热解终温对酚醛树脂层压板真空热裂解产物的影响

吴文彪,丘克强

(中南大学 化学化工学院,湖南 长沙,410083)

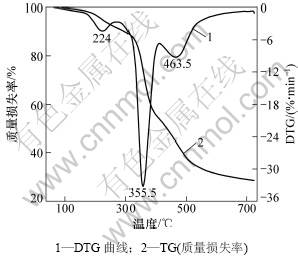

摘要:采用程序升温的热解反应器对酚醛树脂层压板的真空热解规律进行研究,着重考查不同热解终温对热解产物产率和热解油组成的影响,同时利用元素分析、工业分析、热重分析、GC-MS分析对层压板原料及产物油进行分析。研究结果表明:酚醛树脂层压板裂解可获得产率分别为50.25%~54.58%,33.00%~41.00%和8.75%~12.95%的液体、固体和气体,其产物油的成分主要为酚类、磷酸芳基酯类、脂肪酸酯类、腈类等物质;随着热解终温的升高,固体产率逐渐下降,液体产率在650 ℃有1个峰值,而气体产率则呈上升趋势,并且双酚F、双酚A、长链脂肪酸酯、磷酸三芳基酯等相对分子质量较大的物质含量逐渐降低,而苯酚、甲酚、二甲酚、对异丙基苯酚等相对分子质量较小的物质含量逐渐增大;样品有3个主要的质量损失台阶(在190~320,320~390和390~510 ℃),热质量损失率分别为9%,20%和31%。

关键词:层压板;真空热裂解;酚醛树脂;热解终温

中图分类号:X705 文献标志码:A 文章编号:1672-7207(2011)10-2946-06

Effect of final temperature on products of phenolic resin matrix laminate by vacuum pyrolysis

WU Wen-biao, QIU Ke-qiang

(School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: Vacuum pyrolysis of phenolic resin matrix laminate in temperature - programmed furnace reactor was studied. The effect of final temperature on the pyrolysis product yields and the composition of pyrolysis oils was examined. The sample and product oils were analyzed by ultimate analysis, proximate analysis, thermogravimetric analysis(TGA) and gas chromatography - mass spectrometry (GC-MS) analysis. The results show that the pyrolysis of phenolic resin matrix laminate can get 50.25%-54.58% liquid yield, 33.00%-41.00% solid yield and 8.75%-12.95% gas yield under the conditions of the experiment, and the products of the pyrolysis oils mainly consist of phenols, aryl phosphate esters, fatty acid esters, nitriles, and so on. The solid yield decreases gradually when the final temperature increases, and the liquid yield has a peak at 650 ℃, while the gas yield shows a rising trend. However, the content of the compounds with large molecular mass, such as bisphenol F, bisphenol A, long-chain fatty acid esters and aryl phosphate esters decrease as the final temperature increases, and those with relatively small molecular mass, such as phenol, cresols, dicresols and isopropyl phenol gradually increase on the contrary. Phenolic resin matrix laminate has three main mass loss rate steps, i.e., 190-320, 320-390 and 390-510 ℃, result in 9%, 20% and 31% of mass loss rate, respectively.

Key words: laminate; vacuum pyrolysis; phenolic resin; final temperature

随着电子电器产品更新换代频率的增加,大量增长的电子电气废弃物(WEEE)逐渐成为困扰全球的问题。电路板作为废弃电子电器的重要组成部分,其资源化研究已经成为当前电子垃圾处理的热点问题。目前,处理废弃电路板的方法有很多,其中,热解技术具有易分离其中的金属、玻璃纤维和有机物等成分,并且对环境友好的优点,具有广阔的发展前景[1]。目前,采用热解技术来处理环氧树脂基废弃电路板的研究已有大量的报道[1-8],而对于酚醛树脂基电路板的热解处理报道较少[9-10]。酚醛树脂基电路板大多是以桐油改性的酚醛树脂为主体树脂,加入部分环氧树脂、含氮树脂,并与阻燃剂、固化剂、增塑剂等助剂配合使用[11],在组成上与环氧树脂基电路板有很大不同,而且比环氧树脂更复杂,并且酚醛树脂基电路板由于具有柔韧性好、吸水率低、浸水或受潮后的电气绝缘性能高、制造成本低等优点,在一般的低频低压下,在不会引起火源的消费性电子产品如电视机、收录机、电话机、电子钟、监视器、家庭音响、洗衣机、吸尘器及电子玩具、空调机、高级灶具、自动售货机和计算器等中有着广泛的应用[12]。据统计[13],2006年我国用于制造电路板的酚醛树脂达4.7万t,比2005年增长6.8%,呈逐年增长的趋势。因此,对酚醛树脂基电路板进行深入研究,无论是在填补复杂聚合物体系的热处理机理空缺方面,还是在对其资源回收处理方面都有很大的研究价值。在此,本文作者采用真空热裂解技术对阻燃的FR-1型酚醛层压板进行研究,探讨热解终温对酚醛树脂层压板热解产物产率和热解油成分的影响。

1 实验

1.1 仪器与材料

仪器为:NETZSCH STA 409 PG/PC热重分析仪(德国耐驰仪器制造有限公司制造);SHZMADZU-QP2010气相色谱质谱联用仪(日本岛津公司制造);Vario EL Ⅲ CHNS元素分析仪(德国Elementar公司制造);DWJ-3L低温冷阱(北京松源华兴科技发展有限公司制造);WTS型温控装置(东南大学自动化仪表研究所制造);DP-A型精密数字压力计(南京桑力电子设备厂制造);TW-1A型旋片式真空泵(温岭市挺威真空设备有限公司制造);自制加热电阻炉。

材料为:甲醇(色谱纯,天津市大茂化学试剂厂生产);阻燃FR-1型纸基酚醛层压覆铜箔板(长沙维恩电子电路有限公司提供)。

由于电路板上带有大量不同的金属元器件,这些金属元器件对热解反应会产生或多或少的催化或阻化作用;并且对于小试实验,带金属元器件的样品在每次实验中也不能保证其中所含金属的成分及含量相同,因此,为了减少误差,以便更好地反映电路板基材的真空热解规律,本实验暂不考虑金属元素的作用,所用电路板为光板,且板上铜箔已腐蚀去除。

1.2 实验流程和方法

1.2.1 实验流程

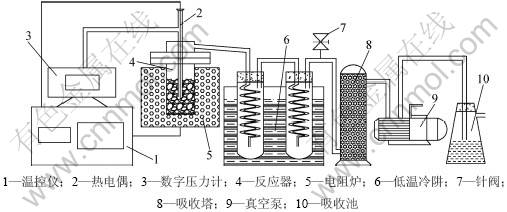

将电路板切割成长×宽为约1 cm×1 cm的碎片,每次称取20.00 g,装入自制热裂解反应器中。实验流程如图1所示。在真空条件下,以设定的升温速率将电路板加热到实验所需的最终热解温度,保温一定时间。裂解反应发生后,产生的气体和气溶胶被真空泵迅速抽离反应器进入低温冷阱(二级,最低温度可达-40 ℃),冷凝得到热解油;未冷凝的部分则通过吸收塔(碱石灰为吸收剂)除去气溶胶和酸性气体,剩下的气体由真空泵抽出,进入气体吸收池(质量分数为30%的NaOH溶液),净化后的气体直接被排空。实验完毕后,分别称量液体产物和固体残渣重量,由差减法求得气体产物质量。每个实验至少重复2次,取其平均值。

图1 实验流程示意图

Fig.1 Schematic diagram of experimental process

1.2.2 实验方法

将热解所得到的油类物质摇匀,采用甲醇溶解(甲醇与热解油体积比为5:1)后,送GC-MS仪器进行检测。GC条件:DB-1色谱柱(长×内径×膜厚为30 m×0.25 mm×0.25 μm);升温程序为:于80 ℃保温3 min,以10 ℃/min升温到280 ℃,保持2 min;分流比为10:1;柱流量为1.2 mL/min;载气(He)流量为3.0 mL/min;柱压为82.9 kPa。MS条件如下:标准EI源,离子源温度为200 ℃,接口温度为250 ℃;质荷比(m/z)为30~800,扫描间隔为0.5 s;电子倍增器电压为0.8 kV。

2 结果与讨论

2.1 热解实验

按照上述流程进行实验,各产物产率的计算式为:

(1)

(1)

(2)

(2)

其中:ω为产率;m为质量;下标solid,liquid,gas和sample分别表示固体、液体、气体和样品。

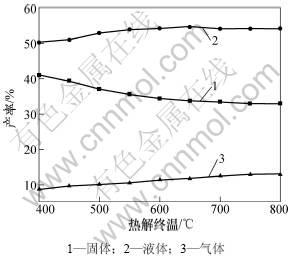

不同的热解终温导致物料升温过程和热解过程不同,从而决定气体、液体和固体产品的产率分布不同。一般来说,低温有利于制炭,高温有利于造气,而处于两者之间的温度则有利于获得油类产品。实验中采用单因素法来确定热解终温因素对热解产物产率的影响,即在固定体系压力为10 kPa,升温速率为40 ℃/min,保温时间为30 min,冷凝温度为-30 ℃条件下,在不同的热解终温条件下进行实验,求出产物的产率,分别以固体产率、液体产率和气体产率对热解终温作图,如图2所示。

由图2可以看出:在本实验的热解终温范围内,随着热解终温的升高,固体产率逐渐下降,液体产率在650 ℃下有1个峰值,而气体产率则呈上升趋势。实验发现:较低温度下热解液体和热解气体的产率都较低,而固体产率则相对较大。这是因为低温下聚合物体系中只有部分化学键发生断裂脱离聚合物主体,而多数化学键则由于提供的能量不够高而不发生断裂或断裂不完全,从而结焦成焦炭;随着热解终温的提高,提供给热解反应的能量增大,在低温下不发生断裂或断裂不完全的化学键开始断裂脱离聚合物主体,从而得到更多的液体和气体产物,而固体残留物则逐渐减少。但如果温度过高,聚合物体系中的化学键在断裂脱离主体结构前会再次发生断裂,从而形成更多的小分子化合物,使气体产物增多,液体产率则相对减少。因此,液体产率会在经过1个峰值后,随着热解终温的升高而有所下降。本实验中,当热解终温在700 ℃以上时,可以发现液体、固体和气体的产率变化很小,表明裂解反应在该条件下已基本进行完全。

图2 产品产率随热解终温的变化

Fig.2 Relationship between product yield and final temperature

2.2 元素分析及工业分析

利用Vario EL Ⅲ CHNS分析仪对电路板元素含量进行分析,其中C,H和N含量(质量分数,下同)分别为55.31%,6.554%和5.562%,不含S。根据GB/T212—2001对样品进行工业分析,其中空气干燥基水分、灰分、挥发分、固定碳的含量分别为4.08%,1.02%,70.82%和24.08%。

2.3 热重分析

图3所示为在真空及40 ℃/min升温速率条件下酚醛树脂层压板的TG及DTG曲线。从图3可以看出:在190 ℃左右时,样品开始发生热分解,至700 ℃左右热解反应基本停止,与热解实验结果一致。DTG曲线显示样品的最大质量损失速率分别发生在224.0,355.5和463.5 ℃。TG曲线则表明:样品的质量损失存在3个主要台阶,在第2个台阶(320~390 ℃)样品的质量损失率最大,约为31%;而第1个台阶(190~320 ℃)和第3个台阶(390~510 ℃)的质量损失率分别为9%和20%;510 ℃以后样品也发生了质量损失,但质量损失速率比较缓慢,在220 ℃的温度区间内只产生了约8%的质量损失;最后还剩29%的固体残渣。此外,由图3还可以看出:190 ℃以前,样品也产生了约3%的质量损失,这主要是电路板中自由水受热挥发所致,与样品的工业分析结果差别不大。

图3 酚醛树脂层压板的TG及DTG曲线

Fig.3 TG and DTG curves of laminate substrate from phenolic resin

2.4 GC-MS分析

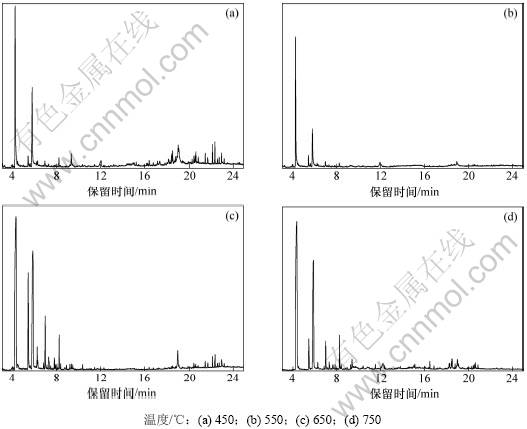

图4所示给出了体系压力为10 kPa,升温速率为40 ℃/min,保温时间为30 min,冷凝温度为-30 ℃时,不同热解终温条件下热解油的总离子流图谱。

在气相色谱中,若保持固定相和操作条件不变,则在相同的保留时间下流出的组分是相同的[14]。由于解析结果是由所得到物质的质量色谱图与标准质谱库中纯物质的质量色谱图进行匹配得到的,因此,解析结果的匹配相似度越高,则越接近该纯物质。然而,由于仪器本底、色谱柱流失以及未分开的组分等也会产生相应离子,使所得到的质量色谱图存在或多或少的噪声。因此,一般来说,当匹配相似度在90%以上时,可认为该解析结果是正确的。

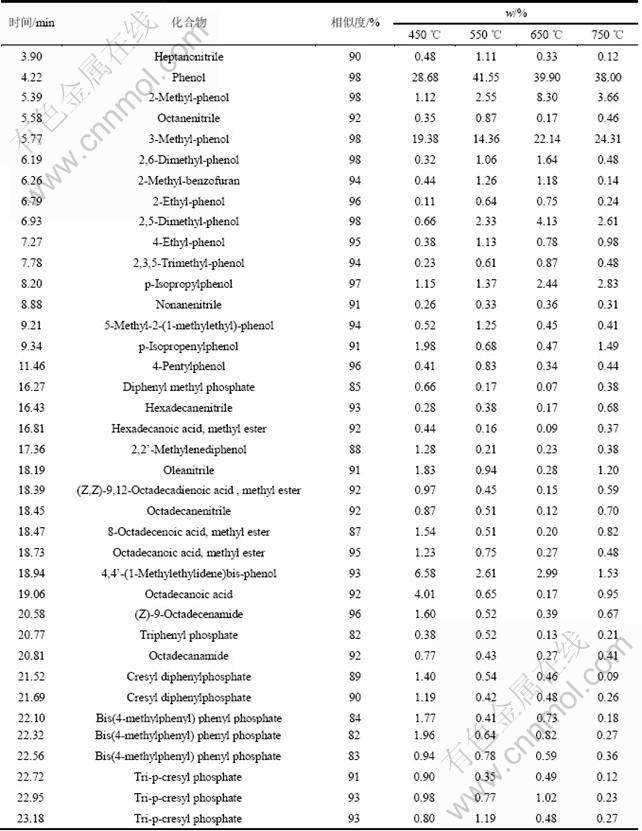

表1所示为不同热解终温下,各谱图主要成分的解析结果。该解析结果是与NIST05标准质谱库匹配得到的,对于匹配相似度较低的组分,则是根据相应物质质量色谱图的分子离子峰及特征碎片离子峰推断而得到的;各热解终温条件下各物质的相对含量则是采用峰面积归一化法得到的。由表1可以看出:酚醛树脂层压板裂解产物油的成分主要为酚类、磷酸芳基酯类、脂肪酸酯类和腈类等物质。

从机理来看,聚合物的热降解主要可分为解聚反应、无规则断链反应和主链不断裂的小分子消除反应3种类型[15],主要是由聚合物的组成和成键特点来区分。本实验所用层压板,其树脂组成包括桐油改性酚醛树脂、环氧树脂、含氮树脂、阻燃剂、固化剂、增塑剂等,这些物质相互交联形成一个巨大的三维网状结构。不同热解终温条件下的热解油解析结果见表1。从表1可见:随着热解终温的增加,双酚F、双酚A、长链脂肪酸酯、磷酸三芳基酯等相对分子质量较大的物质含量逐渐降低,而苯酚、甲酚、二甲酚、对异丙基苯酚等相对分子质量较小的物质含量则逐渐增大。这一点进一步证明了随着热解终温的升高,聚合物体系中的化学键在断裂脱离主体结构前会再次发生断裂,使本来可以形成大分子化合物的物质(如双酚A)因为吸收了更多的能量而断裂,形成相应的小分子化合物(如对异丙基苯酚)。

图4 不同热解终温条件下热解油的总离子流图

Fig.4 Total ion current chromatograms of pyrolysis oil at different final temperatures

表1 不同热解终温条件下的热解油解析结果(质量分数)

Table 1 Analysis results of pyrolysis oil at different final temperatures

3 结论

(1) 在本实验的热解条件下,酚醛树脂层压板热解液体的产率为50.25%~54.58%,而固体、气体产物的产率则分别为33.00%~41.00%和8.75%~12.95%;并且随着热解终温的升高,固体产率逐渐下降,液体产率在650 ℃有1个峰值,而气体产率则呈上升趋势。

(2) 酚醛树脂层压板随着温度的升高主要经历以下几个阶段:在190 ℃以前,层压板中所含的自由水受热挥发,产生约3%的质量损失;接下来样品在190~320,320~390和390~510 ℃出现3个主要的质量损失台阶,分别产生9%,20%和31%的质量损失;在510 ℃以后样品也发生了质量损失,但损失速率比较缓慢,在220 ℃的温度区间内只产生了约8%的质量损失,最后还剩29%的固体残渣。

(3) 酚醛树脂层压板裂解产物油的成分主要为酚类、磷酸芳基酯类、脂肪酸酯类、腈类等物质,其中苯酚、甲酚、二甲酚、对异丙基苯酚、双酚F、双酚A等是重要的有机化工原料,具有较大的应用价值。随着热解终温的增加,双酚F、双酚A、长链脂肪酸酯、磷酸三芳基酯等相对分子质量较大的物质含量逐渐降低,而苯酚、甲酚、二甲酚、对异丙基苯酚等相对分子质量较小的物质含量则逐渐增大。因此,可以根据实际需要,选择不同的条件以增大目标产物的产率。

参考文献:

[1] William J H, Williams P T. Separation and recovery of materials from scrap printed circuit boards[J]. Resources, Conservation and Recycling, 2007, 51(3): 691-709.

[2] Chiang H L, Lin K H, Lai M H, et al. Pyrolysis characteristics of integrated circuit boards at various particle sizes and temperatures[J]. Journal of Hazardous Materials, 2007, 149(1): 151-159.

[3] Blazsó M, Czégény Z, Csoma C. Pyrolysis and debromination of flame retarded polymers of electronic scrap studied by analytical pyrolysis[J]. Journal of Analytical and Applied Pyrolysis, 2002, 64(2): 249-261.

[4] Balabanovich A I, Hornung A, Merz D, et al. The effect of a curing agent on the thermal degradation of fire retardant brominated epoxy resins[J]. Polymer Degradation and Stability, 2004, 85(1): 713-723.

[5] Luda M P, Balabanovich A I, Camino G. Thermal decomposition of fire retardant brominated epoxy resins[J]. Journal of Analytical and Applied Pyrolysis, 2002, 65(1): 25-40.

[6] Barontini F, Marsanich K, Petarca L, et al. Thermal degradation and decomposition products of electronic boards containing BFRs[J]. Ind Eng Chem Res, 2005, 44(12): 4186-4199.

[7] Chien Y C, Wang H P, Lin K S, et al. Fate of bromine in pyrolysis of printed circuit boards[J]. Chemosphere, 2000, 40(4): 383-387.

[8] 彭绍洪, 陈烈强, 甘舸, 等. 废旧电路板真空热解[J]. 化工学报, 2006, 57(11): 2720-2726.

PENG Shao-hong, CHEN Lie-qiang, GAN Ge, et al. Vacuum pyrolysis of waste printed circuit boards[J]. Journal of Chemical Industry and Engineering, 2006, 57(11): 2720-2726.

[9] 周文贤, 陈烈强, 关国强. 废旧酚醛树脂印刷电路板的热解特征[J]. 环境化学, 2009, 28(1): 99-102.

ZHOU Wen-xian, CHEN Lie-qiang, GUAN Guo-qiang. Pyrolysis characteristic waste phenolic resin based printed circuit boards[J]. Environmental Chemistry, 2009, 28(1): 99-102.

[10] 关国强, 周文贤, 陈烈强, 等. 碳酸钙强化酚醛型线路板热解脱溴[J]. 化工学报, 2009, 60(1): 216-222.

GUAN Guo-qiang, ZHOU Wen-xian, CHEN Lie-qiang, et al. Pyrolytic debromination of phenolic re sin type PCB enhanced by calcium carbonate[J]. Journal of Chemical Industry and Engineering, 2009, 60(1): 216-222.

[11] 田民波, 林金堵, 祝大同. 高密度封装基板/新材料及在高技术中的应用丛书[M]. 北京: 清华大学出版社, 2003: 332.

TIAN Ming-bo, LIN Jin-du, ZHU Da-tong. Series of high-density packaging substrate/new materials and its application in high-tech[M]. Beijing: Tsinghua University Press, 2003: 332.

[12] 刘红, 谢美丽, 蔡兴贤. 桐油改性酚醛树脂的进展[J].绝缘材料通讯, 1991(1): 8-13.

LIU Hong, XIE Mei-li, CAI Xing-xian. Progress of tung oil modified phenolic resin[J]. Insulating Materials, 1991(1): 8-13.

[13] 唐路林, 李乃宁, 吴培熙. 高性能酚醛树脂及其应用技术[M]. 北京: 化学工业出版社, 2007: 15-25.

TANG Lu-lin, LI Nai-ning, WU Pei-xi. High-performance phenolic resin and its application[M]. Beijing: Chemical Industry Press, 2007: 15-25.

[14] 朱诚身. 聚合物结构分析[M]. 北京: 科学出版社, 2004: 304.

ZHU Cheng-shen. Polymer structure analysis[M]. Beijing: Science Press, 2004: 304.

[15] 钟世云, 许乾慰, 王公善. 聚合物降解与稳定化[M]. 北京: 化学工业出版社, 2002: 19-20.

ZHONG Shi-yun, XU Qian-wei, WANG Gong-shan. Polymer degradation and stabilization[M]. Beijing: Chemical Industry Press, 2002: 19-20.

(编辑 陈灿华)

收稿日期:2011-01-10;修回日期:2011-03-25

基金项目:国家高技术研究发展计划(“863”计划)项目(2006AA06Z375)

通信作者:吴文彪(1986-),男,江西广丰人,博士研究生,从事废弃电路板资源的回收利用研究;电话:0731-88877364;E-mail:xiaobiao248@163.com