文章编号: 1004-0609(2005)07-1124-07

低相变温度宽相变滞后的Cu-Al-Mn-Nb形状记忆合金

董桂霞1, 2, 谷南驹3, 马晓丽3

(1. 北京有色金属研究总院 能源材料与技术研究中心, 北京 100088; 2. 天津理工大学 材料科学与工程学院, 天津 300191; 3. 河北工业大学 材料科学与工程学院, 天津 300132)

摘要: 通过恰当的成分设计, 获得了具有较低马氏体相变温度及较宽相变滞后的Cu-Al-Mn-Nb形状记忆合金。 用差热分析法(DSC)测得Cu-26.8Al-4.8Mn-1.0Nb(摩尔分数, %)合金在降温时马氏体相变最激烈的温度为-32℃; 升温时奥氏体相变最激烈时的温度为68℃; 相变滞后宽度达100℃。 透射电镜、 扫描电镜及X射线衍射分析表明, 该合金的马氏体为2H型结构, 宽滞后效应是由于合金进行马氏体相变时析出了点状富铌颗粒从而松驰掉一部分弹性应变能而产生的。 该合金在表面应变为4%时, 弯曲变形试样的形状回复率达93%以上, 在室温下时效2个月后, 其形状回复率没有发生明显恶化。 室温下其抗拉强度约为550MPa, 屈服强度约为380MPa, 塑性延伸率约为7%。

关键词: Cu-Al-Mn-Nb; 形状记忆合金; 相变滞后; 记忆效应; 力学性能 中图分类号: TB331

文献标识码: A

Cu-Al-Nb shape memory alloys with low phase transformation temperature and broad hysteresis

DONG Gui-xia1, 2, GU Nan-ju3, MA Xiao-li3

(1. Research Center of Energy Materials and Technology, Beijing General Research Institute for Nonferrous Metals, Beijing 10088, China;

2. School of Materials Science and Engineering, Tianjin University of Technology, Tianjin 300191, China;

3. School of Materials Science and Engineering, Hebei University of Technology, Tianjin 300132, China)

Abstract: Cu-Al-Mn-Nb shape memory alloy with broad hysteresis and low martensitic transformation temperature can be obtained by properly designing on its composition. Differential scanning calorimetry (DSC) analyses show that the tM* of the alloy is about -32℃, tA* is about 68℃, and the hysteresis range is about 100℃. Transmitted electronic microscopy (TEM), scanning electronic microscopy (SEM) and X-ray diffractrometry (XRD) analyses indicate that the martensite in the alloy is characterized by 2H-type texture, and its broad hysteresis effect is likely a result of Nb-rich grains separated out during the martensitic transformation, which would have relaxed some elastic strain energy. The alloy has favorable mechanical properties and shape memory effect, with tensile strength of about 250MPa, the yield stress of about 380MPa, the plastic elongation of about 7%, and the shape recovery rate over 93% after bending deformation at surface strain of 4%. Aging at room temperature for 2 months the shape recovery rate of the alloy has not evidently deteriorated.

Key words: Cu-Al-Mn-Nb; shape memory alloy; phase transformation hysteresis; shape memory effect; mechanical properties

近年来Cu-Al-Mn形状记忆合金引起了人们的极大关注[1-3]。 形状记忆合金的一个重要用途是作为连接件, 如管接头、 铆钉等。 实用上要求其有宽的相变滞后(>90K), 以便连接件在低温扩孔或变形后, 可以在室温储存, 使用时再加热到奥氏体相变终了温度(TAf)以上时, 即可达到牢固连接的目的[4]。 因此, 宽滞后效应引起众多研究者的兴趣[5]。 一般来说, 马氏体相变起始温度(TMs)高的Cu基合金易得到较宽的相变滞后。 根据SC-SRO理论[6], 当TMs/Tm(Tm为合金的熔点)比值较高时合金在瞬间即产生了马氏体时效效应, 即刚淬火后的马氏体已经出现了稳定化现象, 因此使合金的逆相变温度升高, 相变滞后增大。 如具有较高马氏体相变温度的Cu-13.5Al-2.5Mn-1.36Zn(质量分数%)[7]、 Cu-Al-Nb[8]、 Cu-Al-Ag及Ni60Al19Mn16-Fe5[9]合金等。 这种宽滞后的形状记忆合金由于Ms过高, 虽然可在室温下扩孔及储存, 如果作为常温下的连接件使用, 使用温度处于马氏体单相区, 也就是说当合金受力作用时, 其中已经存在热诱发马氏体。 那么, 在极小力的作用下就会引起马氏体变体的再取向(马氏体内部孪晶界运动), 从而不经弹性区(单晶)[10]或经过很小的弹性变形(多晶)就产生了宏观上的塑性变形, 合金的屈服强度极低, 而合金所能产生的最大回复力正是合金的屈服强度, 这样连接件之间就不可能产生牢固的连接。 因此, 合金的TMs最好能比使用温度低40K以上, TAs最好比室温高40K以上, 合金在室温处于奥氏体相区, 具有较高的屈服强度。 因此, 研究低相变温度、 宽相变滞后的形状记忆合金具有重要意义。

目前, 关于合金在淬火态不经其它处理、 在较低相变温度及较好形状记忆效应的前提下获得较宽相变滞后方面的研究很少。 电子辐照[11]及时效[12]均可使铜基形状记忆合金的相变滞后略有增加, 但常会导致马氏体或母相分解。 此外, 随着合金在马氏体态变形量的增大其相变滞后也会明显增大, 如Wang等[13]把铸态(经冷、 热轧后)Cu-10.2Al- 4.9Mn-4.6Zn-0.3Zr合金(TMs=308K, 相变滞后为40K)深冷后得到马氏体, 然后在室温(TMs以下)使其变形, 发现随着变形量的增加, 相变滞后增大 (可达90K以上)。 但与此同时, 合金中可逆相变的马氏体量减少, 形状记忆效应恶化。

1实验

选择纯度为99.95%的电解铜、 99.93%的L01高纯Al、 99.9%电解锰及99.9%Nb作为原材料。 用电弧炉快速熔炼Cu-Mn-Nb三元中间合金, 再用适量的铜和铝在氩气保护下的感应电炉内稀释上述中间合金, 得到所需成分的合金。

试样在氩气保护下进行900℃, 10h扩散退火, 然后进行热轧和温轧。 热轧最高温度为800℃, 最大变形量为50%; 温轧最高温度为500℃, 最大变形量为15%, 得到长方体试样母材。 此后, 不同实验所需要试样均从母材上切取。

热处理工艺主要为室温水冷及液氮深冷。 把试样在电阻炉内加热到850℃(氩气保护), 保温10~15min, 然后用室温水冷或把试样放在装有液氮的保温瓶中, 根据试样与液面之间的距离, 在室温~-196℃范围内深冷。

用DSC204差式扫描量热仪来测量合金的相变点。 在本实验中, 试样的质量为60~70g, 升降温速度均为10℃/min, 升降温温度范围为-200~200℃。

在PHILIPS XL30扫描电镜(SEM)上观察试样微观形貌, 腐蚀液为三氯化铁(5%~ 8%, 质量分数, 下同)+盐酸(1%~5%)+酒精(余量)。 用于X射线衍射分析的粉末是用手工钢锉从块状试样上锉下, 然后用磁铁选出混入粉末中的铁基合金, 放到D/max-2500X射线衍射仪上进行结构测试, 铜靶、 最大工作电压为40kV, 最大工作电流为40mA。 用于TEM分析的薄膜试样的制备过程是: 把试样用手工磨到0.1 mm以下, 在专用冲床上冲出直径为3 mm的圆片, 放到Gatan机械减薄仪上进行挖坑, 最后在Gatan离子减薄仪上减薄到所需的厚度。 制备好的试样在TEKNA1200型透射电子显微镜上进行结构分析。

用WE-300型液压式万能实验机测试合金的力学性能。

2实验结果

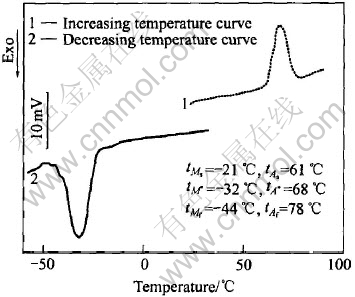

图1所示为室温水冷后Cu-26.8Al-4.8Mn-1.0Nb合金的差热曲线, 由此曲线可知合金逆相变的开始温度tAs=61℃; 逆相变最激烈的温度tA*=68℃; 逆相变终了温度tAf=78℃。 正相变开始温度tMs=-21℃; 正相变最激烈的温度tM*= -32℃; 逆相变终了温度tMf=-44℃。

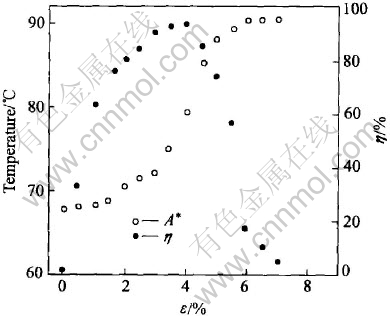

图2所示为试样进行液氮深冷(为了获得马氏体)之后, 在室温下弯曲变形, 用差热分析方法测得逆相变

温度与表面应变 , 其中

, 其中

图1 水冷Cu-26.8Al-4.8Mn-1.0Nb 合金的DSC曲线

Fig.1 DSC curves of Cu-26.8Al-4.8Mn-1.0Nballoys by water-cooling

图2 液氮深冷后Cu-26.8Al-4.8Mn-1.0Nb合金的逆相变温度及形状恢复率与变形量之间的关系

Fig.2 Relation among shape deformation capacity, reverse transformation temperature and shape recovery rate diagram for Cu-26.8Al-4.8Mn-1.0Nb alloy under liquid nitrogen-cooling conditions

d和R分别为试样的厚度和弯曲后的曲率半径)之间的关系。 可见, 当ε≤6%时, 试样的逆相变温度随着ε的增大而升高; 当ε在6%~7%之间时, 逆相变温度达到极大值; 当ε>7%时, 在差热曲线上观察不到逆相变时的吸热峰。 与此同时, 测得试样的形状恢复率η(设试样在马氏体态变形后的曲率半径为R1, 加热到奥氏体态后的曲率半径为R2, 则试样的形状回复率 与ε之间的关系亦如图2所示。

与ε之间的关系亦如图2所示。

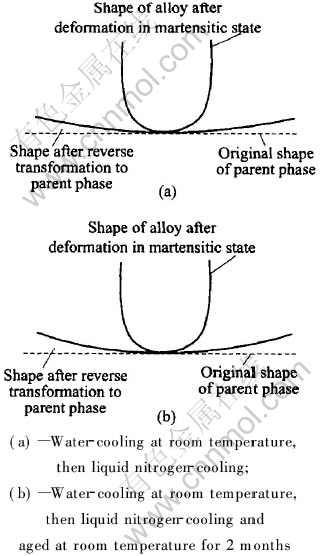

图3(a)和(b)所示分别为液氮深冷及液氮深冷之后再在室温下放置2个月, 试样的形状记忆效应测试结果。 由图3可知, 未经时效处理的弯曲变形试样的形状回复率达93%以上。 室温时效2个月, 其形状回复率仍在91%以上, 没有明显恶化。

图3 合金的形状记忆效应测试结果

Fig.3 Sketches of shape memory effect of alloy by different treatments

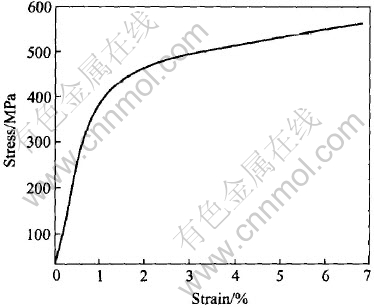

Cu-26.8Al-4.8Mn-1.0Nb合金经奥氏体化后的薄片状拉伸试样的应力—应变曲线如图4所示, 根据图4所示的实验结果可知: σb≈550MPa, σ0.2≈380MPa, δ≈7%。

图4 Cu-26.8Al-4.8Mn-1.0Nb合金的应力—应变曲线

Fig.4 Stress-strain curve of Cu-26.8Al-4.8Mn-1.0Nb alloy

3分析与讨论

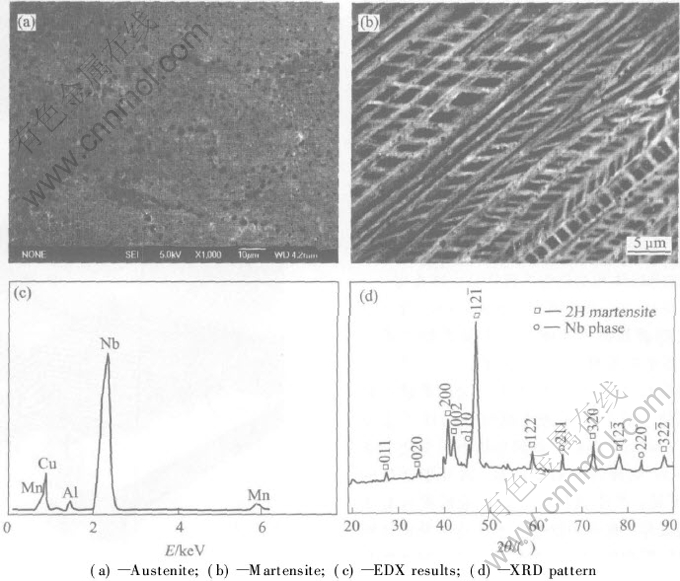

图5(a)及(b)所示分别为室温下Cu-26.8Al-4.8Mn-1.0Nb合金处于奥氏体(室温水冷)和马氏体状态(液氮深冷)的扫描电镜分析结果, 图5(c)所示为对图5(a)中点状相进行扫描电镜能谱分析(EDS)的结果。 图5(d)所示为与图5(b)取自同一试样的X射线衍射(XRD)分析结果。 可见, Cu-26.8Al-4.8Mn-1.0Nb合金中有富Nb相存在, 对图5(a)中多个点状析出相进行能谱分析, 测得Nb含量为79% ~ 91%。 这些析出相不但使合金的逆相变温度升高, 而且由图5(a)还可以发现, 析出相在奥氏体晶界处聚集, 阻碍了晶粒的长大, 从而细化晶粒。 而晶粒内部析出相又可对奥氏体产生弥散强化[14], 因此使合金具有良好的力学性能。

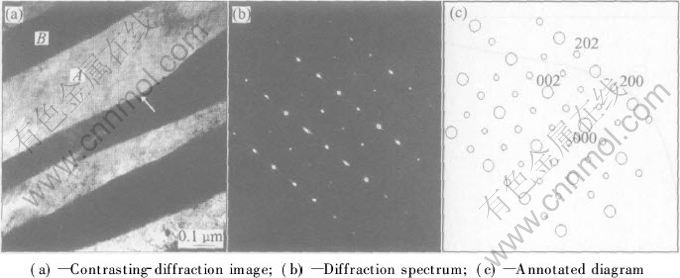

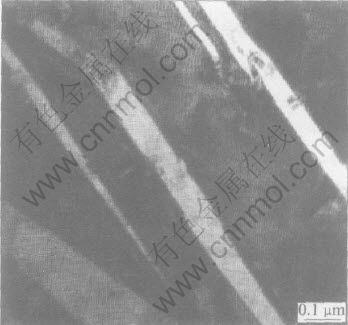

图6(a)所示为Cu-26.8Al-4.8Mn-1.0Nb合金的TEM像, 图6(b)及(c)所示分别为与图6(a)中A处相对应的电子衍射谱及其标注结果。 用于透射电镜分析试样的处理工艺与图5(b)试样的处理工艺相同。 根据衍射谱标注结果可知, 图6(a)中的马氏体为2H马氏体, 其中变体A和B呈孪晶关系。 2H马氏体的孪晶面一般为{1, 1, 1}2H或{1, 2, 1}2H[15]。 另外, 图6(a)中箭头所指的界面已经不再平直, 变为弧形, 这可能是马氏体相变时为了减小应变能, 马氏体变体间除了以孪晶关系进行自协作外, 还发生了“塑性协调”。 Cu-26.9%Al-2.5%Mn-1.3%Zn(摩尔分数)合金的马氏体相变也有类似现象发生[16], 且该合金也具有较宽的相变滞后。 这可能是因为马氏体相变时的“塑性协调”松驰了储存于其中的部分弹性应变能, 使得合金的逆相变温度升高, 相变滞后增大。

图5 Cu-26.8Al-4.8Mn-1.0Nb合金的SEM像和X射线衍射谱

Fig.5 SEM images and XRD patterns of Cu-26.8Al-4.8Mn-1.0Nb alloy

图6 Cu-26.8Al-4.8Mn-1.0Nb合金的透射电镜分析结果

Fig.6 TEM analyses of Cu-26.8Al-4.8Mn-1.0Nb alloy

常见的铜基合金, 如Cu-Zn-Al、 Cu-Al-Ni及Cu-Al-Mn合金的马氏体相变均为热弹性马氏体相变[17-20]。 热弹性马氏体相变的判据为[21]: 1) 临界相变驱动力小、 热滞小(一般在10~30℃左右); 2) 相界面能作往复(正、 逆)迁动; 3)形状应变为弹性协作。 具有热弹性马氏体相变的合金相变滞后小, 是因为马氏体内的弹性储存能对逆相变驱动力做出贡献, 使逆相变较容易发生。 由图1可知, 本文所研究的Cu-26.8Al-4.8Mn-1.0Nb合金的相变滞后达100℃以上, 其中部分原因在于合金中含有1%Nb。 众所周知, Nb在Cu基合金中的溶解度很小, 约0.12%左右[8], 因此多余的Nb将以富Nb沉淀相的形式析出, 松驰掉一部分马氏体逆相变时的弹性驱动力, 从而使合金的逆相变温度升高, 相变滞后增大。 但由图2可知Cu-26.8Al-4.8Mn-1.0Nb具有良好的形状记忆效应, 即其母相与马氏体相之间的相界面能进行可逆迁动, 且其形状应变为弹性协作。 因此, 此合金的马氏体相变仍为热弹性马氏体相变。

由图2可知, Cu-26.8Al-4.8Mn-1.0Nb合金的逆相变温度随着其在马氏体态变形量的增大而升高, 相变滞后也跟着升高。 当变形量ε达6%时, 合金的相变滞后可达130℃, 但此时合金的形状记忆效应明显恶化。 图7所示为将试样在马氏体态变形, 变形量ε=6%, 然后加热到形状不再变化为止(100℃左右), 试样再冷却到室温, 其变形部位的TEM像。 可见, 其中仍存在一定数量的没有发生逆相变的马氏体, 有很多位错堆积在这些马氏体周围, 使它难以发生逆相变。 因此, 使合金的可恢复形变减少, 记忆效应恶化。

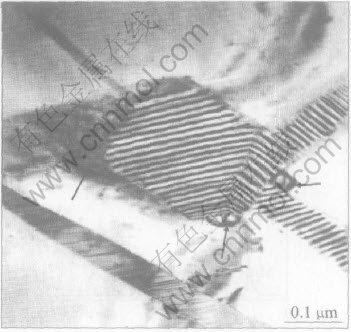

图8所示为水冷+液氮深冷后, 未变形试样的透射电镜像。 从中可以观察到析出相与马氏体之间的相互作用, 可见, 镶嵌在马氏体片周围的小析出相粒子(如箭头所指)与马氏体之间的交界面是形成不同取向马氏体细片的极佳位置, 可能正是由于析出粒子与马氏体相之间的这种作用, 才使合金具有如图2所示的较好形状记忆效应[8]。

图7 合金的透射电镜像

Fig.7 TEM image of alloy at ε=6%

图8 水冷+液氮深冷后合金的透射电镜像

Fig.8 TEM image of alloy after water-cooling and liquid nitrogen-cooling

4结论

1) 水冷+液氮深冷处理后的Cu-26.8Al-4.8Mn-1.0Nb合金具有较低的马氏体相变温度(tMs=-32℃)及较宽的相变滞后(tA*-tM*=100℃)。 当对其在马氏体态进行变形时, 随着变形量的增大, 相变滞后增大, 当变形量达6%时, 相变滞后达到最大值, 约为130℃, 但此时合金的形状记忆效应明显恶化。

2) 合金经水冷+深冷处理后具有较好的形状记忆效应, 当表面应变为4%时, 弯曲试样的形状回复率达93%以上, 室温时效2个月后, 合金的形状记忆效应没有明显恶化。

3) 室温下, 处于奥氏体状态的Cu-26.8Al-4.8Mn-1.0Nb合金具有较好的力学性能: 抗拉强度约为550MPa, 屈服强度约为380MPa, 塑性延伸率约为7%。

REFERENCES

[1]Kokorin V V, Kozlova L E, Titenko A N. Temperature hysteresis of martensite transformation in aging Cu-Al-Mn alloy[J]. Scripta Materialia, 2002, 47: 499-503.

[2]Wang R H, Gui J N, Chen X M, et al. EBSD and TEM study of self-accommodating martensites in Cu75.7Al15.4Mn8.9 shape memory alloy[J]. Acta Materialia, 2002, 50: 1835-1839.

[3]Sutou Y, Omori T, Wang J J, et al. Characteristics of Cu-Al-Mn-based shape memory alloys and their applications[J]. Mater Sci Eng A, 2004, A25: 278-282.

[4]徐祖耀, 江伯鸿, 杨大智, 等. 形状记忆材料[M]. 上海: 上海交通大学出版社, 2000. 178-179.

XU Zu-yao, JIANG Bo-hong, YANG Da-zhi, et al. Shape Memory Materials[M]. Shanghai: Shanghai Jiaotong University Press, 2000. 178-179.

[5]千东范, 高宝东, 刘雅秀. 宽滞后形状记忆合金的研制[J]. 材料工程, 1995, 12: 17-20.

QIAN Dong-fan, GAO Bao-dong, LIU Ya-xiu. The developing of shape memory alloys with broad hysteresis of phase transformation[J]. Materials Engineering, 1995, 12: 17-20.

[6]Otsuka K, Ren XB. Mechanism of martensite aging effects and new aspects[J]. Mater Sci Eng A, 2001, A312: 207-218.

[7]董桂霞, 谷南驹, 孙永昌. 高温宽相变滞后Cu-Al-Mn形状记忆合金的研究[J]. 材料热处理学报, 2004, 24(4): 17-21.

DONG Gui-xia, GU Nan-ju, SUN Yong-chang. Cu- Al- Mn shape memory alloys with high temperature and broad hysteresis of phase transformation[J]. Transactions Of Materials And Heat Treatment, 2004, 24(4): 17-21.

[8]Morawiec H, Leltko J, Koval Y, et al. High-temperature Cu-Al-Nb shape memory alloys[J]. Materials Science Forum, 2000, 327-328: 291-294.

[9]贺志荣, 王永善, 周敬恩. NiAlMnFe高温形状记忆合金的马氏体相变行为[J]. 中国有色金属学报, 2003, 13(4): 840-845.

HE Zhi-rong, WANG Yong-shan, ZHOU Jing-en. Martensitic transformation behaviors of NiAlMnFe high temperature shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 840-845.

[10]Otsuka K, Wayman C M, Nakai K, et al. Superelasticity effects and stress-induced martensitic transformations in Cu-Al-Ni alloys[J]. Acta Metallurgica, 1976, 24(3): 207-226.

[11]刘丽娟, 祖小涛, 沈保罗, 等. 电子辐照对CuZnAl形状记忆合金相变温度的影响[J]. 中国有色金属学报, 2001, 11(2): 164-166.

LIU Li-juan, ZU Xiao-tao, SHEN Bao-luo, et al. Effect of electron irradiation on transition temperature of CuZnAl shape memory alloys[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 164-166.

[12]汪明朴, 金展鹏, 尹志民, 等. B1相非等温时效对Cu-Al-Ni-Mn-Ti合金热弹性马氏体相变的影响[J]. 中国有色金属学报, 1996, 6(2): 73-77.

WANG Ming-pu, JIN Zhan-peng, YIN Zhi-min, et al. Effect of non-isothermal B1-phase aging on thermo-elastic martensite transformation of Cu-Al-Ni-Mn-Ti alloy[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(2): 73-77.

[13]Wang M P, Yin Z M, Sun X H, et al. Wide transformation hysteresis effect in Cu-10.2Al- 4.9Mn-4.6Zn-0.3Zr alloy[A]. Shape Memory Materials94, Proc of the International Symposium on Shape Memory Materials[C]. Beijing: International Academic Press, 1994. 412-417.

[14]Zhao L C, Duerig T W, Justi S, et al. The study of niobium-rich precipitates in a Ni-Ti-Nb shape memory alloy[J]. Scripta Metallurgica et Materialia, 1990, 24(2): 221-225.

[15]Saburi T, Wayman C M. Crystallographic Similarities in Shape Memory Martensites[J]. Acta Metalluraica, 1979, 27: 979-995.

[16]董桂霞. 铜基合金的相变及记忆特性的研究[D]. 天津: 河北工业大学, 2004.

DONG Gui-xia. Martensitic Transformation and Shape Memory Property of Cu-based Alloys[D]. Tianjin: Hebei University of Technology, 2004.

[17]Li J C, Ansell G S. The effect of thermal cycling on the thermoelastic martensitic transformation in a Cu-Zn-Al alloy[J]. Metallurgical Transactions A, 1983, 14A: 1293-1297.

[18]Otsuka K, Shimisu K. Memory effect and thermoelastic martensite transformation in Cu-Al-Ni alloy[J]. Scrip Metall, 1970, 4: 469-472.

[19]Kainuma R, Takahashi S, Ishida K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys[J]. Metall Mater Trans A, 1996, 27A: 2187-2195.

[20]芦笙, 林萍华, 陈静. 组织及相结构对Cu2Al2-Be2B形状记忆合金阻尼与力学性能的影响[J]. 中国有色金属学报, 2002, 12(6): 1123-1129.

LU Sheng, LIN Ping-hua, CHEN Jing. Effects of microstructure and phase structure on damping and mechanical properties of Cu2Al2Be2B shape memory alloys[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1123-1129.

[21]徐祖耀. 马氏体相变的分类[J]. 金属学报, 1997, 33(1): 45-53.

XU Zu-yao. The classifying of martensitic transformation[J]. Acta Metallurgica Sinica, 1997, 33(1): 45-53.

基金项目: 国家攀登计划特别支持资助项目(1999[045])

收稿日期: 2004-09-10; 修订日期: 2005-04-29

作者简介: 董桂霞(1966-), 女, 博士.

通讯作者: 董桂霞, 博士; 电话: 010-82241241; 传真: 010-82241239; E-mail: dgxdgx01@163.com

(编辑 龙怀中)