Viscoelasto-plastic properties of deep hard rocks under water environment

CAO Ping, WAN Lin-hui, WANG Yi-xian, HUANG Yong-heng, ZHANG Xiang-yang

School of Resources and Safety Engineering, Central South University, Changsha 410083, China

Received 10 March 2011; accepted 24 September 2011

Abstract: Using a circular incremental step load and unload method, a set of rheological experiments were performed to study the viscoelasto-plastic properties of amphibolite in Jinchuan No.2 diggings under different environments. Based on the scientific analysis on rheological experimental data, the viscoelasto-plastic properties of amphibolite under different environments were studied. The results show that the instantaneous elastic modulus and viscoplastic properties of amphibolite are affected little, the viscoelastic properties of amphibolite are significantly affected. Based on the experimental results and characteristics of recovered rock specimen, a generalized Kelvin model was chosen to simulate rheological properties of amphibolites and key parameters were obtained. It is found that the creep deformation modulus E1 is significantly influenced by the water, while the instant elastic modulus E2 is not significantly affected. The discreteness of the viscosity coefficient η is large, the influence of water on η is not clear and needs to be further studied.

Key words: water; viscoelasto-plastic property; circular incremental step load and unload; generalized Kelvin model

1 Introduction

It is well known that rocks possess viscoelasto- plastic properties and exhibit time-dependent behavior during deformation, engineering practice shows that the long-term stability of rock engineering is closely related to the rheological deformation characteristics of rocks [1-4]. In practical engineering, many rock engineers are immersed in water, such as the dam and underground engineering in groundwater. Water has a significant influence on the long-term stability of rock engineering, the failure of support usually appears on the site with large moisture content or in water [5]. In order to ensure the long-term stability of rock engineering in water environment, it is necessary to study the rheological characteristics of rocks in water environment.

At present, the maximum mining depth of Jinchuan mining area is about 1 000 m. According to the stress measurement in-situ and the geological survey, the maximum in-situ stress is up to 30-40 MPa and all rocks are immersed in groundwater or water of construction [6]. The deep tunnel engineering was destroyed seriously and the failure characteristics were time-dependent [7]. The tunnel cross section shrank continuously with time until the support was destroyed. A lot of human and material resources had been devoted to maintaining tunneling support, and the stability of the deep tunnel seriously affects safe production and economic benefit of Jinchuan mining area. To improve the long-term stability of the deep tunnel, it is necessary to study mechanical characteristics of rocks at depth. CAO et al [6-9] have studied the influence of water on fracture mechanics characteristics of deep rocks in the Jinchuan mining area.

Highly porous tuff and rock whose porosity has increased as a result of weathering have different strengths in air-dried (dry) conditions compared with water-saturated (wet) conditions [10]. Some researchers have researched the rheological characteristics of water-saturated rocks. BOUVARD and STUTZ [11], YANG et al [12] have researched triaxial rheological deformation and failure mechanism of hard rock. LI et al [13] and OKUBO [10] have studied and compared rheological properties of granite in air-dried and saturated states, and they found that the long-term strength of water-saturated granite decreased significantly and the rheological rate and deformation increased obviously. XIE and SHAO[14], ZHU and YE [15] have studied mechanical properties of rock creep in saturation and discussed the effect of water on instantaneous elastic modulus, limit creep deformation modulus and viscosity coefficient. ZHOU and CHENG [16] have studied the influence of water content on creep characteristics of xylonite and studied the failure characteristics of F1 faulty clay in Jinchuan open-pit. At present, these studies were on saturated rocks, not on rocks in water environment. Only OKUBO [3] studied the long-term creep characteristics of tuff under the water environment and YAN et al [17] have studied seepage-rheology coupling of rocks by self-developed experimental equipment. As rocks under the water environment are closer than saturated rocks to engineering practice, the results of studying rocks under the water environment should be more practical significance. In this work, by a circular increment step load and unload method, the author studied rheological characteristics of deep rocks in Jinchuan No.2 diggings with RYL-600 rock-shear- rheometer and analyzed differences of instantaneous deformation and creep characteristics of air-dried and water-saturated rock specimen. The results can provide references for designing and monitoring the deep rock engineering practices in Jinchuan No.2 diggings.

2 Experimental

2.1 Rock specimens

The rock specimens are fabricated from amphibolite blocks, quarried from 850-978 m horizontal section ramp in Jinchuan No.2 diggings. Amphibolite is a weakly weathered brittle rock with good integrity and high uniaxial compressive strength. The dimension of the rock sample and its mechanical properties are listed in Table 1.

2.2 Experimental apparatus

The experiments were conducted in the rock shear-rheological laboratory of Central South University, China. The computer-controlled rock shear-rheometer RYL-600 was used for this test which was produced by Rising Sun Testing Instruments company. This apparatus was controlled by electro-hydraulic servo. It features simple operations highly controlled precision, accurate measurements, excellent durability and high reliability. The precision of force and displacement measurement and the fluctuation range of long time controlling was within ±0.5%.

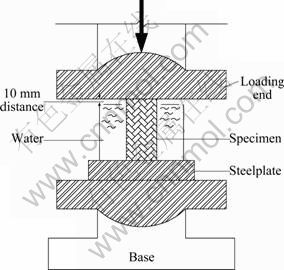

The loading equipment is shown in Fig. 1. In order to ensure rock specimens in water environment, we added a container with a stiffness bearer between loading equipments. According to the results of multiple tests, we found the specimens would be failed when the loading displacement reached 7-8 mm. Therefore, 10 mm in distance was kept between the upper of container and loading end to guarantee enough loading displacement.

Fig. 1 Experimental device for rheological experiment in water environment

2.3 Experimental process

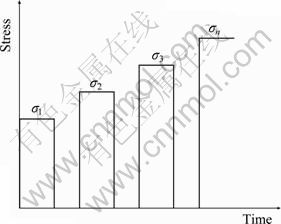

In order to accurately analyze the viscoelasto-plastic properties of rock specimens, a circular increment step load and unload method (see Fig. 2) was used for all tests. This method can reflect the deformation features of rock specimens during loading and unloading [18]. Test results of rocks creep can be decomposed to instantaneous deformation and viscoelasto-plastic deformation. Then we can obtain all data of rock specimens about instantaneous elasticity, instantaneous plasticity, viscoplasticity and viscoelasticity. We also can apply an appropriate rheological model and identify the parameter of rheological model.

We determined load increment of step load according to experimental process. The initial increment of load was 5.09 MPa. The load increment decreased when the stress was close to compressive strength of rocks. The initial loading rate and the unloading rate were 300 and 1 000 N/s respectively. The duration of the loading steps are determined with the strain rate of specimen. As the axial deformation of specimen was less than 0.001 mm within 24 h, the deformation of specimen was assumed to be stable. When there is no lagging recovery within 24 h, the next loading circulation would be started until the failure of the specimen. The loading and unloading curves of specimens are shown in Fig. 3.

Table 1 Test specimen size and mechanical properties

Fig. 2 Circular incremental step load and unload

Fig. 3 Loading and unloading creep test curves of amphibolites: (a) Water-saturated specimen; (b) Air-dried specimen

3 Data processing and analysis

3.1 Test data processing

The loading and unloading creep test curves of specimens (Fig. 3) show the features of elasticity, viscosity and plasticity. The total deformation should consist of instantaneous elastic deformation, viscoelastic deformation, instantaneous plastic deformation and viscoplastic deformation. Correspondingly, the total strain ε should consist of recoverable instantaneous elastic strain εie, viscoelastic strain εve, unrecoverable instantaneous plastic strain εip, and viscoplastic strain εvp. The total strain ε can be written as

(1)

(1)

In the loading process, the instantaneous strain under the nth level stress σn is composed of two parts:

(2)

(2)

where εie is the instantaneous elastic strain under the nth level stress σn;  is instantaneous plastic strain increment under the nth level stress increment Δσn. The instantaneous elastic strain can be recovered immediately after the unloading, and thus its value is equal to instantaneous recoverable strain.

is instantaneous plastic strain increment under the nth level stress increment Δσn. The instantaneous elastic strain can be recovered immediately after the unloading, and thus its value is equal to instantaneous recoverable strain.

The creep strain  under the nth level stress σn is given by

under the nth level stress σn is given by

(3)

(3)

where  is the viscoelastic strain under the nth level stress σn;

is the viscoelastic strain under the nth level stress σn;  is the viscoplastic strain increment under the nth step stress increment Δσn. The viscoelastic strain will be completely recoverable with time, so the unloading curve and creep curve are assumed to be symmetrical. Then we found that the value of viscoelastic strain was equal to the value of lagging recovery after the unloading.

is the viscoplastic strain increment under the nth step stress increment Δσn. The viscoelastic strain will be completely recoverable with time, so the unloading curve and creep curve are assumed to be symmetrical. Then we found that the value of viscoelastic strain was equal to the value of lagging recovery after the unloading.

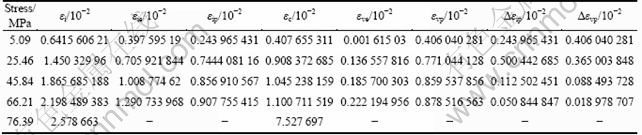

Then we obtained the measured viscoelasto-plastic value of specimens, as shown in Table 2 and Table 3.

3.2 Experimental results and deformation form of specimen

The experimental results showed that the stress (76.39 MPa) of air-dried failure specimen was lower than the stress (106.95 MPa) of water-saturated specimen. This is probably due to the inhomogeneity of rock specimens. The examination of the recovered failure specimens exhibits that the air-dried specimen has more development joints and the dominant failure mechanism is shearing; while the water-saturated specimen has less joints but more micro-fissures.

The results of tests showed that the stress of the air-dried failure specimen was 76.39 MPa, 0.576 times uniaxial compressive strength; the failure stress of the water-saturated specimen was 106.95 MPa and 0.865 times saturated uniaxial compressive strength. This shows that the strength of amphibolites decreases significantly under long-term load. We should not ignore it in practical engineering.

Table 2 Testing results of visco-elastic-plastic strain of water-saturated specimen

Table 3 Testing results of visco-elastic-plastic strain of air-dried specimen

At a low stress (5.09 MPa), the creep deformation of the water-saturated specimen was very small (only 0.011 mm) and the deformation could be almost recovered, which showed that the specimen was in elastic state under low stress level; the creep deformation of the air-dried specimen was 0.041 mm and 3.73 times that of the water-saturated specimen, and the residual deformation of the air-dried specimen was 0.006 5 mm and 4.33 times that of the air-dried specimen. The reasons were that the fissure and void of the water-saturated specimen were full of water and water could not drain under low stress, the void water thus can bear parts of the stress, which makes the water-saturated specimen more integrated in macro-level and shows stronger resistance against deformation.

At higher stress (25.46-66.21 MPa) level, the instantaneous deformation of the air-dried specimen was larger than that of the water-saturated specimen. The creep deformation of the water-saturated specimen was larger than that of the air-dried specimen, which showed that water could increase the creep deformation of amphibolites like as the deep tunnel deformation in Jinchuan No.2 diggings. The convergence deformation of the tunnel in water was larger within the same time range. Under the instant loading the void water could not timely diffuse and drain, and it was close to solid and had a very high compressive strength. However, the air-dried specimen had no characteristics as the water-saturated specimen. Therefore, the instantaneous deformation of the air-dried specimen was larger than that of a air-dried specimen. In the long term, the void water was drained gradually with time. The water corrosion mineral was carried away by the void water which made the space of the fissure and void larger. Under a higher stress, the water in the fissure and void diffused and the split effect of pressure water made the specimen generate some new fissures and increase the space of fissures. These fissures of the air-dried specimen were closed and the compression space became smaller. So, the creep deformation of the water-saturated specimen was larger under the same stress level.

As shown on creep curves in Fig. 3, after loading, specimens had instantaneous elastic response and then had growth creep deformation with time. Before failure of the sample, the rate of creep deformation decreased gradually under every levels of stress and tended to be stable at last. Under the failure stress, the rate of creep deformation increased and specimens damaged quickly. As shown in Fig. 4, the elapsed time of specimens from loading to failure was less than 0.8 h and the time of accelerating creep was very short, which showed the failure of amphibolites was brittle.

It can be seen from Fig. 3 that the time of the air-dried creep deformation specimen reaching stability increased with the increasing stress; the water-saturated specimen had no law, but its creep deformation reaching stability needed much longer time than the air-dried specimen at the same stress level. Specimens would have new damage and fissure with the increasing stress, then water permeated into the new fissure and corroded the peripheral minerals around fissure. The corrosion is a long and slow process. Besides, water in fissure and void is more difficultly compressed than air in fissure and void. These reasons determined that the creep deformation of the water-saturated specimen needed much longer time.

Fig. 4 Accelerating creep curves

4 Viscoelasto-plastic properties

4.1 Instantaneous deformation and elastic modulus

As shown in Fig. 5, Fig. 6, Table 2 and Table 3, specimens had linear relationship between step stress and instantaneous elastic strain and the slopes were 0.0146 (air-dried) and 0.008 (water-saturated) respectively. The instantaneous plastic strain of the two specimens increased with the increasing stress, but the instantaneous plastic strain increment decreased with the increasing stress. This showed that the fissure of specimens was compressed gradually and the resisting deformation ability of specimens increased gradually. The instantaneous plastic strain increment of the air-dried specimen decreased to 0.050844847×10-3 from 0.500442685×10-3 and reduced by about 90%. The instantaneous plastic strain increment of the water-saturated specimen decreased to 0.071215×10-3 from 0.2849674×10-3 and reduced by about 75%. This shows that water made the instantaneous plastic deformation decrease. The void water of water-saturated specimen cannot timely diffuse and drain under the instant loading, and water in fissures and voids is more difficultly compressed than in air, which delayed closing of fissure. As shown in Fig. 7, the stress—instantaneous elastic modulus curves of the specimens are similar to logarithmic curve. The formula (4) is used to fit curve and two fitting correlation coefficients are more than 0.90. This shows that water has little influence on instantaneous elastic modulus and the specimens have the trend of strain-hardening under circular increment step loading and unloading.

(4)

(4)

where Ei is instantaneous elastic modulus; σn is the nth level stress; a and b are constants.

Fig. 5 Relation curves of step stress and instantaneous strain: (a) Water-saturated specimen; (b) Air-dried specimen

Fig. 6 Strain increment under unit stress increment: (a) Water-saturated specimen; (b) Air-dried specimen

4.2 Creep deformation

The creep strain of specimens is very small under the first step stress (5.09 MPa), so the creep strain under the first step stress is not discussed. As shown in Fig. 8, Table 2 and Table 3, the creep strain includes viscoelastic and viscoplastic strain and its value increases with the increasing stress. Under every step stress, the creep strain of the air-dried specimen accounts for 33.4%-38.5% of the total strain and the creep strain of the water-saturated specimen accounts for 50.9%-61.6% of the total strain. This shows that water increases the creep strain of the specimen.

Fig. 7 Fitting curves of instantaneous elastic modulus with stress

Fig. 8 Relation curves of step stress and creep strain: (a) Water-saturated specimen; (b) Air-dried specimen

As shown in Fig. 8, the viscoelastic strain increases with the increasing stress. Under every step stress, the viscoelastic strain of the air-dried specimen accounts for 15%-20% of the total creep strain and that of the water-saturated specimen accounts for 32.7%-50.71% of the total creep strain. After stress increasing, the viscoplastic strain of the water-saturated specimen increases slowly and the increment tends to be stable; the viscoplastic strain of the air-dried specimen also increases, but the increment decreases with the increasing stress. As shown in Table 2 and Table 3, under three step stresses (25.46, 45.846, 66.216 MPa) the viscoplastic strains of two specimens are similar. Based on the above analysis, water increases the viscoelastic strain and has little influence on the viscoplastic strain.

5 Rheological model of rock and parameter identification

5.1 Rheological model of amphibolites

The results of testing (Fig. 3) show that under every step stress the creep strain values of two specimens tend to be stable before failure and water has little influence on the viscoplastic strain. Based on the above analysis, the influence of water on rheological characteristics of amphibolite the viscoplastic strain can be ignored. Therefore, we selected the generalized Kelvin model (see Fig. 9) to describe rheological characteristics of amphibolites.

Constitutive equation:

(5)

(5)

Creep equation:

(6)

(6)

Fig. 9 Generalized Kelvin model

Table 4 E1, E2, η of air-dried and water-saturated specimens under different stress levels

Unloading equation:

(7)

(7)

where ε is the strain of Kelvin model; E1 is the creep deformation modulus; E2 is the instant elastic modulus; η is the coefficient of viscosity; σ0 is the initial stress; ε0 is he initial strain when the Kelvin model is relaxing; t is time.

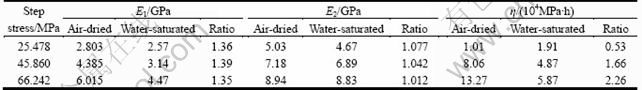

According to the results of specimens, the parameter of rheological model is identified by the curve fitting method [19]. The parameters are shown in Table 4.

5.2 Parameter comparison of rheological model

As shown in Table 4, the ratio of the parameter E2 of two kinds of samples is between 1.012 and 1.077, which shows that water has little influence on instantaneous elastic modulus and it is consistent with the results in Section 4.1. The parameter E1 of the generalized Kelvin model is to control the final creep strain amount of specimens. As shown in Table 4, the ratio of the parameter E1 of two kinds of samples is between 1.35 and 1.39, which shows that water has a large influence on E1. This means that water has a large influence on the final creep deformation amount of amphibolites and raises the aging characteristics of amphibolite, and it is consistent with the results in Section 4.2, showing that the generalized Kelvin model can simulate the experimental results of amphibolites. The viscosity coefficient η increases with the increasing stress, but there is no obvious variation law and the viscosity coefficients η of specimens are discrete. Because rocks not only have viscosity but also have elasticity of resisting external force deformation and the rheological characteristics of rocks are codetermined by viscosity and elasticity.

6 Conclusions

1) The results of rheological test with a uniaxial compression circular increment step load and unload method clearly show the viscoelastic-plastic law of rocks and can provide complete basic data for identifying parameters of the rheological model.

2) Water reduces the instantaneous deformation of amphibolites because water cannot timely drain and enhance resisting deformation ability of rocks. But water has little influence on the instantaneous elastic modulus.

3) Under every step stress, the creep strain of the air-dried specimen accounts for 33.4%-38.5% of the total strain and the creep strain of the water-saturated specimen accounts for 50.9%-61.6% of the total strain, which shows that water increases the creep deformation amount.

4) The influence of water on the creep deformation of amphibolites mainly embodies the influence on viscoelastic deformation and water has little influence on the viscoplastic deformation.

5) The generalized Kelvin model can simulate the rheological characteristics of amphibolites; water has a significant influence on the parameter E1 and has little influence on the parameter E2.

References

[1] BARLA G, WANE M T. Analysis of the borehole stress-relief method in rocks with rheological properties [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1968, 5: 187-193.

[2] KOHLSTEDT D L. Properties of rocks and minerals-constitutive equations, rheological behavior, and viscosity of rocks [C]// Treatise on Geophysics. Amsterdam: Elsevier, 2007: 389-417.

[3] OKUBO S, FUKUI K, HASHIBA K. Long-term creep of water-saturated tuff under uniaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 2010, 47: 839-844.

[4] ZHOU Yong-sheng, HE Chang-rong, HUANG Xiao-ge, SONG Juan, SANG Zu-nan, KONG Hu. Rheological complexity of mafic rocks and effect of mineral component on creep of rocks [J]. Earth Science Frontiers, 2009, 16: 76-87.

[5] LIPPONEN A, YANG Hui, JIANG Xue-liang, GHEN Yu, MA Chun-de. Effect of water and geological factors on the long-term stability of fracture zones in the P?ij?nne Tunnel, Finland: A case study [J]. International Journal of Rock Mechanics and Mining Sciences, 2005, 42: 3-12.

[6] CAO Ping, YANG Hui, JIANG Xue-liang, CHEN Yu, MA Chun-de. Subcritical crack growth of rock during water-rock interaction [J]. Journal of Central South University: Science and Technology, 2010, 41(2): 649-654. (in Chinese)

[7] WANG Yi-xian, CAO Ping, HUANG Yong-heng, WEN You-dao, WAN Lin-hui, LI Jiang-teng. Time-dependence of damage and fracture effect for strain softening of soft rock under water corrosion [J]. Journal of Sichuan University: Engineering Science Edition, 2010, 42(1): 55-62. (in Chinese)

[8] WAN Lin-hui, CAO Ping, HUANG Yong-heng, WANG Yi-xian. Study on subcritical crack growth of rocks and threshold values in different environments [J]. Rock and Soil Mechanics, 2010, 31(9): 2737-2742. (in Chinese)

[9] WANG Yi-xian, CAO Ping, CHEN Yu, WAN Lin-hui, HUANG Yong-heng, ZHAO Yan-lin. Testing study on damage and fracture mechanical effects for swelling soft rock during water corrosion [J]. Journal of Central South University: Science and Technology, 2011, 42(6): 1685-1691. (in Chinese)

[10] OKUBO S, FUKUI K, GAO X. Rheological behaviour and model for porous rocks under air-dried and water-saturated conditions [J]. The Open Civil Engineering Journal, 2008, 2: 88-98.

[11] BOUVARD D, STUTZ P G. Experimental study of rheological properties of a sand using a special triaxial apparatus [J]. Test Journal, 1986, 9: 10-18.

[12] YANG Sheng-qi, XU Wei-ya, XIE Shou-yi, SHAO Jian-fu. Studies on triaxial rheological deformation and failure mechanism of hard rock in saturated state [J]. Chinese Journal of Geotechnical Engineering, 2006, 28(8): 962-969. (in Chinese)

[13] LI You, ZHU Wei-shen, BAI Shi-wei, YANG Chun-he. Uniaxial experimental study on rheological properties of granite in air-dried and staturated states [J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(10): 1673-1677. (in Chinese)

[14] XIE S Y, SHAO J F. Elastoplastic deformation of a porous rock and water interaction [J]. International Journal of Plasticity, 2006, 22: 2195-2225.

[15] ZHU He-hua, YE Bin. Experimental study on mechanical properties of rock creep in saturation [J]. Chinese Journal of Rock Mechanics and Engineering, 2002, 21(12): 1791-1796. (in Chinese)

[16] ZHOU Rui-guang, CHENG Bin-fang. Failure character of fault clay at the slope in Jinchuan opencut under the actions of water and rock [J]. Engineering Reconnaissance, 1996, 23(3): 26-29. (in Chinese)

[17] YAN Yan, WANG En-zhi, WANG Si-jing, HU Yu. Study of seepage-rheology coupling experiment of rocks [J]. Rock and Soil Mechanics, 2010, 31(7): 2095-2103. (in Chinese)

[18] ZHAO Yan-lin, CAO Ping, CHEN Yuan-jiang, LI Jiang-teng, YUAN Hai-ping. Creep properties experiment and model of jointed soft rocks under step load and unload [J]. Journal of China Coal Society, 2008, 33(7): 748-753. (in Chinese)

[19] FENG Zhi-jun, ZHOU De-pei, ZHOU Ying-hua. Application of origin in rheologic experimental data processing of rock and soil material [J]. Road Bed Engineering, 2005, 123(6): 4-6. (in Chinese)

水环境下深部硬岩的黏弹塑性

曹 平, 万琳辉, 汪亦显, 黄永恒, 张向阳

中南大学 资源与安全工程学院,长沙 410083

摘 要:采用分级增量循环加卸载方式,对金川有色金属公司二矿区深部斜长角闪岩进行干燥与水环境下的流变实验,分析流变实验数据,研究各级应力水平下斜长角闪岩两种试样的黏弹塑性。结果表明:水对岩石的瞬时弹模及黏塑特性的影响不大,对岩石黏弹性影响显著。分析水对岩石黏弹塑性影响的原因。根据试样的实验破坏前特点,选用广义开尔文模型描述斜长角闪岩流变特性,求得两种试样的岩石流变模型参数。模型参数分析发现:水对参数E1影响明显,而对参数E2影响不大;黏滞系数的离散性大,水对其影响不明确。

关键词:水;黏弹塑性;分级加卸载;广义开尔文模型

(Edited by LI Xiang-qun)

Foundation item: Project (10972238) supported by the National Natural Science Foundation of China; Project (2009bsxt061) supported by the Thesis Innovation Funds for the Central South University, China; Project (2009) supported by Hunan Administration of Work Safety Fund, China

Corresponding author: WAN Lin-hui; Tel: +86-13787012284; E-mail: wlh9818@163.com

DOI: 10.1016/S1003-6326(11)61114-X