文章编号:1004-0609(2010)S1-s0463-05

Ti43.5Ni47.0Nb9.0Zr0.5合金的相变和记忆功能

王 健,张慧博,金 伟,刘羽寅

(中国科学院 金属研究所,沈阳 110016)

摘 要:通过示差扫描量热仪、扫描电镜和电子试验机研究Ti43.5Ni47.0Nb9.0Zr0.5丝的相变、显微组织和记忆功能。结果表明:热拉态Ti43.5Ni47.0Nb9.0Zr0.5丝在室温至170 ℃的温度范围内观察不到相变发生,在750 ℃退火时,Ms点和As点分别为-107 ℃和-12 ℃;随着变形量的增加,逆马氏体相变温度大幅度升高,相变热滞变宽;当变形量为13%时,恢复应力达到最大值,为682 MPa,此时恢复应变为6.3%;恢复应力松弛曲线显示Ti43.5Ni47.0Nb9.0Zr0.5丝达到最大恢复应力后随温度的降低,恢复应力下降,在-20~-30 ℃范围内,恢复应力降至300 MPa以下。

关键词:Ti43.5Ni47.0Nb9.0Zr0.5合金;热拉;相变;记忆功能

中图分类号:TF 804.3 文献标志码:A

Phase transformation and memory function of Ti43.5Ni47.0Nb9.0Zr0.5 alloy

WANG Jian, ZHANG Hui-bo, JIN Wei, LIU Yu-yin

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The phase transformation, microstructure and memory function of Ti43.5Ni47.0Nb9.0Zr0.5 wire were studied by differential scanning calorimetry, scanning electronic microscopy and electronic tensile machine. The results show that phase transformation of hot-drawn Ti43.5Ni47.0Nb9.0Zr0.5 does not appear between room temperature and -170 ℃. After annealing at 750 ℃, Ms is -107 ℃, and As is -12 ℃. The reverse transformation temperature increases quickly and transformation hysteresis becomes wide with increasing deformation. The recovery stress reaches the maximum value of about 682 MPa with deformation of 13%, and the recovery strain is 6.3%. The curve of recovery stress relaxation indicates that the recovery stress begins to drop with decreasing temperature after the maximum recovery stress appear, the recovery stress is lower than 300 MPa between -20 ℃ and -30 ℃.

Key words: Ti43.5Ni47.0Nb9.0Zr0.5 alloy; hot-drawing; phase transformation; memory function

TiNiNb合金是在TiNi合金基础上发展起来的宽热滞形状记忆合金[1-4]。与TiNi合金相比,TiNiNb合金的相变温度滞后明显加宽[5-8],其中以Ti44Ni47Nb9合金的热滞变宽最为显著。Ti44Ni47Nb9合金因其良好的形状记忆效应和力学性能成为良好的管接头材料而备受关注。在TiNiNb合金中添加微量的Zr有助于改善合金的强度,这是因为Zr与Ti在化学周期表中处于同一族,在合金中可以占据Ti位。为了进一步提高Ti44Ni47Nb9合金的性能,本文作者研究在Ti44Ni47Nb9合金中添加微量Zr后合金的相变和记忆功能的变化。

1 实验

以Ti44Ni47Nb9合金为母合金,以0.5%(摩尔分数)Zr代Ti,采用真空感应熔炼,锭型为10 kg,铸锭经锻造、热轧、热拉成d1.7 mm的丝材,用线切割切取试样进行差热、显微组织、拉伸和记忆功能测试,试样的热处理制度为750 ℃,25 min,AC。将差热试验样品磨去氧化层。通过PekinElmer Pyis Dyiamond示差扫描量热仪测定热拉态和热处理后样品的相变过程。升、降温速率为20 ℃/min,用切线法在DSC曲线上确定相变温度。显微组织试样经镶嵌、研磨、抛光和腐蚀,在SHIMADZU SSX-550 型扫描电镜下观察其显微组织。在电子试验机上测定试样在不同温度下的拉伸性能,记忆功能的测量方法是将试样降温至-50 ℃,分别施以7%、10%、13%和17%的预变形,卸载后升温测定恢复应变和恢复力。

2 结果与讨论

2.1 退火温度对DSC曲线的影响

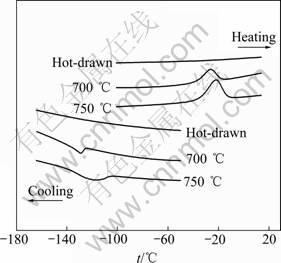

图1所示为热拉态和经700 ℃、750 ℃处理后Ti43.5Ni47.0Nb9.0Zr0.5丝的DSC曲线。

图1 退火温度对Ti43.5Ni47.0Nb9.0Zr0.5热拉丝DSC曲线的影响

Fig.1 Effects of annealing temperature on DSC curves of Ti43.5Ni47.0Nb9.0Zr0.5 wire

由图1可知,热拉态的Ti43.5Ni47.0Nb9.0Zr0.5丝在冷却和加热过程中没有发生相变,经700 ℃处理后,形变缺陷密度降低,应力场对相变的抑制作用逐渐减小,相变出现。冷却时,Ms点出现在-125 ℃,马氏体相变峰很小;加热时,逆马氏体相变开始温度为-17 ℃;热处理温度升至750 ℃,冷却和加热时相变峰变得很明显,并向高温方向移动,Ms点升高了近20 ℃,为-107 ℃。

2.2 热拉对显微组织的影响

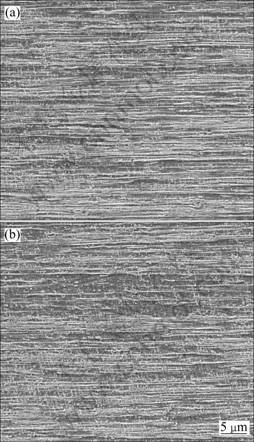

图2所示为 Ti43.5Ni47.0Nb9.0Zr0.5合金丝沿轴线方向的显微组织。由图2可知,热拉态和经750 ℃处理后的合金丝沿轴向方向均可以观察到明显的加工流线,只是后者的加工流线密度较小, 750 ℃处理可以在一定程度上消除热加工对合金内部组织形态的影响,降低形变缺陷。

图2 Ti43.5Ni47.0Nb9.0Zr0.5热拉丝平行轴向的显微组织

Fig.2 Microstructures of Ti43.5Ni47.0Nb9.0Zr0.5 wire parallel to axis: (a) Hot-drawing; (b) 750 ℃, 25 min, AC

2.3 变形温度对拉伸性能的影响

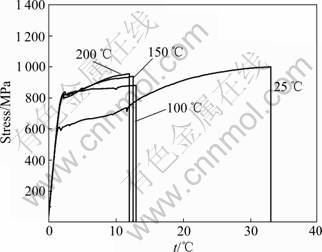

图3所示为Ti43.5Ni47.0Nb9.0Zr0.5丝经750 ℃处理后在不同温度下的拉伸曲线。由图3可以看出,Ti43.5Ni47.0Nb9.0Zr0.5丝的拉伸性能随拉伸温度的变化呈明显区别。室温拉伸时,屈服强度σ0.2为603 MPa,伸长率δ为32.8%;而变形温度在100~200 ℃之间时,合金丝的塑性迅速恶化,强度明显提高;100 ℃时,伸长率降至13%,同时屈服强度σ0.2超过800 MPa,继续升高变形温度至150和200 ℃后,屈服强度变化不大,伸长率略有下降。

Ti43.5Ni47.0Nb9.0Zr0.5丝室温下拉伸,屈服时产生应力诱发马氏体相变,同时伴有富Nb相的塑性变 形,此时的强度较低。变形温度超过100 ℃后,合金在母相弹性变形结束后直接产生塑性变形然后断裂。由于母相的屈服强度远高于应力诱发马氏体相变的临界应力[9-11],所以屈服点明显高于室温的。同时,由于缺少应力诱发马氏体相变产生的延伸塑性,导致伸长率大幅下降,低于15%。

图3 Ti43.5Ni47.0Nb9.0Zr0.5丝不同温度下的拉伸性能

Fig.3 Tensile properties of Ti43.5Ni47.0Nb9.0Zr0.5 wire at different temperatures

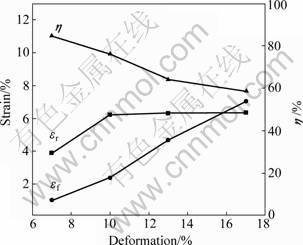

图4所示为升温测得的变形量与恢复应变和形状恢复率的关系。由图4可看出,变形量在7%至17%之间变化时,随着变形量的增加可恢复应变量不断提高,但变化过程分为两个阶段,变形量不超过10%时,增加变形量使可恢复应变量迅速上升;当变形量为7%时,εr为3.9%;当变形量增至10%时,εr为6.2%。由此可看出,变形量变化3%,可恢复应变量提高了2.%,在这个区间内变形,合金丝处于马氏体再取向和弹性变形初始阶段, 此时的变形量的增加主要由由母相的弹性变形和马氏体相马氏体再取向和弹性变形提供,卸载后,升温已经转变的马氏体相很容易重新转变为母相,因而可恢复应变量迅速提高。形状回复率也保持在很高的水平上,超过了75%。变形量由10%升至7%的过程中,可恢复应变量的增加变得非常缓慢,变形量增加了7%,可恢复应变量只提高了不到0.2%。而残余变形却以近似线性的方式大幅度增加,在17%的变形处,残余变形为7.1%,已经明显高于可恢复应变量(6.4%),导致形状恢复率迅速降低。这主要是因为随着变形超过13%,再取向马氏体相弹性变形结束,从而进入塑性变形阶段,因塑性变形引入的位错和滑移等缺陷会使升温时逆马氏体相变过程受到阻碍,可恢复应变的增加量迅速降低,形状恢复率也随之降低。

图4 变形量对Ti43.5Ni47.0Nb9.0Zr0.5丝εr, εf和η影响

Fig.4 Effects of deformation on εr, εf and η of Ti43.5Ni47.0Nb9.0Zr0.5 wire

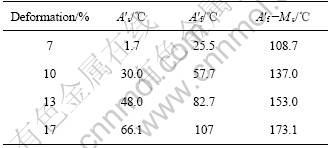

表1所列为变形量不断增大后逆相变温度A′s和A′f以及热滞(A′f -M s)的变化。

表1 不同变形量下Ti43.5Ni47.0Nb9.0Zr0.5丝的逆相变温度

Table 1 Reverse transformation temperature of Ti43.5Ni47.0- Nb9.0Zr0.5 wire after different deformations

随着变形量上升,A′s和A′f点向高温区间移动的同时相变热滞得到大幅度提高;变形量为7%时,A′s为1.7 ℃,继续加大变形量至10%后,A′s提高到30 ℃;变形量为17%时,A′s点达到66 ℃,相变热滞超过170 ℃。由此判断,要想使Ti43.5Ni47.0Nb9.0Zr0.5热拉丝变形后避免在室温发生形状恢复,其变形量应当超过10%。Ti43.5Ni47.0Nb9.0Zr0.5合金丝变形量的增加导致逆相变温度升高的原因可以用Ti44Ni47Nb9合金的宽热滞效应理论来解释[8-9],Ti43.5Ni47.0Nb9.0Zr0.5合金内存在富Nb相和基体相,富Nb相属于软相,在应力诱发马氏体相变过程中,当变形量达到一定程度时,富Nb相产生塑性变形会弛豫马氏体相变的弹性应变能[12-15],使马氏体稳定化,从而提高了逆马氏体相变温度。

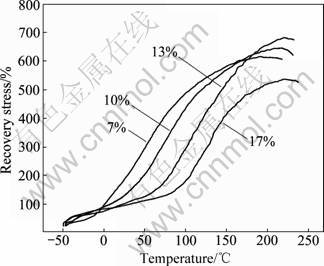

2.4 变形量对恢复应力的影响

图5所示为不同变形量下Ti43.5Ni47.0Nb9.0Zr0.5热拉丝恢复应力—温度曲线。由图5可知,增大变形量恢复应力随之上升,变形量增至13%时,恢复应力达到最大值,为682 MPa;继续增大变形量,恢复应力迅速下降,当变形量达到17%后,恢复应力降至535 MPa,降低近150 MPa。当变形量低于13%时,合金丝发生马氏体相再取向和再取向马氏体的弹性变形,增大的变形量主要由基体相转变的马氏体再取向和弹性变形提供,升温时,逆转变的马氏体量增加,恢复应力不断升高;当变形量超过13%后,已经转变的马氏体相开始出现塑性变形,回复能力减弱,同时由于富Nb相塑性变形的弛豫,导致升温时逆转变的马氏体量减小,恢复应力降低。

图5 不同变形量下Ti43.5Ni47.0Nb9.0Zr0.5丝恢复应力—温度曲线

Fig.5 Recovery stress—Temperature curves of Ti43.5Ni47.0- Nb9.0Zr0.5 wire at different deformations

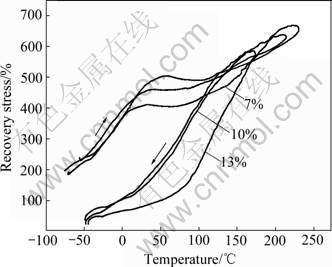

2.5 恢复应力的松弛行为

利用形状记忆合金在形状恢复时,位移受到约束条件产生恢复应力的特性可以制作紧固或连接件,而紧固或连接的可靠性取决于其产生的最大恢复应力。温度变化时,将导致恢复应力发生变化,出现应力松弛,严重时被紧固或连接件因应力松弛而拉脱失效。目前,有关高温应力松弛行为报道的较多,低温条件下的应力松弛行为报道很少。因此,有必要了解合金产生最大恢复应力后,温度降低时恢复应力的变化过程。

图6所示为在约束条件下升温、冷却过程中不同变形量时Ti43.5Ni47.0Nb9.0Zr0.5丝的恢复应力随温度的变化曲线。由图6可看出,达到最大恢复应力后,恢复应力在降温时的变化过程分为两个阶段。第一阶段,恢复应力随温度的下降逐渐降低,温度降至室温附近时,曲线出现拐点,拐点以下温度继续降低直至Ms点附近时,恢复应力迅速下降,在-20~-30 ℃范围内,恢复应力降至300 MPa以下失去紧固连接的可靠性。

图6 不同变形量下Ti43.5Ni47.0Nb9.0Zr0.5丝低温恢复应力松弛曲线

Fig.6 Recovery stress relaxation curves at low temperature of Ti43.5Ni47.0Nb9.0Zr0.5 wire at different deformations

3 结论

1) 热拉态Ti43.5Ni47.0Nb9.0Zr0.5丝在室温至170 ℃的温度范围内观察不到相变发生,经750 ℃退火时,Ms点为-107 ℃。

2) 恢复应力随着变形量的增大而上升,变形量为13%时,恢复应力达到最大值,为682 MPa;此时恢复应变为6.3%,继续增大变形量,恢复应力迅速下降。

3) Ti43.5Ni47.0Nb9.0Zr0.5热拉丝达到最大恢复应力后,随温度降低恢复应力下降,在-20~-30 ℃范围内,恢复应力降至300 MPa以下。

REFERENCES

[1] GRENIGER A B, MOORADIAN V G. Phase transformation in alloy system[J]. Trans AIME, 1983, 128: 337-341.

[2] CHANG L C, READ T A. Plastic deformation and diffusionless phase changes in metals-the gold-cadmium beta phase[J]. Trans AIME, 1951, 189: 47-52.

[3] BUEHLER M J, GILFRICH J V, WELLERY K G. Effect of low-temperature phase change on the mechanical properties of alloys near composition TiNi[J]. J Appl Phys, 1963, 34: 1475-1477.

[4] MELTON K N, SIMPSON J, DUERIG T W. ICOMT 1986, Jap Inst Metals, 1986, 1053:

[5] MYAZAKI S, OTSUKA K. Stress-induced martensite in a NiTiNb shape memory alloy[J]. INIJ International, 1989, 29: 353-356.

[6] ZHAO L C. Study of Ti-Ni-Nb shape memory alloys with a wide hysteresis[J]. Materials Science Forum, 2000, 327/328: 23-30.

[7] 舟久保, 熙 康. 形状记忆合金[M]. 北京: 机械工业出版社, 1992.

ZHOU Jiu-bao, XI Kang. Shape memory alloy[M]. Beijing: China Machine Press, 1992.

[8] DUERIG T W, MELTON K, PROFT J L. Wide hysteresis shape memory alloys[M]. London: Tterworth-Heinemann Press, 1990: 130-136.

[9] 赵连成, 蔡 伟, 郑玉峰. 合金的超弹性和形状记忆效应[M]. 北京: 国防工业出版社, 2002.

ZHAO Lian-cheng, CAI Wei, ZHENG Yu-feng. Shape memory alloy and superelasticity[M]. Beijing: National Defense Industry Press, 2002.

[10] ZHANG L C, ZHAO L C, DUERIG T W, WAYMAN C M. Effect of deformation on the transformation hysteresis and shape memory effect in a Ni47Ti44Nb9 alloy[J]. Scr Metall Mater, 1990, 24: 1807-1812.

[11] 蔡 伟, 张春生, 赵连城. 热变形对Ni-Ti-Nb宽滞后记忆合金显微组织和力学性能的影响[J]. 中国有色金属学报, 1994, 14(4): 69-72.

CAI Wei, ZHANG Chun-sheng, ZHAO Lian-cheng. Effects of hot deformation on microstructure and mechanic properties of wide hysteresis Ni-Ti-Nb alloy[J]. The Chinese Journal of Nonferrous Metals, 1994, 14(4): 69-72.

[12] PIAO M, MIYAZAKI S, OTSUKA K. Characteristics of deformation and transformation in Ti44Ni47Nb9 shape memory alloys[J]. Materials Transactions JIM, 1992, 33(4): 346-357.

[13] MYAZAKI S, OTSUKA K. Development of shape memory alloy[J]. ISIJ International, 1989, 29: 353-377.

[14] ZHANG C S, ZHAO L C, DUERIG T W, WAYMAN C M. Effect of deformation on the transformation hysteresis and shape memory effect in aNi47Ti44Nb9 alloy[J]. Scr Metall Mater, 1990, 24(4): 1807-1812.

[15] ZHAO L C, DUERIG T W, JUSTI S, MELON K K, et al. The study of niobium-rich precipitates in a Ni-Ti-Nb shape memory alloy[J]. Scr Metall Mater, 1990, 24: 221-225.

(编辑 龙怀中)

通信作者:王 健;电话:024-23971956;E-mail: jianwen6@imr.ac.cn