Microstructures and tensile properties of

hot-extruded composite Bi2O3-coated ABOw/Al composite

LI Zhi-jun(李志军), WANG Li-dong(王黎东), YUE Hong-yan(岳红彦), FEI Wei-dong(费维栋)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 28 July 2006; accepted 15 September 2006

Abstract: A pure aluminum matrix composite reinforced by Bi2O3-coated aluminum borate whisker was fabricated by a squeeze casting method. The mass ratio of Bi2O3 to whisker is 1?30. The interfacial reaction between Bi2O3 coating and aluminum takes place during casting process. Deformation behavior and formability of ABOw reinforced aluminum (ABOw/Al) composites with and without Bi2O3 coating were investigated by the extrusion deformation at 400 ℃. The results show that the steady-state extrusion load and the probability of whisker fracture of extruded ABOw/Al composite with Bi2O3 coating are lower than those of extruded ABOw/Al composite, and its surface quality is better than that of extruded ABOw/Al composite. Evaluation of the tensile properties shows that the extruded ABOw/Al composite with Bi2O3 coating have the ultimate tensile strength and yield strengths with 0.2% superior to those of ABOw/Al composite.

Key words: aluminum matrix composite; Al18B4O33 whisker; extrusion deformation; liquid bismuth

1 Introduction

In the past decades, aluminum matrix composites reinforced by aluminum borate (Al18B4O33, denoted ABO) whisker have emerged as an important class of high performance structural materials owing to their rather low cost, high specific strength and modulus [1-5].

Normally, when MMCs are applied on precise and complicated component, the hot plastic forming procedure has to be adopted due to their low plasticity and poor formability at room temperature. The hot extrusion, one of the hot forming methods, has been used as the most common secondary processing operation because of its excellent preferential axial alignment of discontinuous whiskers as well as its large compressive hydrostatic stress state [6-7]. But some critical disadvantages related to the hot extrusion of the whisker-reinforced MMCs, such as whisker fracture and surface crack, still exist, which greatly decreases the mechanical properties of the composites. Many attempts have been made including enhancing the extrusion ratio and extrusion temperature and so on [6-8]. But the disadvantage of the hot extrusion deformation has not been overcome completely yet. Recently, CHINO et al [9] researched that a small volume of liquid phase presented in materials could improve the formability during semi-solid deformation processing.

In this study, bismuth with low melting point was introduced at the whisker/matrix interface by the interfacial reaction between Bi2O3 coating of whisker and aluminum matrix in the composite. The effects of liquid Bi on the extrusion deformation behaviors of composites were investigated. The tensile properties of extruded ABOw reinforced aluminum matrix composites with and without Bi2O3 coating were presented and discussed.

2 Experimental

The materials used are pure aluminum and ABOw with a diameter of 0.5-1.5 μm and length of 20-50 μm. The volume fraction of ABOw in the composite was 20%. Bi2O3 was coated on the surface of whisker using a simple and cheap chemical method [10-11] and the mass ratio of Bi2O3 to whisker is 1:30. Bi2O3-coated aluminum borate whisker reinforced aluminum composite (denoted as ABOw/BO/Al) and aluminum borate whisker reinforced aluminum composite (ABOw/Al) were fabricated using squeeze casting method.

The extrusion billets with the shape of approxi- mately 19 mm in diameter and 25 mm in length were extruded at 400 ℃ with the extrusion ratio of 10?1. The graphite was selected as a lubricant. Prior to extrusion, the die was heated to the same temperature as the billets. The composites were extruded on a 30 t vertical extrusion press at a ram fixed speed of 15 mm/min.

The interface structure of ABOw/BO/Al composite was observed on a CM12 type transmission electronic microscope (TEM), and the specimens for TEM observation were thinned by ion milling. Tensile test was performed on an Instron 5590 tensile machine. The dimension of tensile specimen is shown in Fig.1.

Fig.1 Dimension of tensile specimen

3 Results and discussion

3.1 Interfacial reaction

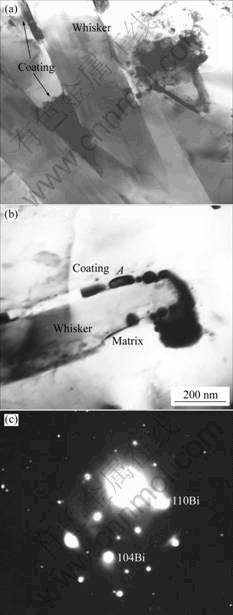

TEM images and selected area electron diffraction pattern (SADP) of the interface in the as-cast ABOw/BO/Al composite are represented in Fig.2, respectively. It is clear in Figs.2(a) and (b) that the black products on the interface may be Bi-rich phase due to larger atomic number of element bismuth, and are distributed clearly on the surface of whiskers and inter-whisker regions. Fig.2(c) shows the selected area electron diffraction pattern (SADP) corresponding to region “A”, and the black product is identified as Bi. Because the whisker coating is Bi2O3 after whisker preform has been sintered, the interfacial reaction between Bi2O3 coating and aluminum matrix is considered as Eqn(1) [12].

Bi2O3+2Al→2Bi+Al2O3 (1)

On the basis of above analysis, the interfacial reaction has taken place during the fabrication process of the composite.

3.1 Extrusion characteristics

The curves of extrusion load-ram displacement of ABOw/BO/Al and ABOw/Al composites extruded at 400 ℃ are presented in Fig.3. As shown in Fig.3, the extrusion process of composites may be divided into two steps: filling and compression step and steady-state extrusion step. The load required driving the extrusion rises rapidly to reach a peak as the extrusion starts to emerge, and the steady-state extrusion load of ABOw/BO/Al composite is 100 kN lower than that of ABOw/Al composite. Actually, it is bismuth metal not Bi2O3 that influences the extrusion load because Bi2O3 is deoxidized into bismuth metal during squeeze casting process.

Fig.2 TEM photographs of as-cast ABOw/BO/Al composite: (a), (b) images; (c) SADP corresponding to region “A” in Fig.(b)

Fig.3 Relationships between extrusion load and ram displacement at 400℃

Fig.4 shows the morphology of specimens extruded at 400 ℃. It can be clearly observed that many fir-tree cracks appear on the surface of ABOw/Al specimen, which was generated during extrusion processing. However, quite different from ABOw/Al, no cracks can be found on the surface of ABOw/BO/Al specimens. This big difference in surface morphology indicates that liquid Bi existing at the interface plays an important role during extrusion deformation process, and improves the formability of ABOw/BO/Al composite.

Fig.5 shows the microstructures of the distribution of ABO whisker in the composites extruded at 400 ℃, and all SEM photographs of extruded composites were taken in the plane parallel to the extrusion direction. A preferred orientation of longitude direction of whiskers along the extrusion axis is observed for all extruded composites. It can be found clearly in Fig.6 that the average length of whisker of extruded ABOw/BO/Al composite is longer than that of the extruded ABOw/Al composite.

Fig.4 Surface morphologies of extruded composite rods extruded at 400 ℃

Fig.5 SEM photographs of composites extruded: (a) ABOw/BO/Al; (b) ABOw/Al

The length distributions of whisker of extruded composites are shown in Fig.6. It is noticeable the clearly smaller whisker length in the extruded ABOw/Al composite than that in ABO/BO/Al composite, the breakage of whisker during the extrusion of ABOw/Al composite is very serious. It is obvious that the presence of liquid Bi can decrease the probability of whisker breakage and effectively improve the length of whiskers for extruded ABOw/BO/Al composites.

Fig.6 Distribution histogram of whisker length of extruded composites: (a) ABOw/BO/Al; (b) ABOw/Al

It can be seen that the addition of Bi2O3 coating improves the formability of ABOw/Al composite during hot extruded deformation. The low melting point Bi (271.5 ℃) introduced at the whisker/matrix interface could hardly dissolve into aluminum matrix according to Al-Bi phase diagram [13]. When the hot deformation temperature is 400 ℃, the liquid Bi existing at the interface can serve to relax easily the stress concentration of the whisker/matrix interface, which decreases the load-transfer capability from matrix to ABO whisker, thus the reinforcement effect of ABO whisker becomes weak accordingly. On the other hand, liquid Bi can work well as lubricant for the sliding and rotation of whisker, which helps to finish the hot deformation of ABOw/BO/Al composites. So the extrusion load of ABOw/BO/Al composite decreases compared with ABO/Al composite and the length of ABO whisker increases correspondingly. Furthermore, liquid Bi, as self-lubricant, can decrease the wear resistance exerted on ABOw/BO/Al composite during extrusion processing and improve formability of extruded ABOw/BO/Al composite. Thus the surface quality of ABOw/BO/Al composite extruded at 400 ℃ is smooth and free cracks compared with ABOw/Al composite.

3.2Tensile properties

Fig.7 shows the ultimate tensile strength (UTS) and yield strength with 0.2% (YS) of extruded ABOw/BO/Al and ABO/Al composites. The results show that the tensile properties of extruded composites are influenced by Bi2O3 coating. UTS and YS of extruded ABOw/BO/Al composite are higher than those of extruded ABOw/Al composite. It is understood that the increase in tensile properties of extruded ABOw/BO/Al composite can be explained by the improvement of whisker length compared with extruded ABO/Al composite, because the increase in length of whisker enhances the load-transfer capability from matrix to whisker.

Fig.7 Tensile properties of extruded composites

4 Conclusions

1) Bi2O3 coating can react with aluminum during the squeeze casting process, which produces the low melting point bismuth.

2) Compared with ABOw/Al composite, the extruded load and probability of whisker fracture in ABOw/BO/Al composite are much lower during extrusion deformation, and its surface quality is better.

3) In addition, the tensile properties of extruded ABOw/BO/Al composite are superior to those of extruded ABOw/Al composite.

References

[1] SUGANUMA K, FUJITA T, SUZUKI N, NIIHARA K. Aluminum composites reinforced with a new aluminum borate whisker [J]. Journal of Materials Science Letters, 1990, 9: 633-635.

[2] BI G, RAO Q, XI F. Controlling the interface reaction in Al18B4O33w/AC8A composite by nitrided nano-coating [J]. Mater Lett, 2004, 58(5): 833-836.

[3] YAO L J, FUKUNNAGA H. TEM study on the interfacial reaction of Al18B4O33/Al composites [J]. Scripta Materialia, 1997, 36: 1267- 1271.

[4] LI G, FEI W D. Abnormal thermal expansion behavior of aluminum borate whisker reinforced aluminum composite containing Fe3O4 particles [J]. Materials Chemistry and Physics, 2006, 99: 34-38.

[5] YUE HY, FEI W D, WANG L D, LI Z J. An aluminum borate whisker-reinforced aluminum matrix composite with high plasticity [J]. Materials Science and Engineering, 2006, A 430: 260-265.

[6] STANDFORD-BEALE C A, CLYNE T W. Extrusion and high-temperature deformation of fibre reinforced aluminium [J]. Comp Sci Tech ,1989, 35(2): 121-157.

[7] ZHANG W L, CAI L C, PENG H X. Forming process of hot extruded SiCw/6061Al composites(Ⅰ)[J]. Trans Nonferrous Met Soc of China, 1998, 8(3): 432-436.

[8] KANG C G, KIM N H. Effect of die shape on the hot extrudability and mechanical properties of 6061 Al/Al2O3 composites [J]. Mater Proc Tech, 2000, 100(1): 53-62.

[9] CHINO Y, KOBATA M, MABUCHI M. An investigation of compressive deformation behaviour for AZ91 Mg alloy containing a small volume of liquid [J]. Acta Materialia, 2003, 51: 3309-3318.

[10] FEI W D, LI Y B. Effect of NiO coating of whisker on tensile strength of aluminum borate whisker-reinforced aluminum composite [J]. Mater Sci Eng, 2004, A379(1-2): 27-32.

[11] FEI W D, LI Z J, LI Y B. Effects of T4 treatment on hot rolling behavior and tensile strength of aluminum matrix composite reinforced by aluminum borate whisker with NiO coating [J]. Materials Chemistry and Physics, 2006, 97: 402-409.

[12] LI Z J, FEI W D, WANG L D. Hot compressive deformation behavior of aluminum matrix composite reinforced by Al18B4O33 whisker coated with Bi2O3 [J].Materials Science and Engineering, 2006, A432: 275-280.

[13] MONDOLFO L F. Aluminum Alloy: Structure and Properties[M]. Butter Worths London-Boston Press, 1976: 234.

(CHEN Ai-hua)

Foundation item: Projects supported by the Reward of the Outstanding Young Teacher’s Teaching Scientific Research of Institution of Higher Education

Corresponding author: LI Zhi-jun; Tel: +86-451-86414392; E-mail: lizhijun@hit.edu.cn