DOI: 10.11817/j.issn.1672-7207.2016.09.002

MgO含量及来源对磁铁精矿球团固结行为的影响

潘建,于鸿宾,朱德庆,春铁军

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:对普通磁铁矿球团、高镁磁铁矿球团和普通磁铁矿配加MgO粉的球团固结行为进行研究,考察MgO含量(质量分数)及来源对球团固结行为的影响。研究结果表明:当焙烧温度低于1 210 ℃时,MgO来源对焙烧球团抗压强度影响显著,表现为普通磁铁矿焙烧球团抗压强度最高,高镁磁铁矿球团次之,普通磁铁矿配加MgO粉球团抗压强度最低。当焙烧温度高于1 240 ℃时,MgO含量对焙烧球团抗压强度影响较大,焙烧球团抗压强度随MgO含量的增加而降低;在MgO含量相同条件下,高镁磁铁矿球团强度高于配加MgO粉球团。来源不同的MgO均抑制磁铁矿球团氧化和新生物相的分布,从而影响了球团的固结强度。矿化是配加MgO粉球团固结的限制性环节,提高焙烧温度有助于强化外加MgO粉的矿化并减弱MgO来源的影响,进而提高焙烧球团强度。

关键词: 氧化镁;磁铁矿;抗压强度;微观结构

中图分类号:TF046.6 文献标志码:A 文章编号:1672-7207(2016)09-2914-07

Effect of MgO content and sources on induration behavior of magnetite concentrate pellets

PAN Jian, YU Hongbin, ZHU Deqing, CHUN Tiejun

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Three different kinds of pellets (common magnetite pellet, magnetite with high MgO content pellet and magnetite pellet adding MgO powder) were studied to investigate the effect of MgO content and sources on induration behavior of pellets. The results show that MgO sources have a great influence on the compressive strength of fired pellets when fired temperature is below 1 210 ℃, and the compressive strength of common magnetite pellets are maximal, followed by the pellets made of magnetite with high MgO content, and the pellets adding MgO powder are minimum. The MgO content has greater effect on the compressive strength of fired pellets when fired temperature is above 1 240 ℃, and the compressive strength decreases with the increase of MgO content. Meanwhile, the strength of fired pellets composed by magnetite with high MgO content is higher at the same level of MgO content. Induration mechanism research shows that MgO affects not only the pellets oxidation but also new phase distribution. As a result, it influences the compressive strength of pellets. The mineralization is the restricted factor for pellets adding MgO powder. Higher roasted temperature is conducive to strengthening MgO powder mineralization and weakening the influence of MgO sources, leading to the high compressive strength.

Key words: MgO; magnetite; compressive strength; microstructure

近年来,受市场资源的影响,钢铁企业为降低成本,在烧结生产中采取了大量配加印度、澳矿、非洲塞拉利昂高铝粗粉等经济料的措施,致使高炉炉渣中Al2O3明显升高,给高炉操作带来了很大难度[1]。解决高炉中Al2O3 含量高的问题,通常的做法是提高入炉料中的MgO含量。目前,高炉炉料的普遍模式为高碱度烧结矿配加酸性炉料(氧化球团、普通烧结矿或天然块矿)[2],导致高炉炼铁中所需的MgO几乎全部由烧结矿提供,而MgO含量过高将直接影响烧结矿的产质量[3-4],从而给烧结生产带来严重压力。将一定量的MgO转移到球团矿中,不仅能改善炉渣流动性,还能提高烧结矿质量和高炉技术经济指标。研究表明[5-13]:含镁熔剂性球团具有较高的还原度和较好的软熔特性,因而能够降低焦比、提高高炉产量,但是,镁质球团矿存在焙烧性能差和抗压强度低等不足[14-18]。研究发现[16]:以蛇纹石、MgO粉和菱镁石等作为含镁添加剂,预热球和焙烧球团的抗压强度都会降低,而且球团强度随着MgO含量的增加急剧下降。当球团中MgO含量(质量分数)大于2.4%时,预热球强度甚至不足200 N/个,焙烧球团强度也低于1 500 N/个,远低于工业生产对预热球团抗压强度大于500 N/个,焙烧球团抗压强度大于2 500 N/个的要求,不利于球团矿生产的大型化。因此,研究MgO对氧化球团固结的影响十分重要。然而当前MgO来源对球团固结机理的研究较少,尤其是对MgO以类质同象形式存在的高镁磁铁矿球团,为此,本文作者对普通磁铁矿球团(低MgO含量),高镁磁铁矿球团和普通磁铁矿配加MgO粉的球团进行固结行为研究,探讨MgO含量及来源对磁铁精矿球团固结行为的影响,揭示其作用机理。

1 原料性能与研究方法

1.1 原料性能

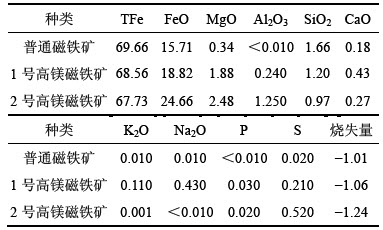

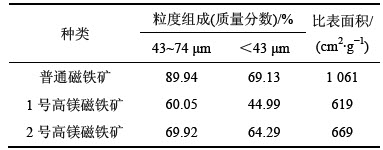

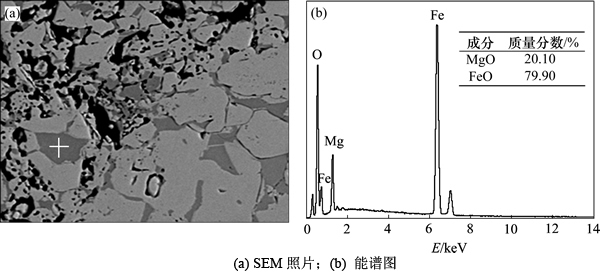

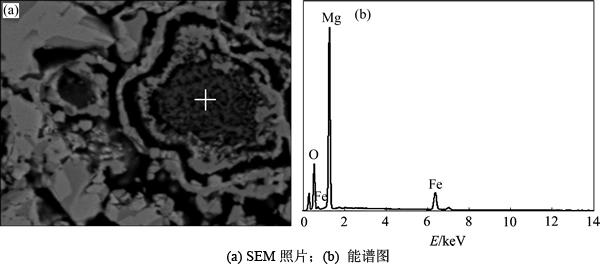

本试验采用3种高品位磁铁精矿,化学成分与物理性能见表1和表2。由表1可见:试验用3种磁铁矿TFe品位较高,均大于67%,同时,SiO2含量也都较低,是3种优质的球团原料。1号和2号高镁磁铁矿MgO含量(质量分数)分别为1.88%和2.48%,均远比普通磁铁矿的高。1号和2号高镁磁铁矿扫描电镜能谱图如图1和图2所示。由图1和图2可知:磁铁矿晶格中均存在一定量的MgO。其中1号高镁磁铁矿晶格中MgO质量分数为1.47%,2号高镁磁铁矿晶格中MgO质量分数为2.18%,这说明Mg2+取代了磁铁矿中的Fe2+以类质同象的形式存在于磁铁矿晶格中。

表1 磁铁精矿化学成分(质量分数)

Table 1 Chemical compositions of magnetite concentrates %

表2 磁铁精矿物理性能

Table 2 Physical properties of magnetite concentrates

图1 1号高镁磁铁矿扫描电镜能谱图

Fig. 1 SEM image and EDS analysis of No.1 magnetite with high MgO content

图2 2号高镁磁铁矿扫描电镜能谱图

Fig. 2 SEM image and EDS analysis of No.2 magnetite with high MgO content

研究发现[19]:用比表面积评价原料造球性能更可靠,造球物料适宜的比表面积为1 500~1 900 cm2/g。由表2可知:2种磁铁矿粒度较大,比表面积较小,造球前需通过高压辊磨预处理,提高其比表面积,改善其成球性。

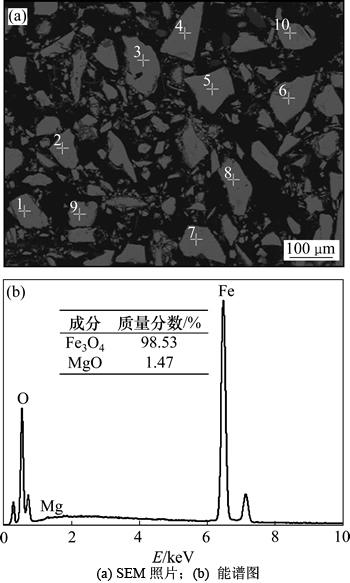

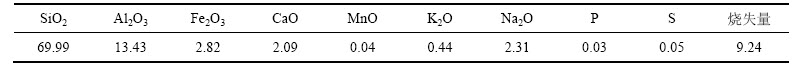

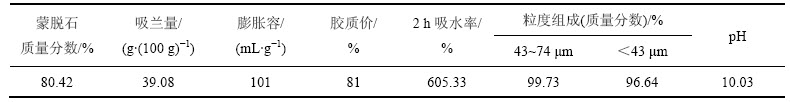

试验所用膨润土的化学成分与物理性能见表3和表4。由表3和表4可知:该钠基膨润土蒙脱石含量高,吸水率较大且粒度细,属于优质的球团黏结剂。试验所用含镁添加剂为MgO分析纯试剂,MgO质量分数为98%。

1.2 研究方法

球团制备试验流程模拟工业生产氧化球团的工艺流程,首先进行原料准备,然后按配料、混合、造球、烘干、预热、焙烧的过程依次进行。3种磁铁精矿先经高压辊磨预处理至比表面积约为1 500 cm2/g,采用高压辊磨机进行预处理,在开路条件下,辊磨压力为3.5 t,转速为40 r/min,物料水分为7.0%。造球试验在直径为1 000 mm的圆盘造球机中进行,转速为28 r/min,边高h=150 mm,倾角α=47°。造球时间为12 min,紧密2 min。取直径为12.5 mm左右的生球在105 ℃的温度下干燥4 h,进行预热焙烧试验。预热焙烧试验在卧式电热管炉中进行,预热温度为950 ℃,预热时间为12 min。焙烧球团抗压强度测定设备为ZQYC-智能抗压测量仪。成品球团矿显微结构的鉴定和分析采用Leica DMRXE光学显微镜和扫描电镜。

2 实验结果及分析

2.1 MgO含量及来源对抗压强度的影响

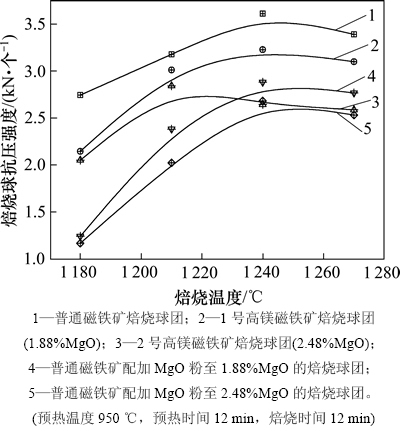

焙烧温度对焙烧球团抗压强度的影响见图3。由图3可见:随着焙烧温度的升高,不同焙烧球团的抗压强度先显著增加,然后有所降低。氧化球团在焙烧过程的固结机理是通过新生赤铁矿的再结晶与晶粒之间互连强化球团抗压强度,温度的升高能够促进矿物晶格中质点的可动性,强化新生赤铁矿的再结晶,同时促使其与相接触的Fe2O3聚集成较大晶体颗粒[19]。当焙烧温度低于1 210 ℃时,MgO来源对焙烧球团抗压强度影响显著,表现为普通磁铁矿焙烧球团的抗压强度最大,可达3 178 N/个;高镁磁铁矿次之,1号高镁磁铁矿球团和2号高镁磁铁矿球团抗压强度分别为3 012 N/个和2 843 N/个;而配加MgO粉的球团强度最低,配加至MgO质量分数为1.88%和2.48%的焙烧球团抗压强度分别只有2 383 N/个和2 024 N/个。当焙烧温度高于1 240 ℃时,MgO质量分数对焙烧球团抗压强度影响较大,配加MgO粉(MgO质量分数1.88%)的磁铁矿焙烧球团抗压强度为2 881 N/个,大于MgO质量分数为2.48%的高镁磁铁矿球团(2 645 N/个),但仍低于MgO质量分数为1.88%的高镁磁铁矿球团(3 228 N/个)。这是由于MgO粉在球团中矿化需要较高的焙烧温度[4],在低温焙烧时,配加MgO粉的球团矿化困难,阻碍新生赤铁矿的结晶和互联,从而成为限制性环节。随着温度的升高,MgO的矿化完善,有助于MgO进入铁相中,从而减弱MgO来源的影响,此时,MgO含量对球团强度的影响起主导作用。

表3 膨润土化学成分(质量分数)

Table 3 Chemical compositions of bentonite %

表4 膨润土物化性能

Table 4 Physical properties of bentonite

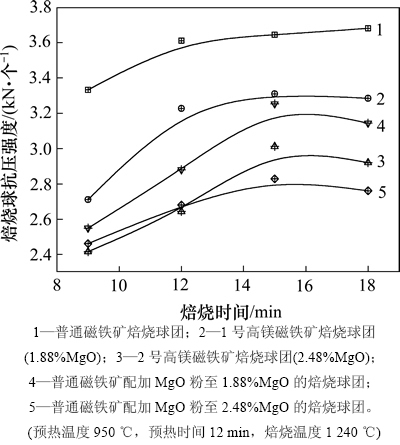

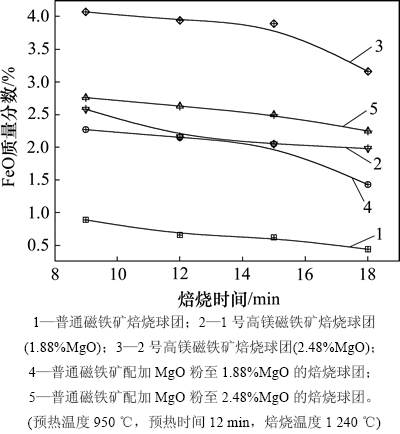

焙烧时间对焙烧球团抗压强度的影响见图4。由图4可知:随着焙烧时间的延长,焙烧球的抗压强度随之增加。当焙烧时间从9 min增加至15 min,普通磁铁矿焙烧球团抗压强度从3 333 N/个提高至3 644 N/个;而MgO质量分数为1.88%和2.48%的高镁磁铁矿焙烧球团分别从2 712 N/个和2 417 N/个提高到3 310 N/个和3 013 N/个;普通磁铁矿配加MgO粉至质量分数为1.88%和2.48%的焙烧球团抗压强度也分别从2 550 N/个和2 463 N/个升高到3 254 N/个和2 829 N/个。这是由于高温停留时间的延长有助于晶粒的长大和充分结晶[19]。从图5可以看到:焙烧球团中FeO含量随时间的延长而下降。当焙烧时间为18 min时,普通磁铁矿焙烧球团中FeO质量分数仅为0.44%,MgO质量分数均为1.88%的高镁磁铁矿球团和普通磁铁矿配加MgO粉的球团中FeO质量分数分别为1.98%和1.43%,而MgO质量分数均为2.48%的高镁磁铁矿球团和普通磁铁矿配加MgO粉的球团中FeO质量分数却高达3.16%和2.25%,这表明MgO来源及含量对球团氧化均会产生影响。对MgO含量相同的球团,高镁磁铁矿比普通磁铁矿配加MgO粉的球团氧化困难。而对MgO来源相同的球团,MgO含量越高,球团氧化越困难。

图3 焙烧温度对焙烧球团抗压强度的影响

Fig. 3 Effect of firing temperature on compressive strength of fired pellets

图4 焙烧时间对焙烧球团抗压强度的影响

Fig. 4 Effect of firing time on compressive strength of fired pellets

图5 焙烧时间对焙烧球团中FeO质量分数的影响

Fig. 5 Effect of firing time on content of FeO in fired pellets

2.2 MgO含量及来源对焙烧球团微观结构的影响

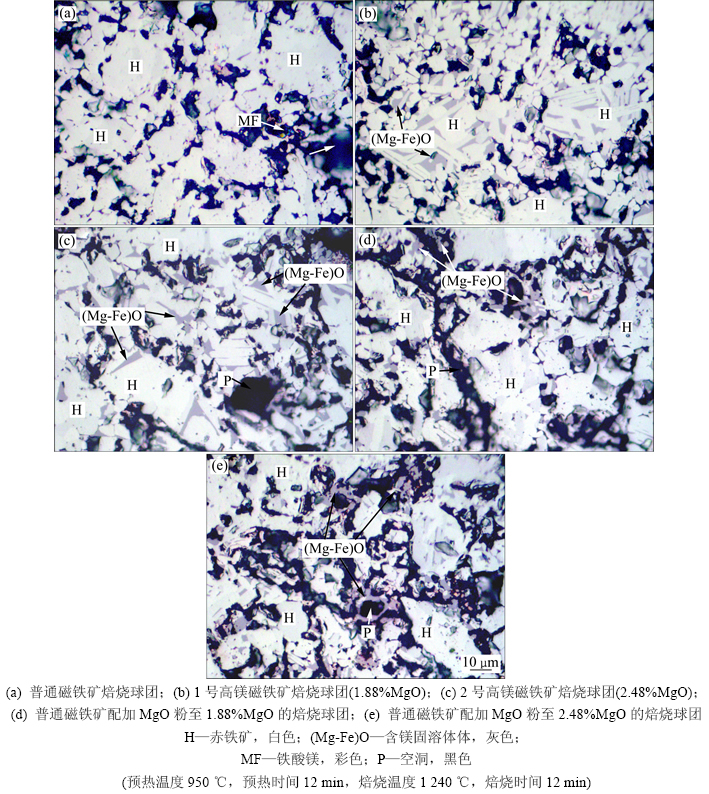

焙烧球团微观结构见图6。由图6可见:普通磁铁矿的焙烧球团内部以Fe2O3为主,晶粒粗大,互联成片,连接紧密,同时存在微量铁酸镁,所以,球团抗压强度最高。而高镁磁铁矿球团和普通磁铁矿配加MgO粉的球团内部,除了新生赤铁矿与铁酸镁外,同时球团内部存在大量灰色、不规则状颗粒。SEM-EDS证实这种物体为含镁固溶体(见图7),含镁固溶体的存在导致骸晶的产生,影响Fe2O3再结晶,所以球团的抗压强度较低。含镁固溶体在MgO来源不同的焙烧球团内部存在形式具有差异,高镁磁铁矿球团中的含镁固溶体在球团固结过程中大部分存在于铁相之中;而普通磁铁矿配加MgO粉的球团在焙烧过程中形成的含镁固溶体则主要赋存在Fe2O3晶粒之间,形成渣相连接,这势必会影响球团强度。这是由于磁铁矿氧化和铁离子扩散比镁离子快得多[20],导致外加MgO无法全部扩散到磁铁矿晶格中,致使球团内部仍存在少量未矿化的MgO颗粒(见图8)。而对于高镁磁铁矿,由于大部分MgO以类质同象的形式存在会使Mg2+更多的赋存在晶格内部,并不存在未矿化的MgO颗粒和大量渣相连接,从而导致在MgO含量相同的条件下,高镁磁铁矿球团抗压强度较高。

图6 光学显微镜下焙烧球团矿显微结构

Fig. 6 Mineral phases of fired pellets under optical microscope

图7 2号高镁磁铁矿焙烧球团扫面电镜能谱图(2.48%MgO)

Fig. 7 SEM image of fired pellets made of No.2 magnetite with high MgO(2.48%) content with EDS

图8 普通磁铁矿配加MgO粉至2.48%MgO的焙烧球团扫描电镜能谱图

Fig. 8 SEM images of fired pellet adding 2.48% MgO powder with EDS

3 结论

1) MgO含量及来源对磁铁精矿焙烧球团抗压强度影响显著。当焙烧温度低于1 210 ℃时,MgO来源对球团抗压强度影响较大,普通磁铁矿焙烧球团抗压强度最高,高镁磁铁矿球团次之,配加MgO粉的球团强度最低。当焙烧温度大于1 240 ℃,MgO含量对球团抗压强度影响较大,焙烧球团抗压强度随MgO含量的增加而降低,而在MgO含量相同时,高镁磁铁矿球团抗压强度相对配加MgO粉的高。

2) MgO含量及来源均影响磁铁精矿球团氧化。MgO含量越高,球团氧化越困难,致使球团内残留的FeO含量越高。在MgO含量相同的条件下,高镁磁铁矿中以类质同象形式存在的MgO对球团氧化影响更大。

3) MgO含量对球团固结影响显著。普通磁铁矿的焙烧球内部以Fe2O3为主,晶粒粗大,互联成片。而高镁磁铁矿球团和配加MgO粉的磁铁矿球团内部存在大量含镁固溶体,含镁固溶体的存在导致骸晶的产生,影响Fe2O3再结晶,降低含镁球团的抗压强度。

4) MgO来源则对焙烧球团固结形式的影响存在差异。高镁磁铁矿球团中的含镁固溶体大部分存在于Fe2O3之中。而配加MgO粉的磁铁矿球团在焙烧过程中形成的含镁固溶体则主要赋存在Fe2O3晶粒之间,形成渣相连接,同时球团内部仍存在少量未矿化的MgO颗粒,从而导致在MgO含量相同的条件下,高镁磁铁矿球团抗压强度较高。

参考文献:

[1] 张丙怀, 刁岳川, 廖东海, 等. 富三氧化二铝高炉炉渣的流动性[J]. 钢铁研究学报, 2005, 17(4): 14-16, 25.

ZHANG Binghuai, DIAO Yuechuan, LIAO Donghai, et al. Fluidity of high alumina blast furnace slag[J]. Journal of Iron and Steel Research, 2005, 17(4): 14-16, 25.

[2] 王筱留. 钢铁冶金学: 炼铁部分[M]. 北京: 冶金工业出版社, 2008: 72-75.

WANG Xiaoliu. Iron and steel metallurgy: iron part[M]. Beijing: Metallurgical Industry Press, 2008: 72-75.

[3] 吴胜利, 韩宏亮, 姜伟忠, 等. 烧结矿中MgO作用机理[J]. 北京科技大学学报, 2009, 31(4): 428-432.

WU Shengli, HAN Hongliang, JIANG Weizhong, et al. MgO interaction mechanism in sinter[J]. Journal of University of Science and Technology Beijing, 2009, 31(4): 428-432.

[4] 黄柱成, 韩志国, 江源, 等. MgO对以细磁铁精矿为主的低硅烧结的影响[J]. 中南大学学报(自然科学版), 2005, 36(5): 800-806.

HUANG Zhucheng, HAN Zhiguo, JIANG Yuan, et al. Influence of MgO on sinter mainly made from fine magnetite concentrate[J]. Journal of Central South University (Science and Technology), 2005, 36(5): 800-806.

[5] DWARAPUDI S, GHOSH T K, SHANKAR A, et al. Effect of pellet basicity and MgO content on the quality and microstructure of hematite pellets[J]. International Journal of Mineral Processing, 2011, 99(1/2/3/4): 43-53.

[6] DWARAPUDI S, GHOSH T K, SHANKAR A, et al. Effect of pyroxenite flux on the quality and microstructure of hematite pellets[J]. International Journal of Mineral Processing, 2010, 96(1/2/3/4): 45-53.

[7] 陈耀铭, 陈锐. 烧结球团矿微观结构[M]. 长沙: 中南大学出版社, 2011: 121-122, 124-125.

CHENG Yaoming, CHEN Rui. Microstructure of sinter and pellet[M]. Changsha: Central South University Press, 2011: 121-122, 124-125.

[8] 姜鑫, 吴钢生, 李光森, 等. 改善含MgO铁矿石软熔性能的研究[J]. 东北大学学报(自然科学版), 2007, 28(3): 365-368.

JIANG Xin, WU Gangsheng, LI Guangsen, et al. Study on improving the softening-melting properties of MgO-bearing iron ores[J]. Journal of Northeastern University (Natural Science), 2007, 28(3): 365-368.

[9] GAO Qiangjian, SHENG Fengman, WEI Guo, et al. Effects of MgO containing additive on low-temperature metallurgical properties of oxidized pellet[J]. Journal of Iron and Steel Research International, 2013, 20(7): 25-28.

[10] 张汉泉. 熔剂性球团的生产及发展[J]. 中国矿业, 2009, 18(4): 89-92.

ZHANG Hanquan. Production and development of fluxed pellet[J]. China Mining Magazine, 2009, 18(4): 89-92.

[11] 张晓萍, 金俊, 覃德波. 马钢生产镁质球团矿的可行性研究[J]. 烧结球团, 2010, 35(5): 16-19.

ZHANG Xinping, JIN Jun, QING Debo. Feasibility study on MgO-containing pellet production in masteel[J]. Sintering and Pelletiziing, 2010, 35(5): 16-19.

[12] 李圣辉, 陈铁军, 张一敏, 等. 含镁添加剂用于铁矿球团的试验研究[J]. 烧结球团, 2011, 36(1): 33-37.

LI Shenghui, CHEN Tiejun, ZHANG Yimin, et al. Experimental study on application of Mg-bearing additives in iron ore pellet[J]. Sintering and Pelletizing, 2011, 36(1): 33-37.

[13] 周明顺, 沈峰满, 翟立委, 等. MgO添加方式对改善球团矿冶金性能的影响[J]. 钢铁, 2012, 47(4): 14-18.

ZHOU Mingshun, SHENG Fengman, ZHAI Liwei, et al. Influences of MgO adding method on improving metallurgical properties of pellet[J]. Iron and Steel, 2012, 47(4): 14-18.

[14] 甘敏, 范晓慧, 陈许玲, 等. 钙和镁添加剂在氧化球团中的应用[J]. 中南大学学报 (自然科学版), 2010, 41(5): 1645-1651.

GAN Min, FAN Xiaohui, CHEN Xuling, et al. Application of Ca, Mg-additives in oxidized pellets[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1645-1651.

[15] FAN Xiaohui, GAN Min, JIANG Tiao, et al. Influence of flux additives on iron ore oxidized pellets[J]. Journal of Central South University of Technology, 2010, 17(4): 732-737.

[16] 范晓慧, 谢路奔, 甘敏, 等. 高镁球团焙烧特性及其固结强化机理[J]. 中南大学学报(自然科学版), 2013, 44(2): 449-455.

FAN Xiaohui, XIE Luben, GAN Min, et al. Roasting characteristics of magnesium pellets and mechanism of strengthening concretion[J]. Journal of Central South University (Science and Technology), 2013, 44(2): 449-455.

[17] 宋招权. 磁铁精矿球团氧化动力学及竖炉热工制度的研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2000: 19-25.

SONG Zhaoquan. Research on oxidation kinetics of magnetite pellet and shaft-kiln operating parameter[D]. Changsha: Central South University. School of Minerals Processing and Bioengineering, 2000: 19-25.

[18] 高强健, 魏国, 何奕波, 等. MgO对球团矿抗压强度的影响[J]. 东北大学学报(自然科学版), 2013, 34(1): 103-106.

GAO Qiangjian, WEI Guo, HE Yibo, et al. Effect of MgO on compressive strength of pellet[J]. Journal of Northeastern University (Natural Science), 2013, 34(1): 103-106.

[19] 傅菊英, 姜涛, 朱德庆. 烧结球团学[M]. 长沙: 中南工业大学, 1996: 286-302.

FU Juying, JIANG Tao, ZHU Deqing. Principle of sintering and pelletizing[M]. Changsha: Central South University of Technology Press, 1996: 286-302.

(编辑 赵俊)

收稿日期:2015-05-11;修回日期:2015-09-07

基金项目(Foundation item):国家自然科学基金资助项目(51474161);国家科技部火炬计划项目(2011GH561685) (Project(51474161) supported by the National Natural Science Foundation of China; Project(2011GH561685) supported by the Torch Plan of the Ministry of Science and Technology of China)

通信作者:潘建,博士,教授,从事烧结球团、直接还原、二次资源利用和钢铁冶金环境保护等研究;E-mail: pjcsu@csu.edu.cn