DOI: 10.11817/j.ysxb.1004.0609.2020-35906

电子束冷床炉熔炼TA15钛合金的工艺技术

杜 彬1, 2,张志斌1,雷云清1,钱光凝1, 2,孙宁宁1,王 倩1

(1. 青海聚能钛业股份有限公司 技术研发部,西宁 810007;

2. 青海省钛及钛合金工程技术研究中心,西宁 810007)

摘 要:在工业化条件下,利用电子束冷床熔炼炉(EB炉)一次熔炼制备TA15钛合金铸锭,对熔炼工艺参数与铸锭化学成分均匀性之间的关系进行分析,采用赫兹-克努森-朗缪尔定律对熔炼过程中Al、Zr元素的挥发规律做简要的数值分析,并与实际挥发规律进行比较分析。结果表明:在EB炉熔炼过程中,Al、Zr元素的挥发规律符合朗缪尔定律;其中,Al元素挥发严重,理论挥发率为18.69%,实际挥发率为15.33%;Zr元素挥发率相对较低,理论挥发率为2.80%,实际挥发率达到3.33%;Ti基体的理论挥发率为2.86%。EB炉熔炼功率、真空度及各工艺参数之间的匹配性是影响Al、Zr元素挥发的关键因素;通过合理的工艺参数制备的铸锭整体化学成分均匀性良好。

关键词:TA15钛合金;电子束冷床熔炼;Al元素挥发;成分均匀性

文章编号:1004-0609(2020)-11-2706-08 中图分类号:TG146.2 文献标志码:A

先进的飞机设计理念及高推重比航空发动机发展的需求,对航空发动机的寿命及可靠性提出了越来越高的要求。因此,高洁净度、高品质钛合金铸锭成为制备航空发动机用关键钛合金部件首要解决的问题。钛合金是最具代表性的高比强度合金之一,因其综合力学性能优异,因此得到了广泛应用[1-2]。在飞机上钛合金的应用水平是衡量飞机先进程度的重要标志之一,是影响飞机战斗性能的重要方面。一般来说,飞机用钛比例越高,其综合性能越高[3]。

TA15钛合金(Ti-6.5Al-2Zr-1Mo-1V)是一种综合性能优良的中强钛合金,室温强度较TC4(Ti-6Al-4V)钛合金高30~50 MPa,且焊接性能良好,具有与α型钛合金同样好的焊接性能和接近α+β型合金的工艺塑性,可在450~500℃温度范围长期使用。该合金具有中等的室温和高温强度,良好的热稳定性,抗蠕变性能,可用于生产棒材、薄板、锻件、厚板、型材、模锻件和线材等产品,在飞机的发动机以及机身结构中有着广泛应用[4-6]。

长期的应用及研究表明,真空自耗电弧熔炼(VAR)无法彻底去除钛合金中的高、低密度夹杂,熔炼过程中容易出现夹杂、偏析等冶金缺陷。国外优先选用冷床炉熔炼+真空自耗电弧重熔的工艺[7],以保证航空发动机用钛合金材料的冶金质量。而国内依然依赖于VAR熔炼,电子束冷床熔炼(EBCHM)技术尚处于起步阶段。冯寅楠等[8]综合介绍了国内外近年来EBCHM技术在多个材料领域的最新研究和实际生产现状,比较了国内外EMCHM 技术的发展和设备熔炼能力现状。对于应用最为广泛的TC4合金的EB熔炼技术已取得了一定的成果[9-10];国内外相关科研人员应用各种方法研究熔炼过程中Al元素的挥发和精确控制[11-14],但国内目前对EB炉熔炼技术的研究仅局限于TC4等简单的钛合金,对于中高温钛合金TA15的冷床炉制备技术尚未见报道。目前,国内对于EBCHM设备的研究已基本达到了工业化应用水平,钛行业内对EB熔炼技术及产品的认可度亦逐步提升,但对其认识仍停留在纯钛产品的制备工艺上,对于航空用钛等高端材料依然采用传统的VAR技术,或者完全依赖于进口。因此,充分挖掘EBCHM技术熔炼高洁净度钛材的潜力、推动国内EB熔炼水平的提升是亟待解决的问题;只有完全打破VAR技术的局限性、赶超国际EBCHM技术水平的发展,方能为国内高端钛材的发展、甚至航空航天工业的发展打下坚实的基础。本文对TA15合金的EB熔炼技术展开研究,旨在探索高品质TA15合金材料的制备工艺路线,为我国航空发动机用高温钛合金的发展提供可靠的基础数据。

1 实验

实验材料选用1级海绵钛、Al-Mo合金、Al-V合金、Al-Zr合金、Al豆,按设计配比混料后在TPH67-1600油压机上压制为150 mm×380 mm×580 mm的钛块,单块质量为100 kg。

熔铸实验在青海聚能钛业股份有限公司BMO-25型国产化电子束冷床炉(简称EB炉)上进行,熔炼得到规格为d 380 mm×1500 mm的扁锭,编号依次为1~6,具体的工艺参数如表1所列。铸锭经扒皮后在对角棱边取样,用ONH2000氧氮仪检测O、N含量;在铸锭表面及横截面上取屑样,经1:2硫酸溶解后用美国PE公司的ICP-7300V电感耦合等离子发射光谱仪分析Al、Zr、Mo、V含量。

2 结果与讨论

2.1 熔炼工艺参数控制

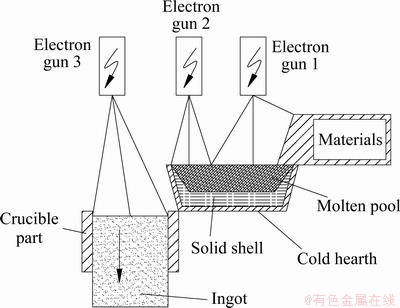

BMO-25型电子束冷床炉额定功率为1350 kW,熔炼区域及各电子枪扫描区域示意图如图1所示。其中1#电子枪负责熔化物料,2#电子枪负责冷床内金属液的精炼,3#电子枪负责结晶器中金属液的冷却及凝固结晶。

图1 EB炉熔炼区域及各电子枪扫描区域示意图

Fig. 1 Diagram of melting area and scanning area of electron gun of EB furnace

电子束冷床熔炼(EB)炉与真空自耗电弧(VAR)炉在熔炼热源、凝固方式、真空度要求等方面存在明显的不同,真空度的差异虽不是最大的区别,却是对熔炼过程及铸锭质量控制的重要影响因素。EB炉熔炼真空度比VAR炉的高1~2个数量级,因此脱气效果优异、但化学成分的烧损控制难度亦较大。TA15钛合金EB熔炼过程中,轻质元素Al的挥发控制是主要考虑的技术难点,电子束功率、电子束扫描花样及熔炼速度是影响Al等元素挥发的主要因素[15];其中电子枪电流的运行趋势(电流曲线的变化)是用于衡量熔炼质量判定的重要依据。

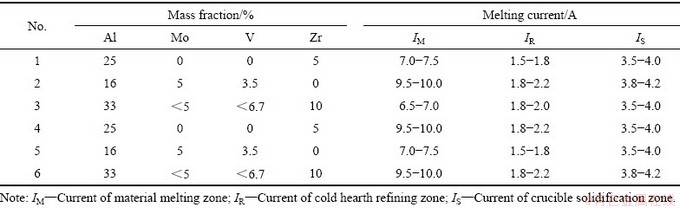

图2所示为1号熔铸实验熔炼过程中,熔炼工艺参数的变化曲线。电子束冷床熔炼(EB)炉的熔炼特性决定了其熔炼过程具备明显的阶段性,一般分为三个阶段:首先,启枪烘炉阶段—— 启动电子枪+烘炉阶段(见图2(a)中阶段1),启动电子束枪开始烘炉,待炉内真空度达到熔炼要求后,按要求提升熔炼电流熔化冷凝壳及物料,当冷床中金属液面达到溢流液位时,化开冷床浇道口,合金液流入结晶器,进入第二阶段(即制作底托阶段),如图2(a)中阶段2。所谓底托即为铸锭尾部与拉锭装置连接的一部分铸锭,在该阶段必须要注意熔炼结晶的质量,保证铸锭底托的冶金质量,避免出现大面积的冷隔、夹杂等缺陷。待结晶器中金属液位达到标记线位置时,降低电子枪电流进行冷却,然后开启拉锭机构,进入稳定熔炼阶段,如图2(a)中阶段3所示。

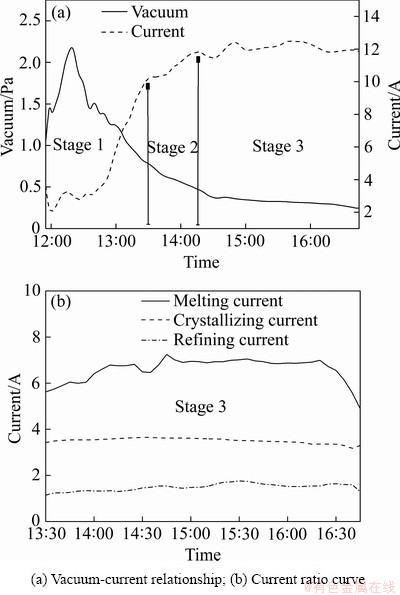

表1 TA15钛合金EB熔炼工艺参数

Table 1 EB melting process parameters of TA15 alloy

图2(a)所示为炉内真空-电子束枪电流(各枪电流加总)变化曲线,炉内真空直接影响电子束枪电流(功率)的稳定性。阶段1真空度稳定性较差,随着电子束枪的启动及电流的提升,物料开始大量放气,使得炉内真空度大幅下降、真空值持续升高,最高达到2.20 Pa以上;随着冷凝壳及物料的熔化,物料放气量逐渐减小,真空度随着电流的提升而升高。阶段2是真空度不断优化、电流稳步提升的过程,但是阶段1熔化工艺参数的剧烈波动导致物料化学成分的挥发烧损较大,因此在此阶段制作的铸锭尾部(底托)的化学成分偏差亦较大。阶段2结束后,将结晶区电流(IS)暂停提升2~3 min,然后提升电流,进入稳定熔炼阶段。阶段3主要特征是:炉内真空度不断优化,如图2(a)中真空曲线持续走低;各枪电流在设定值附近小幅波动。图2(b)所示为稳定熔炼阶段物料熔化区、冷床精炼区及结晶区电子枪电流的运行情况,三区电流按照设定的比值稳定运行,这是保证TA15钛合金顺利熔炼的基本前提。

图2 熔炼工艺参数变化曲线

Fig. 2 Variation curve of melting process parameters

由图2可知,稳定熔炼阶段电流的波动及电子束扫描轨迹的变化是决定铸锭化学成分均匀的关键。一方面,电流稳定则液态金属保持的时间稳定,“三区”扫描轨迹的合理分布可保证液态金属的持续流动、不断流。另一方面,扫描轨迹及电流稳定保证单位时间内物料接受的电子束功率基本保持不变,即限制熔体的温度变化范围;从金属元素挥发热力学角度分析,高温下随着温度升高,高饱和蒸气压组元的各元素的饱和蒸气压增大,纯金属的挥发趋势增强[16]。待物料熔炼完毕,进入补缩阶段;但补缩会造成铸锭头部Al元素大量挥发、不利于回收重熔,故综合考虑不进行头部补缩,切头料便于进行回收重熔。

1号熔铸实验稳定熔炼阶段熔化区、精炼区及结晶区电子束功率(电流)的分配比例为58%:13%:29%,这一比例能够保证设备运行、熔炼速度与铸锭化学成分的最佳匹配。1号熔铸实验的熔炼速度为1.089× 10-4 m/s (即200 kg/h)。

2.2 合金元素挥发控制

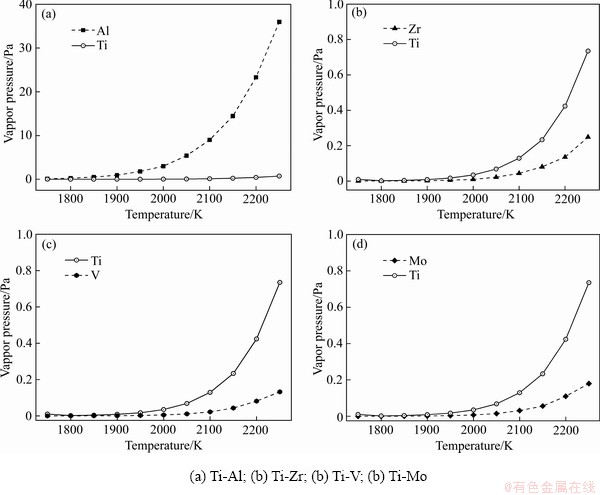

文献[13, 17]显示,金属元素在真空熔炼过程中的挥发规律显著依赖于其饱和蒸气压;高温下,钛合金中的常用金属元素V、Zr、Mo等元素的饱和蒸气压相对较低,Al、Sn等元素的饱和蒸气压相对较高,Al元素的饱和蒸气压比钛基体的高4个数量级。然而,TA15钛合金中Zr、Mo元素的饱和蒸气压低于Ti基体的饱和蒸气压,而Al元素饱和蒸气压远高于Ti的,Ti元素的饱和蒸气压介于Al和Zr的饱和蒸气压之间。这就说明,TA15钛合金熔炼过程中,Al、Zr、Ti元素存在一定的蒸发行为,其中Al元素的挥发损失是必须考虑的问题。

TA15钛合金EB炉熔炼过程中,合金元素Al的挥发较难控制,从而导致铸锭中的化学成分均匀性变差;Zr元素的挥发损失相对较小,控制难度亦较 小。合金元素在熔池表面的挥发行为服从Langmuir定律[18]:

(1)

(1)

式中:Ji为i组元的挥发传质速率(kg/s); 为凝固系数,Langmuir证明一般金属的

为凝固系数,Langmuir证明一般金属的 ≈1;

≈1; 为i组元的饱和蒸气压(Pa);

为i组元的饱和蒸气压(Pa); 为i组元的活度系数;xi为i组元的摩尔分数;S为熔体的表面积;Mi为i组元的摩尔质量;R为摩尔气体常数,8.314 J/(mol·K);T为熔体温度。

为i组元的活度系数;xi为i组元的摩尔分数;S为熔体的表面积;Mi为i组元的摩尔质量;R为摩尔气体常数,8.314 J/(mol·K);T为熔体温度。

合金熔体中某组元i的饱和蒸气压 可表示为

可表示为

(2)

(2)

式中: 为纯组元i的饱和蒸气压。根据文献[16, 19]可知,各纯组元的饱和蒸气压可通过下式进行计算:

为纯组元i的饱和蒸气压。根据文献[16, 19]可知,各纯组元的饱和蒸气压可通过下式进行计算:

(3)

(3)

式中:A、B、C、D为金属蒸气压常数,可以在文献中查到。

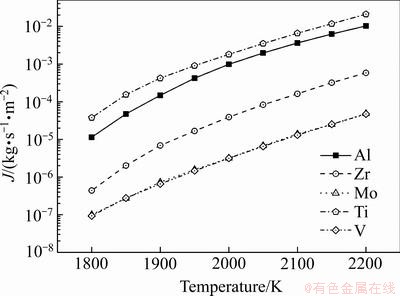

结合式(2)和(3),计算并绘制TA15钛合金熔体中Ti、Al、、Zr、V、Mo元素的饱和蒸气压和温度的关系曲线如图3所示。

由图3可知,随着温度的增加,Al元素的饱和蒸气压均有明显升高,Ti基体的次之,且Al升高速率高于其他元素(包括Ti基体)的升高速率。V、Mo元素的饱和蒸气压升高不明显,而Zr元素的饱和蒸气压较V、Mo元素的明显升高;而且同一温度下,Al元素的饱和蒸气压最高,Ti、Zr元素次之。这说明Al、Zr元素是TA15钛合金EB熔炼过程中主要的挥发元素,其中Al元素挥发最为严重,Zr元素次之,V、Mo元素的挥发可以忽略不计。

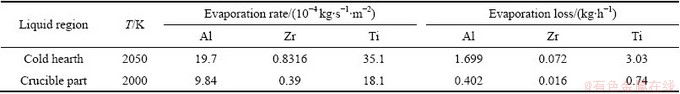

结合式(1)~(3),即为TA15钛合金EB炉熔炼过程合金元素的挥发模型。通过计算得出1号实验过程中,Al元素在冷床及结晶器中的挥发速率与温度的关系如图4所示,熔炼温度下的挥发率如表2所列。

本实验中冷床面积为600 mm×400 mm,结晶器横截面积为 d 380 mm,熔炼时炉内压力约为0.20~ 0.50 Pa左右。1号试验物料投入520 kg,其中Al元素总量为38.95 kg,Zr元素总量为10.91 kg,Ti元素总量为456.22 kg;熔炼时长为208 min。根据所建立的挥发模型及表2中数据,可知熔炼过程中Al元素的理论挥发率为18.69%,铸锭中Al元素的理论含量为6.16%;Zr元素的理论挥发率为2.80%,铸锭中Zr元素的理论含量为2.06%;Ti基体的理论挥发率为2.86%。

图3 TA15钛合金熔体中各元素的饱和蒸气压和温度的关系

Fig. 3 Relationship between vapor pressure and temperature for alloying element in TA15

表2 TA15合金EBCHM过程中合金元素的挥发损失

Table 2 Alloying elements evaporation loss of TA15 alloy during EBCHM

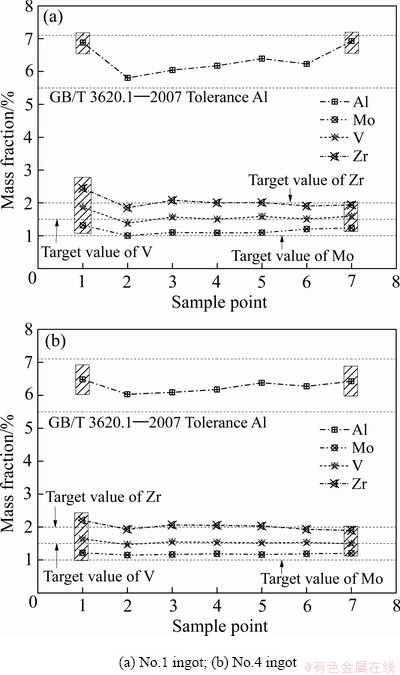

本文对熔炼获得的TA15钛合金铸锭进行化学成分分析(选择1号和4号试验数据),铸锭化学成分分布如图5所示。可见,经过EBCHM一次熔炼后TA15钛合金铸锭的化学成分符合国家标准的要求。

图4 TA15钛合金各元素的自由挥发速率与温度的关系

Fig. 4 Maximum evaporation rate of alloying element in TA15 changing with temperature

图5 TA15合金铸锭轴向化学成分分布

Fig. 5 Axial direction distribution of chemical component of TA15 alloy ingot

根据图5化学成分数据(Al含量均值6.35%、Zr含量均值2.03%)计算铸锭中Al、Zr元素实际挥发率分别为15.33%和3.33%。可见,EBCHM过程中Al、Zr元素的实际挥发率与Langmuir定律及挥发模型吻合度较高,Al元素实际挥发率低于理论挥发率,Zr元素的实际挥发率略高于理论值。这种挥发率的偏差主要是由两方面原因造成的:一是挥发模型本身固有的缺陷(理想熔体与实际熔体的差异);二是EB熔炼过程中工艺参数的可变因素较多,如电子束枪运行稳定性受真空波动的影响明显,如此便会造成局部熔体的温度及流速变化,进而合金元素的挥发亦会有所不同。理论与实际挥发率虽然存在偏差,但足以应对EB熔炼挥发规律的预测及验证。此外,可以通过对预测模型的修正及EB熔炼工艺的优化改进来提高模型的预测/验证的准确性。

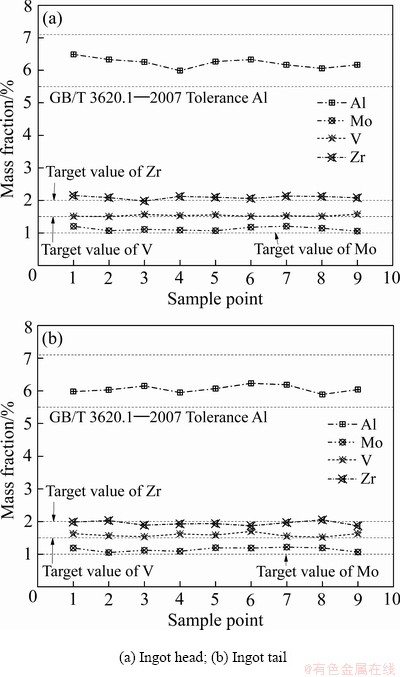

图6所示为1号铸锭头、尾部横截面化学成分分布(取样点呈“十字型”分布)。可见,铸锭横截面上各元素分布均匀性良好,铸锭心部、边部未出现较大的成分偏差,未发现明显的结晶偏析。

图6 1号铸锭横截面化学成分分布

Fig. 6 Chemical composition distribution on cross section of TA15 alloy ingot

根据表3数据(以6.35%计算)计算铸锭中Al元素实际挥发率为16.9%。可见,EBCHM过程中Al元素的实际挥发率高于理论挥发率。

2.3 熔炼工艺参数的合理匹配

通过上述分析可知,利用电子束冷床熔炼炉熔炼钛合金时需合理设计EB熔炼工艺参数,原材料中合金元素配比不同,熔炼工艺需做出相应的调整。熔炼工艺匹配需综合考虑电子束功率、电子束扫描花样及熔炼速度等因素,具体如下:1) 原材料配料:原料中Al元素的加入形式对其挥发具有重要影响;单质Al的加入势必会造成Al过量挥发,单质Al占比小于50%时,挥发量较易控制,以Al-Mo(V、Zr等)中间合金形式加入能有效抑制Al的挥发率。2) 电子束功率:BMO-25型EB炉电子束枪的最大额定功率为450 kW/枪,大量试验积累可知,熔化区功率保持在150~330 kW之间时即可满足钛合金的熔炼需求。电子束功率高低决定了温度场的温度分布、同时决定了熔体的流动性,结合挥发动力学/热力学,对合金元素挥发造成重要影响。电子枪功率小于240 kW时,Al挥发率一般在18%~30%;电子枪功率大于240 kW时,Al挥发率一般能够控制在≤18%。3) 电子束扫描花样:EB炉熔炼时,金属熔体液面的面积主要由冷床和结晶器构成,在熔炼速度一定的情况下,可近似认为合金元素挥发用时恒定。故电子束扫描花样影响瞬时熔体的挥发。高频率、瞬时低功率扫描花样(电子束斑直径细小、移速高)不会造成熔体局部高温、亦不会造成合金元素的高蒸气压差,有利于合金元素的挥发控制;低频率、瞬时高功率扫描花样(电子束斑直径较大、轰击强度大、移速低)会导致熔体局部过热及高蒸气压差,发生喷溅、熔体液态保持时间长而过量挥发等问题,此外还会降低熔炼速度的连续性。4) 熔炼速度:首先,熔炼速度受电子束功率分布的影响,高功率对应较快的熔炼速度;其次,合理选择结晶区电流分配是保证熔炼速度稳定的关键,结晶电流高,则铸锭下拉速度慢,反之亦然。

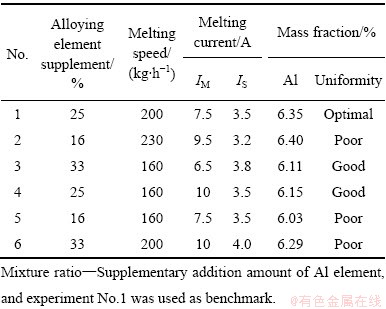

按照试验方案完成熔炼工艺及铸锭质量分析,将1~6号试验的分析结果列于表3中。经过多次试验分析,TA15钛合金EB熔炼过程中Al、Zr等元素的挥发烧损得到了有效控制,合金元素挥发率最大不超过16%。此外,通过对工艺参数的优化及熔炼过程的合理设计,将铸锭成材率提升至92%以上,鉴于EB炉熔炼钛合金的特点(头、尾部成分偏差较大,需锯切),随着铸锭规格的放大,成材率会进一步提升。1号试验铸锭的化学成分均匀性最佳,选用的工艺参数最为合理,即1号试验方案为BMO-25型EB炉熔炼TA15钛合金的最佳技术条件。

表3 EB熔炼工艺对Al元素挥发的影响

Table 3 Effect of EB melting process on volatilization of Al element

3 结论

1) TA15钛合金EB炉熔炼过程中,Al元素是主要的挥发元素,Zr元素亦存在一定的挥发;Al、Zr元素的实际挥发率分别为15.33%和3.33%,与Langmuir定律及挥发模型计算结果吻合度较高。

2) 铸锭化学成分均匀性主要受原材料配料、熔炼功率、熔炼速度等工艺参数的影响,Al元素以Al-Mo(V、Zr等)中间合金的形式加入能有效抑制Al过量挥发;熔炼电子枪的功率须达到240 kW以上,能够有效降低Al元素的挥发率(≤18%)。

3) 在本文试验及试生产条件下,将拉锭速度控制在1.089×10-4 m/s 左右时,各项工艺参数之间达到良好匹配,获得的铸锭化学成分均匀性良好。

REFERENCES

[1] 张绪虎, 单 群, 陈永来, 杜志惠. 钛合金在航天飞行器上的应用和发展[J]. 中国材料进展, 2011, 30(6): 28-32.

ZHANG Xu-hu, SHAN Qun, CHEN Yong-lai, DU Zhi-hui. Application and development of titanium alloys for aircrafts[J]. Materials China, 2011, 30(6): 28-32.

[2] 陈 峰. Ti-6.5Al-Mo-1Zr-1Sn-1W-0.2Si(TC25)钛合金熔炼工艺研究[D]. 西安: 西安建筑科技大学, 2015.

CHEN Feng. Study on melting technique of Ti-6.5Al-2Mo-1Zr-1Sn-1W-0.2Si (TC25) alloy[D]. Xi’an: Xi’an University of Architecture and Technology, 2015.

[3] 张延东. TA15钛合金熔炼工艺及成分优化[D]. 西安: 西安建筑科技大学, 2006.

ZHANG Yan-dong. Melting technology and composition control of TA15 titanium alloy[D]. Xi’an: Xi’an University of Architecture and Technology, 2006.

[4] 安耀辉, 高 博, 马 龙, 岳 旭, 于海慧.超大规格TA15钛合金棒材锻造工艺研究[J]. 钛工业进展, 2013, 30(5): 22-25.

AN Yao-hui, GAO Bo, MA Long, YUE Xu, YU Hai-hui. Research on forging process of super large-sized TA15 titanium alloy bars[J]. Titanium Industry Progress, 2013, 30(5): 22-25.

[5] 隋 楠, 曹京霞, 黄 旭, 高 帆, 谭启明. 合金成分对TA15钛合金组织及力学性能的影响[J]. 航空材料学报, 2019, 39(1): 48-54.

SUI Nan, CAO Jing-xia, HUANG Xu, GAO Fan, TAN Qi-ming. Effect of composition on microstructure and mechanical properties of TA15 titanium alloy[J]. Journal of Aeronautical Materials, 2019, 39(1): 48-54.

[6] 史莹莹, 刘 钊, 陈 峰, 郑亚波, 毛玲玲. Φ1040 mm规格TA15钛合金铸锭生产工艺研究[J]. 世界有色金属, 2018(23): 9-12.

SHI Ying-ying, LIU Zhao, CHEN Feng, ZHENG Ya-bo, MAO Ling-ling. Preparation technology research of Φ1040 mm TA15 titanium alloy ingot[J]. World Nonferrous Metals, 2018(23): 9-12.

[7] MITCHELL A. The electron beam melting and refining of titanium alloys[J]. Materials Science and Engineering A, 1999, 263(2): 217-223.

[8] 冯寅楠, 闫 鹏, 贾国斌. 电子束冷床熔炼的应用现状[J]. 中国材料进展, 2020, 39(4): 295-303.

FENG Yin-nan, YAN Peng, JIA Guo-bin. Application status of electron beam cold hearth melting technology[J]. Materials China, 2020, 39(4): 295-303.

[9] 杜 彬, 唐增辉, 韵海鹰, 周 武. 电子束冷床炉制备的TC4合金直轧工艺性能研究[J].热加工工艺, 2018, 47(23): 34-37.

DU Bin, TANG Zeng-hui, YUN Hai-ying, ZHOU Wu. Investigation of direct rolling process performance of TC4 alloy using electron beam cold hearth melting[J]. Hot Working Technology, 2018, 47(23): 34-37.

[10] 刘千里, 李向明, 蒋业华, 周 荣. 工艺条件对大规格TC4扁锭连铸过程固液界面的影响[J]. 中国有色金属学报, 2016, 26(8): 1641-1648.

LIU Qian-li, LI Xiang-ming, JIANG Ye-hua, ZHOU Rong. Effect of process condition on solid liquid interface during continuous solidification process of large scale TC4 titanium alloy slab ingot[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1641-1648.

[11] HRABE N, QUINN T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), part 1: Distance from build plate and part size[J]. Materials Science and Engineering A, 2013, 573(20): 264-270.

[12] HRABE N, QUINN T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location[J]. Materials Science and Engineering A, 2013, 573(20): 271-277.

[13] 毛小南, 罗 雷, 于兰兰, 雷文光. 电子束冷床熔炼工艺参数对TC4钛合金Al元素挥发的影响[J]. 中国有色金属学报, 2010, 20(S1): 419-424.

MAO Xiao-nan, LUO Lei, YU Lan-lan, LEI Wen-guang. Effects of melting process parameters of electron beam cold hearth on Al element evaporation in TC4 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 419-424.

[14] GAO Lei, HUANG Hai-guang, JIANG Ye-hua, CHEN Guo, CHATTOPADHYAY K, ZHOU Rong. Numerical study on the solid-liquid interface evolution of large-scale titanium alloy ingots during high energy consumption electron beam cold hearth melting[J]. JOM, 2020, 72(5): 1953-1960.

[15] VUTOVA K, MLADENOV G. Computer simulation of the heat transfer during electron beam melting and refining[J]. Vacuum, 1999, 53(1): 87-91.

[16] 罗 雷, 于兰兰, 雷文光, 毛小南, 杨冠军, 牛蓉蓉, 张英明, 王 琛. 电子束冷床熔炼TC4合金元素挥发机制研究[J]. 稀有金属材料与工程, 2011, 40(4): 625-629.

LUO Lei, YU Lan-lan, LEI Wen-guang, MAO Xiao-nan, YANG Guan-jun, NIU Rong-rong, ZHANG Ying-ming, WANG Chen. Research on evaporation mechanism of elements in TC4 alloys during electron beam cold hearth melting[J]. Rare Metal Materials and Engineering, 2011, 40(4): 626-629.

[17] 罗 雷. TC4钛合金电子束冷床熔炼技术研究[D]. 西安: 西安建筑科技大学, 2010.

LUO Lei. Research on melting technology of electron beam cold hearth melting of TC4 titanium alloy[D]. Xi’an: Xi’an University of Architecture and Technology, 2010.

[18] 张英明, 周 廉, 孙 军, 韩明臣, 杨建朝, 倪沛彤, 赵永庆. TC4合金电子束冷床熔炼过程中Al元素的挥发计算研究[J]. 稀有金属材料与工程, 2008, 37(S3): 99-101.

ZHANG Ying-ming, ZHOU Lian, SUN Jun, HAN Ming-cheng, YANG Jian-chao, NI Pei-tong, ZHAO Yong-qing. Calculation of Al evaporation loss of TC4 alloy during electron beam cold hearth remelting process[J]. Rare Metal Materials and Engineering, 2008, 37(S3): 99-101.

[19] 刘仲贵, 苏彦庆, 郭景杰, 丁宏升, 贾 均, 傅恒志. Ti-13Al-29Nb-2.5Mo合金ISM熔炼过程中多组元挥发损失[J]. 稀有金属材料与工程, 2003, 32(2): 108-112.

LIU Zhong-gui, SU Yan-qing, GUO Jing-jie, DING Hong-sheng, JIA Jun, FU Heng-zhi. Evaporation loss of the components in Ti-13Al-29Nb-2.5Mo Melt during ISM process[J]. Rare Metal Materials and Engineering, 2003, 32(2): 108-112.

Melting technology of electron beam cold hearth melting of TA15 titanium alloy

DU Bin1, 2, ZHANG Zhi-bin1, LEI Yun-qing1, QIAN Guang-ning1, 2, SUN Ning-ning1, WANG Qian1

(1. Technology R&D Department, Qinghai Supower Titanium Co., Ltd., Xi′ning 810007, China;

2. Titanium and Titanium Alloys Engineering Research Center of Qinghai Province, Xi′ning 810007, China)

Abstract: Under industrialization conditions, the TA15 titanium alloy ingot was prepared by one-time smelting using an electron beam cold-bed melting furnace (EB furnace). The relationship between the smelting process parameters and the homogeneity of the chemical composition of alloy ingot was analyzed. A brief numerical analysis of the volatilization law of Al and Zr element was studied by Hertz-Knudsen-Langmuir's law, and it was compared with the actual volatility law. The results show that the volatilization law of Al and Zr elements during EB melting process complies with Langmuir’s law. Among them, the Al element volatilization is serious, the theoretical volatilization rate is 18.69%, and the actual volatilization rate is 15.33%. The Zr element volatilization rate is relatively lower, the theoretical volatilization rate is 2.80%, the actual volatilization rate is 3.33%; the theoretical volatilization rate of the Ti matrix is 2.86%. The EB furnace melting power, vacuum degree and the matching between various process parameters are the key factors which affecting the volatilization of Al and Zr elements. The chemical composition of alloy ingot prepared by reasonable process parameters has good uniformity.

Key words: TA15 titanium alloy; electron beam cold hearth melting; Al element evaporation; composition uniformity

Foundation item: Project(TC150B5C0) supported by the National Strong Industrial Project in 2015, China; Project (2018-Y-09) supported by the Key R&D and Transformation Plan Project in Qinghai Province, China

Received date: 2019-12-24; Accepted date: 2020-04-20

Corresponding author: DU Bin; Tel: +86-971-8827509; E-mail: dubin0327wat@126.com

(编辑 王 超)

基金项目:国家2015年工业强基工程项目(TC150B5C0);青海省重点研发与转化计划项目(2018-Y-09)

收稿日期:2019-12-24;修订日期:2020-04-20

通信作者:杜 彬,工程师;电话:0971-8827509;E-mail:dubin0327wat@126.com