasing speed[6]. The foam melting and liquid products gasification in the retreating metal-foam interface consume the heat from metal front, simultaneously, as the contact time of the liquid metal front with the cooling coating and the surrounding sand increases, the heat loss of the metal front to the cooling coating and the surrounding sand increases, which further increases the heat loss to the metal front, so the temperature of the liquid metal front would decrease continuously. On the other hand, the contact time and the temperature difference between the following liquid metal and the heated coating become smaller, which made the heat loss of the following metal ever-decreasing. As a result, a positive thermal gradient from the gate to the end of the casting will be established after the mold filling[12-16].

Fig.6 Effect of pattern thickness on solidification time of magnesium alloy lost foam castings at pouring temperature 750 ℃

Fig.7 Effect of pattern thickness on temperatures in magnesium alloy castings after mold filling(750 ℃ pouring temperature was used): (a) Temperature distributions in magnesium alloy castings; (b) Average temperatures of magnesium alloy castings

With the pouring temperature increasing, greater amount of liquid products at the metal-pattern interface will be gasified and consume more heat from the metal front, and the greater temperature difference between liquid metal front and the cooling coating also increases the heat loss of the metal front, thus the temperature of the metal front declines rapidly. Meanwhile, the temperature of the following liquid metal is becoming higher because of the less heat transfer time during mold filling. Therefore, the average temperature and temperature gradient in the castings increases with pouring temperature[14]. The effect of pattern thickness is just as that of pouring temperature, for the heat content of liquid metal per unit of surface area increases with pattern thickness.

2) Heat transfer during mold filling process with vacuum

During the mold filling process with vacuum, high metal filling velocity increases heat radiation and heat conduction rate of the filling metal, for the rapid foam melting and removing of pattern degradation product which carried away heat from the liquid metal. However, the temperature loss of the liquid metal front for foam decomposition and transfer to the moldings per unit of filling distance is not greater than that without vacuum, for the small contact time of the metal front with the foam and the coating[12]. As the plastic sheet near the pouring cup is burnt up during metal pouring process, a lot of fresh air is sucked into the mold to maintain vacuum in the mold[3]. Because the gap between grits close to the coating layer is decreased by the compaction of the vacuum, the fresh air will flow at a high speed in these gaps, the heat convection effect will surpass heat radiation and heat conduction and become the major mode of the heat loss of liquid metal. The heat convention effect on the liquid metal will decrease sharply with the increasing distance from sprue, because the amount and flow speed of the sucked fresh air decrease greatly.

The effect of heat convection of the sucked fresh air on the liquid metal will depend on the time of the liquid metal staying at the sprue near the pouring cup. As the filling liquid metal velocity varies greatly and at no mode under vacuum[7], if the filling rate of the metal front is slower, the filling liquid metal will stay a longer time near the pouring cup, heat convection of the sucked fresh air will make the temperature of the casting where this filling liquid metal stays after the mold filling much lower. As a result, the varying temperatures of the liquid metal in the casting had no distinct relations with the positions during the mold filling process. The fluctuations of the filling metal rate increase with vacuum, pouring temperature and pattern thickness[7], understandable, the fluctuation of temperature in the castings will be increased with vacuum, pouring temperature and pattern thickness.

Increasing the vacuum, the increase of the average metal filling velocity reduce the time of heat convection, however, the increase of the sucked air quantity and the reduce of the grits gaps make the fresh air flowing speed increase greatly, thus the heat convection effect increases, and increasing vacuum decreases the average temperature of the filling metal. Increasing the pouring temperature and pattern thickness, the temperature of the following filling liquid metal increases. The average metal filling rate increases, which could decrease the heat transfer time, as a result, the average temperature of the castings increases. However, the greater temperature difference enhances the heat loss by the heat convection, the average temperature increases less rapidly than that without vacuum.

4.2 Heat transfer during solidification process 1) Heat transfer during solidification process without vacuum

The coating plays a key role in the heat transfer of the LFC process, and its heat transfer coefficient varies with the temperature of the casting. As the liquid metal cools down, the liquid metal and coating will contact directly when the liquid products are removed out through the minute voids in coating, and the heat transfer capacity of the metal-coating interface reaches the maximum. As the temperature of the coating continues increasing, the burned organic ingredients in coating increase the amount of minute void in the coating, which decreases the heat transfer capacity of the coating. As the wide solidification temperature zone of magnesium alloy, the magnesium alloy will solidify in mushy mode. When the consecutive solid skeleton was formed in the casting, the solidification shrinkage of the casting increased the gap of the metal-coating interface; meanwhile, the dilapidation and heat expansion of the coating also increase the gap of the metal-coating interface. The existence of the gap greatly decreases the heat transfer capacity of the metal-coating interface, which will become the major heat resistance in the metal solidification, and have decisive effect on the casting cooling rate[17]. Besides, the thermal transfer coefficient of the dried sand in the LFC process is only one fifth of that of the traditional molding sand, because the heat transfer area of point contact grits is very small, and the thermal resistance of surrounding dried sand in the casting is very large[12, 16]. Consequently, the cooling rate in solidification process of LFC casting is very small.

Without vacuum, the metal positioned nearer to the gate will keep liquid state longer, both because the metal temperature is high, and because the long-time heated coating makes the temperature difference at metal-coating interface small[17], which decreases the heat loss rate of the metal, therefore, the casting cooling rate increases with the distance from the gating, and casting solidifies in the directional solidification mode. Increasing the pouring temperature and pattern thickness would increase the average temperature of the casting and the temperature gradient in casting, and the solidification time of the casting increases inversely with the distance from the sprue.

2) Heat transfer during solidification process with vacuum

Although applied vacuum increases the contact area of the surrounding dried sands in the casting, which is propitious to heat loss of the casting, the cooling rate of the casting during the solidification period still lies on the heat transfer coefficient of the metal-coating interface. Compared with that without vacuum, the casting solidification starts under the great supercooling, the shrinking after the forming of the consecutive solid skeleton in the casting occurs earlier. Moreover, the liquid metal with coating under vacuum will contact more closely before solidification, which accelerates the loss of organic ingredient in coating and the decrease of coating intensity, hence, the appearance of casting-coating interface gap during solidification may be earlier. On the other hand, the air in the casting-coating interface gap is more rare than that without vacuum[17], thereby, the heat transfer coefficient of casting-coating interface during solidification is much smaller than that without vacuum, and so does the cooling rate of the casting.

Applying vacuum, temperature of the filling metal in casting decreases greatly and distributes in no mode after mold filling. The casting still solidifies from the casting end to the gating, even if the temperature of the liquid metal locating at some place near the gating is lower than the temperature of the casting end. This is because that the liquid metal there will accept heat from the casting end, and the solidification of the liquid metal there is hard to happen.

The solidification time reflects the ultimate result of the heat transfer in the LFC process. The effect of vacuum on solidification time is closely related to the pouring temperature. At the lower pouring temperature, the cooling effect of vacuum causes the liquid metal lie in a great supercooling state after mold filling, the quantity of heat loss for the liquid metal to solidify is greatly reduced, which leads to a shorter solidification time of the casting. Although the temperature of the liquid metal is remarkably reduced after mold filling on the high pouring temperature, the liquid metal will not solidify until the superheat is transferred out completely. The long contact time between the liquid metal and coating decrease the temperature difference of the casting-coating interface, and the applied vacuum causes the heat transfer coefficient at metal-coating interface reduce sharply, therefore, the solidification time of the casting would be increased. By the same reason, the solidification time of the casting under vacuum will increase with the increasing pouring temperature and the pattern thickness.

5 Conclusions

1) The applied vacuum played a different role in the heat transfer during the mold filling and solidification process, it significantly increased the cooling rate of the filling melt, but decreased the cooling rate of casting during solidification period.

2) Without vacuum, a positive thermal gradient from the gate to the end of the casting was formed immediately after the mold filling. The temperature gradient increased with pouring temperature and pattern thickness. When vacuum was applied, the temperature of the liquid metal dropped sharply and varied greatly in the casting after the mold filling, and the temperature distribution had no apparent mode in the casting. The temperature fluctuations in the casting increased with vacuum, pouring temperature and pattern thickness. The average temperature of the casting decreased with vacuum, and increased with pouring temperature and pattern thickness, but increased less rapidly than that without vacuum.

3) Whether adopting vacuum or not, the solidification time in the casting increased inversely with the distance from the gating, and the solidification time of the casting increased with pouring temperatures and pattern thickness. The effect of vacuum on the solidification times of castings was found to depend on pouring temperature. Vacuum made solidification time increase greatly at high pouring temperature, while decrease slightly at low pouring temperature.

References

[1] Nicholas j. High-performance magnesium[J]. Advanced Materials and Processes, 2005, 193(9): 65-67.

[2] LUO A A. Recent magnesium alloy development for automotive powertrain applications[J]. Materials Science Forum, 2003, 419-422: 57-65.

[3] LIU Zi-li, HU Jing-yu, DING Wen-jiang, ZHU Yan-ping, LU Yi-zhen, CHEN Wen-zhou. Evaluation of the effect of vacuum on mold filling in the magnesium EPC process[J]. Journal of Materials Processing Technology, 2002, 120: 94-100.

[4] HAND B. High-alloy and stainless steel applications of the EPC process[J]. AFS Transactions, 1993, 101: 323-326.

[5] PAN Env-ning, LIAO Kao-yu. Analysis of the flow and solidification patterns of the lost foam(EPC) A356 Al cast alloy[J]. Journal of the Chinese Society of Mechanical Engineers, 2000, 21(3): 283-92.

[6] LIU Zi-li, DING Wen-jiang, HU Jing-yu, ZHU Yan-ping. Study on the EPC AZ91 magnesium alloy[J]. Material Science and Technology, 2001, 9(2): 189-194.(in Chinese)

[7] LIU Zi-li, WU Guo-Hua, DING Wen-Jiang, ZHU Yan-ping, LI Qiang. Study on molding filling velocity in AZ91 magnesium alloy LFC process with vacuum[J]. Journal of Aeronautical Materials, 2002, 22(2): 12-16.(in Chinese)

[8] Anon. Genesis of a new process: magnesium lost foam casting[J]. Modern Casting, 2003(4): 26-28.

[9] Bichle L, Ravindran C, Machin A. Challenges in lost foam casting of AZ91 alloy[J]. Materials Science Forum, 2003, 426-432: 533-538.

[10] Cho G S, Lee K W, Kim S K. Expendable pattern casting of AZ91D magnesium alloy[J]. Materials Science Forum, 2003, 426-432: 623-628.

[11] TIAN Xue-feng, FAN Zi-tian, HUANG Nai-yu. Microstructure and mechanical properties of magnesium alloy prepared by lost foam casting[J]. Trans Nonferrous Met Soc China, 2005, 15(1): 7-13.

[12] Shivkumar S. Casting characteristics of aluminum alloys in the EPC process[J]. AFS Transactions, 1993, 101: 513-518.

[13] Shivkumar S. Modelling of temperature losses in liquid metal during casting formation in expendable pattern casting process[J]. Mater Sci Tech, 1994, 10 (11): 986-992.

[14] Bennett S, Ramsay C W, Askeland D R. Temperature gradients during fill and solidification of Al LFCs[J]. AFS Transactions, 1998, 106: 357-363.

[15] Shivkumar S, Wang L, Apelian D. The lost-foam casting of aluminum alloy components[J]. JOM, 1990, 42(11): 38-44.

[16] Yao X, Shivkumar S. Mold filling and solidification in the lost foam process[J]. AFS Transactions, 1995, 103: 761-765.

[17] Venkataramani R, Ravindran C. Effects of coating thickness and pouring temperature on thermal response in lost foam casting[J]. AFS Transactions, 1996, 104: 281-290.

Foundation item: Project(2005037697) supported by China Postdoctoral Science Foundation; Project(Y04850-61) supported by Creative Program of Nanjing University of Aeronautics and Astronautics

Corresponding author: LIU Zi-li; Tel: +86-25-52112626; E-mail: zililiu@sohu.com

(Edited by LONG Huai-zhong)