文章编号:1004-0609(2015)-01-0080-06

添加微量TiC对钨的性能与显微组织的影响

孙志雨,范景莲,李鹏飞,成会朝,田家敏

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:为细化钨晶粒,采用粉末冶金方法通过添加加量TiC于钨基体中制备W-TiC合金,研究了微量TiC的添加对钨性能与显微组织的影响。结果表明:当TiC的添加量为1%(质量分数),烧结温度为1890 ℃时,W-TiC合金具有最佳性能,其拉伸强度可达401 MPa,致密度为97.4%;添加的TiC粉末以球状二次相粒子形式分布于晶界和晶内,与纯钨相比,TiC的添加有效地抑制了晶粒长大,对钨基体起到细晶强化与弥散强化作用。

关键词:W-TiC合金;二次相粒子;细晶强化;弥散强化;烧结行为

中图分类号:TG146.4 文献标志码:A

Effect of microscale TiC on performance and microstructure of tungsten

SUN Zhi-yu, FAN Jing-lian, LI Peng-fei, CHENG Hui-chao, TIAN Jia-min

(State Key Laboratory of Power Metallurgy, Central South University, Changsha 410083, China)

Abstract: In order to refine the grain size of W, W-CTiC alloy was fabricated by powder metallurgy method through adding microscale TiC into W matrix. The effects of microscale TiC on performance and microstructure of W were investigated. The results show that W-1TiC (mass fraction, %) exhibits the best performance at the temperature of 1890 ℃, its relative density and tensile strength can reach to 97.4% and 401 MPa, respectively. The microscale TiC in the form of second phase particles disperses on the W transgranular and grain boundary uniformly. Comparing with pure W, the addition of microscale TiC can inhibit the grain growth, which plays the role of fine-grain strengthening and dispersed strengthening.

Key words: W-TiC alloy; second phase particle; fine-grain strengthening; dispersed strengthening; sintering behavior

金属钨具有高熔点、高热导率以及低溅射率、低热膨胀系数等一系列优点,使其成为未来聚变堆中偏滤器及第一壁面向等离子体最有前景的材料之一[1-6]。然而,钨所呈现的低温脆性、再结晶脆性及辐照脆性,在很大程度上限制了其在相关领域的进一步应用[5-10]。

TiC由于具有与钨相近的热膨胀系数和弹性模量,因此,国内外研究人员通过添加TiC颗粒来细化钨晶粒,提高其高温强度及辐照抗力[11]。研究结果表明,与纯钨相比,由于TiC的添加,采用热压或热等静压(HIPed)所制备的W-TiC复合材料,其显微组织明显细化,强度和硬度均得以提高,而且能够降低因辐照引起的材料内部组织转变及硬度的改变,有效地提高合金抵抗中子辐照及He2+ 辐照的能力[12]。为了制 备近全致密超细晶W-TiC合金,KURISHITA等[4]于2000 ℃左右采用热压烧结研究W-(0.3%~0.7%)TiC(质量分数)合金室温力学性能;SONG等[12]采用热压,同样在2000 ℃下烧结制备W-TiC合金,研究其高温热力学性能。本文作者以降低合金烧结温度、提高合金室温强度、细化钨晶粒为目的,采用粉末冶金方法,向钨粉中直接添加微量TiC,在1890 ℃、H 2保护气氛下常压烧结制备了致密度为97.4%的微量TiC细晶强化钨基合金,并研究其烧结性能及其显微组织变化。

1 实验

原始粉末纯钨(纯度>99%)和TiC(纯度>99%)按照一定成分配比(参照表1),将其在高能球磨机上混合80 h。混合粉末于25 t油压机上压制,压制压力为350 MP。压坯于氢气气氛下进行预烧结,预烧温度为1100 ℃,保温1 h。然后于钨棒炉中,进行高温烧结,烧结温度为1890~1980 ℃,保温3 h。

表1 不同W-TiC合金粉末的成分

Table 1 Content of W-TiC alloy powders

采用阿基米德排水法原理测量材料的密度;采用Instron-8802型力学实验机测试样品的拉伸性能;利用MeF3A型金相显微镜观察样品显微组织结构;通过JSM-6630LV型扫描电镜进行断口形貌分析,同时对断口进行EDS能谱分析。

2 结果与分析

2.1 TiC的添加量对合金显微组织及性能的影响

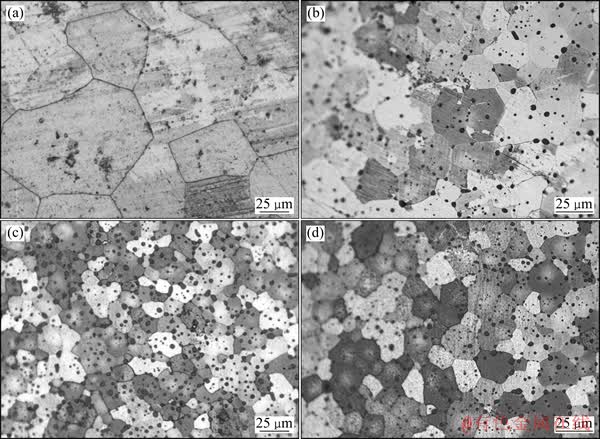

图1所示为纯钨、W-0.1TiC、W-1TiC、W-2TiC(质量分数,%)合金在1890 ℃烧结后的显微组织。通过对比可观察到,纯钨、W-0.1TiC、W-1TiC和W-2TiC合金的晶粒尺寸依次减小,可解释为弥散分布在钨晶界的碳化物颗粒降低钨晶粒的界面能,使钨晶粒长大的驱动力减小,同时,碳化物钉扎原始晶界,增大晶界迁移阻力,有效地阻碍原始晶粒的长大。纯钨的晶粒尺寸在50~100 μm之间,拉伸强度在260 MPa左右,通过添加微量TiC,钨颗粒得到明显细化,进而提高了合金强度。W-0.1TiC和W-1TiC合金中的TiC颗粒均匀分布在钨基体晶界和晶内,而W-2TiC合金中部分TiC粒子聚集长大,钨晶粒呈不规则的长条状,使合金的强度和致密度均有所下降,如图2所示。

图1 纯钨、W-0.1TiC、W-1TiC、W-2TiC合金在1890 ℃烧结后的金相组织

Fig. 1 Metallographs of pure W (a), W-0.1TiC (b), W-1TiC (c) and W-2TiC (d) alloys sintered at 1890 ℃

图2 TiC的添加量对钨相对密度和抗拉强度的影响

Fig. 2 Effects of TiC content on relative density and tensile strength of W

图2所示为1890 ℃下TiC的添加量对钨合金相对密度和抗拉强度的影响。由图2(a)可以看出,W-TiC合金致密度≥96%,且随着TiC添加量的增多,致密度呈现下降的趋势。合金中原子的扩散能力、孔隙的数目和大小决定着合金的致密化程度。一方面,由于TiC固有的化学键,使钛、碳原子在烧结过程中不易发生互扩散;且随着TiC含量的增加,TiC颗粒在钨基体及晶界处发生聚集长大(可结合图1所示),因此,部分TiC颗粒与钨颗粒之间的接触面积减小,进而阻碍原子在晶界的扩散作用,加大合金局部烧结难度[12-13],导致致密度降低。另一方面,据文献[14]报道,在高于1800 ℃下,TiC与坯体中的微量氧发生反应,生成非化学计量的氧化物或含氧化合物,反应式如下:

TiC+O2→TixOy/(TiCx)Oy+CO/CO2 (1)

坯体中由于气体压力而产生孔隙,因此,随着TiC添加量增加,孔隙增多增大[14-15]。综合以上因素,合金的致密度将随着TiC含量的增加而下降。

由图2(b)可见,增加TiC的含量,W-TiC合金的抗拉强度基本呈现先上升后下降的趋势,在含量为1%(质量分数)时,合金的抗拉强度最高。其原因主要为TiC的添加对合金起到细晶强化及弥散强化的作用,随着TiC含量的增多,这种效果更加明显,但当TiC粒子含量增加到一定程度时,由于二次相粒子在该温度下烧结困难,进而降低合金的致密度,在外加载荷的作用下,低致密度对裂纹增殖有较低的抗力,且材料内部不同形状的微孔,将会作为裂纹源残留在晶界处,增大了合金发生沿晶断裂的可能性,这种副作用削弱了细晶强化效果,从而导致合金的抗拉强度下降。

2.2 烧结温度对合金拉伸性能及显微组织的影响

图3所示为W-1TiC合金的拉伸强度随温度变化的曲线。由图3可见,合金抗拉强度随温度的升高呈现先增大后降低,在1890 ℃出现峰值。由于烧结温度均在1800 ℃以上,因此,致密度的变化幅度不是很明显。据统计W-1TiC合金在以下温度点烧结时,致密度在97%~98%范围内变化。

图3 W-TiC合金的抗拉强度与烧结温度的关系

Fig. 3 Relationship between tensile strength and sintering temperature of W-TiC alloy

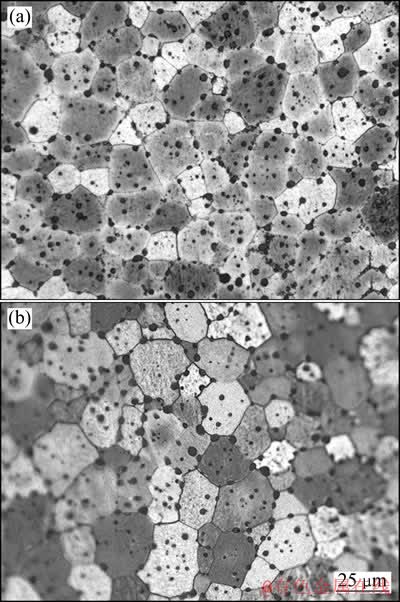

图4所示为W-1TiC合金于1950 ℃和1980 ℃下烧结的金相显微组织。参照图1(c) (W-1TiC在1890 ℃下烧结) 进行对比观察,从中明显看出,合金晶粒发育充分,呈现多边形等轴状,晶粒尺寸在10~15 μm之间,TiC均匀地分布在钨基体中,其粒度尺寸在0.5~2 μm范围内变化;少量TiC分布在晶界,细化了钨晶粒[16]。由图4(a)可看出,随着温度的升高,W-TiC合金晶粒开始长大,且晶粒形状不规则,其晶粒尺寸范围为15~25 μm,从而影响合金的力学性能,这与图4中的拉伸曲线相互吻合。从图4(b)可看出,W-1TiC合金在1980 ℃下烧结,其平均晶粒尺寸与图4(a)的晶粒尺寸大致相同,说明在1950 ℃时,钨晶粒几乎已经停止长大。

图4 W-1TiC合金在1950 ℃和1980 ℃烧结3 h的显微组织

Fig. 4 Microstructures of W-1TiC alloy at sintering temperatures of 1950 ℃ (a) and 1980 ℃ (b) for 180 min

2.3 合金断口形貌

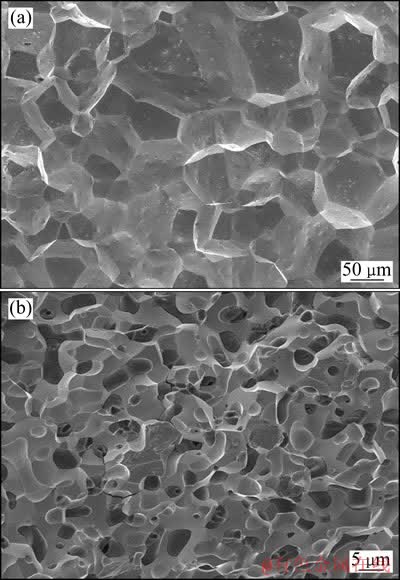

1890 ℃下,纯钨、W-1TiC的断口扫描图片如图5(a)和(b)所示。由图5(b)观察出,W-1TiC合金基体多处呈现穿晶断裂,少数二次相粒子同时也出现穿晶,这说明部分二次相粒子与钨基体晶界结合强度很好,起到了承受载荷的作用[17]。由此可见,W-1TiC的断裂类型可断定为脆性穿晶解离和沿晶断裂的混合型,且穿晶断裂占主导;对比之下图5(a)中的纯钨断口呈明显的冰糖块状,属于典型的沿晶断裂。

当TiC含量较少时,合金呈穿晶断裂占主导的脆性断裂,可以解释为,弥散分布于钨基体中的TiC作为一种硬脆相粒子,引起位错组态发生变化。集中分布在晶内的二次相粒子,使滑移过程中大量位错被二次相粒子钉扎在晶内,从而晶界附近滑移带的位错密度降低,这种位错组态延缓了沿晶裂纹的形成。因此,与纯钨相比,添加微量TiC的钨基合金,其拉伸强度有所提高。

图6所示为1890℃下W-1TiC合金的断口形貌及EDS谱。从图6中可看出,二次相粒子中含有碳、氧、钛、钨4种元素。对于碳、氧和钛的存在,可解释为合金内部发生了反应(1),团聚的TiC粒子与氧结合,发生脱碳反应,生成CO/CO2;根据文献[1]和[2]报道的相关XRD及TEM分析,图谱中钨峰的出现是由于在烧结过程中,钨原子置换部分钛原子,进而钨与TiC粒子形成非化学计量系数的(Tix,W1-x)Cy固溶体,因此,出现明显的钨峰。综合以上分析,理论上,二次相粒子中可能存在碳、氧、钛和钨4种元素,与图中的实验结果相吻合。

图5 1890 ℃时纯钨和W-1TiC合金的断口形貌

Fig. 5 Fracture morphologies of pure W (a) and W-TiC alloy (b) at temperature of 1890 ℃

图6 1890 ℃时W-1TiC合金的断口形貌及EDS谱

Fig. 6 Fracture morphology and EDS spectrum of W-1TiC alloy at 1890 ℃

3 结论

1) 当TiC的添加量为1%时,合金具有最佳性能,其致密度为97.4%,室温拉伸强度达401 MPa。

2) 微量TiC均匀分布在钨晶内及晶界,与纯钨相比,微量TiC的添加有效地抑制了钨晶粒的长大,使晶粒尺寸控制在10 μm左右,因此,对钨基体起到了弥散强化与细晶强化的作用。

REFERENCES

[1] GENC A, S COSKUN ML. Decarburization of TiC in Ni activated sintered W-xTiC (x=0, 5, 10, 15 wt%)[J]. Journal of Refractory Metals Hard Materials, 2010, 28(3): 451-458.

[2] GEN A, CO KUN S, VE O LU M L. Microstructural characterizations of Ni activated sintered W-2wt% TiC composites produced via mechanical alloying[J]. Journal of Alloys and Compounds, 2010, 497(1/2): 80-89.

[3] KURISHITA H, MASTUO S, ARAKAWA H, SAKAMOTO T, KOBAYASHI S, NAKIDA T, TAKIDA T, KATO M, KAUAI M, YOSHIDA N. Development of re-crystallized W-1.1%TiC with enhanced room-temperature ductility and radiation performance[J]. Journal of Nuclear Materials, 2010, 398(1/3): 87-92.

[4] KURISHITA H, AMANO Y, KOBAYASHI S, NAKAI K, ARAKAWA H, HIRAOKA Y, TAKIDA T, TAKEBE K, MATSUI H. Development of ultra-fine grained W–TiC and their mechanical properties for fusion applications[J]. Journal of Nuclear Materials, 2007, 367/370: 1453-1457.

[5] KURISHITA H, KOBAYASHI S, NAKAI K, OGAWA T, HASEAWA A, ABE K, ARAKAWA H, MATSUO S, TAKIDA T, TAKEBE K, KAWAI M, YOSHIDA N. Development of ultra-fine grained W-(0.25-0.8)wt%TiC and its superior resistance to neutron and 3MeV He-ion irradiations[J]. Journal of Nuclear Materials, 2008, 377(1): 34-40.

[6] KURISHITA H, MATSUO S, ARAKAWA H, NARUI M, YAMAZAKI M, SAKAMOTO T, KOBAYASHI S, NAKAI K, TAKIDA T, TAKEBE K, KAWAI M, YOSHIDA N. High temperature tensile properties and their application to toughness enhancement in ultra-fine grained W-(0-1.5)wt% TiC[J]. Journal of Nuclear Materials, 2009, 386/388: 579-582.

[7] VELEVA L, SCH UBLIN R, PLOCINSKI T, WALTER MARIO, BALUC NADINE. Processing and characterization of a W–2Y material for fusion power reactors[J]. Fusion Engineering and Design, 2011, 86(9/11): 2450-2453.

[8] KURISHITA H, MATSUO S, ARAKAWA H, KOBAYASHI S, NAKIDA T, TAKIDA T, TAKEBE K, KAWAI M. Superplastic deformation in W-0.5wt.% TiC with approximately 0.1um grain size[J]. Materials Science and Engineering A, 2008, 477(1/2):162-167.

[9] VELOA L, OKSIUTA Z, VOGT U, BALUC N. Sintering and characterization of W-Y and W-Y2O3 materials[J]. Fusion Engineering and Design, 2009, 84(7/11): 1920-1924.

[10] WANG Shu-ming, SUN Chong-xiao, GUO Wen-hao, GE Chang-chun, YANG Qing-zhi, ZHOU Qiang, CHEN Peng-wan, CHEN Zhi-Bao. Modifying the properties of tungsten based plasma facing materials with single-wall carbon nanotubes[J]. Journal of Materials Science & Technology, 2013, 29(10): 919-922.

[11] WURSTER S, BALUC N, BATTABYAL M, CROSBY T, DU J, GARCIA-ROSALES. HOFFAON A, KIMUR A, KURISHITA A, KURTZ R J, LI H, NOH S, REISER J, RIESCH J, RIETH M, SETYAWAN W, WALTER M, YOU J H, PIPPAN R. Recent progress in R&D on tungsten alloys for divertor structural and plasma facing materials[J]. Journal of Nuclear Materials, 2013, 442(1/3): S181-S189.

[12] SONG Gui-ming, WANG Yu-jin, ZHOU Yu. Thermomechanical properties of TiC particle-reinforced tungsten composites for high temperature applications[J]. International Journal of Refractory Metals and Hard Materials, 2003, 21(1/2): 1-12.

[13] CHEN Y, WU Y C, YU F W, CHEN J L. Microstructure and mechanical properties of tungsten composites co-strengthened by dispersed TiC and La2O3 particles[J]. International Journal of Refractory Metals and Hard Materials, 2008, 26(6): 525-529.

[14] 卢明园, 范景莲, 成会朝, 廖跃辉,田家敏. TiC的添加对Mo-Ti合金性能与组织结构的影响[J]. 稀有金属材料与工程, 2010, 39(6): 985-988.

LU Ming-yuan, FAN Jing-lian, CHENG Hui-chao, LIAO Yue-hui, TIAN Jia-min. Influence of TiC Addition on properties and microstructure of Mo-Ti alloys[J]. Rare Metal Materials and Engineering, 2010, 39(6): 985-988.

[15] 卢明园, 范景莲, 成会朝, 刘 涛, 田家敏, 黄伯云. Ti对Mo-Ti合金拉伸强度及显微组织的影响[J]. 中国有色金属学报, 2008, 18(3): 409-413.

LU Ming-yuan, FAN Jing-Lian, CHENG Hui-chao, LIU Tao, TIAN Jia-min, HUANG Bai-yun. Effects of Ti on tensile strength and microstructure of Mo-Ti alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 409-413.

[16] 胡赓祥,蔡 珣. 材料科学基础[M]. 上海: 上海交通大学出版社, 2000: 138.

HU Geng-xiang, CAI Xun. Fundamentals of materials science[M]. Shanghai: Shanghai Jiao Tong University Press, 2000: 138.

[17] 张 顺, 范景莲, 成会朝, 刘 涛, 田家敏. 常压H2气氛烧结W-TiC合金的致密化行为和性能[J]. 粉末冶金材料科学与工程, 2011, 16(6): 900-905.

ZHANG Shun, FAN Jing-lian, CHENG Hui-chao, LIU Tao, TIAN Jia-min. Densification behavior and mechanical properties of W-TiC alloy prepared by pressure sintering in H2 protective atmosphere[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(6): 900-905.

(编辑 李艳红)

基金项目:国家科技部重大专项(2014GB115000);教育部博士点基金资助项目(20130162130002)

收稿日期:2014-04-16;修订日期:2014-09-16

通信作者:范景莲,教授,博士;电话:0731-88836652;E-mail:fjl@csu.edu.cn