AZO溅射靶材的热压制备

来源期刊:中国有色金属学报(英文版)2011年第7期

论文作者:王星明 白雪 段华英 石志霞 孙静 卢世刚 黄松涛

文章页码:1550 - 1556

关键词:AZO;溅射靶材;热压;气孔;相结构

Key words:aluminum-doped ZnO (AZO); sputter target; hot pressing; pore; phase structure

摘 要:

按质量比92:2将ZnO和Al2O3粉末采用热压方法制备AZO溅射靶材。研究温度、压力、保温和保压时间等热压工艺条件对靶材相对密度的影响,研究致密化过程中的气孔演化和相结构变化。结果表明:采用分段热压方式,即在压力35 MPa下,在温度1 050 ℃和1 150 ℃分别保温保压1 h,所制备的AZO靶材具有最大的相对密度99%。在温度为1 050 ℃时,靶材中的闭合气孔率最低;当热压温度低于900 ℃时,靶材中存在Al2O3相;当温度升高到1 000 ℃以后,Al2O3相消失,但有ZnAl2O4相生成,且ZnAl2O4相随着温度的升高而增加。与无压烧结比较,热压烧结具有烧结温度低、ZnAl2O4相含量低的优点。靶材电阻率随着热压温度的升高和保温、保压时间的延长而降低。在热压温度1 100 ℃、压力35 MPa、保温和保压时间10 h下制备了电阻率低达3×10-3 Ω·cm的AZO靶材。

Abstract:

Al-doped ZnO (AZO) target was prepared by hot pressing using ZnO and Al2O3 powder in mass ratio of 98:2. The effects of hot pressing conditions including temperature, pressure and preserving time on relative density were investigated. Pore evolution and phase structure change during densification process were studied. The results show that AZO target with super high relative density of 99% was prepared by two-stage hot pressing method under pressure of 35 MPa, temperature of 1 050 ℃ and 1 150 ℃ with preserving time of 1 h, respectively. At temperature around 1 050 ℃, the number of isolated pore was minimum. At temperature lower than 900 ℃, there existed Al2O3 phase. At temperature higher than 1 000 ℃, ZnAl2O4 phase was generated and its content was increased with temperature increasing. Hot pressing method had the advantage over pressureless sintering that the content of ZnAl2O4 was lower and sintering temperature could be also lower. With increasing the hot pressing temperature and preserving time, the electric resistivity of AZO target decreased greatly. A low resistivity of 3×10-3 Ω·cm was achieved under the temperature of 1 100 ℃, pressure of 35 MPa and preserving time of 10 h.

WANG Xing-ming, BAI Xue, DUAN Hua-ying, SHI Zhi-xia, SUN Jing, LU Shi-gang, HUANG Song-tao

General Research Institute for Nonferrous Metals, Beijing 100088, China

Received 29 March 2011; accepted 4 May 2011

Abstract: Al-doped ZnO (AZO) target was prepared by hot pressing using ZnO and Al2O3 powder in mass ratio of 98:2. The effects of hot pressing conditions including temperature, pressure and preserving time on relative density were investigated. Pore evolution and phase structure change during densification process were studied. The results show that AZO target with super high relative density of 99% was prepared by two-stage hot pressing method under pressure of 35 MPa, temperature of 1 050 °C and 1 150 °C with preserving time of 1 h, respectively. At temperature around 1 050 °C, the number of isolated pore was minimum. At temperature lower than 900 °C, there existed Al2O3 phase. At temperature higher than 1 000 °C, ZnAl2O4 phase was generated and its content was increased with temperature increasing. Hot pressing method had the advantage over pressureless sintering that the content of ZnAl2O4 was lower and sintering temperature could be also lower. With increasing the hot pressing temperature and preserving time, the electric resistivity of AZO target decreased greatly. A low resistivity of 3?10-3 W×cm was achieved under the temperature of 1 100 °C, pressure of 35 MPa and preserving time of 10 h.

Key words: aluminum-doped ZnO (AZO); sputter target; hot pressing; pore; phase structure

1 Introduction

It is well known that aluminum-doped ZnO (AZO) thin film has a high transmittance in the visible region, and a low resistivity, and its optical band gap can be controlled by Al content. AZO films have potential applications in solar cells, antistatic coatings, solid-state display devices, optical coatings, heaters, defrosters, etc [1-4]. Comparing with indium oxide, ZnO has the advantage that raw materials are cheaper and non-toxic. Particularly, AZO film is more stable. Therefore, AZO is one of the best substitutes of ITO using as transparent conductive film (TCO) [5].

AZO film can be deposited by a few methods [6-10]. Presently, magnetron sputtering was widely used because of its high deposition rate and good adhesion between film and substrate. Metallic targets were used to deposit AZO film. But it was found that the target life was limited because an oxide layer was often formed on the surface of target. So, ceramic targets were preferably used.

AZO is a kind of heavily doped n-type semiconductor material. For an AZO ceramic target, density, phase structure, pore size and its distribution, grain size and resistivity are basic properties. Recently, many researchers investigated the preparation of AZO sputter target with super high density and low resistivity [11-16]. But little attention was paid to structure change and pore evolution during the sintering. Also, when sintering process was carried out in atmosphere, increasing sintering temperature is a way to achieve high density, but simultaneously the content of second phase ZnAl2O4 will be increased, which results in bad electric property of the AZO target. High sintering temperature may bring more possibilities of abnormal grain growth. Sintering under super high pressure and sol-gel are two methods to achieve high density. Unfortunately, they are too costly to be industrialized. Comparably, hot pressing is a moderate way by which the target can be densified under moderate pressure and temperature. In addition, it is a kind of rapid densification process and the grain growth happens very slightly.

Therefore, in the present work, the AZO target is made by hot pressing method. Relative density, pore evolution, fracture morphology, phase structure change and resistivity are investigated to illustrate the preparation processes of AZO target.

2 Experimental

Commercial zinc oxide (mean particle size of about 600 nm) (Sinopharm Chemical Reagent Beijing Co., Ltd) and alumina (mean particle size of about 100 nm) (Hebei Pengda Advanced Materials Technology Co., Ltd) powders were used. Using a double shaft mixer, ZnO and Al2O3 powders in mass ratio of 98:2 were ball-mixed for 32 h in a bottle with agate balls.

The mixed powder was poured into a graphite mold. The mold was placed in the furnace of hot pressing machine. Under a certain pressure and temperature for a preserving time, AZO targets were densified with argon gas protection.

The density was measured by Archimedes method. The fracture morphology was observed using a scanning electron microscope (JSM-6510, Japan electronics). The pore size and its distribution were analyzed using a mercury intrusion porosimeter (Auto Pore IV 9510, Micromeritics Instrument, Inc.). The phase structure was analyzed using an X-ray diffractometer with a monochromated Cu Kα X-ray source(D/max 2500, Japan Electronics). The resistivity was measured by four-point probe (SDY4, Guangzhou Institute of Semiconductor Materials).

3 Results and discussion

3.1 Effects of hot pressing conditions on relative density of AZO target

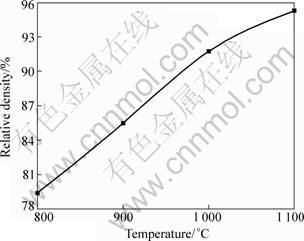

The theoretical density of AZO (2% Al2O3) is 5.56 g/cm3. Figure 1 shows the effect of temperature on the relative density of AZO target.

Fig. 1 Effect of temperature on relative density of AZO target densified at 35 MPa for 120 min

As shown in Fig. 1, with increasing the temperature from 800 °C to 1 100 °C, the relative density of AZO target increases rapidly from 79.4% to 95.2%. During sintering process, the driving forces that accelerates particles to contact with each other include van de Walls force, electrostatic force, chemical bond force and electronics force. Especially, the chemical bond force plays a major role because there are a large number of dangling bonds on the particle surface. With increasing temperature, atom diffusion is enhanced. Thus, the two surface atoms can cross the potential barrier more easily to join together by chemical bond [16]. Therefore, the effect of temperature on the relative density is very significant.

Figure 2 shows the effect of pressure on the relative density of AZO target. With increasing the pressure from 15 MPa to 35 MPa, the relative density increases from 88% to 95.2%.

Fig. 2 Effect of pressure on relative density of AZO target densified at 1 150 °C for 120 min

SHI [17] deduced a densification equation for hot pressing:

![]() (1)

(1)

where ρ is the density; t is the time; K is the ratio of the total number of pores to the number of particles; Deff is the effective diffusion coefficient; Ωa is the volume of diffusing particles; D is the average particle size; k is the Boltzmann constant; T is the thermodynamic temperature; σeff is the effective compressive stress; γs is the surface tension. There exists an equation among σeff, ρ and outer pressure pa.

![]() (2)

(2)

Eq. (2) shows that the effective compressive stress (σeff) is the function of pressure and density. When the pressure was increased from 15 MPa to 20 MPa, σeff increased. Thus, the pressure played the major role in increasing the relative density from 88% to 90.5%. When the pressure was between 20 MPa and 30 MPa, the densification rate was accelerated with increasing pressure. But in return, when the relative density was higher, the effective compressive stress would be decreased, resulting in a lower densification rate. So, the final relative density of target was slightly increased from 90.5% to 91.6%. When the pressure was higher than 30 MPa, the pressure played the major role again in increasing the relative density from 91.6% to 95.2% sharply. Therefore, the final relative density was the interaction of pressure and relative density itself. As shown in Fig. 2, with increasing the pressure, the relative density was S-shapedly increased.

Apart from temperature and pressure, the preserving time also has effect on relative density of AZO target. When densified at 1 100 °C and 35 MPa with 0.5, 1 and 2 h of preserving time, the relative densities of target achieved 92.5%, 94.6% and 95.2%, respectively. At 1 100 °C and the same pressure, even when the preserving time was increased to 10 h, there was limited increase in the final relative density which only reached 94.1%; while the sample hot pressed at 1 100 °C with preserving time of 1 h could reach 94.6%. It is concluded that the temperature played the most important role in AZO target densification. However, pressure and preserving time are also important factors to achieve high density target.

3.2 Pore evolution

In ceramic target, there are two kinds of pores, channel pores and isolated pores. According to Coble’s definition [18-19], the channel pores exist in the first and second stages, and the isolated pores are generated in the third stage. WILKINSON and ASHBY [20] studied the hot pressing sintering process and found that it can be divided into two stages: the channel pore stage and the isolated pore stage. The channel pore size and its distribution can be measured by mercury intrusion porosimeter. The isolated pore size cannot be tested directly but its volume content can be calculated from the relative density and the volume content of channel pores according to the following equation.

φRD+φC+φI=1 (3)

where φRD is the relative density of target; φC is the volume fraction of the channel pores; φI is the volume fraction of the isolated pores. Thus, from φRD and φC, φI can be derived.

In order to investigate pore evolution during densification process, the mixed powder of ZnO and Al2O3 were baked at 900 °C for 2 h so that the volatile or moisture was removed. Also, since the temperature was the most important factor, this investigation mainly focused on the effect of temperature on pore change during hot pressing densification.

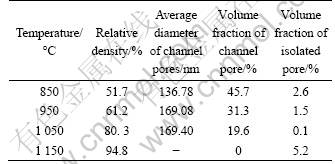

When the pressure was 18 MPa, the preserving time was 30 min, and temperatures were 850, 950, 1 050 and 1 150 °C, respectively, target specimens were hot pressed separately. φRD, φc, φI were analyzed and the results are shown in Table 1.

As shown in Table 1, with increasing the temperature from 850 °C to 1 050 °C, φRD was increased sharply from 51.7% to 80.3%, at the same time, φC decreased greatly from 45.7% to 19.6%. When the hot pressing temperature was increased to 1 150 °C, φC decreased to 0, revealing that all channel pores became isolated. As seen in Table 1, the average diameter of channel pores was increased from 136.78 nm to 169.08 nm with increasing temperature from 850 °C to 950 °C. It was shown that there is channel pore combination and growth during densification process. Actually, this kind of combination and growth is also one of the driving forces of densification. Figure 3 reveals the details of the evolution of channel pores. When temperature was 950 °C, the pore diameter was increased. Furthermore, with temperature going up, the pore size distribution was narrowed though the average diameter was not changed greatly. However, the number of channel pore decreased to 0 when temperature was 1 150 °C, which means that all channel pores became isolated.

Table 1 Pore evolution in AZO target at different temperatures by hot pressing

Fig. 3 Cumulative pore area vs pore diameter in AZO target densified at different temperatures for 30 min

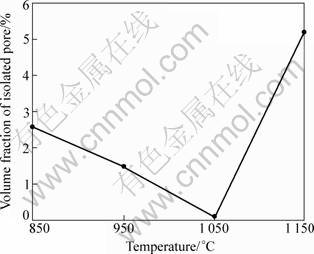

Figure 4 shows the change of isolated pores. The volume fraction is minimum at temperature of 1 050 °C. At lower temperature, some isolated pores were opened during densification, and at temperature higher than 1 050 °C, the volume fraction went up greatly. It can be seen that at temperature of 1 150 °C, the volume fraction of isolated pores was 5.2%. Possibly, it was contributed to super fast neck growth at high temperature.

Fig. 4 Volume fraction of isolated pores in AZO target vs temperature

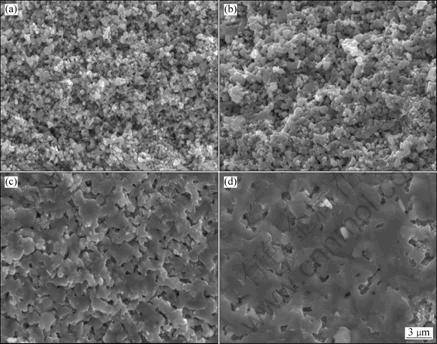

Figure 5 shows SEM images of the fracture morphology of AZO target specimens. As shown in Fig. 5, the neck growth can be clearly observed. When the temperature was 850 °C, the particles became closer, the sintering neck just began to form but no obvious neck growth happened. Pores were connected to each other. The isolated pores were not visible. In Fig. 5(b), the neck growth began and resulted in pore growth. The pores were still channel. When the temperature was increased up to 1 050 °C, further neck growth occurred. However, as shown in Fig. 4, the pores were of still channel. When the temperature was 1 150 °C, significant neck growth could be observed. At the same time, the particles became connected to each other, and the pores became isolated.

XIAO et al [11] introduced the formation of nodule while target sputtered. Low density was possible reason to result in nodules. However, the isolated pores may be another factor to bring nodules. Because the isolated pores would be exploded when plasma hit it during magnetron sputtering. Hence, it was very important to minimize the volume fraction of the isolated pores.

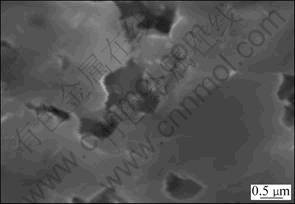

Figure 6 shows SEM image of AZO target hot pressed at 18 MPa and 1 150 °C for 2 h.

The relative density was measured to be 96% and slightly increased. Mercury intrusion porosimeter did not detect the channel pores. As shown in Fig. 6, the pores were isolated, revealing that with prolonging the preserving time, the isolated pores could not be removed efficiently.

Heating rate, density of green compact and temperature are the main factors which can result in isolated pores. As shown in Fig. 4, the volume fraction of isolated pores was minimum at the temperature of 1 050 °C. Therefore, in order to achieve higher-density target with minimized volume fraction of the isolated pores, two-stage hot pressing was carried out. In the first stage, hot pressing was made at 1 050 °C for 1 h, and then target was further hot pressed at 1 150 °C for another 1 h. Figure 7 shows SEM fracture morphology of AZO target. As shown in Fig. 7, the target was very dense. Few isolated pores could be observed. The relative density was measured to be 99%, very close to the theoretical density.

Fig. 5 SEM images of fracture morphology of AZO targets made at different temperatures and 18 MPa for 30 min: (a) 850 °C; (b) 950 °C; (c) 1 050 °C; (d) 1 150 °C

Fig. 6 SEM image of AZO target hot pressed at 18 MPa and 1 150 °C for 2 h

Fig. 7 SEM image of AZO target made by two-stage hot pressing

SUN et al [15] prepared AZO target with the relative density of 99.6% by pressureless sintering of slip casting. But the sintering temperature of 1 400 °C was much higher.

3.3 Phase structure change during hot pressing

The spinel phase content was compared between targets made by hot pressing and sintering in atmosphere at temperature of 1 100 °C. Figure 8 presents the difference in XRD patterns of AZO targets. As shown in Fig. 8(a), the main peaks were almost the same. Figure 8(b) shows the magnified profiles of ZnAl2O4 peak at 2θ=64.7°-65.6°.

During the hot pressing process of AZO target, two reactions happen. One is that Al dopant diffuses into ZnO lattice to substitute Zn, the other is that ZnO reacts with Al2O3 to form spinel phase of ZnAl2O4. The two reactions can be expressed as follows:

![]() (4)

(4)

![]() (5)

(5)

It can be seen from Fig. 8(b) that the content of spinel in hot pressed target was lower than that made by sintering in atmosphere. Actually, the sintering temperature was usually higher than 1 300 °C in pressureless sintering. So, the spinel phase content in target made by sintering in atmosphere was much higher than that in target made by hot pressing.

Figure 9 shows the phase structure evolution with temperature during hot pressing. It can be seen that at temperature lower than 900 °C, there is Al2O3 phase in target. When the temperature was 1 000 °C, the Al2O3 phase disappears but the ZnAl2O4 phase occurs. And at the temperature of 1 100 °C, the content of ZnAl2O4 phase is slightly increased.

Fig. 8 XRD patterns of AZO targets made by hot pressing and sintering in atmosphere: (a) XRD patterns; (b) Magnified profiles at 2θ=64.7°-65.6°

Fig. 9 Phase structure evolution of AZO targets made at different temperatures by hot pressing at 35 MPa for 2 h

3.4 Effects of temperature and preserving time on electric resistivity of AZO target

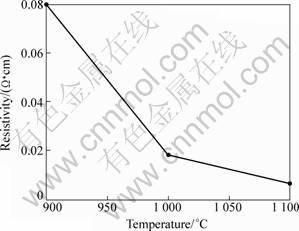

According to reaction (4), when one Al3+ replaces one Zn2+, one excess electron is generated. Thus, AZO target can be good conductor of electricity. The resistivity of AZO target depends on the amount of Zn2+ ions replaced by Al3+ ions during hot pressing. Figure 10 shows the change of resistivity of AZO target with hot pressing temperature.

Fig. 10 Effect of hot pressing temperature on resistivity of AZO at 35 MPa for 2 h

From Fig. 10, it can be seen that at temperature of 900 °C, the substitution reaction happened though there is Al2O3 phase, as shown in Fig. 9. But because the substitution reaction did not happen efficiently, the resistivity was at high level. When the hot pressing temperature was increased to 1 000 °C, the resistivity decreased sharply, from 0.08 W×cm to 0.018 W×cm. It reveals that many Zn2+ ions were replaced by Al3+ ions. However, when the temperature was increased to 1 100 °C, the resistivity went down further to 0.006 3 W×cm. It showed that many Zn2+ ions were further replaced by Al3+. Meanwhile, with the generation of more ZnAl2O4, as shown in Fig. 9, the decline trend of resistivity was slowed because ZnAl2O4 acted as the electron scattering center which lowered the mobility of electron.

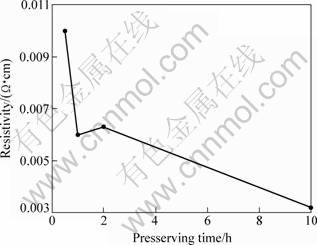

Figure 11 shows the development trend of the resistivity of AZO target with the preserving time at hot pressing temperature of 1 100 °C. Generally, the resistivity was going down with the increase of preserving time. From 0.5 h to 1 h, the resistivity was decreased from 0.01 W×cm to 0.006 W×cm quickly. During this stage, the substitution is the dominated process, which results in lower resistivity. From 1 h to 2 h, the resistivity was almost the same. Probably, during this stage, the effect of substitution reaction and generation of ZnAl2O4 is balanced. With hot pressing going on, the substitution became dominated process again which led electric resistivity go down to 3?10-3 W×cm.

Fig. 11 Effect of preserving time on resistivity of AZO target hot pressed at 1 100 °C and 35 MPa

4 Conclusions

1) With increasing the temperature, pressure and preserving time, the relative density of AZO target made by hot pressing method was increased. However, temperature was more important factor. At 1 050 °C, the volume fraction of the isolated pores was the minimum.

2) Super high density AZO target (99% of relative density) was made by two-stage hot pressing method.

3) At temperature lower than 900 °C, there was Al2O3 phase; at temperature higher than 1 000 °C, ZnAl2O4 phase was generated and its content was increased with temperature increasing.

4) Hot pressing method had the advantage over sintering in atmosphere that the content of ZnAl2O4 was lower and the sintering temperature could be lower also.

5) With increasing hot pressing temperature and preserving time, the electric resistivity of AZO target decreased greatly. A low resistivity of 3?10-3 W×cm was achieved under pressure of 35 MPa, temperature of 1 100 °C for 10 h of preserving time by hot pressing.

References

[1] WANG W W, DIAO X G, WANG Z, YANG M, WANG T M, WU Z. Preparation and characterization of high-performance direct current magnetron sputtered ZnO:Al films [J]. Thin Solid Films, 2005, 491: 54-60.

[2] DAI L P, DENG H, MAO F Y, ZANG J D. The recent advances of research on p-type ZnO thin film [J]. J Mater Sci, 2008, 19(8-9): 727-734.

[3] RUSKEA F, PFLUGA A, SITTINGERA V, WERNERA W, SZYSZKAA B, CHRISTIE D J. Reactive deposition of aluminium-doped zinc oxide thin films using high power pulsed magnetron sputtering [J]. Thin Solid Films, 2008, 516(14): 4472-4477.

[4] OH B Y, JEONG M C, MOON T H, LEE W, YOUNG J M, HWANG J Y, SEO D S. Transparent conductive Al-doped ZnO films for liquid crystal displays [J]. J Appl Phys, 2006, 99(12): 124505-4.

[5] YASUIA K, ASANOA A, OTSUJIA M, KATAGIRIB H, MASUDAC A, NISHIYAMAA H, INOUEA Y, TAKATA M, AKAHANE T. Improvement of the uniformity in electronic properties of AZO films sing an RF magnetron sputtering with a mesh grid electrode [J]. Mater Sci Eng B, 2008, 148(1-3): 26-29.

[6] LIU Jiang, ZHUANG Da-ming, ZHANG Gong, LI Chun-lei, DUAN Yu-bo. Al-doped ZnO (ZAO) films prepared by middle-frequency alternative magnetron sputtering [J]. China Surface Engineering, 2010, 23(1):15-23. (in Chinese)

[7] NATSUME Y, SAKATA H. Zinc oxide films prepared by sol-gel spin-coating [J]. Thin Solid Films, 2005, 372: 30-36.

[8] LIU Xin-yu, JIANG Min-hong, ZHOU Xiu-juan, CHEN Jun, WANG Zhong-min. RF magnetron sputtering process and photoelectric property of A1 doped ZnO films [J]. Materials Engineering, 2008(10): 215-218. (in Chinese)

[9] ZHANG Yang, FAN Shu-jing, WANG Hong-ying, LI Guo-jing, ZHAO Shu-jin. Preparation and electric properties of aluminum-doped ZnO thin films [J]. Materials Review, 2009, 23(1): 356-358. (in Chinese)

[10] LI Wei, SUN Yun, HE Qing, LIU Fang-fang, LI Feng-yan. Physical properties of ZnO: Al films by DC magnetron sputtering with facing targets [J]. Jounal of Synthetic Crystals, 2006, 35(4): 761-764. (in Chinese)

[11] XIAO Hua, WANG Hua, REN Ming-fang, XU Ji-wen. Research on the effect of solid phase sintering technology on microstructure and properties of ZAO target [J]. Journal of Functional Materials, 2006, 37(1): 36-39. (in Chinese)

[12] YANG Wei-fang, LIANG Zhan-hong, HOU Ya-qi, ZHUANG Da-ming, ZHANG Gong. Properties of zinc aluminum oxide films and its ceramic target fabrication [J]. Chinese Journal of Vacuum Science and Technology, 2008, 28(1): 59-63. (in Chinese)

[13] CHEN Zhu, ZHANG Shu-ren, DU Li-bo, SHAN Yi, YANG Cheng-ta, ZENG Ze-yu, SUN Ming-xia. Li-doped ZnO ceramic target preparation and RF magnetron sputtering ZnO films [J]. Journal of Inorganic Materials, 2006, 21(4): 1011-1017. (in Chinese)

[14] CHEN Zhu, ZHANG Shu-ren, DU Shan-yi, YANG Cheng-tao, SUN Ming-xia. The experimental investigation on preparation of Li-doped ZnO ceramic targets and sputtering thin films [J]. Journal of Functional Materials, 2006, 37(4): 583-587. (in Chinese)

[15] SUN Yi-hua, XIONG Wei-hao, LI Chen-hui. Fabrication of ultrahigh density ZnO-Al2O3 ceramic composites by slip casting [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(4): 624-631.

[16] ZHAO Da-qing, FAN Jin-peng, WU Min-sheng, DONG Min-chao. Research on sintering model of ZAO ceramics [J]. Powder Metallurgy Technology, 2002, 20(5): 267-270. (in Chinese)

[17] SHI Jian-lin. Solid state sintering (I)—Pore micro structural model and thermodynamics stability, densification equations[J]. Journal of the Chinese Ceramic Society, 1997, 25(5): 499-513. (in Chinese)

[18] COBLE R L. Sintering crystalline solids (I)—Intermediate and final state diffusion models [J]. J Appl Phys, 1961, 32: 787-792.

[19] COBLE R L. Sintering crystalline solids (Ⅱ)—Experimental test of diffusion models in powder compacts [J]. J Appl Phys, 1961, 32: 793-799.

[20] WILKINSON D S, ASHBY M F. Pressure sintering by power law creep [J]. Acta Metallurgica, 1975, 23(11): 1277-1285.

王星明,白 雪,段华英,石志霞,孙 静,卢世刚,黄松涛

北京有色金属研究总院,北京 100088

摘 要:按质量比92:2将ZnO和Al2O3粉末采用热压方法制备AZO溅射靶材。研究温度、压力、保温和保压时间等热压工艺条件对靶材相对密度的影响,研究致密化过程中的气孔演化和相结构变化。结果表明:采用分段热压方式,即在压力35 MPa下,在温度1 050 °C和1 150 °C分别保温保压1 h,所制备的AZO靶材具有最大的相对密度99%。在温度为1 050 °C时,靶材中的闭合气孔率最低;当热压温度低于900 °C时,靶材中存在Al2O3相;当温度升高到1 000 °C以后,Al2O3相消失,但有ZnAl2O4相生成,且ZnAl2O4相随着温度的升高而增加。与无压烧结比较,热压烧结具有烧结温度低、ZnAl2O4相含量低的优点。靶材电阻率随着热压温度的升高和保温、保压时间的延长而降低。在热压温度1 100 °C、压力35 MPa、保温和保压时间10 h下制备了电阻率低达3×10-3 Ω?cm的AZO靶材。

关键词:AZO;溅射靶材;热压;气孔;相结构 (Edited by YANG Hua)

Foundation item: Project (31001) supported by the Technology Development Foundation of Ministry of Science and Technology, China

Corresponding author: WANG Xing-ming; Tel: +86-10-82241320; E-mail: wxm@grinm.com

DOI: 10.1016/S1003-6326(11)60895-9