Synthesis of nano- to micrometer-sized B4C particle-reinforced aluminum matrix composites via powder metallurgy and subsequent heat treatment

来源期刊:中南大学学报(英文版)2021年第8期

论文作者:王文先 刘瑞峰 陈洪胜

文章页码:2295 - 2306

Key words:nano- to micrometer-size; B4C/6061 Al composites; T6 heat treatment

Abstract: B4C/6061Al composites reinforced with nano- to micrometer-sized B4C particles were fabricated via powder metallurgy route consisting of spark plasma sintering (SPS) and hot extrusion and rolling (HER), followed by T6 treatment. The microstructural evolution and mechanical properties were investigated. Results showed that the status of B4C particles changed from a network after SPS to a dispersion distribution after HER. The substructured grains reached 66.5% owing to the pinning effect of nano-sized B4C, and the grain size was refined from 3.12 μm to 1.56 μm after HER. After T6 treatment, dispersed Mg2Si precipitated phases formed, and the grain size increased to 1.87 μm. Fine recrystallized grains around micro-sized B4C were smaller than those in the areas with uniform distribution of nano-sized B4C and Mg2Si. The stress distributions of as-rolled and heated composites were similar, considering that the T6 heat treatment was only effective in eliminating the first internal stress. The Vickers, microhardness, and tensile strength of as-SPSed composites were greatly improved from HV 55.45, 0.86 GPa, and 180 MPa to HV 77.51, 1.08 GPa, and 310 MPa, respectively. Despite the precipitation strengthening, the corresponding values of as-heated composites decreased to HV 70.82, 0.85 GPa, and 230 MPa owing to grain coarsening.

Cite this article as: LIU Rui-feng, WANG Wen-xian, CHEN Hong-sheng. Synthesis of nano- to micrometer-sized B4C particle-reinforced aluminum matrix composites via powder metallurgy and subsequent heat treatment [J]. Journal of Central South University, 2021, 28(8): 2295-2306. DOI: https://doi.org/10.1007/s11771-021-4770-2.

J. Cent. South Univ. (2021) 28: 2295-2306

DOI: https://doi.org/10.1007/s11771-021-4770-2

LIU Rui-feng(刘瑞峰)1, 2, WANG Wen-xian(王文先)2, 3, CHEN Hong-sheng(陈洪胜)2, 4

1. College of Aeronautics and Astronautics, Taiyuan University of Technology, Taiyuan 030024, China;

2. Shanxi Key Laboratory of Advanced Magnesium-based Materials, Taiyuan 030024, China;

3. College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

4. College of Mechanical Engineering, Taiyuan University of Technology, Taiyuan 030024, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: B4C/6061Al composites reinforced with nano- to micrometer-sized B4C particles were fabricated via powder metallurgy route consisting of spark plasma sintering (SPS) and hot extrusion and rolling (HER), followed by T6 treatment. The microstructural evolution and mechanical properties were investigated. Results showed that the status of B4C particles changed from a network after SPS to a dispersion distribution after HER. The substructured grains reached 66.5% owing to the pinning effect of nano-sized B4C, and the grain size was refined from 3.12 μm to 1.56 μm after HER. After T6 treatment, dispersed Mg2Si precipitated phases formed, and the grain size increased to 1.87 μm. Fine recrystallized grains around micro-sized B4C were smaller than those in the areas with uniform distribution of nano-sized B4C and Mg2Si. The stress distributions of as-rolled and heated composites were similar, considering that the T6 heat treatment was only effective in eliminating the first internal stress. The Vickers, microhardness, and tensile strength of as-SPSed composites were greatly improved from HV 55.45, 0.86 GPa, and 180 MPa to HV 77.51, 1.08 GPa, and 310 MPa, respectively. Despite the precipitation strengthening, the corresponding values of as-heated composites decreased to HV 70.82, 0.85 GPa, and 230 MPa owing to grain coarsening.

Key words: nano- to micrometer-size; B4C/6061 Al composites; T6 heat treatment

Cite this article as: LIU Rui-feng, WANG Wen-xian, CHEN Hong-sheng. Synthesis of nano- to micrometer-sized B4C particle-reinforced aluminum matrix composites via powder metallurgy and subsequent heat treatment [J]. Journal of Central South University, 2021, 28(8): 2295-2306. DOI: https://doi.org/10.1007/s11771-021-4770-2.

1 Introduction

With excellent comprehensive mechanical properties, particle-reinforced Al matrix composites (PAMCs) have acquired wide attention in the defense and aerospace industries [1-4]. For the selection of the enhancement phase, most research has focused on micro-sized particles, but the strengthening effect of the addition of micro-sized particles is at the expense of plasticity. Nano-sized particles, with few surface defects and good wetting with alloy matrix, have attracted considerable attention from scientific researchers in recent years [5-7]. The agglomeration phenomenon leads to the limited volume fraction of nano-sized particles.

Uniformly dispersed nanoparticles are critical for enhancing the mechanical properties of nanocomposites. Therefore, PAMCs reinforced with nano- to-micrometer-sized particles are a promising path that can enhance the mechanical property and maintain excellent plasticity.Casting has been widely used to fabricate PAMCs [8, 9]. Meanwhile, hot isostatic pressing has also been reported [10]. Powder metallurgy [11] and spark plasma sintering (SPS) [12-14], with the advantages of uniform distribution of enhanced particles, low sintering temperature, and high pressure, have been recognized as perfect techniques in the fabrication of PAMCs.

Hot extrusion and rolling (HER) have been extensively used to improve particle distribution and enhance the interface bonding for PAMCs, especially for nanocomposites. T6 heat treatment (solid solution at 530 °C for 2 h and aging at 175 °C for 6.5 h in this work) is also considered an effective method to strengthen nanocomposites [15-17]. CASATI et al [16] fabricated SiC and oxide nanoparticle-reinforced 2618Al matrix composites and demonstrated that ball milling led to the formation of crystal defects, which in turn extend the solid solution and decrease the driving force for aging. MIRJAVADI et al [17] prepared a graphene nanoplatelet-reinforced Al-10Zn-3.5Mg-2.5Cu nanocomposite by casting and hot extrusion, followed by T6 treatment. The nanocomposite strength was greatly improved after hot extrusion and T6 treatment due to precipitation hardening. The purpose of this study is to prepare aluminum matrix composites with excellent strength and plasticity through the combination of advanced powder metallurgy route and heat treatment.

In this study, the effects of HER and T6 heat treatment on the microstructure and mechanical property of nano- to micrometer-sized B4C particle-reinforced 6061Al matrix composites were investigated. The distribution of B4C and precipitated phases, recrystallization behavior, nanoindentation, and tensile properties were examined systematically. The fracture failure mechanism was analyzed, and the theoretical yield strength (YS) was calculated for comparison with the experimental YS.

2 Experimental procedure

The 6061Al alloy powders used in this work had an average size of 13 μm, and the average size of nano-to-micrometer-sized B4C particles was set to 50 nm. The chemical compositions are shown in Tables 1 and 2. First, 6061Al powders and B4C particles were subjected to high-energy milling (HEM) at a speed of 1400 r/min for 12 h. Second, the remaining 6061Al powders and mixed powder produced by HEM were subjected to low-energy milling (LEM) for 2 h at a speed of 200 r/min. The protection of argon gas was applied to avoid oxidation in the HEM and LEM processes.

Table 1 Chemical composition of 6061Al alloy (wt%)

Table 2 Chemical composition of B4C (wt%)

After the ball milling process, a vacuum glove box (O2 content<1×10-6) was used when the blended powder was placed into graphite dies. Then, DR.SINTER-type SPS331-Lx equipment with a pulse duration of 40 ms and a vacuum chamber was employed in the sintering process. The vacuum pump was in continuous operation. The vacuum was maintained under ~20 Pa, and all gases were pumped out using the vacuum pump during SPS. The sintering temperature was 570 °C, which was considerably lower than the melting point of 6061Al alloy powders (660 °C) and B4C particles (2350 °C). The final dimension of as-SPSed billets was 30 mm in height and 30 mm in diameter. For improving the distribution of nano-sized B4C particles and mechanical property, hot extrusion at 500 °C with an extrusion ratio of 16:1 was applied to the as-SPSed samples. The obtained as-extruded samples were 15 mm in width and 3 mm in thickness. After extrusion, the as-extruded samples were rolled at 500 °C with a speed of 20 mm/s, from 3 mm to 1.5 mm in three passes. Lastly, a solid solution treatment at 530 °C for 2 h and aging at 175 °C for 6.5 h, named T6 heat treatment, were applied to modify the B4C/6061Al composites under a vacuum atmosphere. Figure 1 shows the process diagram.

Microstructural characterization was achieved using a scanning electron microscope (JSM-6700F, equipped with EDS and EBSD system). All the samples were characterized without any coating. The phases were tested by X-ray diffraction (XRD). The nanoindentation properties were characterized by nanoindentation test (Agilent G200) with a load of 30 mN. All loading-unloading processes were repeated 3 times for an accurate characterization.

Figure 1 Process diagram of whole process

The tensile-testing specimens were cut in the direction parallel to the HER direction, and the tensile test was conducted by employing an Instron Series 5569 test machine at room temperature with a speed of 0.2 mm/min.

3 Results and discussion

3.1 Relative density

Table 3 shows the measured and theoretical density values of the B4C/6061Al composites. The relative density of B4C/6061Al composites decreases with increasing B4C volume fraction, and the values of as-SPSed composites are all above 98.2%. For composites with the same volume fraction, the relative density of B4C/6061Al composites is higher than that of as-SPSed composites after extrusion and rolling deformation. Almost completely dense composites are obtained. After T6 heat treatment, the relative density of composites does not change remarkably.

Table 3 Measured and theoretical density values of B4C/6061Al composites with different volume fractions

3.2 Microstructure

Figure 2 presents the raw and mixed powders after the ball milling process. As shown, the maximum size of the micro-sized B4C particles is approximately 3 μm. The nano-sized B4C particles are uniformly located on the matrix particle surface (Figure 2(c)) after ball milling, which can be attributed to the selection of a micro-sized Al matrix and nano- to micrometer-sized B4C particles.Figure 2(d) shows the high magnification of Figure 2(c). The nano-sized B4C particles are embedded into soft matrix particles, and cold welding exists at the Al/ B4C interface under the tremendous energy output. Nano-sized B4C distributes evenly after HEM and LEM, as confirmed in Figure 2(f).

Figure 3 shows the EBSD image, EDS, and inverse pole figure of B4C/6061Al composites at three statuses. Nano-sized B4C particles mainly distribute at the Al particle boundary for as-SPSed composites (≈network reinforcement architecture) [18, 19]. For as-rolled composites (Figure 3(b)), the nano-sized B4C particles are redistributed under substantial plastic deformation. After T6 heat treatment, the distribution of nano-sized B4C remains the same as that of the as-rolled composites, while some precipitated phases appear. The EDS result shows that the precipitated phase in Figure 3(d) is an intermetallic mainly composed of Al, Si, and Mg, which seems to form during the aging treatment, as shown in Figure 3(e). In sum, the atomic ratio shown in Figure 3(e) can prove that the white-like precipitated phases are Mg2Si. Mg and Si are the main alloy elements, and Mg2Si phase will precipitate for 6061Al alloys after T6 heat treatment. This condition has been confirmed by previous works [3, 20]. As shown in Figures 3(f)-(h), the grain orientation with a random distribution for as-SPSed composites changes to the majority of {101} and {111} orientations along with HER and T6 treatment, indicating the appearance of an intense texture orientation.

Figure 2 Morphology of raw powders:

Figure 3 Microstructure and EDS of as-SPSed, as-rolled and as-heated B4C/6061Al composites:

Figure 4 shows the XRD results of B4C/6061Al composites at three statuses. Only the Al phase is detected in every status. No B4C and Mg2Si are tested due to the low quantity of B4C particles and limited precipitation. Low-volume B4C and precipitated phases make them difficult to detect; similar results have been found in our previous work [12].

Figure 5 shows the high-angle grain boundary (HAGB>15°, black), low-angle grain boundary (LAGB<15°, green), and distinguished recrystallized (blue), substructured (yellow), and deformed grains (red) of B4C/6061Al composites at three statuses. For the as-SPSed composites in Figure 5(a), HAGBs occupy the majority, and the average misorientation angle reaches 29.34°. Considerable plastic deformation will introduce substantial subgrains with an extremely small misorientation, and then LAGBs will transform to HAGBs [21]. After HER, the fraction of LAGBs is calculated to be 30%, and the average misorientation angle decreases to 9.56°. In this condition, the dislocation tangles through the pinning effect of nano-sized B4C form substructures [22]. As shown in Figure 5(b), the fraction of substructured grains increases to 67.8%.

Figure 4 XRD patterns of as-SPSed, as-rolled and as-heated B4C/6061Al composites

Figure 5 EBSD results of as-SPSed, as-rolled and as-heated B4C/6061Al composites:

Corrected curve means that misorientations are calculated from neighboring points, and uncorrected curve implies that misorientations are calculated from random points. Random curve stands for the random distribution of misorientation with no preferential orientation. For the as-rolled composites in Figure 5(b), “Uncorrelated” curve shows misfit between 10°-25° and 35°-50° compared with “Random” curve. For PAMCs, the free energy of the Al matrix will be improved, and the nonuniform nucleation will be stimulated when the area around micro-sized particles is full of dislocations [23, 24], named particle-stimulated nucleation (PSN). The density of dislocation in the area with uniformly distributed nano-sized B4C particles remains or even increases after solid solution treatment and aging. Two factors cause this condition: 1) the generated dislocation will increase the nucleation rate, which will lead to the formation of a dispersed precipitated phase; 2) the evident pinning effect of small precipitated phases and nano-sized B4C leads to dislocation entanglement [12, 25]. As shown in Figure 5c, the fraction of substructured grains is kept at 66.5% after T6 treatment given only partial recrystallization around micro-sized B4C particles. The average grain size increases from 1.56 to 1.87 μm during the process of T6 treatment, even if partial grain refinement occurs around micro-sized B4C particles. In general, a large number of dislocations are retained after T6 heat treatment, which will increase the nucleation rate of the precipitated phase during the process of heat treatment. Substantial phases are precipitated, as shown in Figure 3. Overall, recrystallization behavior occurs around micro-sized B4C particles, and recovery behavior is the main softening mechanism in the area with dispersed nano-sized B4C particles in the process of T6 treatment.

Figures 6(a)-(c) show the measured KAM maps of B4C/6061Al composites at three statuses. As shown, the as-SPSed composites own the lowest stress compared with the as-rolled and as-heated composites. As HER proceeds, the average angle shows an increasing trend, and the stress increases remarkably, especially for the fine-grain zone. Generally, T6 heat treatment is only effective in eliminating the first internal stress, and the lattice distortion caused by numerous defects in the HER deformation process remains. Therefore, the stress distribution after heat treatment is similar to that of the as-rolled composites. Figures 6(d)-(f) exhibit the local strain distribution of the B4C/6061Al composites. Heterogeneous distribution of strain and component gradient is evidently shown, and the fine-grain region has the maximum strain distribution at three different stages. Figure 7 shows the schematic of the microstructural evolution of the B4C/6061Al composites under different statuses.

Figure 6 Measured KAM maps and local strain distribution of B4C/6061Al composites:

Figure 7 Schematic diagram of microstructure evolution of B4C/6061Al composites:

3.3 Mechanical properties

Microstructural evolution must lead to the corresponding changes in the mechanical properties of PAMCs. Figure 8 shows the load-displacement curve, microhardness, and elasticity modulus results of B4C/6061Al composites at three statuses. Under the same load of 30 mN, the indentation depth first decreases and then increases as the hot rolling and T6 heat treatment proceed (Figure 8(a)). That is, the microhardness should first increase and then decrease, which is consistent with the results in Figure 8(d). The reasons for the increase in Vickers hardness and microhardness after HER are grain refinement and dislocation strengthening. For as-heated composites, the release of stress and grain coarsening result in decreases in Vickers hardness and microhardness even with the formation of a dispersed precipitated phase. The slope of the unloading curve represents the elasticity modulus, as shown in Figure 8(e). The unloading curves are becoming steeper as the hot rolling and T6 heat treatment proceed, which means that the elasticity modulus shows an increasing trend (Figure 8(e)).

The deformation zone around micro-sized B4C particles results from the recrystallization during T6 heat treatment. Figure 8(b) shows the loading-unloading curves located at different distances from micro-sized B4C particles. The indentation depth decreases with increasing distance from micro-sized B4C particles. The loading-unloading curve of the deformation zone (1.5 μm) almost coincides with the curve obtained by the matrix. That is, the width of the particle deformation zone ranges between 1.0 and 1.5 μm.

Figure 9 shows the tensile stress-strain curves of B4C/6061Al composites at three statuses. For the composites fabricated by SPS, the YS (0.2% proof stress) and ultimate tensile strength (UTS) are only 104 and 180 MPa, respectively. Nano-sized B4C particles gather at the particle boundary of matrix particles, which makes the particle boundary a weak point in the process of tensile test. After extrusion, fine-grain strengthening enhances the tensile strength, YS, and elongation of the composites. In the rolling process, YS and UTS increase to 211 MPa and 310 MPa, respectively, accompanied by a slight decrease in the elongation to fracture from 14% to 12.5%. The following factors cause the change: 1) the distribution of nano-sized B4C changes from the aggregation at the boundary of matrix particles to a uniform distribution at the Al matrix after HER, which is vital to the strengthening of nano-sized particle-reinforced metal matrix composites; 2) HER refines the Al grains effectively (from 3.12 to 1.56 μm), and the contribution of fine-grain strengthening accounts for the majority compared with other strengthening mechanisms, which has been confirmed in our previous study [7]. At the same time, the fine matrix grains promote rapid strain hardening at the beginning of the tensile test. Thus, a high UTS is obtained, as shown in the curve of as-rolled composites in Figure 9(a); 3) a mass of dislocations are accumulated after HER, especially for the condition of the pinning effect of nano-sized B4C particles.

T6 treatment has a remarkable effect on the strength and plasticity of composites. YS and UTS are decreased to 93 and 198 MPa, respectively, whereas the elongation to fracture increases from 12.5% to 15.3% for as-heated composites (solution treatment). After aging treatment, YS and UTS increase to 170 and 230 MPa, respectively, whereas the elongation to fracture decreases to 12.5% owing to the appearance of Mg2Si precipitated phases. For the nanocomposites, grain boundary strengthening is critical for enhancing YS. That is, the increase in YS by using a dispersive Mg2Si phase is inadequate to compensate for the decrease in grain coarsening. A similar phenomenon in ductility increase of an Al-Mg-Si alloy fabricated by ECAP, followed by artificial aging, was also found, and the annihilation of dislocation after heat treatment was the main factor [26]. HU et al [27] fabricated TiN/Al nanocomposites by an ultrasonic-assisted casting method, followed by T6 treatment, and the tensile strength and elongation were 235 MPa and 9.5%, respectively. SHRIVASTAVA et al [28] fabricated Al6061-Al2O3 nanocomposites by a powder metallurgy route, followed by a solution heat treatment and aging. The results showed that the maximum tensile strength and elongation were 100 MPa and 5.2% for 2 wt.% nanocomposites, respectively. The hardness results indicated that a solution heat treatment followed by aging of composite samples was highly beneficial to the increase in hardness.

Figure 8 Nanoindentation test results of B4C/6061Al composites:

Figure 9 Tensile stress-strain curves of as-SPSed, as-extruded, as-rolled and as-heated B4C/6061Al composites

Figure 10 shows the fracture morphology of B4C/6061Al composites at three statuses. A slice of dimples exists in the matrix after SPS. Meanwhile, entirely whole Al particles, indicated by the yellow arrows, are exposed. The observation of crack in Figure 10(a) demonstrates that the Al particle boundaries are the main crack propagation path. After HER, the as-rolled composites exhibit obvious dimples in the range of 1-3 μm, with severe tearing of the matrix. In Figure 10(c), the tensile fracture is an obvious ductile morphology, with dimples in the range of 1-4 μm, that is, the T6 treatment effectively maintains the plasticity of the B4C/6061Al composites, which is consistent with the tensile stress-strain curve. Figure 10(d) shows the highly magnified image of the fracture morphology of as-heated composites. The micro-sized B4C particles are well bonded to the Al matrix, and the crack propagation can be effectively hindered. All the above mentioned factors contribute to the high ductility of as-heated composites. As shown in Figure 10(d), the particle/matrix interface bonding is well, with matrix fracture preferentially compared with the interface during tensile deformation, which can improve the composite strength.

3.4 Strengthening mechanisms

Several strengthening mechanisms, including load transfer, dislocation, Orowan, and fine-grain strengthening, are working together to improve the mechanical properties of PAMCs.

1) Well interface bonding at the atomic level between nano-sized B4C and Al matrix can bear the tensile load effectively. The load will be transferred from the matrix to the reinforcement through the interface shear, and the increase in YS (σload) is shown by the following equation [29]:

△σload=0.5σm (1)

2) The remarkable difference in the coefficient of thermal expansion between the metal matrix and ceramic particle will generate large thermal mismatch strain at the interface during cooling, and the release of thermal mismatch strain is achieved by releasing the dislocation ring. Therefore, high-density dislocations can strengthen the Al matrix. The increase in YS (σdis) owing to the dislocation strengthening is characterized by the following equation [30]:

(2)

(2)

3) Two paths can be utilized to overcome the obstacle when dislocations interact with particles, that is, dislocation goes straight through the particles or bypassing the particles and continues to move. As for nano-sized particles and the Mg2Si precipitated phase, the resistance on the dislocation line makes it difficult to go straight through the particles, which can only be achieved via a bypassing way, which is also called Orowan strengthening. The dislocation ring released by the dislocation line will increase the dislocation density and improve the strength, and the increase in YS (σOrowan) can be characterized using the following equation [31]:

(3)

(3)

(4)

(4)

4) Recrystallization occurs during hot deformation. The formed HAGBs are pinned by the nano-sized B4C particles and dispersed Mg2Si phase, and the growth of recrystallized grains is restrained effectively, thereby obtaining fine grains in the composite. The increase in YS (σgb) due to fine-grain strengthening can be calculated using the following equation [32]:

(5)

(5)

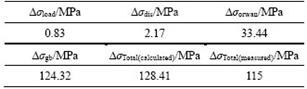

Table 4 lists the parameters for the calculation of the theoretical YS of as-heated composites. In summary, the increase in YS can be attributed to the coupling functions of the four strengthening mechanisms listed above. The quadratic sum of the four strengthening mechanisms is always used to calculate the theoretical YS [33]. On the basis of the calculated results in every single strengthening mechanism, the increase in YS through theoretical calculation and experimental measurement is listed in Table 5. △σTotal (measured) can be calculated by comparing with the yield stress of the 6061Al matrix. The increment in YS via theoretical calculation is almost consistent with the experimental measurement, and only 13.41 MPa deviation exists.

(6)

(6)

Figure 10 Fracture surface of B4C/6061Al composites:

Table 4 Values of parameters for calculating theoretical σYS of 3% as-heated B4C/6061Alcomposites

Table 5 Calculated contribution of different strengthening mechanisms to σYS of 3% as-heated B4C/6061Al composites

4 Conclusions

The effects of T6 heat treatment and HER on the microstructure and mechanical properties of nano- to micrometer-sized B4C PAMCs were investigated. The main conclusions are drawn as follows:

1) Nano-sized B4C is embedded onto the surface of 6061 matrix particles after ball milling and mainly distributes at the connection boundary of the 6061 matrix particles after SPS. Uniform distribution of nano-sized B4C particles is achieved after HER. The Mg2Si phase is precipitated after T6 heat treatment.

2) The microstructure of as-SPSed composites is dominated by recrystallized grains. After HER, substructured grains with LAGBs account for the majority due to the pinning effect of nano-sized B4C. The substructured grains remain and the average grain size increases from 1.56 to 1.87 μm, although fine recrystallized grains caused by PSN can be observed around the micro-sized B4C particles after T6 heat treatment.

3) The Vickers, microhardness, and tensile strength of as-rolled composites are increased to HV 77.51, 1.08 GPa, and 310 MPa, respectively, owing to the fine-grain and dislocation strengthening effects. The corresponding mechanical properties of as-heated composites decrease to HV 70.82, 0.85 GPa, and 230 MPa owing to grain coarsening.

4) The calculated YS agrees well with the experimental YS for the nano- to micrometer-sized B4C PAMCs produced by powder metallurgy, including SPS, HER, and T6 heat treatment.

Contributors

LIU Rui-feng provided the concept and edited the draft of manuscript. WANG Wen-xian conducted the literature review and wrote the first draft of the manuscript. CHEN Hong-sheng edited the draft of manuscript.

Conflict of interest

LIU Rui-feng, WANG Wen-xian and CHEN Hong-sheng declare that they have no conflict of interest.

References

[1] MOSTAAN H, MEHRIZI M Z, RAFIEI M, MAHDI R, REZA B, AHMAD R A. Contribution of mechanical activation and annealing in the formation of nanopowders of Al(Cu)/TiC-Al2O3 hybrid nanocomposite [J]. Ceramics International, 2017, 43(2): 2680-2685.

[2] HOSSEINI N, KARIMZADEH F, ABBASI M H, ENAYATI M H. A comparative study on the wear properties of coarse-grained Al6061 alloy and nanostructured Al6061-Al2O3 composites [J]. Tribology International, 2012, 54: 58-67.

[3] VEERESH G B, RAO C S P, SELVARAJ N. Studies on mechanical and dry sliding wear of Al6061-SiC composites [J]. Composites Part B: Engineering, 2012, 43(3): 1185-1191.

[4] GHASALI E, YAZDANI-RAD R, ASADIAN K, EBADZADEH T. Production of Al-SiC-TiC hybrid composites using pure and 1056 aluminum powders prepared through microwave and conventional heating methods [J]. Journal of Alloys and Compounds, 2017, 690: 512-518.

[5] ALIPOUR M, FARSANI R. Synthesis and characterization of graphene nanoplatelets reinforced AA7068 matrix nanocomposites produced by liquid metallurgy route [J]. Materials Science and Engineering A, 2017, 706: 71-82.

[6] HUANG Yi, BAZARNIK P, WAN Di-qing, DAN Luo, PEREIRA P H, LEWANDOWSKA M, YAO Jin, HAYDEN B E, LANGDON T G. The fabrication of graphene-reinforced Al-based nanocomposites using high-pressure torsion [J]. Acta Materialia, 2019, 164: 499-511.

[7] LIU Rui-feng, WANG Wen-xian, CHEN Hong-sheng, TAN Min-bo, ZHANG Yu-yang. Microstructure and mechanical properties of B4C/6061Al nanocomposites fabricated by advanced powder metallurgy [J]. Advanced Engineering Materials, 2018, 20: 1701133.

[8] AMOURI K, KAZEMI S, MOMENI A, KAZAZIC M. Microstructure and mechanical properties of Al-nano/micro SiC composites produced by stir casting technique [J]. Materials Science and Engineering A, 2016, 674: 569-578.

[9] LIU Bin, HUANG Wen-mao, WANG Hao-wei, WANG Ming-liang, LI Xian-feng. Compressive behavior of high particle content B4C/Al composite at elevated temperature [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 2826-2832.

[10] FARVIZI M, KAHKHAEIJAVAN M, AKBARPOUR M R, KIM H S. Fabrication of NiTi and NiTi-nano Al2O3 composites by powder metallurgy methods: Comparison of hot isostatic pressing and spark plasma sintering techniques [J]. Ceramics International, 2018, 44(13): 15981-15988.

[11] ZHANG Peng, LI Yu-li, WANG Wen-xian, GAO Zhan-pin, WANG Bao-dong. The design, fabrication and properties of B4C/Al neutron absorbers [J]. Journal of Nuclear Materials, 2013, 437 (1-3): 350-358.

[12] LIU Rui-feng, WANG Wen-xian, CHEN Hong-sheng, TAN Min-bo, ZHANG Yu-yang. Microstructure evolution and mechanical properties of micro-/nano-bimodal size B4C particles reinforced aluminum matrix composites prepared by SPS followed by HER [J]. Vacuum, 2018, 151: 39-50.

[13] VINTILA R, CHAREST A, DREW R A L, BROCHUA M. Synthesis and consolidation via spark plasma sintering of nanostructured Al-5356/B4C composite [J]. Materials Science and Engineering A, 2011, 528: 4395-4407.

[14] WU Chuan-dong, FANG Pan, LUO Guo-qiang, CHEN Fei, SHEN Qiang, ZHANG Lian-meng, LAVERNIA J. Effect of plasma activated sintering parameters on microstructure and mechanical properties of Al-7075/B4C composites [J]. Journal of Alloys and Compounds, 2014, 615: 276-282.

[15] YAZDANI Z, TOROGHINEJAD M R, EDRIS H, NGAN A H W. A novel method for the fabrication of Al-matrix nanocomposites reinforced by mono-dispersed TiAl3, intermetallic via a three-step process of cold-roll bonding, heat-treatment and accumulative roll bonding [J]. Journal of Alloys and Compounds, 2018, 747: 217-226.

[16] CASATI R, FIOCCHI J, FABRIZI A, LECIS N, BONOLLO F, VEDANI M. Effect of ball milling on the aging response of Al2618 composites reinforced with SiC and oxide nanoparticles [J]. Journal of Alloys and Compounds, 2017, 693: 909-920.

[17] MIRJAVADI S S, ALIPOUR M, HAMOUDA A M S, KORD S, GKOPPADE P, ABUZIN Y A, KESHAVAMURTHY R. Effect of hot extrusion and T6 heat treatment on microstructure and mechanical properties of Al-10Zn-3.5Mg-2.5Cu nanocomposite reinforced with graphene nanoplatelets [J]. Journal of Manufacturing Processes, 2018, 36: 264-271.

[18] ZHANG Wen-cong, WANG Meng-meng, CHEN Wen-zhen, FENG Yang-ju, YU Yang. Evolution of inhomogeneous reinforced structure in TiBw/Ti-6AL-4V composite prepared by pre-sintering and canned β extrusion [J]. Materials & Design, 2015, 88: 471-477.

[19] ALIHOSSEINI H, DEHGHANI K, KAMALI J. Microstructure characterization, mechanical properties, compressibility and sintering behavior of Al-B4C nanocomposite powders [J]. Advanced Powder Technology, 2017, 28(9): 2126-2134.

[20] SHRIVASTAVA V, GUPTA G K, SINGH I B. Heat treatment effect on the microstructure and corrosion behavior of Al-6061 alloy with influence of a-nanoalumina reinforcement in 3.5% NaCl solution [J]. Journal of Alloys and Compounds, 2019, 775: 628-638.

[21] CHEN Hong-sheng, WANG Wen-xian, NIE Hui-hui, ZHOU Jun, LI Yu-li, ZHANG Peng. Microstructure and mechanical properties of B4C/6061Al laminar composites fabricated by power metallurgy[J].Vacuum, 2017, 143: 363-370.

[22] ZHANG Wen-cong, WANG Meng-meng, CHEN Wen-zhen. Preparation of TiBw/Ti-6Al-4V composite with an inhomogeneous reinforced structure by a canned hot extrusion process [J]. Journal of Alloys and Compounds, 2016, 669: 79-90.

[23] ZHU Ru-fei, JIANG Yan-bin, GUAN Lei, LI Huai-lin, TANG Guo-yi. Difference in recrystallization between electropulsing-treated and furnace-treated NiTi alloy [J]. Journal of Alloys and Compounds, 2016, 658: 548-554.

[24] CHEN Hong-sheng, WANG Wen-xian, NIE Hui-hui, ZHOU Jun, LI Yu-li, LIU Rui-feng, ZHANG Yu-yang, ZHANG Peng, WU Qiao-chu. Microstructure evolution and mechanical properties of B4C/6061Al neutron absorber composite sheets fabricated by powder metallurgy [J]. Journal of Alloys and Compounds, 2018, 730: 342-351.

[25] AKBARI M K, BAHARVANDI H R, SHIRVANIMOGHADDAM K. Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites [J]. Materials and Design, 2015, 66: 150-161.

[26] ZHU Man, JIAN Zeng-yun, YANG Gen-cang, ZHOU Yao-he. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys [J]. Materials and Design, 2012, 36: 243-249.

[27] HU Jiao-yu, LIU Jun, WANG Chun-xia, TANG Xin. Effect of TiN-Coated Al Powders on the microstructure and mechanical properties of A356 Alloy [J]. Journal of Materials Engineering and Performance, 2017, 26: 51-60.

[28] SHRIVASTAVA V, DUBEY S, GUPTA G K, SINGH I B. Influence of alpha Nanoalumina reinforcement content on the microstructure, mechanical and corrosion properties of Al6061-Al2O3 Composite [J]. Journal of Materials Engineering and Performance, 2017, 26: 4424-4433.

[29] CHEN Hong-sheng, WANG Wen-xian, LI Yu-li, ZHANG Peng, NIE Hui-hui, WU Qiao-chu. The design, microstructure and tensile properties of B4C particulate reinforced 6061Al neutron absorber composites [J]. Journal of Alloys and Compounds, 2015, 632: 23-29.

[30] MAZAHERY A, ABDIZADEH H, BAHARVANDI H R. Development of high-performance A356/nano-Al2O3 composites [J]. Materials Science and Engineering: A, 2009, 518: 61-64.

[31] HABIBNEJAD-KORAYEM M, MAHMUDI R, POOLE W J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3, nano-particles [J]. Materials Science and Engineering A, 2009, 519: 198-203.

[32] EMBURY J D. Strengthening mechanisms in Al alloys-an overview of natural limits and engineering possibilities [J]. Materials Science Forum, 1996, 217-222: 57-70.

[33] SHEN Jiang-hua, YIN Wei-hua, WEI Qiu-ming, LIU Yu-long. Effect of ceramic nanoparticle reinforcements. The quasistatic and dynamic mechanical properties of magnesium-based metal matrix composites [J]. Journal of Materials Research, 2013, 28: 1835-1852.

(Edited by YANG Hua)

中文导读

微/纳双尺寸B4C颗粒增强铝基复合材料的粉末冶金合成及后续热处理

摘要:采用放电等离子烧结(SPS)、热挤压+轧制(HER)、粉末冶金工艺及后续T6热处理制备了微/纳双尺寸B4C颗粒增强铝基复合材料。研究了制备过程中复合材料的显微组织演变和力学性能。结果表明:B4C颗粒分布由SPS状态的网状分布转变为挤压轧制态的均匀分布,平均晶粒尺寸由烧结态的3.12 μm细化至挤压轧制态的1.56 μm。由于纳米B4C的钉扎作用,亚结构比例达到66.5%。T6热处理后,材料内部析出弥散分布的Mg2Si。微米B4C周围分布明显的动态再结晶晶粒,且晶粒尺寸远小于弥散分布Mg2Si的基体区域。由于T6热处理只能有效地消除第一内应力,因此轧制态和热处理态复合材料的应力分布相似。烧结态复合材料的维氏硬度、显微硬度和抗拉强度分别从HV 55.45、0.86 GPa和180 MPa提高到HV 77.51、1.08 GPa和310 MPa。T6热处理后,尽管内部存在着析出强化,但由于晶粒粗化,复合材料的析出强度分别为HV 70.82、0.85 GPa和230 MPa。

关键词:微/纳双尺寸;B4C/6061 Al复合材料;T6热处理

Foundation item: Projects(51775366, 51805358) supported by the National Natural Science Foundation of China; Project(20130321024) supported by the Key Science and Technology Program of Shanxi Province, China

Received date: 2020-10-09; Accepted date: 2020-12-21

Corresponding author: WANG Wen-xian, PhD, Professor; Tel: +86-351-6010076; E-mail: wangwenxian@tyut.edu.cn; ORCID: https://orcid.org/0000-0003-0688-767X