文章编号:1004-0609(2011)04-0829-07

高频脉冲电沉积改善Ni镀层的组织和性能

王子涵1, 杨 滨1, 2, 蒋春丽3, 王庆富3, 张鹏程3,范爱萍1

(1. 北京科技大学 新金属材料国家重点实验室,北京 100083;

2. 中国科学院 国际材料物理中心,沈阳 110016;

3. 中国工程物理研究院 表面物理与化学国家重点实验室,绵阳 621900)

摘 要:采用高频脉冲电沉积制备纳米Ni镀层,研究高频脉冲频率对纳米Ni镀层组织、腐蚀性能和摩擦性能的影响;室温下,在含50 μg/g Cl-的氯化钾溶液中通过测试Ni镀层的极化曲线和电化学阻抗谱(EIS)研究其腐蚀性能。结果表明:在实验脉冲频率范围内(30~100 kHz),提高脉冲频率,可使Ni镀层晶粒细化;电极过程的转移电阻从30 kHz时沉积Ni镀层的1.97×104 Ω·cm2增大到100 kHz时的6.56×104 Ω·cm2,自腐蚀电位从-551.41 mV 正移到-420.28 mV,这表明高频沉积的Ni镀层晶粒更细小,致密性更高,因而耐蚀性更强。摩擦试验结果表明:摩擦因数由30 kHz时沉积Ni镀层的0.39降低到100 kHz时的0.25,说明高频沉积的Ni镀层具有更强的耐磨性;镀层晶粒细化、较高的致密性和硬度是耐磨性提高的主要原因。

关键词:Ni镀层;脉冲电沉积;耐蚀性;摩擦因数

中图分类号:TQ153 文献标志码:A

Improvement of microstructure and properties of Ni coating prepared by high frequency pulsed-electrodeposition

WANG Zi-han1, YANG Bin1, 2, JIANG Chun-li3, WANG Qing-fu3, ZHANG Peng-cheng3, FAN Ai-ping1

(1. State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing,

Beijing 100083, China;

2. International Centre for Materials Physics, Chinese Academy of Sciences, Shenyang 110016, China;

3. National Key Laboratory for Surface Physics and Chemistry, Chinese Academy of Engineering Physics,

Mianyang 621900, China)

Abstract: The effects of pulse frequency on the microstructure, corrosion and wear resistance properties of a nanocrystalline Ni coating produced by high frequency pulsed-electrodeposition technique were studied. The corrosion behavior of the Ni deposit was also evaluated by polarization curves and electrochemical impedance spectroscopy (EIS) in 50 μg/g potassium chloride aqueous solution with at room temperature. The results show that the grain size of the Ni coating is refined with the increase of pulse frequency from 30 to 100 kHz. The charge transfer resistance and self-corrosion potential of the coating are increased from 1.97×104 to 6.56×104 Ω·cm2 and from -551.41 to -420.28 mV, respectively with increasing frequency from 30 to 100 kHz, revealing that the corrosion resistance of the Ni coating is improved owing to its grain-refinement and higher compactness. The tribological tests show that the friction coefficient of the Ni coating decreases from 0.39 to 0.25 with frequency increasing from 30 to 100 kHz. The reason is suggested to its grain-refinement, higher compactness and microhardness.

Key words: Ni coating; pulsed-electrodeposition; corrosion resistance; friction coefficient

相对普通粗晶材料,晶粒尺寸小于100 nm的纳米材料具有优异的力学、物理、化学和电化学性能,因此吸引了材料科学工作者的广泛关注[1]。在现有的纳米材料制备方法(如溶胶凝胶法、化学气相沉积法、电沉积法和机械合金化法等[2])中,电沉积法是目前研究的一个热点,研究的体系包括Ni、Co、Cu、Ni-P、Fe-Ni和Ni-SiC等[3]。

电沉积纳米Ni的主要制备方法有直流法[4]、脉冲法和喷射法等[5]。脉冲法是近十多年来发展起来的一种新型电沉积技术,依据的电化学原理是利用电流(或电压)脉冲的张弛增加阴极的活化极化和降低阴极的浓差极化,以达到改善镀层物理化学性能的目的[6]。以往脉冲电沉积的研究都局限在低频(10 kHz以下)范围内[7-9],更高频脉冲电沉积对镀层组织和性能的影响研究鲜见系统的报道,一些研究者[10-13]认为,在高频脉冲下,增大频率能细化镀层晶粒的主要原因是镀层沉积次数增加和镀液浓度恢复速度加快。考虑到Ni镀层不仅仅用于装饰性镀层,还广泛应用于耐腐蚀和耐磨镀层。因此,本文作者选择30~100 kHz的脉冲频率,研究高频脉冲电沉积Ni镀层的组织、耐腐蚀和耐磨性能,探讨高频脉冲细化Ni镀层组织、改善性能的机理。

1 实验

阳极采用Ni板,阴极采用钢板。电解液采用氨基磺酸镀液,基本组成如下:500 g/L氨基磺酸镍、30 g/L硼酸及15 g/L氯化钠(所用试剂均为分析纯)。用10%氢氧化钠溶液调节镀液pH值。电沉积过程使用北京好源科技有限公司制造的T100型单向方波高频脉冲电源,主要技术参数如下:输入电压为220 V单向工频交流电压;输出峰值电压为32 V;输出峰值电流为20 A;输出脉冲频率为20~140 kHz,连续可调;输出脉冲占空比为0.1~0.9,连续可调。电镀操作条件如下:温度60 ℃,pH值3~4,电流密度1 A/dm2,占空比45%,频率30~100 kHz,沉积时间2 h,由耐腐蚀磁力过滤泵进行搅拌。实验中固定上述工艺条件,仅改变脉冲频率,研究其对Ni镀层组织和性能的影响。

将沉积后的镀层从基板上剥离后,通过打磨抛光等处理后制成d 3 mm的小圆片,采用MTP-1型电解双喷仪减薄;电解液为20%高氯酸+80%酒精溶液,温度为-25~-30 ℃,电流为100 mA;利用Tecnai F20 场发射透射电镜(TEM)研究Ni镀层结构和形貌。用SUPPR5 ZEISS场发射扫描电镜(SEM)观察Ni镀层磨痕形貌。电化学腐蚀介质为含Cl- 50 μg/g的氯化钾溶液;动电位极化曲线测量使用Perkin Elmer Model 273A型恒电位仪,扫描速率为2 mV/s,CorrView2软件用于极化曲线分析;PARSTAT 2263 DC+AC电化学综合测试仪用于Ni镀层的电化学阻抗谱(EIS)研 究,阻抗频率范围为0.1 Hz~10 kHz,阻抗信号幅值为5 mV,Zview2软件用于电化学阻抗谱分析。采用HVS-1000数字显微硬度仪测试镀层显微硬度,在镀层表面任取5点,取平均值。MMW-1A微机控制万能摩擦磨损试验机用于Ni镀层的摩擦磨损研究,测试条件如下:摩擦副采用小止推环,载荷100 N,时间250 s,转速200 r/min,温度17 ℃,湿度48%。

2 结果与讨论

2.1 Ni镀层的微观组织

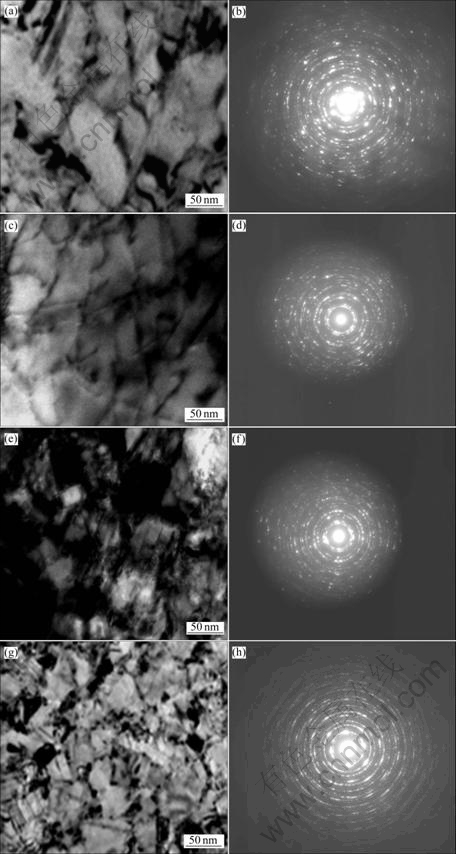

本文作者的前期研究发现[14],当脉冲频率从 30 kHz增大到100 kHz时,Ni镀层的(200)面衍射峰显著宽化,用Scherrer公式计算各强峰的晶粒尺寸,结果表明平均晶粒尺寸逐渐减小。镀层截面的SEM观察也发现,晶粒尺寸随频率的增加而减小。TEM结果进一步表明,随脉冲频率增加,镀层晶粒细化,组织均匀(见图1(a)~(d))。

图1(e)~(h)显示明显的FCC多晶衍射环。对比发现,随频率的增加,衍射环连续性更好,表明选区内的微观组织更细小均匀。

由电化学基本定义[15]可知,脉冲平均电流密度Jm与频率f有如下关系式:

(1)

(1)

式中:Jp为峰值电流密度; 为占空比;ton为导通时间;toff为关断时间;周期q = ton+toff;频率f = 1/q。

为占空比;ton为导通时间;toff为关断时间;周期q = ton+toff;频率f = 1/q。

由式(1)可知,当Jm和 不变时,Jp为恒定值,因而提高脉冲频率f,ton必然减小。

不变时,Jp为恒定值,因而提高脉冲频率f,ton必然减小。

液相扩散传质在脉冲沉积过程中,限制了脉冲条件的有效范围和最大沉积速度,影响所得镀层的结构和性质,同样也影响镀液的宏观和微观分散能力。IBL等[15]认为在脉冲沉积过程中,电极表面存在双扩散层,在靠近阴极的内扩散层中,金属离子浓度随频率变化而波动,因此,根据Fick第二定律,推导了电沉积过程内扩散层厚度δp 与导通时间ton的关系式[6]:

(2)

(2)

式中:D为镀液的扩散常数。

图1 不同脉冲频率沉积的Ni镀层TEM像及对应的选区电子衍射图

Fig.1 TEM images((a), (c), (e), (g)) and corresponding SAED patterns((b), (d), (f), (h)) of Ni coating electrodeposited at 30 kHz ((a), (e)), 60 kHz ((b), (f)), 90 kHz ((c), (g)) and 100 kHz ((d), (h))

式(2)表明,随着ton的减小,扩散层厚度δp减小。由电化学理论可知,随着扩散层的减薄,放电离子向电极表面扩散的阻力将减小,即扩散速度加快,导致阴极表面放电离子数量增多。在瞬时脉冲峰值电流密度Jp相同的情况下,更高的频率意味着更高的形核速率。另外,提高脉冲频率,导通时间ton缩短,当阴极表面附近金属离子浓度还未降到最低点时,电结晶过程随即终止,这样既可以避免浓差极化对电结晶过程的影响,又能抑制已有晶核的进一步成长,有助于获得晶粒细小且光滑致密的金属层。总之,提高脉冲频率,既加速了晶粒的形核过程,又抑制了晶粒长大,有利于细化Ni镀层晶粒。

2.2 Ni镀层抗腐蚀性能

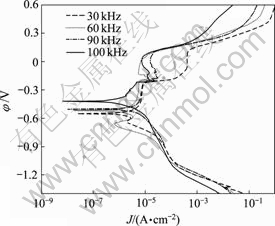

图2所示为不同频率电沉积Ni镀层的动电位极化曲线。由图2可见,各曲线形状基本相似,在腐蚀电位附近,极化电流随极化过电位的增大而快速增加,表明电极极化过程受电子转移的电化学活化控制。当阳极极化到弱极化区后,极化电流随极化电位的升高而增大,极化曲线的斜率愈来愈大,即电极过程的阻力越来越大,Ni镀层出现了“伪钝化”现象[16],电子在镀镍层与离子导体(Cl-含量为50 μg/g的水溶液)之间的转移越来越困难。当极化电位进一步升高,极化曲线出现转折点。在转折点以上,极化电流迅速增加,表明Ni镀层出现了点蚀,局部活性点构成了大阴极小阳极的腐蚀原电池,从而加速了Ni镀层样品的腐蚀。

图2 不同脉冲频率下沉积的Ni镀层的动电位极化曲线

Fig.2 Polarization curves of Ni coating electrodeposited at various pulse frequencies

表1所列为图2中Ni镀层的极化曲线拟合结果。由表2可知,随着脉冲频率增加,镀层的自腐蚀电位逐渐升高,从30 kHz的-551.41 mV正移至140 kHz的-420.28 mV。根据腐蚀热力学理论可知[17],镀层自腐蚀电位越高,其耐腐蚀性能也越强。另从图2右上部分也可观察到,在相同电极电位下,较高频率沉积的Ni镀层腐蚀电流较小,对应的腐蚀速度较慢。分析认为,主要是高频脉冲沉积的Ni镀层晶粒更小,致密性更高。

表1 Ni镀层动电位极化曲线拟合结果

Table 1 Fitting results of polarization curves of Ni coating electrodeposited at various pulse frequencies

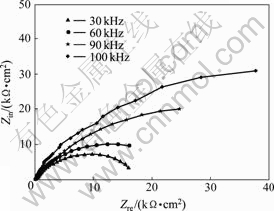

图3所示为不同脉冲频率沉积的Ni镀层的Nyquist阻抗谱。由图3可见:各镀层均呈现出显著的容抗弧特性;且随着沉积频率增加,镀层交流阻抗的容抗弧呈扩张趋势,这表明提高脉冲频率有利于获得更高阻抗幅值的Ni镀层。

图3 不同脉冲频率沉积的Ni镀层的Nyquist阻抗谱

Fig.3 Nyquist plots of Ni coating electrodeposited at various pulse frequencies

高频脉冲沉积的Ni镀层,虽然较致密,但仍存在少量微孔。这是由于Ni2+在阴极还原过程中往往伴随析氢副反应,部分氢原子如果团聚形成氢气泡吸附于镀层而未破裂,会在下一个导通时间内继续长大,直到Ni镀层生长将其压碎,最终在镀层内形成微孔隙。浸泡4 h后,电解液将通过这些微孔隙逐渐渗透到达Ni/钢板界面并构成腐蚀微电池。由此,根据混合电位的EIS原理[17],推测出Ni镀层交流阻抗等效电路图(见图4)。在EIS数据拟合过程中,为了获得更精确的拟合结果,用常相位角元件(Constant phase element)代替双电层电容(C)[18-19],所以,该等效电路图组成一个Rs(Q1(R1(Q2Rct)))复合元件。其中:Rs为溶液电阻,Q1为表征镀层表面电容的常相位角元件(CPE),R1为镀层孔隙内的溶液电阻,Q2(CPE)和Rct并联代表Ni镀层缺陷或钢基体处金属电荷的传递过程。

图4 Ni镀层在电解液中的等效电路

Fig.4 Equivalent circuit of Ni coating in electrolyte (Rs, R1 and Rct are resistors, Q1 and Q2 are CPEs)

将图3中各试样的阻抗谱采用图4所示的等效电路进行拟合,结果如表2所列。由表2可知,Ni镀层的微孔电阻R1和电荷转移电阻Rct均随沉积频率提高而增大,其中微孔电阻由30 kHz时的81.7 Ω·cm2增加到100 kHz的766.3 Ω·cm2,而转移电阻也从1.97× 104 Ω·cm2增加到6.56×104 Ω·cm2。通常,微孔电阻R1越大,镀层微孔率越低;电极过程电荷转移电阻Rct越大,镀层耐腐蚀性越强。上述结果表明,在实验范围内,提高脉冲频率,有利于减少镀层孔隙率,提高镀层致密性,进而增强其耐蚀性,加强对基体的保护作用。

2.3 不同脉冲频率下Ni镀层的摩擦磨损性能

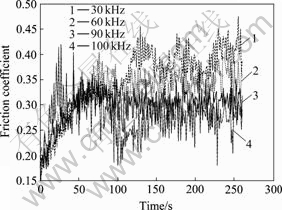

图5所示为不同脉冲频率沉积的Ni镀层的摩擦因数与摩擦时间的关系。由图5可知,试样的摩擦因数先逐渐上升,然后缓慢降低,最后趋于稳定。主要原因如下:当摩擦副在Ni镀层表面开始滑动时,由于镀层表面较为粗糙,易发生磨损变形,结果使摩擦副与镀层接触面积加大,进而增大了摩擦力,导致摩擦因数逐渐上升,随着摩擦持续进行,试样表面趋于平滑,摩擦因数缓慢下降,磨损也趋于稳定。对比图5中不同频率沉积镀层的摩擦因数可见,随频率提高,摩擦因数逐渐下降,由30 kHz时的大约0.39下降到100 kHz时的0.25,表明在更高频率沉积的Ni镀层的耐磨能力更强。

图5 不同脉冲频率沉积的Ni镀层摩擦因数随时间变化 曲线

Fig.5 Relationship between friction coefficient and slide time for Ni coating electrodeposited at various pulse frequencies

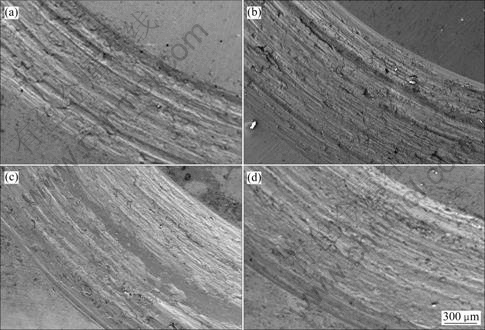

试样的磨痕形貌如图6所示。由图6可见:镀层的磨痕中均有犁沟。进一步比较发现,30 kHz时沉积的Ni镀层磨痕最深,60 kHz时的次之,而90和100 kHz时的则较浅,表明提高频率沉积的Ni镀层致密性更好,耐磨能力更强。

频率为30、60、90和100 kHz时沉积的Ni镀层显微硬度依次为285、371、385和450 HV,这说明随着频率的提高,镀层的显微硬度逐渐增大,其主要原

表2 不同脉冲频率沉积的Ni镀层阻抗拟合结果

Table 2 Fitting results of impedance of Ni coating electrodeposited at various pulse frequencies

图6 不同脉冲频率沉积的Ni镀层磨痕的SEM像

Fig.6 SEM images of worn surfaces of Ni coating electrodeposited at 30 kHz (a), 60 kHz (b), 90 kHz (c) and 100 kHz (d)

因是镀层的晶粒更细化。通常硬度较大的镀层的抗磨能力较强。因此,沉积频率越高,Ni镀层的致密性越好,硬度也越大,结果使镀层的摩擦因数降低,磨痕变浅,耐磨性增强。

3 结论

1) 在30~100 kHz频率范围内,提高脉冲频率,可以细化Ni镀层晶粒和提高其显微硬度。

2) 电化学腐蚀测量结果显示,Ni镀层的电极反应电荷转移电阻由30 kHz时沉积的1.97×104 Ω·cm2增加到100 kHz时的6.56×104 Ω·cm2,自腐蚀电位亦由-551.41 mV正移至-420.28 mV,表明Ni镀层的耐腐蚀性随频率增加而提高。

3) 摩擦试验结果显示,Ni镀层的摩擦因数从30 kHz时沉积的0.39降低到100 kHz时的0.25,表明高频脉冲电沉积可以改善Ni镀层的耐磨性。

REFERENCES

[1] WAKABAYASHI H, SATO N, SONE M, TAKADA Y, YAN H, ABE K, MIZUMOTO K, ICHIHARA S, MIYATA S. Nano-grain structure of nickel films prepared by emulsion plating using dense carbon dioxide[J]. Surface & Coatings Technology, 2005, 190: 200-205.

[2] INGUANTA R, PIAZZA S, SUNSERI C. Influence of electrodeposition techniques on Ni nanostructures[J]. Electrochimica Acta, 2008, 53: 5766-5773.

[3] KANG J X, ZHAO W Z, ZHANG J F. Influence of electrodeposition parameters on the deposition rate and microhardness of nanocrystalline Ni coatings[J]. Surface & Coatings Technology, 2009, 203: 1815-1818.

[4] SANSOZ F, STEVENSON K D, GOVINTHASAMY R, MURTHY N S. Making the surface of nanocrystalline Ni on a Si substrate ultrasmooth by direct electrodeposition[J]. Scripta Materialia, 2008, 59: 103-106.

[5] 徐剑刚, 余新泉. 电沉积纳米晶镍的研究现状及展望[J]. 材料导报, 2006, 20(4): 30-33.

XU Jian-gang, YU Xin-quan. Research status and prospects of electrodeposited nanocrystalline nickel[J]. Materials Review, 2006, 20(4): 30-33.

[6] 安茂忠. 电镀理论与技术[M]. 哈尔滨: 哈尔滨工业大学出版社, 2004: 241-243.

AN Mao-zhong. Theory and technology of plating[M]. Harbin: Harbin Institute of Technology Press, 2004: 241-243.

[7] 赵阳培. 电沉积纳米晶材料的研究进展[J]. 材料科学与工程学报, 2003, 21(1): 126-129.

ZHAO Yang-pei. Review of preparing nanocrystalline materials by electrodeposition[J]. Journal of Materials Science and Engineering, 2003, 21(1): 126-129.

[8] 陈艳容, 龙晋明, 裴和中, 洪建平, 石小钊. 脉冲电沉积镍及其合金的研究现状与展望[J]. 电镀与精饰, 2009, 31(2): 16-21.

CHEN Yan-rong, LONG Jin-ming, PEI He-zhong, HONG Jian-ping, SHI Xiao-zhao. Research progress on nickel and nickel-based alloys[J]. Plating and Finishing, 2009, 31(2): 16-21.

[9] 解西峰, 朱 荻. 高频脉冲电铸的试验研究[J]. 航空精密制造技术, 2003, 39(2): 10-13.

XIE Xi-feng, ZHU Di. Research on process of high frequency pulse electroforming[J]. Aviation Precision Manufacturing Technology, 2003, 39(2): 10-13.

[10] 杨玉国, 刘为霞, 许韵华, 沙建萍. 高频脉冲电镀Ni-SiC纳米复合镀层影响因素的研究[J]. 电镀与涂饰, 2006, 25(7): 4-7.

YANG Yu-guo, LIU Wei-xia, XU Yun-hua, SHA Jian-ping. Influential factors of Ni-SiC nano-composite coatings by high frequency pulse electroplating[J]. Electroplating and Finishing, 2006, 25(7): 4-7.

[11] 宫晓静, 许韵华, 杨玉国, 曹克宁, 赵 宇. 高频脉冲电镀镍钴合金耐蚀性的研究[J]. 表面技术, 2007, 36(6): 4-6.

GONG Xiao-jing, XU Yun-hua, YANG Yu-guo, CAO Ke-ning, ZHAO Yu. Corrosion resistance of high frequency pulse electroplating Ni-Co coating[J]. Surface Technology, 2007, 36(6): 4-6.

[12] 宫晓静, 许韵华, 杨玉国, 曹克宁, 赵 宇. 高频脉冲电镀镍钴合金拉伸强度的研究[J]. 材料开发与应用, 2007, 22(6): 28-30.

GONG Xiao-jing, XU Yun-hua, YANG Yu-guo, CAO Ke-ning, ZHAO Yu. Tensile strength of high frequency pulse electroforming Ni-Co alloy[J]. Development and Application of Materials, 2007, 22(6): 28-30.

[13] 曹克宁, 许韵华, 杨玉国, 赵 宇, 宫晓静. 高频脉冲镀 Ni-Co合金的形貌、微观结构及耐蚀性研究[J]. 电镀与涂饰, 2007, 26(12): 1-3.

CAO Ke-ning, XU Yun-hua, YANG Yu-guo, ZHAO Yu, GONG Xiao-jing. Analysis of the microstructure of high frequency pulse electroformed Ni-Co nanocomposite bulk materials[J]. Electroplating and Finishing, 2007, 26(12): 1-3.

[14] 王子涵, 杨 滨, 铁 军, 姜 涛, 杨玉国, 张济山. 脉冲频率对Ni镀层组织性能的影响[J]. 稀有金属材料与工程, 2007, 36(S3): 620-622.

WANG Zi-han, YANG Bin, TIE Jun, JIANG Tao, YANG Yu-guo, ZHANG Ji-shan. The effect of pulse frequency on the microstructure and tensile properties of Ni sheets[J]. Rare Metal Materials and Engineering, 2007, 36(S3): 620-622.

[15] IBL N. Some theoretical aspects of pulse electrolysis[J]. Surface Technology, 1980, 10: 81-104.

[16] TAIT W S. An introduction to electrochemical corrosion testing for practicing engineers and scientists[M]. Wisconsin: Pair O Docs Publications, 1994: 72.

[17] 曹楚南. 腐蚀电化学原理[M]. 北京: 化学工业出版社, 2004: 169-231.

CAO Chu-nan. Theory of corrosion electrochemistry[M]. Beijing: Chemical Industry Press, 2004: 169-231.

[18] 王庆富. 铀上脉冲电镀镍的组织结构和性能研究[D]. 绵阳: 中国工程物理研究院, 2004: 57-62.

WANG Qing-fu. Analysis of microstructure and properties of Ni deposit pulse-plated on uranium surface[D]. Mianyang: Chinese Academy of Engineering Physics, 2004: 57-62.

[19] 张金涛, 胡吉明, 张鉴清. 环氧涂层金属体系的串联双槽电化学阻抗谱分析[J]. 金属学报, 2006, 42(8): 857-860.

ZHANG Jin-tao, HU Ji-ming, ZHANG Jian-qing. EIS analysis of epoxy-coated metal system by series double-cell compartment[J]. Acta Metallurgica Sinica, 2006, 42(8): 857-860.

(编辑 龙怀中)

基金项目:表面物理与化学国家重点实验室开放基金资助项目(SPC200704)

收稿日期:2010-03-22;修订日期:2010-04-28

通信作者:杨 滨,教授,博士;电话:010-62333351;E-mail: byang@ustb.edu.cn