文章编号:1004-0609(2013)S1-s0480-05

β固溶处理对TC21合金组织性能的影响

侯智敏1, 2 ,毛小南1, 赵永庆1, 2, 张鹏省1, 雷文光1, 于兰兰1

(1. 西北有色金属研究院 钛合金研究所,西安 710016;

2. 西北工业大学 材料学院,西安 710072)

摘 要:对等轴组织TC21合金进行β相区高温固溶+α/β相区低温固溶+低温时效热处理;分析β相区高温固溶冷却速率、α/β相区低温固溶温度对TC21合金组织和性能的影响。结果表明:随着β相区固溶冷却速率的增加,α/β相区固溶热处理后合金中条状α相尺寸明显减小,α条厚度减小;随着α/β区固溶处理温度的降低,在相同的β相区固溶冷却速率下,合金中的初生条状初生α相尺寸有一定的减小,相含量增加。经过(960 °C, 1 h, FC)+(890 °C, 1 h, AC)+(620 °C, 6 h, AC)三重热处理后,TC21合金的强度、塑性和韧性匹配较好。这表明三重热处理可以改善常规锻造TC21合金的综合力学性能。

关键词:β固溶处理;TC21合金;冷却速率;强韧性匹配

中图分类号:TB 804.3 文献标志码:A

Effect of β solution treatment on morphology and mechanical properties of TC21 alloy

HOU Zhi-min1, 2, MAO Xiao-nan1, ZHAO Yong-qing1, 2, ZHANG Peng-sheng1, LEI Wen-guang1, YU Lan-lan1

(1. Titanium Alloy Research Center, Northwest Institute for Non-ferrous Metal Research, Xi’an 710016, China;

2. School of Materials Science and Engineering, Northwest Polytechnical University, Xi’an 710072, China)

Abstract: The equiaxed TC21 alloy samples were β solution treated, followed by α/β solution treatment and then aged at low temperature. The effect of β heat treatment cooling rate and temperature of α/β heat treatment on the morphology of TC21 alloy was analyzed. The results show that higher cooling rate of β heat treatment leads to the shrinking of platelet α phase, in the α/β heat treatment process. It is also confirmed that lower α/β heat treatment temperature, after the same beta heat treatment process, results in the decrease of width and increase of the content of platelet α phase. After optimized triplex heat treatment (960 °C, 1 h, FC)+(890 °C, 1 h, AC)+(620 °C, 6 h, AC), the strength, plasticity and fracture toughness match well, indicating that the triplex heat treatment can improve the synthetical mechanical properties of TC21 alloy.

Key words: β solution treatment; TC21 alloy; cooling rate; matching of strength and fracture toughness

TC21钛合金是我国具有自主知识产权的损伤容限型两相钛合金,具有高强度(1 100 MPa)、高韧性(70 MPa·m1/2)和较低的裂纹扩展速率(da/dN)等特点[1-3]。它优良的综合性能特别适合用于制造框、梁等主承力结构件[4]。随着我国航空航天事业的发展,需要制备出更大规格的高品质承力结构件。由于锻造过程中存在的不均匀变形,大规格锻件需要多火次的大变形量才能保证组织的均匀性。如果通过β热处理对大规格锻件进行均匀化热处理,再通过α/β区固溶+时效进行性能调控,可以满足TC21合金的使用要求,降低大规格锻件的组织均匀性要求,从而降低锻造火次,节省生产成本。

研究表明,与TC21合金相近的高强高损伤容限型Ti-622222s合金[5]通过在β相区高温固溶+α/β相区低温固溶+时效的三重热处理工艺,可以获得强度、塑性和韧性匹配良好的全网篮组织,并且已形成相关热处理规范[4-5]。对于TC21合金,国内一般通过近β锻、准β锻或β锻获得强韧性匹配较好的三态组织或网篮组织[8-9],而β相区高温固溶方面的研究较少。本文作者对常规锻造的等轴组织TC21合金进行β相区高温固溶+α/β相区低温固溶+时效的三重热处理,分析β相区高温固溶冷却速率、α/β相区低温固溶温度对TC21合金组织的影响,并进一步分析优化的热处理工艺对合金综合力学性能的影响。

对于β热处理后出现的连续α晶界问题, SCHMIDT和CHRIST[10]研究发现,通过合理的后续热处理,可以消除连续晶界α相,作者正在做相关的工作。

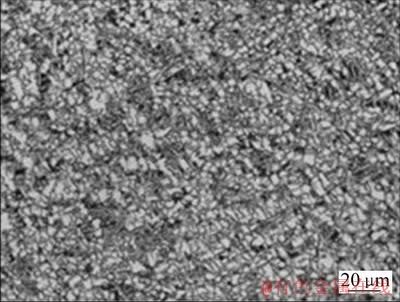

1 实验

实验所用TC21合金为西北有色金属研究院熔炼的6t铸锭,经多火次开坯锻和常规改锻后制备的直径为200 mm的棒材,其锻态组织为等轴组织,如图1所示,相变点为(947±5)°C。从棒材上切下d 10 mm×15 mm、d 10 mm×70 mm和62 mm×65 mm×67 mm的试样,分别用于金相分析、拉伸性能测试和断裂韧性(KIC)测试。先对TC21合金金相样品分别进行(960 °C, 1 h, WQ/AC/FC) β相区固溶热处理;再对不同冷却速率的β热处理样品分别进行(925 °C, 1 h, AC)和 (890 °C, 1 h, AC) α/β相区固溶热处理,然后对所有双重固溶热处理的样品进行(620 °C, 6 h, AC)的时效热处理,分析固溶冷却速率及固溶温度对合金显微组织的影响。在此基础上,选定合理的双重固溶工艺和时效工艺对室温拉伸和断裂韧性样品进行热处理。金相试样抛光后,采用HF+HNO3+H2O (体积比为1:3:10)的腐蚀液浸蚀,通过OLYMPUS/PMG3光学显微镜观察不同热处理工艺对合金微观组织的影响。固溶/时效处理后,在Instron 1185力学试验机上测试TC21合金的力学性能。

图1 TC21合金常规锻后金相组织

Fig. 1 Optical microstructure of normal forged TC21 alloy

2 结果与讨论

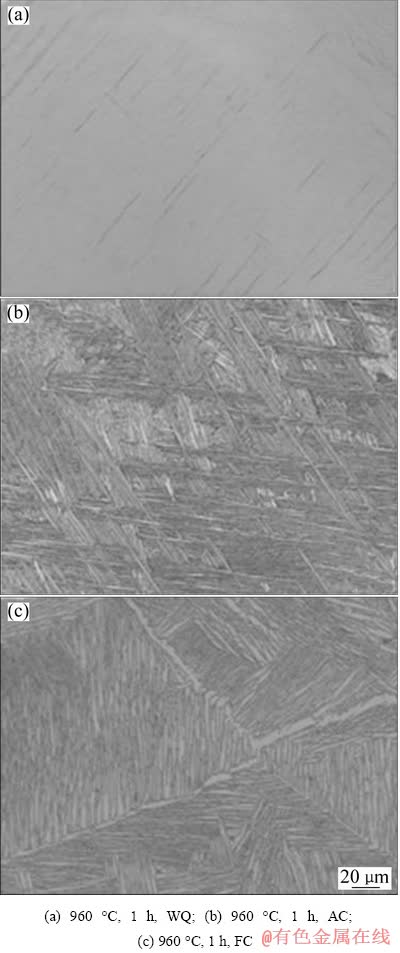

2.1 β相区固溶冷却速率对TC21合金显微组织的影响

TC21合金等轴组织试样经β固溶热处理后(960 °C+1 h, WQ/AC/FC)的显微组织如图2所示。可以看出,水冷试样金相组织中只能看到针状马氏体(见图2(a)),而空冷(见图2(b))及炉冷样品(见图2(c))金相组织都是由α束集和β基体组成。与空冷样品相比,炉冷样品中α条长度减小,厚度增加,这表明降低β相区固溶冷却速率,可以降低条状α相的长宽比。

图2 TC21合金不同工艺热处理后的金相组织

Fig. 2 Optical microstructures of TC21 alloy by different heat treatments

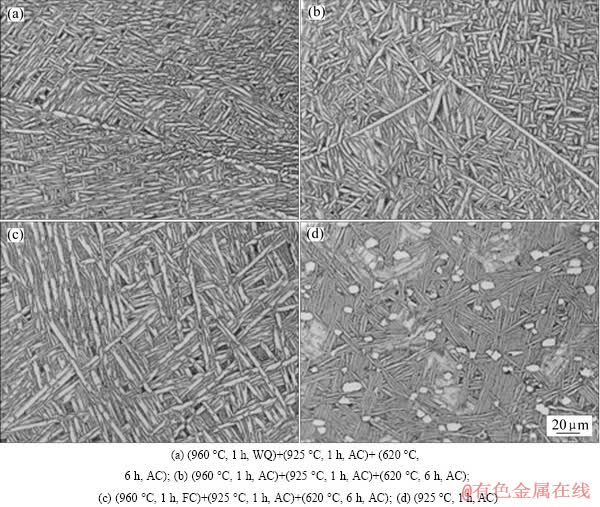

2.2 β相区固溶冷却速率对α/β相区固溶+时效热处理后TC21合金组织性能的影响

TC21合金(960 °C, 1 h) β热处理后,在不同冷却速率下冷却的试样的α/β相区在(925 °C, 1 h)+AC固溶热处理后的金相组织如图3所示。可以看出,β相区固溶水冷样品α/β相区(925 °C, 1 h)+AC热处理后(见图3(a)),其金相组织为细小的网篮组织,在粗的初生条状α相组成的网篮组织中嵌套有细小的次生条状α相组成的网篮组织,形成双网篮组织。与水冷样品相比,空冷样品中(见图3(b))初生条状α相长度明显增加,部分初生条状α相厚度明显增加,部分初生条状α相厚度变化不明显,次生条状α相尺寸明显增加。由于初生条状α相长度增加明显,与水冷样品相比,其长宽比的平均值有一定的增加。初生条状α相形成网篮组织,次生α相交织度较低。与空冷试样相比,炉冷样品中(见图3(c))初生条状α相长度、厚度均明显增加,α条的顶端出现明显的分叉,α条长宽比增加,初生条状α相组成网篮组织;次生条状α相长度明显增加,厚度没有明显的变化,次生α条呈团簇状分布。TC21合金(925 °C, 1 h, AC)固溶热处理后的金相组织如图3(d)所示。可以看出,其金相组织由初生等轴α相及次生条状α相组成,α条呈团簇状分布。上述分析表明,与单重α/β相区固溶相比,增加β相区固溶预处理可以形成网篮组织,且随着β相区固溶冷却速率的减小,条状初生α相厚度明显增加。

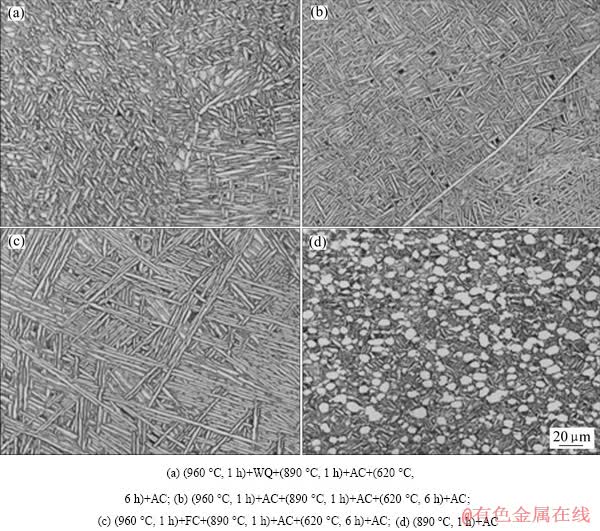

TC21合金x (960 °C, 1 h) β热处理后,于不同速率冷却,固溶热处理后的金相组织如图4所示。与 (925 °C, 1 h)+AC固溶热处理相比,(890 °C, 1 h, AC)固溶热处理后β相区固溶冷却速率对合金金相组织的影响规律基本一致。不同点在于,随着固溶冷却速率的降低,条状初生α相厚度增加不明显。此外,在更低的温度进行α/β相区固溶热处理,其金相组织更加细密;若只进行两相区单重热处理(见图4(d)),则等轴α相含量明显增加,次生条状α相更加细小。

图3 TC21合金经不同工艺热处理后的金相组织

Fig. 3 Optical microstructures of TC21 alloy heat treated by different processes

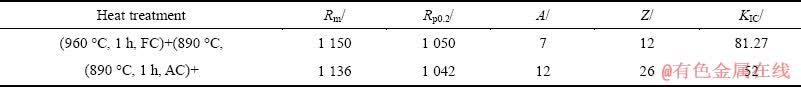

综上所述,通过(960 °C, 1 h, FC)+(890 °C, 1 h, AC)+ (620 °C, 6 h, AC)热处理可以获得片层厚度最大的条状初生α相。由于α相片层厚度的增加可以明显改善合金的断裂韧性,且TC21合金强度主要受最终的固溶冷却速率控制[8],因此,选择该热处理制度为优化的热处理制度,并与(890 °C, 1 h, AC)+(620 °C, 6 h, AC)常规热处理制度进行比较,具体的力学性能测试结果如表1所列。

与常规热处理相比,虽然TC21合金塑性有一定程度的降低,但是其断裂韧性有明显的改善。这表明通过优化的三重热处理可以改善合金的强度、塑性和韧性的匹配度,满足合金的使用要求。

图4 TC21合金经不同工艺热处理后的金相组织

Fig. 4 Optical microstructures of TC21 alloy heat treated by different processes

表1 TC21合金不同热处理制度下的力学性能

Table 1 Mechanical properties of TC21 alloy heat treated by different processes

3 结论

1) 随着β区固溶冷却速率的减小,TC21合金在两相区相同的固溶热处理制度下,条状初生α相尺寸明显增加。

2) 在相同的β固溶热处理制度下,随着两相区固溶热处理温度的降低,条状初生α相尺寸减小,相含量增加。

3) (960 °C, 1 h, FC)+(890 °C, 1 h, AC)+(620 °C, 6 h, AC)三重热处理可以改善合金的强度、塑性和韧性的匹配。

REFERENCES

[1] 赵永庆, 曲恒磊, 冯 亮, 杨海瑛, 李 辉, 张颖楠, 郭宏超, 黄定坤. 高强高韧损伤容限性钛合金TC21研制[J]. 钛工业进展, 2004, 22(1): 22-24

ZHAO Yong-qing, QU Heng-lei, FENG Liang, YANG Hai-ying, LI Hui, ZHANG Ying-nan, GUO Hong-chao, HUANG Ding- kun. Research on high strength, high toughness and high damage-tolerant titanium alloy-TC21[J]. Titanium Industry Progress, 2004, 22(1): 22-24.

[2] 党 薇, 薛祥义, 李金山, 胡 锐, 朱知寿, 张丰收, 周 廉. TC21合金片层组织特征对其断裂韧性的影响[J]. 中国有色金属学报, 2010, 20(增1): 16-20.

DANG Wei, XUE Xiang-yi, LI Jin-shan, HU Rui, ZHU Zhi-shou, ZHANG Feng-shou, ZHOU Lian. Influence of lamellar microstructure feature on fracture toughness of TC21 alloy, The Chinese Journal of Nonferrous Metals, 2010, 20(s 1): 16-20.

[3] ZHU Yan-chun, ZENG Wei-dong, FENG Fei, SUN Yu, HAN Yuan-fei, ZHOU Yi-gang. Characterization of hot deformation behavior of as-cast TC21 titanium alloy using processing map[J]. Materials Science and Engineering A, 2011, 528: 1757-1763

[4] 周水亮, 陶 军, 郭德伦, TC21细晶钛合金TIG焊接接头组织及力学性能研究[J]. 航空材料学报, 2009, 29(6): 53-58.

ZHOU Shui-liang, TAO Jun, GUO De-lun. Study on micro- structure and mechanical properties of fine grain TC21 alloy in TIG[J]. Journal of Aeronautical Materials, 2009, 29(6): 53-58.

[5] 张颖楠, 赵永庆, 曲恒磊, 杨海瑛, 李 辉, 冯 亮. Zr对Ti-6-22-22S合金显微组织和室温拉伸性能的影响, 金属热处理, 2003, 28(11): 31-34.

ZHANG Ying-nan, ZHAO Yong-qing, QU Heng-lei, YANG Hai-ying, LI Hui, FENG Liang. Effect of Zr on microstructure and tensile properties of Ti-6-22-22S Alloy[J]. Metal Heat Treatment, 2003, 28(11): 31-34.

[6] ZHANG X D, EVANS D J, BAESLACK W A, FRASER H L. Effect of long term aging on the microstructural stability and mechanical properties of Ti-6Al-2Cr-2Mo-2Sn-2Zr alloy[J]. Materials Science and Engineering A, 2003, 343: 210-226.

[7] ZHANG X D, BONNIWELL P, FRASER H L, BEASLACK W A, EVANS D J, GENTER T, BAYHA T, CORNELL B. Effect of heat treatment and silicon addition on the microstructure development of Ti-6Al-2Cr-2Mo-2Sn-2Zr alloy[J]. Materials Science and Engineering A, 2003, 343: 210-226.

[8] 侯智敏, 毛小南, 雷文光, 卢亚锋, 张鹏省, 韩 栋. 固溶处理对近β锻TC21合金组织的影响[J]. 中国有色金属学报, 2010, 20(增1): 581-586.

HOU Zhi-min, MAO Xiao-nan, LEI Wen-guang, LU Ya-feng, ZHANG Peng-sheng, HAN Dong. Effect of solution treatment on morphology of near β forged TC21 alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(s 1): 581-586.

[9] 王新南, 朱知寿, 童路, 周 宇, 周晓虎, 俞汉清. 锻造工艺对TC4 DT和TC21损伤容限型钛合金疲劳裂纹扩展速率的影响[J]. 稀有金属快报, 2008, 28(7): 12-16.

WANG Xin-nan, ZHU Zhi-shou, TONG Lu, ZHOU Yu, ZHOU Xiao-hu, YU Han-qing. The influence of forging processing on fatigue crack propagation rate of damage-tolerant titanium alloy[J]. Rare Metals Letters, 2008, 28(7): 12-16.

[10] SCHMIDT P, CHRIST H J. Microstructure optimization by hydrogen treatment of β-titanium alloys[C]// Proceedings of the 12th World Conference on Titanium. Beijin, China: Science Press Beijing, 2012: 502-507.

(编辑 方京华)

基金项目:国家自然科学基金项目(51001088)

收稿日期:2013-08-01;修订日期:2013-10-08

通信作者:侯智敏,工程师,博士研究生;电话:029-86231078;E-mail:houzhimin1981@126.com