Trans. Nonferrous Met. Soc. China 24(2014) 2320-2325

Effect of heat treatment on stress corrosion cracking, fracture toughness and strength of 7085 aluminum alloy

Song-yi CHEN1,2, Kang-hua CHEN2, Peng-xuan DONG2, Sheng-ping YE2, Lan-ping HUANG2

1. Institute of Light Alloy, Central South University, Changsha 410083, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 17 October 2013; accepted 30 April 2014

Abstract: The influences of heat treatment on stress corrosion cracking (SCC), fracture toughness and strength of 7085 aluminum alloy were investigated by slow strain rate testing, Kahn tear testing combined with scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The results show that the fracture toughness of T74 overaging is increased by 22.9% at the expense of 13.6% strength, and retrogression and reaging (RRA) enhances fracture toughness 14.2% without reducing the strength compared with T6 temper. The fracture toughness of dual-retrogression and reaging (DRRA) is equivalent to that of T74 with an increased strength of 14.6%. The SCC resistance increases in the order: T6<RRA<DRRA≈T74. The differences fracture toughness SCC were explained on basis the of matrix precipitates and grain boundary precipitates.

Key words: 7085 aluminum alloy; heat treatment; stress corrosion cracking; fracture toughness

1 Introduction

Al-Zn-Mg-Cu alloys have been widely used as structural material in aerospace due to their low density, excellent stress corrosion resistance and fracture toughness [1]. The combinations of high strength, well stress corrosion cracking (SCC) resistance and fracture toughness are contradictory, and it is significantly influenced by composition and heat treatment [2-8]. For example, high content of Cu increases SCC resistance with the decrease of fracture toughness [2], Zn and Mg increase the strength while decrease the corrosion resistance, T7x over-aged temper increases SCC resistance at the expense of strength [8].

Varieties of aging heat treatment are put forward to improve SCC resistance and fracture toughness. Retrogression and reaging (RRA) increases SCC resistance and fracture toughness without decreasing the strength [6,9]. The repetitive-RRA improves SCC resistance with similar strength compared to RRA temper [10]. However, these reports in the references are mainly focused on AA7075 and AA7050, or without considering the relationship among strength, fracture toughness and SCC [11-16]. AA7085 has been developed as the new generation of high-strength thick plate with slow quench sensitivity [17,18]. The superiority may be ascribed to the relatively high zinc coupled with low content of copper and magnesium in comparison with the other Al-Zn-Mg-Cu alloys [6,13,15]. Although some works have been done for AA7085 [19-21], especially the strength and electrochemical properties of AA7085 under different heat treatments, there is little information available in the references about the relationship among SCC, fracture toughness and strength of AA7085. The purpose of this work is to investigate the effect of heat treatment on SCC, fracture toughness and strength of AA7085.

2 Experimental

The present study was carried out on thick hot forged AA7085 plate with chemical composition of Al-7.5Zn-1.6Mg-1.5Cu-0.12Zr-0.06Fe-0.02Si (mass fraction, %). Heat treatment procedures are listed in Table 1.

The SCC susceptibility was evaluated using the slow strain rate test (SSRT) and tested at a strain rate of 3.3×10-7s-1 in air and in 3% NaCl (mass fraction)+0.5% H2O2 (volume fraction) aqueous solution, respectively. Rectangular tensile specimens with a gauge length of 30 mm and a width of 6 mm were used. The susceptibility to SCC was calculated by the ratio of loss of elongation (LE). The expression was defined as follows: ISSRT= ICorr/IAir, where ICorr is the elongation in air, IAir is the elongation in corrosion solution. Fracture toughness tests were carried out in longitudinal-transverse according to Kahn method. The test was done by pulling a notched thin specimen (2.54 mm in thickness) at constant speed, with no prior fatigue crack initiation, but a tip radius lower than 0.025 mm. The notch resistance was characterized by the unit initiation energy (UIE). Mechanical properties test was performed on smooth plate specimens by an Instron 3369 testing machine at room temperature with tensile speed of 2 mm/min. The gauge length and width of the specimen were 25 mm and 6 mm, respectively.

Microstructures were studied by TEM (JEOL- 2100F) operated at 200 kV. Thin foils for TEM were prepared by mechanical polishing to 100 μm and final twin-jet electro polishing in the solution of 25% HNO3+75% CH3OH (volume fraction) at -25 °C.

Table 1 Heat treatment procedures used for 7085 aluminum alloy

3 Results

3.1 Effects of heat treatment on SCC

Figure 1 shows the results of slow strain rate testing in atmosphere and in 3% NaCl + 0.5% H2O2 under different heat treatments. It is found that both tensile strength and elongation of the samples in the 3% NaCl + 0.5% H2O2 solution are lower than those in atmosphere, indicating the alloy has the SCC susceptibility.

In order to understand the relationship between heat treatment and SCC better, ISSRT is an efficient method to evaluate the SCC resistance of aluminum alloy [22]. The higher the ISSRT is, the better the SCC resistance is. Figure 2 shows the ISSRT under different heat treatments. It shows that the ISSRT increases in the order: T6<RRA<DRRA≈T74. The SCC the of and In other words, shows highest susceptibility. resistance DRRA temper higher than T6 RRA, while it is similar to that T74.

Fig. 1 SSRT curves of AA7085 under different heat treatment

Fig. 2 ISSRT of AA7085 under different heat treatments

3.2 Effects of heat treatment on fracture toughness

Figure 3 shows the fracture toughness of AA7085 under different heat treatments. For T6 temper samples, the unit initiation energy (UIE) is 148 N/mm. Compared with the T6 temper, the fracture toughness of RRA and T74 temper are increased by 14.2% and 22.9%, respectively. The fracture toughness of DRRA temper specimen is higher than that of T6 and RRA specimen, which is increased by 24.3% and 8.9%, respectively. Meanwhile, the fracture toughness of DRRA specimen is similar to that of T74 specimen.

Fig. 3 Fracture toughness of AA7085 under different heat treatments

The fracture morphologies of AA7085 under different heat treatments are shown in Fig. 4. The fracture surfaces are characterized by large dimples, and the fracture mode is combined with transgranular and intergranular failure for T6 temper specimen (Fig. 4(a)). The fracture surfaces of the T74 temper samples are different from those of T6 temper samples. The size of dimples and the amount of intergranular failure obviously decrease. The fracture mode is high energy transgranular failure with small dimples (Fig. 4(b)). However, for the RRA temper samples, they also exhibit some amount of intergranular fracture, and the fracture mode is predominantly transgranular with occasional intergranular failure along grain boundaries (Fig. 4(d)). The fracture morphology of the DRRA temper is similar to that of the RRA temper (Fig. 4(d)).

3.3 Effects of heat treatment on strength

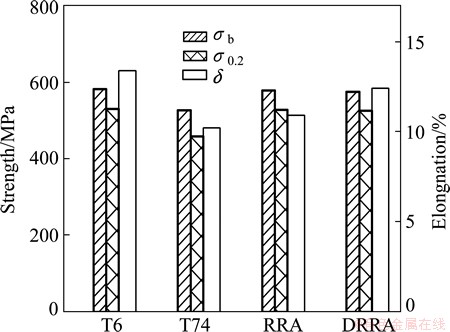

Figure 5 shows the mechanical properties of AA7085 under different heat treatments. For the T6 temper, the ultimate tensile strength (UTS) and yield strength (YS) are 582 MPa and 530 MPa, respectively. Compared with the T6 temper, the UTS and YS of the T74 temper specimen are decreased by 9.6% and 13.6%, respectively. The UTS and YS of the RRA temper specimen are 578 MPa and 528 MPa, respectively, which are slightly lower than those of T6 temper specimen, but significantly higher than those of T74 temper specimen. The UTS and YS of DRRA temper specimen are similar to those of the RRA temper specimen, but higher than those of the T74 temper specimen, which are increased by 9.3% and 14.6%, respectively.

Fig. 4 Fracture morphologies of AA7085 under different heat treatments

Fig. 5 Tensile properties of AA7085 under different heat treatments [21]

4 Discussion

The major microstructural evolution during aging heat treatment of Al-Zn-Mg-Cu alloy is associated with the size, distribution and the content of matrix precipitates and grain boundary precipitates (GBPs). Figure 6 shows the TEM images of the alloy under different heat treatments. At T6 temper, high density precipitates are distributed homogeneously within matrix, and GBPs are small and continuously distributed (Figs. 6(a) and (b)). Compared to T6 temper, the size of precipitates within the matrix increases remarkably (size of 16-27 nm), GPBs are coarser and more sparsely distributed in the T74 temper sample (size of 40-65 nm, interparticle spacing of 30-70 nm) (Figs. 6(c) and (d)). At the RRA temper, fine precipitates are distributed homogeneously within matrix (size of 5-9 nm) and relatively coarser precipitates distributed discontinuously on grain boundaries (size of 20-30 nm, interparticle spacing of 20-45 nm) (Figs. 6(e) and (f)). Precipitates within the matrix are similar to RRA temper (size of 6-10 nm) while GBPs become more discrete and coarser (size of 30-40 nm, interparticle spacing of 25-50 nm) in the DRRA temper sample (Figs. 6(g) and (h)).

Fig. 6 TEM images of AA7085 under different heat treatments

Most recent evidences indicated that the GBPs characteristics play an important role on the SCC resistance, such as the size, interspaces and copper content of GBPs. The copper content of GPBs is difficult to precise determine since the size of GPBs is several nanometers. Therefore, the copper content of GPBs was deduced form Ref. [23]. It was reported that the content of Cu in GBPs was related to aging temperature [23]. The higher the aging temperature is, the higher the copper content of GBPs is. For T6 temper samples, the highest SCC susceptibility is attributed to lower copper and continuous distribution of GBPs. The former leads to corrosion crack initiation as it provides large differences of potential between matrix and GBPs, while the latter promotes stress corrosion crack propagation. The improved SCC resistances of RRA, DRRA and T74 temper samples compared with those of the T6 temper can be attributed to not only the increase in size and the interspaces of GBPs, but also the increase in copper content of GBPs. The two factors decrease the difference of potential between the matrix and GBPs, and increase the SCC resistance.

The fracture toughness mechanisms during aging heat treatment are mainly associated with the strength difference between the matrix and grain boundary [2,26]. The mainly microstructure characters on the strength difference between the matrix and grain boundary are related to the size and amount of matrix precipitates and grain boundary precipitates, and the width of precipitate free zone [24-27]. For T6 temper sample, it shows the lowest fracture toughness, and fracture mode combined with transgranular and intergranular failure. It is attributed to small homogeneously precipitate within matrix, which produces a larger difference in the yield strength between matrix and grain boundary (Figs. 6(a) and (b)). The fracture toughness of T74 temper is higher than that of T6 temper, and the transgranular fracture is the main fracture mode. It can be explained that the matrix strength decreases because the size of matrix precipitates increases and the amounts of precipitates decreases (Figs. 6(c) and (d)). Therefore, the yield strength difference between the grain interior and grain boundary is reduced. However, the sample of RRA temper exhibits higher fracture toughness than that of the T6 temper, which is ascribed to grain boundary precipitates discontinuity and decreased stress concentration on grain boundary (Figs. 6(e) and (f)). The high fracture toughness of the DRRA temper is attributed to the coarsened precipitates in matrix which decreases the difference between the matrix and grain boundary compared with RRA temper samples (Figs. 6(g) and (h)).

5 Conclusions

1) Compared with T6 temper, the fracture toughness of T74 temper is increased by 22.9% at the expense of 13.6% strength while RRA increases fracture toughness without sacrificing the strength.

2) DRRA keeps the strength similar to RRA temper, and the fracture toughness is equivalent to T74 temper.

3) The SCC resistance increases in the order: T6 References

[1] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S,BENEDICTUS R, MILLER W S. Recent development in aluminium alloys for aerospace applications [J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[2] HAN N M, ZHANG X M, LIU S D, KE B, XIN X. Effects of pre-stretching and ageing on the strength and fracture toughness of aluminum alloy 7050 [J]. Materials Science and Engineering A, 2011, 528(1): 3714-3721.

[3] HAN N M, ZHANG X M, LIU S D, HE D G, ZHANG R. Effect of solution treatment on the strength and fracture toughness of aluminum alloy 7050 [J]. Journal of Alloys and Compounds, 2011, 509(10): 4138-4145.

[4] WANG D, MA Z Y. Effect of pre-strain on microstructure and stress corrosion cracking of over-aged 7050 aluminum alloy [J]. Journal of Alloys and Compounds, 2009, 469(1-2): 445-450.

[5] LIN J C, LIAO H L, JEHNG W D, CHANG C H, LEE S L. Effect of heat treatments on the tensile strength and SCC-resistance of AA7050 in an alkaline saline solution [J]. Corrosion Science, 2006, 48(10): 3139-3156.

[6] OLIVEIRA A F Jr, de BARROS M C, CARDOSO K R, TRAVESSA D N. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminium alloys [J]. Materials Science and Engineering A, 2004, 379(1-2): 321-326.

[7] GOKHALE A M, DESHPANDE N U, DENZER D K, LIU J. Relationship between fracture toughness, fracutre path, and microstructure of 7050 aluminum alloy: Part II. Multiple micromechanisms-based fracture toughness model [J]. Metallurgical and Materials Transactions A, 1998, 29(4): 1203-1210.

[8] SARKAR B, MAREK M, STARKE E A. The effect of copper content and heat treatment on the stress corrosion characteristics of Al-6Zn-2Mg-xCu alloys [J]. Metallurgical and Materials Transactions A, 1981, 12(11): 1939-1943.

[9] XIAO Y P, PAN Q L, LI W B, LIU X Y, HE Y B. Influence of retrogression and re-aging treatment on corrosion behaviour of an Al-Zn-Mg-Cu alloy [J]. Materials and Design, 2011, 32(1): 2149-2156.

[10] PENG Guo-sheng, CHEN Kang-hua, CHEN Song-yi, FANG Hua-chan. Influence of repetitious-RRA treatment on the strength and SCC resistance of Al-Zn-Mg-Cu alloy [J]. Materials Science and Engineering A, 2011, 528(12): 4014-4018.

[11] CAI B, ADAMS B L, NELSON T W. Relation between precipitate-free zone width and grain boundary type in 7075-T7 Al alloy [J]. Acta Materialia, 2007, 55(5): 1543-1553.

[12] WANG D, MA Z Y, GAO Z M. Effects of severe cold rolling on tensile properties and stress corrosion cracking of 7050 aluminum alloy [J]. Materials Chemistry and Physics, 2009, 117(1): 228-233.

[13] DESHPANDE N U, GOKHALE A M, DENZER D K, LIU J. Relationship between fracture toughness, fracture path, and microstructure of 7050 aluminum alloy: Part I. Quantitative characterization [J]. Metallurgical and Materials Transactions A, 1998, 29(4): 1191-1201.

[14] HARDWICK D A, THOMPSON A W, BERNSTEIN I M. The effect of copper content and heat treatment on the hydrogen embrittlement of 7050-type alloys [J]. Corrosion science, 1988, 28(12): 1127-1137.

[15] PARK J K, ARDELL A J. Effect of retrogression and reaging treatments on the microstructure of Al7075-T651 [J]. Metallurgical and Materials Transactions A, 1984, 15(8): 1531-1543.

[16] SRIVATSAN T S. Microstructure, tensile properties and fracture behaviour of aluminium alloy 7150 [J]. Journal of Materials Science, 1992, 27(17): 4772-4781.

[17] CHAKRABARTI D J, LIU J, SAWTELL R R, VENEMA G B. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity [J]. Materials Forum, 2004, 28: 969-974.

[18] SHUEY R T, BARLAT F, KARABIN M E, CHAKRABARTI D J. Experimental and analytical investigations on plane strain toughness for 7085 aluminum alloy [J]. Metallurgical and Materials Transactions A, 2009, 40(2): 365-376.

[19] CHEN Song-yi, CHEN Kang-hua, PENG Guo-sheng, CHEN xue-hai, CENG Qing-hua. Effect of heat treatment on hot deformation behavior and microstructure evolution of 7085 aluminum alloy [J]. Journal of Alloys and Compounds, 2012, 537(5): 338-345.

[20] CHEN Song-yi, CHEN Kang-hua, JIA Le, PENG Guo-sheng. Effect of hot deformation conditions on the grain structure and property of 7085 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 329-334.

[21] CHEN Song-yi, CHEN Kang-hua, PENG Guo-sheng, JIA Le, DONG Peng-xuan. Effect of heat treatment on strength, exfoliation corrosion and electrochemical behavior of 7085 aluminum alloy [J]. Materials and Design, 2012, 35(1): 93-98.

[22] LIAO Hsueh-lung, LIN Jing-chie, LEE Sheng-long. Effect of pre-immersion on the SCC of heat-treated AA7050 in an alkaline 3.5%NaCl [J]. Corrosion Science, 2009, 51(2): 209-216.

[23] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys [J]. Acta Materialia, 2010, 58(1): 248-260.

[24] LUDTKA G M, LAUGHLIN D E. The influence of microstructure and strength on the fracture mode and toughness of 7xxx series aluminum alloys [J]. Metallurgical and Materials Transactions A, 1982, 13(3): 411-425.

[25] CVIJOVIC Z, RAKIN M, VRATNICA M, CVIJOVIC I. Microstructural dependence of fracture toughness in high-strength 7000 forging alloys [J]. Engineering Fracture Mechanics, 2008, 75(8): 2115-2129.

[26]  Z, VRATNICA M, RAKIN M. Micromechanical modelling of fracture toughness in overaged 7000 alloy forgings [J]. Materials Science and Engineering A, 2006, 434(1-2): 339-346.

Z, VRATNICA M, RAKIN M. Micromechanical modelling of fracture toughness in overaged 7000 alloy forgings [J]. Materials Science and Engineering A, 2006, 434(1-2): 339-346.

[27] HAHN G T, ROSENFIELD A R. Metallurgical factors affecting fracture toughness of aluminum alloys [J]. Metallurgical and Materials Transactions A, 1975, 6(2): 653-668.

热处理对7085铝合金应力腐蚀开裂、断裂韧性和强度的影响

陈送义1,2,陈康华2,董朋轩2,叶升平2,黄兰萍2

1. 中南大学 轻合金研究院,长沙 410083;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:采用慢应变速率拉伸应力腐蚀测试、Kahn 撕裂实验和室温拉伸实验结合透射电子显微镜和扫描电子显微镜,研究热处理对7085铝合金应力腐蚀开裂、断裂韧性和强度的影响。结果表明:与T6时效相比,经T74时效处理的合金的断裂韧性提高22.9%,但屈服强度降低13.6%;经回归再时效(RRA)处理的合金屈服强度与T6的相当,断裂韧性提高14.2%。经两次回归再时效(DRRA)处理的合金断裂韧性与T74处理的相当,但屈服强度提高14.6%。合金的应力腐蚀开裂抗力依次为:T6 关键词:7085铝合金;热处理;应力腐蚀开裂;断裂韧性

(Edited by Chao WANG)

Foundation item: Projects (2010CB731701, 2012CB619502) supported by the National Basic Research Program of China; Projects (51201186, 51327902) supported by the National Natural Science Foundation of China

Corresponding author: Kang-hua CHEN; Tel: +86-731-88830714; Fax: +86-73188710855; E-mail: khchen@csu.edu.cn

DOI: 10.1016/S1003-6326(14)63351-3