硫酸烧渣综合利用新工艺

来源期刊:中南大学学报(自然科学版)2000年第3期

论文作者:许斌 庄剑鸣 白国华 梁景晟

文章页码:215 - 218

关键词:硫酸烧渣;回收率;综合利用

Key words:pyritic salg; recovery rate; comprehensive utilizing

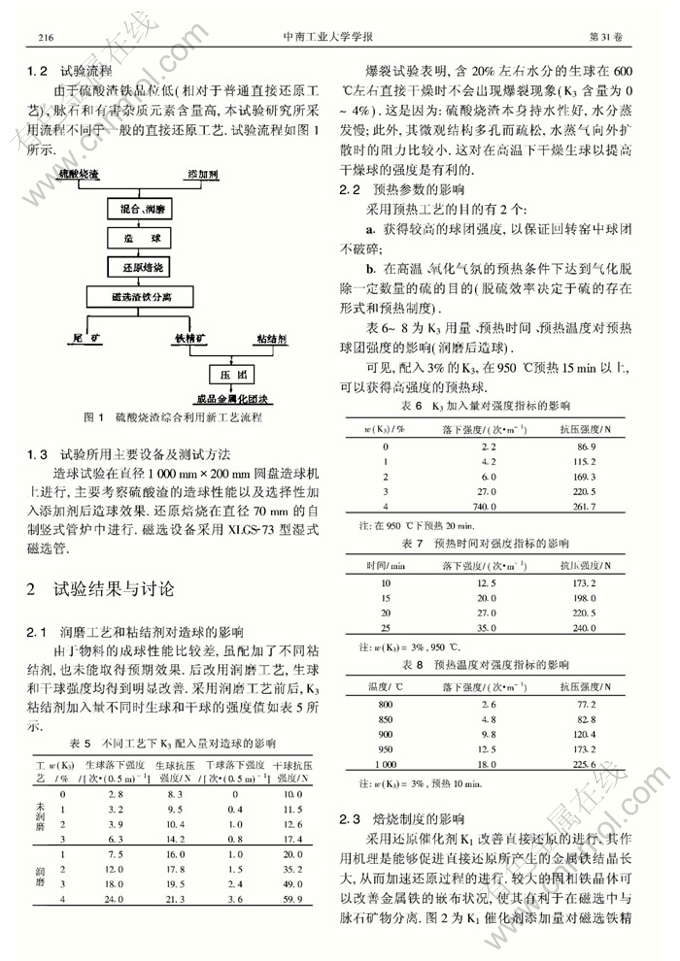

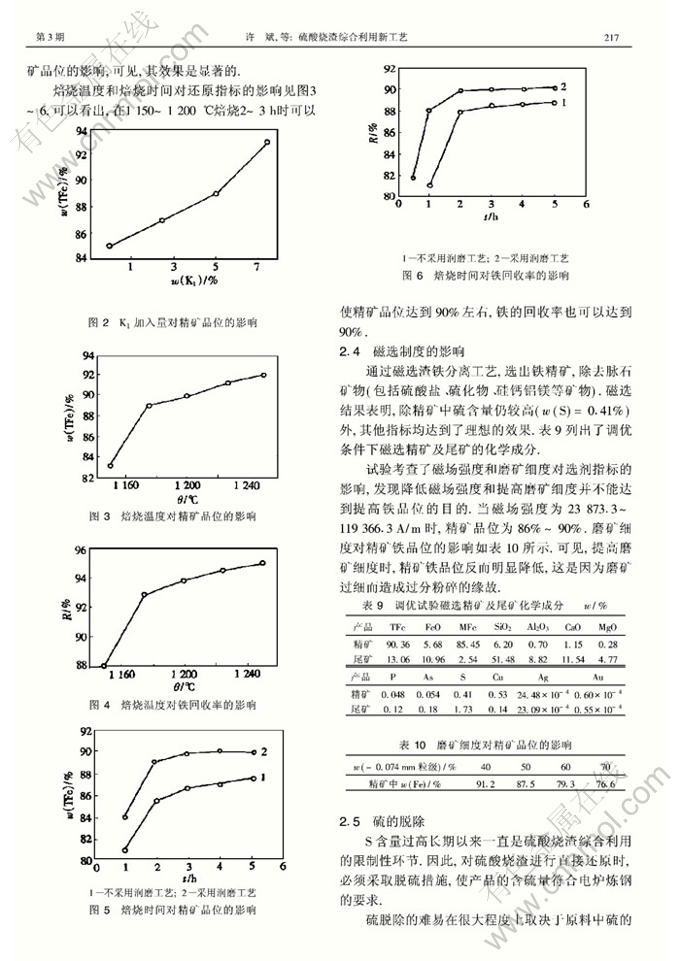

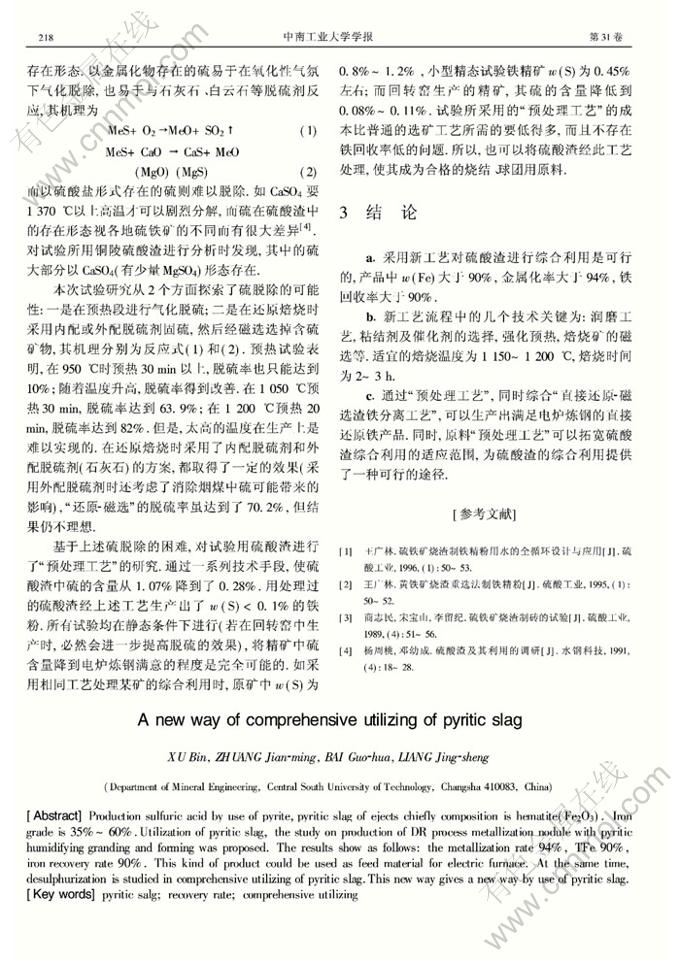

摘 要:用黄铁矿生产硫酸,排放出的硫酸烧渣的主要成分为赤铁矿(Fe2O3),铁品位一般为35%~60%.利用硫酸烧渣,进行了煤基直接还原生产金属化团块的研究,提出了润磨造球-预热焙烧-磁选-冷固结成型的新工艺流程.所得产品金属化率约为94%,含铁品位90%,铁回收率90%.直接还原铁粉冷固成型后可作电炉炼钢原料.同时,针对硫酸烧渣综合利用中的脱硫问题进行了进一步探讨.该工艺为硫酸烧渣的综合利用开辟了新的途径.

Abstract: Production sulfuric acid by use of pyrite,pyritic slag of ejects chiefly composition is hematite(Fe2O3). Iron grade is 35%~60%.Utilization of pyritic slag, the study on production of DR process metallization nodule with pyritic humidifyinggranding and forming was proposed. The results show as follows: the metallization rate 94%, TFe 90%, iron recovery rate 90%. This kind of product could be used as feed material for electric furnace. At the same time, desulphurization is studied in comprehensive utilizingof pyritic slag.This newwaygives a newway by use of pyritic slag.