Numerical study on settlement of high-fill airports in collapsible loess geomaterials: A case study of Lüliang Airport in Shanxi Province, China

来源期刊:中南大学学报(英文版)2021年第3期

论文作者:魏英杰 介玉新 王笃礼 魏弋锋

文章页码:939 - 953

Key words:high-fill airport; collapsible loess; settlement deformation; numerical calculation

Abstract: Foundation settlement is of great significance for high-fill engineering in collapsible loess areas. To predict the construction settlement of Lüliang Airport located in Shanxi Province, China, a plane strain finite element method considering the linear variation in the modulus, was carried out in this paper based on the results of geotechnical tests. The stress and deformation of four typical sections caused by layered fill are simulated, and then the settlement of the high-fill airport is calculated and analyzed by inputting three sets of parameters. The relative soft parameters of loess geomaterials produce more settlement than the relatively hard parameters. The thicker the filling body is, the greater the settlement is. The filling body constrained by mountains on both sides produces less settlement than the filling body constrained by a mountain on only one side even the filling thickness is almost the same. The settlement caused by the original subbase accounts for 56%-77% of the total settlement, while the fill soils themselves accounts for 23%-44% of the total settlement, which is approximately consistent with the field monitoring results. It provides a good reference for predicting the settlement of similar high-fill engineering.

Cite this article as: JIE Yu-xin, WEI Ying-jie, WANG Du-li, WEI Yi-feng. Numerical study on settlement of high-fill airports in collapsible loess geomaterials: A case study of Lüliang Airport in Shanxi Province, China [J]. Journal of Central South University, 2021, 28(3): 939-953. DOI: https://doi.org/10.1007/s11771-021-4655-4.

J. Cent. South Univ. (2021) 28: 939-953

DOI: https://doi.org/10.1007/s11771-021-4655-4

JIE Yu-xin(介玉新)1, WEI Ying-jie(魏英杰)1, 2, WANG Du-li(王笃礼)2, WEI Yi-feng(魏弋锋)3

1. State Key Laboratory of Hydroscience and Engineering, Tsinghua University, Beijing 100084, China;

2. AVIC Institute of Geotechnical Engineering Co., Ltd., Beijing 100098, China;

3. China Airport Construction Group Corporation of CAAC, Beijing 100101, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: Foundation settlement is of great significance for high-fill engineering in collapsible loess areas. To predict the construction settlement of Lüliang Airport located in Shanxi Province, China, a plane strain finite element method considering the linear variation in the modulus, was carried out in this paper based on the results of geotechnical tests. The stress and deformation of four typical sections caused by layered fill are simulated, and then the settlement of the high-fill airport is calculated and analyzed by inputting three sets of parameters. The relative soft parameters of loess geomaterials produce more settlement than the relatively hard parameters. The thicker the filling body is, the greater the settlement is. The filling body constrained by mountains on both sides produces less settlement than the filling body constrained by a mountain on only one side even the filling thickness is almost the same. The settlement caused by the original subbase accounts for 56%-77% of the total settlement, while the fill soils themselves accounts for 23%-44% of the total settlement, which is approximately consistent with the field monitoring results. It provides a good reference for predicting the settlement of similar high-fill engineering.

Key words: high-fill airport; collapsible loess; settlement deformation; numerical calculation

Cite this article as: JIE Yu-xin, WEI Ying-jie, WANG Du-li, WEI Yi-feng. Numerical study on settlement of high-fill airports in collapsible loess geomaterials: A case study of Lüliang Airport in Shanxi Province, China [J]. Journal of Central South University, 2021, 28(3): 939-953. DOI: https://doi.org/10.1007/s11771-021-4655-4.

1 Introduction

For the sustainable development of society and economy, creating more land is an effective way to gain more space for housing, industry and agriculture, and intensive marine reclamation land projects have been carried out in coastal countries and areas [1, 2]. Mountainous areas cover over 68% of the landmass in China, and the lack of land resources has restricted the economic development of cities, especially for those located in western China with ravines and gullies [3]. With the development of national programs, including the Development of the Western Region in China and the Silk Road Economic Belt, land resources have become the main factor restricting the development of local economies, especially infrastructure (i.e., highways, airports, residential buildings, factories). To resolve the issues caused by the lack of land resources in western China, hill flattening and gully filling have become important measures for obtaining more land in mountainous regions, and tens of square kilometers of land have been created in many midwestern cities in China, such as Guizhou, Chongqing, Yichang, Shiyan, Lanzhou and Yan’an, China [3-5].

The newly created flat ground will generate great material wealth as well as ease pressures on agriculturally and culturally valuable land elsewhere, while a series of geological, geotechnical and environmental issues have followed, such as air and water pollution, soil erosion and geological hazards (i.e., subsidence, landslides, flooding) [4, 6, 7]. The security of high-fill foundations has drawn attention of many geotechnical researchers, especially in the settlement deformation of filling bodies, which will cause many engineering problems, including foundation failures, slope cracks and structural damage [3, 8-11]. Settlement deformation has aroused wide concern and high attention in the geotechnical community, and extensive investigations have been carried out by various methods, such as drones and remote sensing [12-14], theoretical analysis [15-19], numerical analysis [20-23], physical modelling [24, 25], and in situ monitoring [26-29].

BJERRUM [30] pointed out the influence of creep on soil properties and proposed a diagram that permits a qualitative evaluation of the settlements of a building founded on clays exhibiting delayed consolidation. SINGH et al [31] obtained the empirical relationship between linear strain and time through different tests. WALKER et al [32] established the empirical formula of creep and time by analyzing the relationship between the coefficient of secondary consolidation and the semilogarithm of time. YIN et al [33] established the relationship between time and stress on the basis of Bjerrum’s isochronous e-lgp curve, and the secondary consolidation was related to time and stress. LIU et al [34] studied the deformation characteristics of a high-fill foundation by a centrifugal model test system, and the results indicated that settlement mainly occurred during the construction period, and the post-construction settlement was less than 10% of the total settlement. Via two series of saturated and unsaturated direct shear tests, NG et al [35] noted that matric suction in the soil plays a vital role in the compression and shear strength behavior of compacted loess. XU et al [36] identified a transitional mode of compacted specimens in oedometer and triaxial tests, and the results indicate that the initial density has a significant influence on soil compression. JIA et al [27] conducted in situ monitoring of the long-term post-construction settlement of a high-fill subgrade. They found that the subgrade settlement increases with time and tends to be stable after one year, and then the exponential model was adopted to accurately predict the settlement. YAO et al [19] proposed a prediction method of creep settlement considering abrupt factors based on the one-dimensional creep theory of the unified hardening (UH) model and compared the prediction results via the proposed method with those of three other methods as well as the monitoring settlement data from several high-fill airports. It was found that the proposed method was more effective and reasonable than other methods in predicting creep settlement. CHEN et al [37] studied the influence of matric suction on non-linear time-dependent compression behavior of a granular fill material and established a linear relationship between the time-dependent compression coefficient and normalized effective vertical loading. Meanwhile, numerical method as a widely used method has also been used to calculate and predict the deformation and stress of stratum in consideration of various influence factors. MINKOFF et al [38] points that accurate prediction requires both mechanical deformation and fluid flow modeling for complex non-linear phenomena often observed in a real field. ZHU et al [39] proposed a 4D multi-physical stress modelling to predict the changes in the stress state, and a permeability stress-sensitivity in 4D flow-geomechanical coupling to show the dynamic evolution of stress and permeability [40]. These tries promote the development of rock and soil mechanics.

In northwest China, loess soil, first identified as sediments from the Pampas region in Argentina, distributes widely, covering approximately 6.6% of the total land in China [41]. Collapsible loess is one of the problematic soils because of the rapid reduction in strength and bearing capacity after water immersion and the breakage of the structure under the combined action of soil self-weight pressure and additional pressure [42]. Therefore, loess is prone to disasters such as slope deformation and landslides, which have been extensively studied [43-48]. The ground treatment and post-construction settlement control technologies have been hot topics in the loess high-fill embankment research area [49].

From the above, it can be found that there are many research results on settlement by using various methods. The numerical method is more advantageous overall in predicting possible settlement than other methods, while there is a knowledge gap between parameter selection and application in numerical calculation, especially in collapsible loess areas.

In this study, a numerical method for settlement of Lüliang Airport engineering with the maximum filling height of 81.9 m is reported. The plane strain finite element method was used to simulate the stress and deformation caused by the layered filling before construction. Four typical sections were selected for calculation, and three sets of parameters were used to conduct numerical simulation considering different foundation conditions. More importantly, the change in the soil modulus with stress was considered in this study. Finally, the stress and deformation are described and analyzed.

2 Project profile

Lüliang Airport is a domestic regional airport located 20.5 km north of Lüliang city in Shanxi Province, China. The landform types for the construction site are mountains and canyons, as shown in Figures 1(a) and (b). There is no flat ground on which to build an airport for which the total length is up to 2720 m, and the end of the runway security zone is 240 m far away from the lift (Figure 1(d)). Hill flattening and gully filling are effective methods to obtain flat ground and provide the basic conditions for airport construction, as shown in Figures 1(c) and (d). The study area is in the loess valleys and hills region, and the nearby mountains, covered by Malan loess  and Lishi loess

and Lishi loess provide the source of the fillings [3]. The ravine on the west side of the runway is nearly northeast-southwest in direction, and it was designed as a test section with intensive monitoring during construction. The length of the ravine is 700 m and the slope rate is approximately 7.1%. The cross-sectional shape from upstream to downstream varies from V to U. The ranges of the cross-section width and height are 10-50 m and 50-100 m, respectively. In addition, the angles of the left and right slopes are approximately 80° and 40°-60°, respectively (see Figure 1(e)).

provide the source of the fillings [3]. The ravine on the west side of the runway is nearly northeast-southwest in direction, and it was designed as a test section with intensive monitoring during construction. The length of the ravine is 700 m and the slope rate is approximately 7.1%. The cross-sectional shape from upstream to downstream varies from V to U. The ranges of the cross-section width and height are 10-50 m and 50-100 m, respectively. In addition, the angles of the left and right slopes are approximately 80° and 40°-60°, respectively (see Figure 1(e)).

Figure 1 (a, b) Pictures of landform; (c) Profile of study site; (d) View of Lüliang Airport; (e) Picture of ravine in study area

Airport engineering started in May 2009 and ended in May 2010. Before airport construction, settlement deformation as an important geotechnical issue needs to be resolved because of the large filling and removal of loess volumes of 1.9×107 m3 and 3.2×107 m3, respectively. Among these, the maximum removal height of the loess beam is 31.4 m and the maximum fill height is up to 81.9 m. For each layer of fill soils (see Figure 2(a)), the subbase with mixing and moistening of the fill is built through layered rolling (see Figure 2(b)) and dynamic compaction (see Figure 2(c)). The moisture is controlled at 13%- 16%, which is higher than the optimal water content of 12.5%. The thickness of the uncompacted filling is 1.0 m, and the compaction degree is controlled at 0.93 or 0.95 in different parts. The high-fill foundation after treatment is shown in Figure 2(d).

3 Methods and materials

3.1 Calculation method

To obtain the stress and deformation caused by layered filling construction, the simple linear elastic model was adopted in the two-dimensional (2D) plane strain finite element numerical calculation in NM2dc (2D) software, which was developed by Yuxin Jie at Tsinghua University in Beijing, China. According to the characteristics of the Lüliang Airport, four typical calculated sections were selected. Sections I and II are along the axis of the runway. Section III is along the road toward the tarmac, and Section IV is along the ravine, as shown in Figure 1(c).

3.2 Finite element mesh

For Sections I-IV, green meshes are the filling area, and red meshes are the original subbase area, as shown in Figure 3. The ordinate is the elevation value. The bottom elevation values of sections I and II, and Sections III and IV are 1050 and 950 m, respectively. All surface elevation values correspond to the elevation value of the filling surface. There are 1842 elements and 1398 nodes in Section I, 1623 elements and 1705 nodes in Section II, 3787 elements and 3887 nodes in Section III, and 3296 elements and 3400 nodes in Section IV. The plane range of the four sections is (horizontal×vertical): 415.9 m×105.5 m, 370.1 m× 117.1 m, 461 m×210.8 m, and 470 m×209.2 m, respectively.

Figure 2 (a) Soil paving; (b) Layered rolling; (c) Dynamic compaction; (d) High-fill foundation

Figure 3 Finite element mesh for various sections (red part: the original subbase; green part: the filling body):

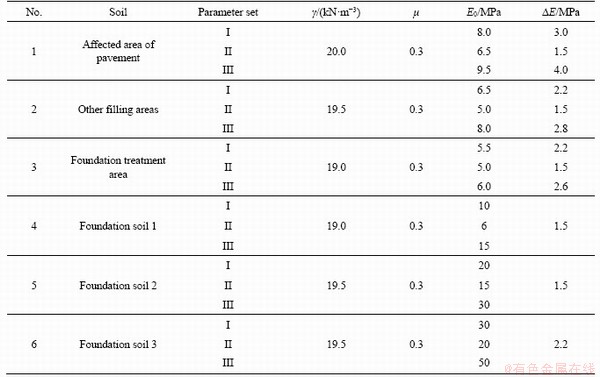

3.3 Materials and parameters

According to the airport engineering foundation design and boreholes, the foundation materials were divided into six materials from top to bottom in the finite element calculation:

1) Filling body in the influence area of the road: parameters from the test curves with the compactness degree of 0.95 under the optimal moisture content;

2) Other filling body: parameters from the test curves with the compactness degree of 0.93 under the optimal moisture content;

3) Foundation treatment area: parameters from the test curves with the compactness degree of 0.93 under the natural moisture content (10 m was adopted at the west ravine with dynamic compaction of 6000 kN·m; 6 m was adopted at the east ravine with dynamic compaction of 6000 kN·m);

4) Foundation soil 1: within 11 m from the foundation treatment area;

5) Foundation soil 2: 10 m below foundation soil 1;

6) Foundation soil 3: all soil layers below foundation soil 2.

Figure 4 shows the compression modulus under various stresses for specimens with different compaction degree and moisture content. Among these, Figure 4(a) shows the test result of a compaction degree of 0.95 under the optimal water content; Figure 4(b) shows the test result of a compaction degree of 0.93 under the optimal water content; and Figure 4(c) shows the test result of a compaction degree of 0.93 under the natural water content. Figure 4 indicates that there is a linear relationship between the compression modulus and stress for specimens with various compaction degree and moisture. In this study, three sets of parameters, I, II and III, were selected. Among these, parameter set I comprises the most likely parameter values according to geotechnical survey results, and the parameters represent average values. Parameter set II is possible but has smaller values (i.e., soft parameters) and the parameters represent a relatively unfavorable condition. Parameter set III is possible but has larger values (i.e., hard parameters) and they represent a relatively favorable condition. The parameters of foundations are summarized according to laboratory tests and field standard penetration tests. The soils of the filling body and foundation treatment area are remolded soils, and their parameters were adopted according to laboratory tests.

Figure 4 Compression modulus vs stress:

The defomation modulus are obtained by using the compression modulus Es and Poisson ratio μ determined by engineers’ experience. The calculation formula is as follows:

(1)

(1)

The Poisson ratio μ is a constant (i.e., 0.3) in this study, therefore; the linear relationship also lies between deformation modulus and stress. The following formula is used to fit the deformation modulus (E) and stress P:

(2)

(2)

where E is the deformation modulus; and E0 and △E are the fitting parameters; P is the average stress; and Pa is the atmospheric pressure (0.1 MPa). In the calculation, the modulus changes with the variety of stresses P, and it will be calculated as E0 when E

3.4 Calculation phase

To simulate the actual stress process, the foundation soils were first calculated by the finite element method, and then the obtained displacement was zeroed while the stress remained unchanged. Afterwards, filling soils were simulated and calculated layer by layer. The filling stress and finite element mesh were applied as 5-10 m at each phase and adjusted according to the mesh status. The total calculation stage is shown in Table 2. The first stage is the calculation of foundation soils. The midpoint increment method was adopted at each stage in consideration of the linear variation in the modulus with stress.

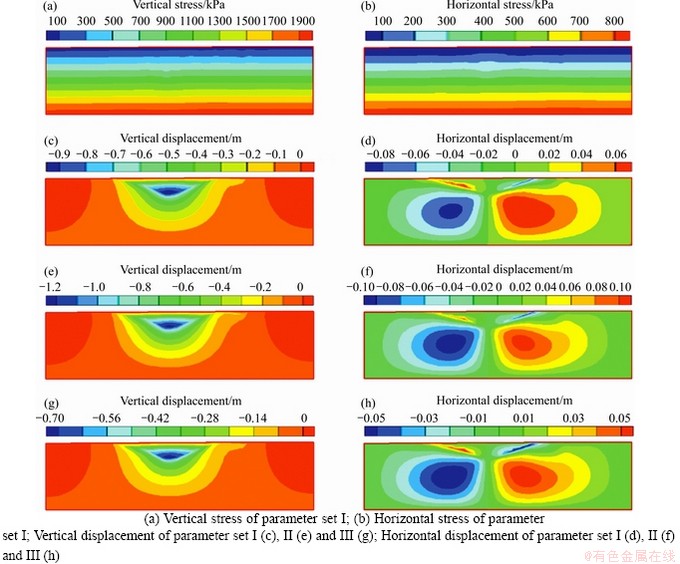

After the calculation, the images of stress (i.e., vertical stress and horizontal stress) and displacement (i.e., vertical displacement and horizontal displacement) utilizing different parameters (i.e., parameter sets I, II and III) for various sections (i.e., Sections I, II, III and IV) are shown in Figures 5-8, respectively. It is worth noting that stress images for the four sections are shown only under the utilization of parameter set I because there are no apparent changes in the stress nephogram by using the other two parameter sets (i.e., parameter sets II and III).

4 Results and discussion

4.1 Effect of selected parameters on settlement

The vertical displacements at various depths for sections I, II, III and IV are plotted in Figure 9, and the relationship between settlement (S) and filling thickness (H) is plotted in Figure 10. For the four sections, the maximum settlement values vary from 0.94-3.67 m when parameter set I is adopted. The maximum settlement value of Section I is the smallest, and that of Section IV is the largest among the four sections. When parameter set II (i.e., soft parameters) is adopted, the increase in the maximum settlement for the four sections is 0.27-1.0 m which corresponds to 27.2%-29.6%. The mean increasement rate is 28.7%. When parameter set III (i.e., hard parameters) is adopted, the decrease in the maximum settlement for the four sections is 0.23-0.86 m which corresponds to 22.4%-24.5%. The mean decrement rate is 23.4%. The results indicate that soft parameters produce more settlement than hard parameters, which can also be seen from Figures 10(a) and (b).

Table 1 Calculation parameter values

Table 2 Calculation phase for various sections

4.2 Effect of filling thickness on settlement

From Section I to IV, the filling thickness increases from 24.36 m to 78.96 m and the settlement under the same parameter series also increases (i.e., for parameter series I: 0.94-3.67 m; for parameter series II: 1.21-4.67 m; for parameter series III: 0.71-2.81 m), as shown in Figure 10(a). This indicates that settlement increases with filling thickness when the same parameter series is selected. That is, the thicker the filling body is, the larger the settlement value is.

4.3 Effect of landform on settlement

The maximum filling thicknesses of Sections III and IV are almost the same (i.e., 77.96 m for section III and 78.96 m for section IV). However, the maximum settlement value and the depth of maximum settlement of Section IV are much larger than those of Section III, which can also be seen from the sudden rise in the broken circle from Figure 10(a). This might be caused by the different landforms. For Section III, the filling body is constrained on both sides, while the filling body in section IV is constrained on only one side. The filling body in Section IV produces more horizontal displacement toward the ravine, and more vertical displacement (i.e., settlement) occurs.

4.4 Effect of original subbase on settlement

For Section I, the filling thickness is up to 24.36 m and the depth for the maximum vertical displacement is 22.12 m (see Figure 9(a)). For Section II, the filling thickness is up to 40.96 m and the depth for the maximum vertical displacement is 32.33 m (see Figure 9(b)). For Section III, the filling thickness is up to 77.96 m and the depth for the maximum vertical displacement is 59.41 m (see Figure 9(c)). Moreover, for Section IV, the filling thickness is up to 78.96 m and the depth for the maximum vertical displacement is 70 m (see Figure 9(b)). It is worth noting that the depth value of the maximum vertical displacement is much larger than half of the filling thickness (i.e., section I: 22.12 m>12.18 m; Section II: 32.33 m>20.48 m; Section III: 59.41 m>38.98 m; Section IV: 70.00 m> 39.48 m). The maximum vertical displacement value and the depth value for the maximum vertical displacement under various parameter sets (i.e., parameter set I, parameter set II, parameter set III) are shown in Table 3.

Figure 5 Stress and displacement for Section I:

The values in brackets are calculated when the modulus of the foundation soils is selected as 2× 104 MPa (similar to bed rock). For embankment dams with bed rock, the depth of the maximum settlement is near the half depth of the filling body (i.e., 12.12 m is closer to 12.18 m in Section I; 17.27 m is closer to 20.48 m in Section II; 39.41 m is closer to 38.98 m in Section III; 40.00 m is closer to 39.49 m in Section IV), as shown in Table 3. However, the depth value of the maximum settlement for all four sections is much larger than half the depth value of the filling thickness. This indicates that the settlement of high-fill engineering in collapsible loess regions is different from the settlement of dam embankment engineering with bed rock. The above phenomena were induced by the settlement of the original subbase. The settlement caused by filling soils itself accounts for 23%-44% of the total settlement, while the settlement caused by subbase soils accounts for 56%-77% of the total settlement. This indicates that the original subbase produced considerable settlement, which makes greater sense for the total settlement at the construction site. For Section III, filed monitoring data can be used, as published in Ref. [50]. The settlement caused by the original subbase soils is 61%-89% of the total settlement, while the settlement caused by filling soils is 11%-39% of the total settlement. The proportions of settlement caused by the original subbase and filling soils based on the numerical calculation and field data are similar. Both the results of field data and the finite element method indicate that subbase soils produce more settlement than filling soils, and the results agree well. The modulus is usually regarded as a constant in numerical calculations in previous studies. However, in this study, the modulus is linearly variable with stress. The variation in the modulus with stress is more reasonable in the numerical method, which might be the reason for good agreement.

Figure 6 Stress and displacement for Section II:

5 Conclusions

The plane strain finite element method considering the linear variation in the soil modulus is used to analyze the stress and deformation at the Lüliang Airport, which is the highest fill airport in the collapsible loess area. Four typical sections were selected for calculation via three sets of parameters. The main findings specific to the calculation are as follows:

1) The selected parameters play an important role in the settlement of high-fill engineering in numerical methods, and the soft parameters produce more settlement than the hard parameters. The maximum settlement of Section I and II along the airport runway caused by filling is 0.94 and 1.37 m, respectively, by utilizing the average value of parameters (i.e., parameter set I), which may reach 1.21 and 1.77 m, respectively, under adverse conditions (i.e., parameter set II). The maximum settlements of Sections III and IV are 3.04 and 3.67 m, respectively, which may reach 3.94 m and 4.67 m under adverse conditions (i.e., parameter set II).

Figure 7 Stress and displacement for Section III:

Figure 8 Stress and displacement for Section IV:

2) The filling thickness is an important factor in settlement in high fill engineering. The settlement value increases with filling thickness; that is, the thicker filling body produces a larger settlement value under the same parameter series.

3) The landform has a significant effect on the settlement of the filling body. Section III, constricted by mountains on both sides, produces less settlement than that in Section IV, which is constricted by a mountain on one side, even though they have similar filling thickness. The phenomena could be attributed to the horizontal displacement induced by the free face caused by the gully.

Figure 9 Vertical displacement vs depth:

Figure 10 (a) Settlement (S) vs filling thickness (H); and (b) S/H under different parameters and various sections

4) The original subbase plays an important role in the settlement of high-fill engineering in collapsible loess regions, which is different from that of dam embankments. The original subbase produces more settlement than the upper filling body. The settlement caused by foundation compression accounts for 56%-77% of the total settlement, while the settlement induced by the filling body accounts for 23%-44%, which is approximately consistent with the field monitoring data. Therefore, the original subbase needs more focus in assessing settlement.

Table 3 The maximum settlement values and their positions

The research provides an important reference for Lüliang Airport before its construction and avoids risk during its construction. Additionally, the research indicates that a simple elastic model could be used to predict the deformation of a high-fill foundation in consideration of actual soil properties based on a series of geotechnical tests. The variation in soil modulus with stress was considered in the numerical method, which provides a reference for similar numerical calculations in high-fill engineering. Nevertheless, the complex geomechnical performance and fluid flow behavoir,such as the process of foundation treatment by various methods, the uneven horizontal seepage caused by rain water, should be considered in the future, and further work needs to be done.

Contributors

The overarching research goals were developed by JIE Yu-xin and WEI Ying-jie. JIE Yu-xin and WEI Yi-feng provided the field data, and JIE Yu-xin and WEI Ying-jie analyzed the data. JIE Yu-xin established the models and calculated the predicted settlement. JIE Yu-xin, WEI Ying-jie and WANG Du-li analyzed the calculated results. The initial draft of the manuscript was written by WEI Ying-jie, JIE Yu-xin and WANG Du-li. All authors replied to reviewer’s comments and revised the final version.

Conflict of interest

JIE Yu-xin, WEI Ying-jie, WANG Du-li and WEI Yi-feng declare that they have no conflict of interest.

References

[1] SHANG J Q, TANG M, MIAO Z. Vacuum preloading consolidation of reclaimed land: A case study [J]. Canadian Geotechnical Journal, 1998, 35(5): 740-749. DOI: 10.1139/cgj-35-5-740.

[2] OHKURA Y. The roles and limitations of newspapers in environmental reporting—Case study: Isahaya bay land reclamation project issue [J]. Marine Pollution Bulletin, 2003, 47(1-6): 237-245. DOI: 10.1016/S0025-326X(03)00057-2.

[3] WANG Jia-ding, XU Yuan-jun, MA Yan, QIAO Shao-nan, FENG Kai-qiang. Study on the deformation and failure modes of filling slope in loess filling engineering: A case study at a loess mountain airport [J]. Landslides, 2018, 15(12): 2423-2435. DOI: 10.1007/s10346-018-1046-5.

[4] LI Pei-yue, QIAN Hui, WU Jian-hua. Accelerate research on land creation [J]. Nature, 2014, 510(7503): 29-31. DOI: 10.1038/510029a.

[5] LIU Yan-sui, LI Yu-heng. China’s land creation project stands firm [J]. Nature, 2014, 511(7510): 410-410. DOI: 10.1038/511410c.

[6] JIN Zhao. The creation of farmland by gully filling on the loess plateau: A double-edged sword [J]. Environment Science & Technology, 2014, 48(2): 883-884. DOI: 10.1021/es405392c.

[7] YIN Xiao-xi, CHEN Lu-wang, HE Jian-dong, FENG Xiao-qing, ZENG Wen. Characteristics of groundwater flow field after land creation engineering in the hilly and gully area of the loess plateau [J]. Arabian Journal of Geosciences, 2016, 9(14): 1-13. DOI: 10.1007/s12517-016-2672-7.

[8] HATAMI K, ESMAILI D, CHAN E C, MILLER G A. Laboratory performance of reduced-scale reinforced embankments at different moisture contents [J]. International Journal of Geotechnical Engineering, 2014, 8(3): 260-276. DOI: 10.1179/1939787914Y.0000000051.

[9] ESMAILI D, HATAMI K. Measured performance and stability analysis of large-scale reinforced model embankments at different moisture contents [J]. International Journal of Geosynthetics and Ground Engineering, 2015, 1(3): 22. DOI: 10.1007/s40891-015-0024-4.

[10] CHEN Dong-feng, LING Jian-ming, LI Dong-xue, ZHENG Chun-yu. Monitoring and evaluating techniques of highway subgrade safety in the operation period [J]. Road Materials and Pavement Design, 2017, 18(S3): 215-225. 10.1080/14680629.2017.1329876.

[11] LE KOUBY A, GUIMOND-BARRETT A, REIFFSTECK P, PANTET A, MOSSER J F, CALON N. Improvement of existing railway subgrade by deep mixing [J]. European Journal of Environmental and Civil Engineering, 2020, 24(8): 1229-1244. DOI: 10.1080/19648189.2018.1456977.

[12] SONNEMANN T E, HUNG J U, HOFMAN C. Mapping indigenous settlement topography in the Caribbean using drones [J]. Remote Sensing, 2016, 8(10): 791. DOI: 10.3390/rs8100791.

[13] YANG Meng-shi, YANG Tian-liang, ZHANG Lu, LIN Jin-xin, QIN Xiao-qiong, LIAO Ming-sheng. Spatio- temporal characterization of a reclamation settlement in the Shanghai coastal area with time series analyses of X-, C-, and L-band SAR datasets [J]. Remote Sensing, 2018, 10(2): 329. DOI: 10.3390/rs10020329.

[14] WANG Hui-qiang, FENG Guang-cai, XU Bing, YU Yong-ping, LI Zhi-wei, DU Ya-nan, ZHU Jian-jun. Deriving spatio-temporal development of ground subsidence due to subway construction and operation in delta regions with PS-InSAR data: A case study in Guangzhou, China [J]. Remote Sensing, 2017, 9(10): 1004. DOI: 10.3390/rs9101004.

[15] Al-SHAMRANI M A. Applying the hyperbolic method and Cα/Cc concept for settlement prediction of complex organic-rich soil formations [J]. Engineering Geology, 2005, 77(1, 2): 17-34. DOI: 10.1016/j.enggeo.2004.07.004.

[16] KONG Xiang-xing. Research and application on the prediction method of pearl model of high filling subgrade settlement [C]// Soil Testing, Soil Stability and ground Improvement, 2018: 356-362. DOI: 10.1007/978-3-319- 61902-6_28.

[17] JIA Liang, HUANG Guang-li. Application of a viscoelastic model to creep settlement of high-fill embankments [J]. Advances in Civil Engineering, 2019: 1-8. DOI: 10.1155/2019/ 4627174.

[18] ZENG Yu-ping. Geotechnical settlement deformation analysis of soft sub-grade embankment filling construction period based on unified hardening model [J]. Geotechnical and Geological Engineering, 2019, 37(6): 5473-5483. DOI: 10.1007/s10706-019-00993-z.

[19] YAO Yang-ping, HUANG Jian, WANG Nai-dong, LUO Ting, HAN Li-ming. Prediction method of creep settlement considering abrupt factors [J]. Transportation Geotechnics, 2020, 22: 100304. DOI: 10.1016/j.trgeo.2019.100304.

[20] LI Shi-yang, HUANG Xin, ZENG Chang-xian. Performance of an embankment foundation with sand over clay: Experimental and numerical analyses [J]. International Journal of Geomechanics, 2017, 17(6): 06016038. DOI: 10.1061/(asce)gm.1943-5622.0000841.

[21] ZHENG Ye-wei, HATAMI K, MILLER G A. Influence of compaction moisture content on wetting-induced settlement of embankments [J]. International Journal of Geosynthetics and Ground Engineering, 2017, 3(1). DOI: 10.1007/ s40891-017-0085-7.

[22] XU Yan-rong, LEUNG C F, YU Jian, CHEN Wen-wu. Numerical modelling of hydro-mechanical behaviour of ground settlement due to rising water table in loess [J]. Natural Hazards, 2018, 94(1): 241-260. DOI: 10.1007/s11069-018-3385-x.

[23] WANG Jia-ding, LI Ping, MA Yan, LI Tong-lu. Influence of irrigation method on the infiltration in loess: Field study in the Loess Plateau [J]. Desalination and Water Treatment, 2018, 110: 298-307. DOI: 10.5004/dwt.2018.22329.

[24] BHANDARI A, HAN Jie. Two-dimensional physical modelling of soil displacements above trapdoors [J]. Geotechnical Research, 2018, 5(2): 68-80. DOI: 10.1680/jgere.18.00002.

[25] ZHANG Chong-lei, JIANG Guan-lu, LIU Xian-feng, SU Li-jun. Centrifuge modelling and analysis of ground reaction of high-speed railway embankments over medium compressibility ground [J]. KSCE Journal of Civil Engineering, 2018, 22(12): 4826-4840. DOI: 10.1007/ s12205-017-0510-4.

[26] JANG Y S. Field-monitored settlement and other behavior of a multi-stage municipal waste landfill, Korea [J]. Environmental Earth Sciences, 2013, 69(3): 987-997. DOI: 10.1007/s12665-012-1982-7.

[27] JIA Liang, GUO Jian, YAO Kai. In situ monitoring of the long-term settlement of high-fill subgrade [J]. Advances in Civil Engineering, 2018: 1-9. DOI: 10.1155/2018/1347547.

[28] WU J T, YE X, LI J, LI G W. Field and numerical studies on the performance of high embankment built on soft soil reinforced with PHC piles [J]. Computers and Geotechnics, 2019, 107: 1-13. DOI: 10.1016/j.compgeo.2018.11.019.

[29] ZHENG Xiao, YANG Yu-you, ZHANG Qian-qing, WU Shi-qian, CUI Wei. A novel method for measuring traffic load-induced settlement at different layers of embankment in highway [J]. Measurement, 2019, 144: 183-191. DOI: 10.1016/j.measurement.2019.05.045.

[30] BJERRUM L. Engineering geology of Norwegian normally-consolidated marine clays as related to settlements of buildings [J]. Géotechnique, 1967, 17(2): 83-118. DOI: 10.1680/geot.1967.17.2.83.

[31] SINGH A, MITCHELL J K. General stress-strain-time function for soils [J]. Journal of the Soil Mechanics and Foundations Division (ASCE), 1968, 94(1): 21-46. DOI: 10.1061/jsfeaq.0001084.

[32] WALKER L K, RAYMOND G P. The prediction of consolidation rates in a cemented clay [J]. Canadian Geotechnical Journal, 1968, 5(4): 192-216. DOI: 10.1139/t68-022.

[33] YIN Zong-ze, ZHANG Hai-bo, ZHU Jun-gao, LI guo-wei. Secondary consolidation of soft soils [J]. Chinese Journal of Geotechnical Engineering, 2003, 25(5): 521-526. (in Chinese)

[34] LIU Hong, ZHANG Zhuo-yuan, HAN Wen-xi. Study on settlement of high fill foundation by centrifugal model test [J]. Journal of Southwest Jiaotong University, 2003, 38(3): 323-326. (in Chinese)

[35] NG C W W, SADEGHI H, JAFARZADEH F. Compression and shear strength characteristics of compacted loess at high suctions [J]. Canadian Geotechnical Journal, 2017, 54(5): 690-699. DOI: 10.1139/cgj-2016-0347.

[36] XU L, COOP M R. The mechanics of a saturated silty loess with a transitional mode [J]. Géotechnique, 2017, 67(7): 581-596. DOI: 10.1680/jgeot.16.P.128.

[37] CHEN Wen-bo, LIU Kai, FENG Wei-qiang, BORANA L, YIN Jian-hua. Influence of matric suction on nonlinear time-dependent compression behavior of a granular fill material [J]. Acta Geotechnica, 2020, 15(3): 615-633. DOI: 10.1007/s11440-018-00761-y.

[38] MINKOFF S E, STONE C M, BRYANT S, PESZYNSKA M, WHEELER M F. Coupled fluid flow and geomechanical deformation modeling [J]. Journal of Petroleum Science and Engineering, 2003, 38(1, 2): 37-56. DOI: 10.1016/S0920- 4105(03)00021-4.

[39] ZHU Hai-yan, TANG Xuan-he, LIU Qing-you, LI Kui-dong, XIAO Jia-lin, JIANG Shu, MCLENNAN J D. 4D multi-physical stress modelling during shale gas production: A case study of Sichuan Basin shale gas reservoir, China [J]. Journal of Petroleum Science and Engineering, 2018, 167: 929-943. DOI: 10.1016/j.petrol.2018.04.036.

[40] ZHU Hai-yan, TANG Xuan-he, LIU Qing-you, LIU Shu-jie, ZHANG Bin-hai, JIANG Shu, MCLENNAN J D. Permeability stress-sensitivity in 4D flow-geomechanical coupling of Shouyang CBM reservoir, Qinshui Basin, China [J]. Fuel, 2018, 232: 817-832. DOI: 10.1016/ j.fuel.2018.05.078.

[41] XING Hao-feng, LIU Liang-liang. Field tests on influencing factors of negative skin friction for pile foundations in collapsible loess regions [J]. International Journal of Civil Engineering, 2018, 16(10): 1413-1422. DOI: 10.1007/ s40999-018-0294-z.

[42] MOMENI M, SHAFIEE A, HEIDARI M, JAFARI M K, MAHDAVIFAR M R. Evaluation of soil collapse potential in regional scale [J]. Natural Hazards, 2012, 64(1): 459-479. DOI: 10.1007/s11069-012-0252-z.

[43] ZHANG De-xuan, WANG Gong-hui, LUO Chun-yong, CHEN Jun, ZHOU Yun-xi. A rapid loess flowslide triggered by irrigation in China [J]. Landslides, 2009, 6(1): 55-60. DOI: 10.1007/s10346-008-0135-2.

[44] ZHANG Fan-yu, PEI Xiang-Jun, CHEN Wen-wu, LIU Gao, LIANG Shou-yun. Spatial variation in geotechnical properties and topographic attributes on the different types of shallow landslides in a loess catchment, China [J]. European Journal of Environmental and Civil Engineering, 2014, 18(4): 470-488. DOI: 10.1080/19648189.2014.881754.

[45] WANG Gen-long, LI Tong-lu, XING Xian-li, ZOU Yu. Research on loess flow-slides induced by rainfall in July 2013 in Yan’an, NW China [J]. Environmental Earth Sciences, 2015, 73(12): 7933-7944. DOI: 10.1007/s12665- 014-3951-9.

[46] GU Tian-feng, WANG Jia-ding, FU Xin-ping, LIU Ya-ming. GIS and limit equilibrium in the assessment of regional slope stability and mapping of landslide susceptibility [J]. Bulletin of Engineering Geology and the Environment, 2015, 74(4): 1105-1115. DOI: 10.1007/s10064-014-0689-2.

[47] YIN Yue-ping, HUANG Bo-lin, CHEN Xiao-ting, LIU Guang-ning, WANG Shi-chang. Numerical analysis on wave generated by the Qianjiangping landslide in three gorges reservoir, China [J]. Landslides, 2015, 12(2): 355-364. DOI: 10.1007/s10346-015-0564-7.

[48] YIN Yue-ping, XING Ai-guo, WANG Gong-hui, FENG Zhen, LI Bin, JIANG Yao. Experimental and numerical investigations of a catastrophic long-runout landslide in Zhenxiong, Yunnan, southwestern China [J]. Landslides, 2017, 14(2): 649-659. DOI: 10.1007/s10346-016-0729-z.

[49] ZHU Cai-hui, LI Ning. Ranking of influence factors and control technologies for the post-construction settlement of loess high-filling embankments [J]. Computers and Geotechnics, 2020, 118: 103320. DOI: 10.1016/j.compgeo. 2019.103320.

[50] ZHU Cai-hui, Li Ning, LIU Ming-zhen, WEI Yi-feng. Spatiotemporal laws of post-construction settlement of loess-filled foundation of Lüliang airport [J]. Chinese Journal of Geotechnical Engineering, 2013, 35(2): 293-301. (in Chinese)

(Edited by ZHENG Yu-tong)

中文导读

湿陷性黄土地区高填方机场沉降的数值模拟:以中国山西吕梁机场为例

摘要:湿陷性黄土地区高填方工程的地基沉降是一个重要问题。为了预测中国山西吕梁机场施工期的沉降,本文基于岩土试验结果,采用了考虑模量线性变化的平面应变有限元法,模拟了四个典型断面分层填筑引起的应力和应变变化,并通过输入三套参数计算和分析高填方机场的沉降。结果表明,相对“软”的黄土参数比相对“硬”的参数引起的沉降更大;填筑体越厚,沉降越大;填筑体厚度接近相同时,两侧受山体约束的填筑体产生的沉降小于一侧受山体约束的填筑体产生的沉降;原地基引起的沉降占总沉降的56%~77%,填筑体引起的沉降占总沉降的23%~44%,与现场监测结果吻合性较好。该研究对相似高填方工程沉降的预测提供了借鉴和参考。

关键词:高填方机场;湿陷性黄土;沉降变形;数值计算

Foundation item: Project(2020M670604) supported by the China Postdoctoral Science Foundation; Project(41790434) supported by the National Natural Science Foundation of China

Received date: 2020-05-14; Accepted date: 2020-12-03

Corresponding author: WEI Ying-jie, PhD, Assistant Professor; Tel: +86-10-82139699; E-mail: weiyj19@tsinghua.org.cn; ORCID: https:// orcid.org/0000-0001-9346-8400