文章编号:1004-0609(2012)10-2951-09

铝电解槽钢棒加高型阴极对铝液中水平电流的优化

杨 帅,李 劼,徐宇杰,张红亮,张翮辉,邹 忠,赖延清

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:为减小传统铝电解槽内铝液中存在的较大水平电流,提出一种阴极钢棒加高型阴极。采用含电接触的有限元模型计算钢棒加高型阴极结构的电场,考察此种阴极对于铝液中水平电流的优化作用。计算结果表明:选择合适的加高位置及加高高度可使铝液中X向水平电流密度的最大值和平均值有效减小,并且可以优化X向水平电流密度的分布,而对于减小Z向水平电流密度的最大值也有一定作用。以300 kA铝电解槽的阴极为例,在距阴极炭块边缘800 mm处钢棒上加高70 mm至90 mm时为最佳加高设计;同时钢棒加高型阴极结构的电压降小于传统结构的,铝液中的等势线分布更平缓。

关键词:铝电解;阴极压降;加高钢棒;水平电流

中图分类号:TF821 文献标志码:A

Optimization of horizontal current in metal pad by using cathode with heightened collector bars in aluminum reduction cell

YANG Shuai, LI Jie, XU Yu-jie, ZHANG Hong-liang, ZHANG He-hui, ZOU Zhong, LAI Yan-qing

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Based on the target of reducing the large horizontal current in metal pad of aluminum reduction cells, a kind of cathode with heightened collector bars was improved. The electric field of the cathode was calculated by using finite element method with an electric contact model, and the optimization effect to horizontal current in metal pad was examined. The results show that an appropriate design scheme of heightened collector bars can effectively reduce the maximum and average values of horizontal current density along X axis in the metal pad, and optimize the current density. The maximum value of horizontal current density along Z axis in metal pad can be reduced at the same time. For the case of cathodes in 300 kA aluminum reduction cells, the best design of heightened position is at a distance of about 800 mm from the edge of cathode carbon block, and the beneficial heightened height ranges from 70 to 90 mm, the cathode with heightened collector bars has a lower voltage drop than the traditional one, and the iso-potential curves in the metal pad shows slightly.

Key words: aluminum electrolysis; cathode voltage drop; heightened collector bar; horizontal current

基金项目:国家自然科学基金青年基金资助项目(51104187);教育部高等学校博士学科点专项科研基金资助项目(20100162120008)

收稿日期:2011-09-19;修订日期:2012-03-20

通信作者:张红亮,讲师,博士;电话:0731-88830474;E-mail: net_hotang@163.com

工业铝电解槽内的电解质和铝液两种高温熔体在电磁力、重力等作用下在槽膛内运动。熔体的运动促进了槽内的传质与传热,对电解槽的稳定运行起着重要作用,然而熔体过大的水平流动及垂直波动都不利于电解槽的稳定运行,严重时甚至引起滚铝等极端现象[1-3]。熔体的运动对电解的经济技术指标如电耗、效率等也有显著影响,因此,追求槽内熔体合理的流动及尽可能小的波动,一直是铝电解槽研究与设计的核心之一。

电磁力是引起槽内熔体运动的主要驱动力,由于熔体流动及波动产生的铝液-电解质界面变形会引起额外的扰动电磁力,扰动电磁力进一步改变熔体的流动及铝液-电解质界面的波动,在此过程可能产生波动的不稳定分量,若这些不稳定分量得不到有效的抑制就会引起槽内磁流体的不稳定现象[4]。LINDSAY和DAVIDSON [5]以及BOJAREVICS和ROMERIO[6]研究指出,由铝液中水平电流与垂直磁场作用产生的扰动电磁力是唯一有重要影响的扰动电磁力组分,因此,从稳定磁流体波动的角度考虑,优化铝液中的垂直磁场以及水平电流都能直接改善槽内磁流体的稳定性。

为改善铝电解槽中的磁流体稳定性,国外与国内的学者都有许多研究,这部分的工作主要集中在优化电解槽的母线结构及进电制度以及提出更有利于铝液中减小垂直磁场的新型阴极结构。GUSEV等[7]以及ZIEGLER和RUAN[8]运用数值仿真的方法,设计出用于电解系列最末端槽的磁场补偿母线结构,并将其结果运用于工业生产中。周萍等[9]、李茂和周孑民[10]以及LI等[11]分别运用数值仿真的方法研究不同的母线结构及进电制度对铝液中垂直磁场的影响及对熔体流动的影响,优化了特定槽型的母线配置及进电制度。刘业翔等[12]设计的底部出电铝电解槽,不仅具有较为理想的垂直磁场分布,而且铝液中的水平电流也相对较小,为实现铝电解槽的大幅节能创造了条件。与以上研究相比,对于减小铝液中水平电流的研究相对要少,而MOREAU和ZIEGLER[13]在很早就指出了减小铝液中水平电流对于增强磁流体稳定性的意义。QI 等[14]计算了阴极结构中的电场,研究铝液高度及伸腿长度对铝液中的水平电流密度的影响,指出铝液中水平电流密度的分布状况和铝液高度及伸腿对铝液中水平电流密度的影响规律。张艳芳等[15]对阴极炭块类型和钢棒类型以及钢棒高度及宽度变化对于铝液中水平电流的影响进行了分析,指出钢棒的电导率越高或增加钢棒的宽度都有助于减小水平电流的分量,并使水平电流密度的分布更均匀。但由于上述针对铝液中水平电流的两项研究在阴极结构上都保持传统形状,而铝液高度及伸腿长度受工艺条件制约并不能随意改变,因此对于优化铝液中的水平电流作用有限。

本文作者提出一种阴极钢棒加高型的新型阴极结构,并且运用此前开发的采用电接触模型的有限元分析方法[16]计算整个阴极结构的电场,探索此种阴极结构对于减小铝液中水平电流的优化作用,初步获得了合理的结构参数,结果可为改善铝电解槽中磁流体稳定性提供一条思路。

1 钢棒加高型阴极结构简介

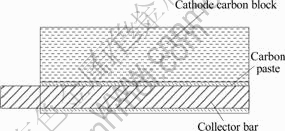

铝电解槽中,电流从阳极导杆流入槽内,经过阳极炭块、电解质、铝液及阴极炭块与钢棒后从槽侧部流出,由于电流的流出方向与流入方向成90°角,并且铝液的电阻率远远小于电解质以及阴极炭块的,因此电流的转向大部分发生在铝液层中,形成了铝液中的水平电流,水平电流与垂直磁场共同作用引起电解质-铝液界面的波动,从而影响到槽内磁流体的稳定性。传统的铝电解槽剖面结构及电流流向示意图如图1所示,半阴极结构剖面图如图2所示。

图1 预焙阳极铝电解槽结构示意图

Fig. 1 Structure diagram of aluminum reduction cell: 1—Aluminum rod; 2—Steel draw; 3—Anode carbon block; 4—Side ledges; 5—Electrolyte; 6—Aluminum melt; 7—Cathode carbon block; 8—Collector bar; 9—Side carbon block; 10—Surrounding paste draw; 11—Refractory brick; 12—Insulating brick; 13—Steel shell

图2 传统阴极结构示意图

Fig. 2 Schematic diagram of traditional cathode structure

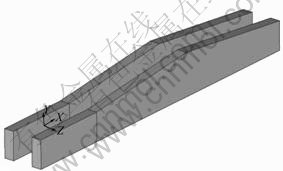

本文作者所提出的钢棒加高型阴极结构的半阴极剖面如图3所示,其实质是在传统阴极结构的基础上对嵌入阴极炭块内的钢棒上对称的某两点从两端进行线性加高(图中所示其中的一点),而伸出阴极炭块部分的钢棒高度保持不变。由于钢棒的导电性优于阴极炭块的,因此,加高型钢棒对于阴极部分的电场分布会有一定影响,从而改变铝液中的电流分布,为优化铝液中水平电流提供了可能性。在此以 表示不同的加高方案,其中a代表加高点距离阴极炭块出电端边缘的水平距离,b表示加高点与初始结构的高度差,单位均为mm,其具体所表示的位置标于图3中。

表示不同的加高方案,其中a代表加高点距离阴极炭块出电端边缘的水平距离,b表示加高点与初始结构的高度差,单位均为mm,其具体所表示的位置标于图3中。

图3 钢棒加高型阴极结构示意图

Fig.3 Schematic diagram of new cathode structure with heightened collector bar

2 理论基础及模型

2.1 控制方程

铝电解槽中导电部分的导电微分方程可表示为拉普拉斯方程,即

(1)

(1)

(2)

(2)

式中:V为标量电位;I为电流;R为电阻;σ为电导率。

2.2 接触压降

阴极钢棒与钢棒糊间的接触压降可由下式计算:

(3)

(3)

式中: 为接触电压;I为电流;Rc为接触电阻率;S为接触面积。

为接触电压;I为电流;Rc为接触电阻率;S为接触面积。

2.3 模型及边界条件

以某300 kA预焙铝电解槽阴极作为研究对象,其初始结构及工艺参数列于表1。此外,加高型钢棒的模型图如图4所示。

表1 阴极初始结构及工艺参数

Table 1 Initial structure parameters of cathode

图4 加高型钢棒模型示意图

Fig. 4 Schematic diagram of heightened collector bars model

考虑到阴极结构的对称性,截取其1/2为计算模型,同时为建模的便捷及计算的效率,不考虑电解槽中不同阴极上通过的电流在大小上的差异,即假定每块阴极上通过电流为总电流在所有阴极上的平均值;不考虑各材料电阻率随温度的变化;不考虑铝液界面的变形。

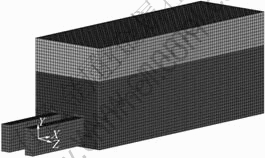

模型在ANSYS中生成并进行网格划分及计算,具体模型及计算流程见文献[16]。半阴极有限元模型如图5所示,X向表示指向电解槽水平短轴方向,Y向指向电解槽高度方向,Z向指向电解槽水平长轴方向。

图5 半阴极有限元模型

Fig. 5 FEM model of half cathode

2.4 材料属性

计算中所需的材料属性见表2。此外,钢棒糊与阴极钢棒间的接触电阻率根据文献[16]取1×10-5 Ω·m。

表2 实验材料的电阻率

Table 2 Electrical resistivity of experimental materials

3 结果与分析

3.1 钢棒加高位置对铝液中水平电流的影响

分别计算初始结构、钢棒加高方案分别为 、

、 、

、 、

、 、

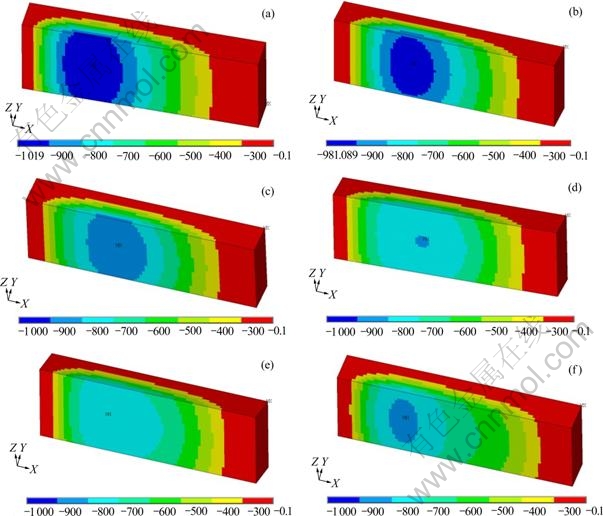

、 的阴极结构的电场,考察钢棒加高位置对铝液中水平电流的影响。各方案铝液中X向水平电流密度分布分别如图6所示,Z向水平电流密度分布如图7所示,电流密度最大值与平均值列于表3。

的阴极结构的电场,考察钢棒加高位置对铝液中水平电流的影响。各方案铝液中X向水平电流密度分布分别如图6所示,Z向水平电流密度分布如图7所示,电流密度最大值与平均值列于表3。

由表3可知,随着钢棒加高位置向阴极内部延伸,铝液中X向水平电流密度的最大值先减小,继而在距炭块边缘800 mm左右的某一位置开始增大,但增大的趋势比减小的趋势小,而X向水平电流密度平均值则随着加高位置向阴极内部延伸而不断减小,减小的绝对量不太大;阴极钢棒的加高位置对Z向水平电流密度最大值的影响与对X向水平电流密度最大值的影响有相似的规律,但其影响的绝对量要小得多;此外,钢棒加高会增大铝液中的Z向水平电流密度平均值,但这种影响非常小,并且大小基本不随加高位置变化而变化,即加高位置的选择对其几乎没有影响。

表3 钢棒不同加高位置铝液中水平电流密度

Table 3 Horizontal current density in metal pad with various heightened positions of collector bars

由图6中X向水平电流密度分布也可以看出,不同加高位置的铝液中X向水平电流密度的分布形态基本一致,电流密度较大的区域分布于偏靠近阴极边缘的位置,钢棒加高位置为距炭块边缘为800 mm处时X向水平电流密度分布最为均匀,电流密度的变化梯度较小,并且最大值达到最小。图7所示的不同加高位置方案的铝液中Z向水平电流密度分布形态基本相同,电流密度较大的区域分布于靠近炭块边缘两端的部位,所占体积较小并且向铝液内部逐渐减小,仅在电流密度最大值上有很小的差别。

图6 钢棒不同加高位置铝液中X向水平电流密度分布

Fig. 6 Horizontal current density along X axis in metal pad with various heightened positions of collector bars (A/m2): (a) Initial structure; (b)  ; (c)

; (c)  ; (d)

; (d)  ; (e)

; (e)  ; (f)

; (f)

图7 钢棒不同加高位置铝液中Z向水平电流密度分布

Fig. 7 Horizontal current density along Z axis in metal pad with various heightened positions of collector bars (A/m2): (a) Initial structure; (b)  ; (c)

; (c)  ; (d)

; (d)  ; (e)

; (e)  ; (f)

; (f)

综上所述,钢棒加高对于减小铝液中的水平电流以及优化其分布有积极效果,加高位置的选择主要影响铝液中的X向水平电流的分布及大小,加高位置在距炭块边缘800 mm处时电流密度最大值达到最小,平均值也有所减小,铝液中X向水平电流密度的分布更加均匀,因而距炭块边缘800 mm处是较为合适的加高位置。

3.2 钢棒加高高度对铝液中水平电流的影响

分别计算钢棒加高方案分别为

、

、 、

、 、

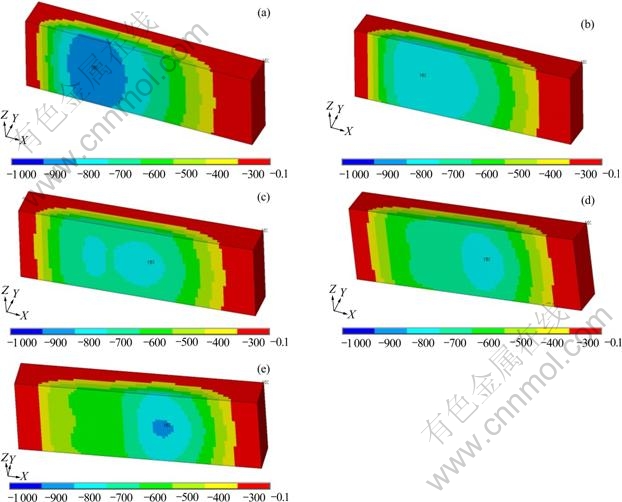

、 的阴极结构的电场,考察钢棒加高高度对于铝液中水平电流的影响。各方案铝液中X向水平电流密度分布分别如图8所示,Z向水平电流密度分布如图9所示,电流密度最大值与平均值列于表4。

的阴极结构的电场,考察钢棒加高高度对于铝液中水平电流的影响。各方案铝液中X向水平电流密度分布分别如图8所示,Z向水平电流密度分布如图9所示,电流密度最大值与平均值列于表4。

由表4可知,钢棒加高高度对铝液中X向水平电流密度影响较大,随着钢棒加高高度的增加,铝液中X向水平电流密度的最大值先减小再增大,在加高高度为70 mm左右达到最小值,而X向水平电流密度的平均值则随着钢棒加高高度的增加而不断减小;阴极钢棒的加高高度对铝液中的Z向水平电流密度也有一定影响,Z向水平电流密度的最大值随着加高高度的增加而不断减小,但平均值随加高高度的增加而不断增加。

表4 钢棒不同加高位置铝液中水平电流密度

Table 4 Horizontal current density in metal pad with various heightened positions of collector bars

由图8可以看出,随着钢棒加高高度的增加,铝液中X向水平电流密度较大的区域向槽中心移动,并且趋向于较为平均的分布,但当加高高度超过90 mm附近的某一值时,开始再次趋向于集中分布。由图9可知,铝液中Z向水平电流密度分布形态基本不受加高高度变化的影响,仅在最大值上有所差别,并且这种差别在数值上相对于X向水平电流密度的变化要小 得多。

图8 钢棒不同加高位置铝液中X向水平电流密度分布

Fig. 8 Horizontal current density along X axis in metal pad with various heightened positions of collector bars (A/m2): (a)  ; (b)

; (b)  ; (c)

; (c)  ; (d)

; (d)  ; (e)

; (e)

图9 钢棒不同加高位置铝液中Z向水平电流密度分布

Fig. 9 Horizontal current density along Z axis in metal pad with various heightened positions of collector bars(A/m2): (a)  ; (b)

; (b)  ; (c)

; (c)  ; (d)

; (d)  ; (e)

; (e)

综上所述,钢棒的加高高度对铝液中X向水平电流密度的分布及大小影响较大,同时对Z向水平电流的也有一定影响,虽然更高的钢棒加高高度能更多的减小铝液中X向水平电流密度的平均值,但从避免Z向水平电流密度平均值升高及较好的X向水平电流密度分布形态考虑,加高高度为70 mm到90 mm是较为合理的加高高度。在加高方案为 时,X向水平电流密度最大值相对于初始结构下降了28.36%,平均值下降了11.11%。

时,X向水平电流密度最大值相对于初始结构下降了28.36%,平均值下降了11.11%。

3.3 钢棒加高对阴极压降的影响

分别计算初始结构、钢棒加高方案分别为 、

、 、

、 、

、 、

、 以及

以及 、

、 、

、 、

、 、

、 的阴极结构压降,考察不同钢棒加高方案对于阴极结构电压降的影响。不同方案的阴极压降列于表5中,其中初始结构及钢棒加高方案为

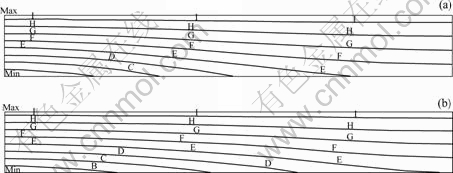

的阴极结构压降,考察不同钢棒加高方案对于阴极结构电压降的影响。不同方案的阴极压降列于表5中,其中初始结构及钢棒加高方案为 时铝液中X向截面等电势线分布如图10所示。

时铝液中X向截面等电势线分布如图10所示。

由表5可知,由于钢棒加高使得阴极结构中电阻率较高的阴极炭块部分被钢棒取代,所以钢棒加高型阴极结构的电压降都小于初始结构的压降,且加高位置越靠近炭块边缘或加高高度越高,则阴极结构的压降越小;在优化水平电流最优的加高方案 时阴极结构的压降为283 mV,相对于初始结构降低了 19 mV。

时阴极结构的压降为283 mV,相对于初始结构降低了 19 mV。

表5 不同阴极结构的电压降

Table 5 Voltage drop with different cathode structures

此外,由图10可以看出,钢棒加高型阴极结构的铝液中X向截面上等电势线分布形态与初始结构相似,但分布更加平缓,更趋向于在铝液中沿垂直的方向分布,而这是对于减小铝液中水平电流最根本的原因。

图10 铝液中X向截面等电势线分布

Fig. 10 Isopotential curves in section along X axis of metal pad: (a)Initial structure; (b)

4 结论

1) 钢棒加高对于减小铝液中的水平电流以及优化其分布有积极效果。随着钢棒加高位置向阴极内部延伸,铝液中X向水平电流密度的最大值先减小,加高位置距炭块边缘800 mm处时电流密度最大值达到最小,平均值也有所减小,铝液中X向水平电流密度的分布最均匀。

2) 随着钢棒加高高度的增加,铝液中X向水平电流密度的最大值先减小再增大,在加高高度为70 mm左右达到最小值,平均值则不断减小;Z向水平电流密度的最大值随加高高度的增加而不断减小,但平均值不断增加,最优加高高度为70 mm至90 mm。

3) 在最优钢棒加高方案 时,X向水平电流密度最大值相对于初始结构下降了28.36%,平均值下降了11.11%,并且阴极结构的电压降相对于初始结构降低了19 mV,铝液中的等势线分布更加平缓。

时,X向水平电流密度最大值相对于初始结构下降了28.36%,平均值下降了11.11%,并且阴极结构的电压降相对于初始结构降低了19 mV,铝液中的等势线分布更加平缓。

REFERENCES

[1] LI Xiang-peng, LI Jie, LAI Yan-qing, ZHAO Heng-qin, LIU Ye-xiang. Mathematical simulation of gas induced bath flow in drained aluminum reduction cell[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(6): 1221-1226.

[2] 刘业翔, 李 劼. 现代铝电解[M]. 北京: 冶金工业出版社, 2008: 222.

LIU Ye-xiang, LI Jie. Modern aluminum electrolysis[M]. Beijing: Metallurgical Industry Press, 2008: 222.

[3] 李 劼, 徐宇杰, 刘 伟, 赖延清. 基于波动模态耦合的铝电解槽磁流体稳定性傅立叶级数法分析[J]. 计算力学学报, 2010, 27(2): 213-217.

LI Jie, XU Yu-jie, LIU Wei, LAI Yan-qing. Aspect ratio research based on magneto-hydrodynamic stability in aluminum reduction cells[J]. Chinese Journal of Computational Mechanics, 2010, 27(2): 213-217.

[4] 徐宇杰, 李 劼, 张红亮, 赖延清. 基于非线性浅水模型的铝电解磁流体动力学计算[J]. 中国有色金属学报, 2011, 21(1): 191-197.

XU Yu-jie, LI Jie, ZHANG Hong-liang, LAI Yan-qing. MHD calculation for aluminium electrolysis based on nonlinear shallow water model[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 191-197.

[5] LINDSAY R I, DAVIDSON P A. Stability of interfacial waves in aluminum reduction cell[J]. J Fluid Mech, 1998, 362: 327-331.

[6] BOJAREVICS V, ROMERIO M V. Long waves instability of liquid metal-electrolyte interface in aluminum electrolysis cells: A generalization of Sele's criteria[J]. European Journal of Mechanics B, 1994, 13: 33-56.

[7] GUSEV A, KRYLOV L, PLATONOV V, VABISHCHEVICH P. Compensation of the magnetic field of the extreme reduction cells in potlines[C]//KVANDE H. Light Metals 2005. San Francisco, CA: TMS, 2005: 475-48.

[8] ZIEGLER D P, RUAN Y M. Busbar arrangement optimization for end cells[C]//BEARNE G. Light Metals 2009. Warrendale, PA: TMS, 2009: 535-538.

[9] 周 萍, 周乃君, 梅 炽, 姜昌伟, 蔡祺风. 铝电解槽内铝液电磁搅拌流动的数值模拟[J]. 过程工程学报, 2003, 3(4): 295-301.

ZHOU Ping, ZHOU Nai-jun, MEI Chi, JIANG Chang-wei, CAI Qi-feng. Numerical simulation of electromagnetic stirring flow of metal pad in aluminum reduction cells[J]. The Chinese Journal of Process Engineering, 2003, 3(4): 295-301.

[10] 李 茂, 周孑民. 大型铝电解槽母线配置的数值仿真与优化[J]. 中南大学学报: 自然科学版, 2009, 40(3): 562-567.

LI Mao, ZHOU Jie-min. Numerical simulation and optimization of busbar configuration in large aluminum electrolysis cell[J]. Journal of Central South University: Science and Technology, 2009, 40(3): 562-567.

[11] LI Jie, LIU Wei, LAI Yan-qing, Li Qing-yu, LIU Ye-xiang. Coupled simulation of 3D electro-magneto-flow field in Hall-Heroult cells using finite element method[J]. Acta Metallurgica Sinica: English Letters, 2006, 19(2): 105-116.

[12] 刘业翔, 梁学民, 李 劼, 张红亮, 徐宇杰, 丁凤其, 邹 忠. 底部出电型铝电解槽母线结构与电磁流场仿真优化[J]. 中国有色金属学报, 2011, 21(7): 1688-1695.

LIU Ye-xiang, LIANG Xue-min, LI Jie, ZHANG Hong-liang, XU Yu-jie, DING Feng-qi, ZOU Zhong. Simulation and optimization of bus structure and electro-magneto-flow field of aluminum reduction cells with vertical bottom bars[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(7): 1688-1695.

[13] MOREAU R J, ZIEGLER D. Stability of aluminium cells-a new approach[C]//MILLER R E. Light Metals 1986. New Orleans, LA: TMS, 1986: 359-364.

[14] QI Xi-quan, L? Ding-xiong, MA Shao-xian, WANG De-quan, MAO Ji-hong. Study of current distribution in the metal pad of aluminum reduction cells[C]//BEARNE G. Light Metals 2009. Warrendale, PA: TMS, 2009: 575-580.

[15] 张艳芳, 赵庆云, 刘吉波, 柴登鹏, 唐新平, 周益文, 王跃勇. 铝电解槽阴极对水平电流影响的模拟与分析[C]//2007中国国际铝冶金技术论坛论文集. 北京: 冶金工业出版社, 2007: 540-543.

ZHANG Yan-fang, ZHAO Qing-yun, LIU Ji-bo, CHAI Deng-peng, TANG Xin-ping, ZHOU Yi-wen, WANG Yue-yong. The simulation and analysis of the affection of the cathode to the horizontal current in the aluminum reduction cell[C]// Proceedings of 2007 China International Conference on Aluminum Metallurgy. Beijing: Metallurgical Industry Press, 2007: 540-543.

[16] LI Jie, LIU Wei, LAI Yan-qing, WANG Zhi-gang, LIU Ye-xiang. Analysis of cathode voltage drop in aluminum electrolysis cells with an electric contact model[C]//SORLIE M. Light Metals 2007. Orlando, FL: TMS, 2007: 465-470.

(编辑 李艳红)