DOI: 10.11817/j.issn.1672-7207.2017.06.014

采煤机无人自适应变速截割控制方法

刘永刚,闫忠良,秦大同,胡明辉,葛帅帅,侯立良

(重庆大学 机械传动国家重点实验室,重庆,400044)

摘要:为了实现采煤机的无人自动化采煤,并使采煤机在截煤时的块煤率及截割比能耗等截割性能参数综合较优,通过分析现有采煤机的工作原理及特性并建立采煤机变速截割仿真模型,得到煤层截割阻抗与截割电机定子电流的关系。在此基础上,提出一种适用于滚筒采煤机的自适应变速截割控制方法,通过划分煤层截割阻抗范围,对采煤机的牵引速度和滚筒转速进行分级优化调节,根据采煤机截割电机定子电流及时间信号,结合所制定的控制策略实现采煤机对煤层截割阻抗的自动识别及自适应调速控制,最后进行仿真分析及试验进行验证。研究结果表明:该控制方法可取得较好效果并具有可行性,为实现采煤机自适应变速截割及无人化自动采矿提供参考。

关键词:截割阻抗识别;截割参数;优化;变速截割;自适应控制

中图分类号:TD421 文献标志码:A 文章编号:1672-7207(2017)06-1513-09

Adaptive control method of unmanned shearer with variable speed cutting

LIU Yonggang, YAN Zhongliang, QIN Datong, HU Minghui, GE Shuaishuai, HOU Liliang

(State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing 400044, China)

Abstract: In order to achieve shearer’s unmanned cutting and obtain the integrated optimal cutting performance parameters such as lump coal rate and energy consumption rate, the relationship between coal seam cutting impedance and cutting motor stator current was acquired by analyzing current shearer’s working theory and building the simulation model. Furthermore, an adaptive control method of shearer with variable speed cutting was presented. The coal seam cutting impedance was divided into different ranges, and each range corresponds to the optimized hauling speed and drum rotation speed. The ranges were identified by using fuzzy control technology based on the cutting motor stator current and the duration time, coal seam cutting impedance identification and adaptive speeds control were implemented with specific strategy. At last, the simulation and experiment were conducted. The results show that this method is favorable and feasible, which provides theoretical reference to the implement of shearer high efficiency cutting and unmanned mining.

Key words: cutting impedance identification; cutting parameters; optimization; variable speed cutting; adaptive control

我国煤炭有90%是井工开采,但目前我国煤矿井下采掘装备的智能化程度不高,导致我国煤矿开采灾害多、用人多、伤亡多、效率低[1]。滚筒采煤机是现代机械化采煤的主要设备,广泛应用于不同地质条件下的煤炭开采。滚筒采煤机生产的主要缺点是块煤率低和工作面粉尘量较大,低块煤率不仅增加采煤比能耗,而且降低了原煤的应用范围和使用价值,同时也是产生粉尘的一个重要原因,而粉尘又严重威胁着工人的身体健康和生命安全, 因此,实现采煤机高效截煤作业及其少人、无人的自动化采矿成为研究热点[2]。国内外学者对采煤机高效截割以及自动化采矿进行了研究,如:刘丹丹等[3]提出基于磁流变阀触觉技术的采煤机恒功率控制方法;赵奕辉等[4]设计了基于模糊控制的电牵引采煤机恒功率自动控制系统;谷勇[5]提出了基于模糊控制的采煤机截割自动调速控制系统,取得了良好效果;黄华[6]采用模糊控制理论对采煤机截割路径进行跟踪,调节采煤机牵引速度和滚筒高度;ZHOU等[7]提出一种基于模糊最优化的记忆截割控制方法,仿真结果表明该方法高效可行;王刚等[8]对薄煤层工作面自动化开采技术应用进行了研究;桓希传等[9]探讨了采煤机截割电机变频调速的必要性,从原理上分析了用变频调速控制采煤机截割电机的可行性;刘送永等[10]根据采煤机截割理论建立了滚筒截割比能耗与滚筒运动参数之间关系的数学模型;刘春生等[11]根据滚筒的截煤和装煤要求研究了牵引速度和滚筒转速的匹配关系;马正兰等[12]开展了在不同截割阻抗煤质条件下的截割速度和牵引速度的优化研究,为变速截割技术的实施提供了理论依据;赵丽娟等[13]基于经济截割对采煤机运动学参数和结构参数进行了优化研究;ORDIN等[14]以最大利润为目标对综采工作面长度和工作效率进行了优化; VENKATARAMAN[15]利用旋转截割试验台研究了截割比能耗、可呼吸粉尘量与相关参数的关系,指出滚筒截割比能耗和可呼吸粉尘量与截齿的几何形状和尺寸、滚筒的截齿布置以及滚筒的牵引和旋转速度有关;EINICKE等[16]对长壁开采的自动化进行了分析研究;澳大利亚煤炭协会发起的“Landmark”项目,其目的也在于研究自动化长壁开采技术[17]。此外,在采煤先进技术及装备等方面,国外学者和企业也进行了大量研究[18],但目前对采煤机无人自适应变速截割的综合研究还较少。为实现采煤机无人化高效截割,本文作者提出一种适用于滚筒采煤机的无人自适应变速截割控制方法。分析现有采煤机工作原理及特性,建立采煤机截割负载与截割电机定子电流的关系;对煤层按截割阻抗范围进行划分并得到优化后的采煤机运动参数,在此基础上采用模糊控制技术结合所制定的控制策略实现采煤机自适应变速截割,并对具体调速方法和控制策略进行仿真分析和试验验证。

1 采煤机载荷分析

采煤机主要由牵引部、截割部及调高机构等组成。本文主要对采煤机牵引部、截割部及其自适应变速截割调速控制进行研究,牵引电机和截割电机均为采用矢量控制变频调速的异步电机。

1.1 采煤机滚筒载荷

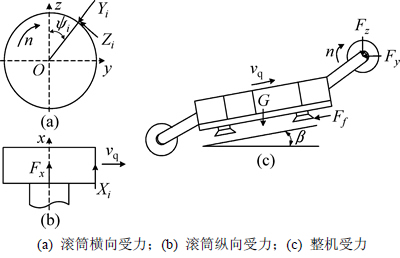

采煤机截割电机输出的转速和转矩经摇臂内惰轮传递后用以驱动滚筒转动并截割煤层,滚筒上截齿与煤层之间产生相互作用力, 因此,滚筒采煤机截割滚筒在工作过程中所受的载荷即为各截齿的合力。由图1可得到滚筒所受三向力为

(1)

(1)

式中:njg为截煤区参与截割的截齿数(个);ψi为第i个截齿的位置角((°));Xi为第i个截齿的侧向力(N);Zi为第i个截齿的截割阻力(N);Yi为第i个截齿的进给阻力(N)。滚筒主要受到的力为进给阻力Fy(N)、侧向力Fx(N)及截割阻力Fz(N)。

图1 滚筒及整机受力分析

Fig. 1 Force analysis of shearer and drum

1.2 采煤机整机载荷

牵引电机驱动整机运动,除克服摩擦力及重力的分力外,还要克服滚筒截煤时产生的进给阻力等。不考虑滚筒调高及进刀等,对整机受力模型进行简化,采煤机整机仅有牵引方向受力Fq,可表示为

(2)

(2)

式中:Ky为进给阻力系数;G为整机重力(N);fq为摩擦阻力系数;β为采煤机工作面倾角((°))。

1.3 运动学分析

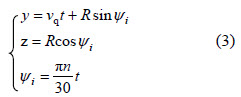

采煤机的截割运动参数直接影响截割负载及截割性能等。固定在滚筒上的截齿除了随滚筒绕其轴线旋转外,还必须随采煤机一起沿工作面作直线运动,其运动学方程为

式中:y为滚筒截齿Y轴坐标;z为滚筒截齿Z轴坐标;R为采煤机滚筒半径(m);t为滚筒工作时间(s);vq为采煤机牵引速度(m/min);n为滚筒转速(r/min)。

1.4 采煤机仿真模型的建立

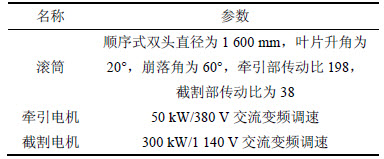

根据采煤机滚筒和整机的载荷分析及其运动学方程,利用Matlab/Simulink工具建立滚筒采煤机变速截割系统的仿真模型,为进行理论研究和仿真分析奠定基础,所建模型的主要参数见表1。

表1 采煤机仿真模型主要参数

Table 1 Main parameters of shearer simulation model

2 煤层截割阻抗识别及截割参数优化

2.1 截割电机定子电流与煤层截割阻抗的关系

不考虑采煤机滚筒调高等,在采煤机正常截煤时,牵引速度vq和滚筒转速n是影响采煤机截割性能的主要运动参数。

采煤机的截割负载是煤的物理机械性质在采煤机截割过程中的综合体现,并随其变化而变化。截割阻抗A综合地反映了被开采煤层可截割性,可用截割阻抗A表征煤岩的物理机械性质。

1) 滚筒上工作的截齿所受瞬时截割力为

(4)

(4)

式中:Z0ij为第i条截线上第j个工作的锐利截齿所承受的截割力(N);i和j为自由指标,为截齿对应的截线号和截线上的截齿号;Ycp-Y0为截齿磨钝时牵引力增量;f为截割阻抗系数,可由经验公式得到A=150f。

2) 瞬时切削厚度为

(5)

(5)

式中:hij为瞬时切削厚度(mm);mi为第i条截线上的截齿数(个);αij为第i条截线上第j个截齿的圆心角((°));vq为采煤机牵引速度(m/min);t为滚筒工作时间(s);n为滚筒转速(r/min)。

3) 滚筒的负载转矩即滚筒上受到的瞬时阻力矩为

(6)

(6)

式中:MZ为瞬时阻力矩(N·m);D为滚筒的直径(m);Zij为载齿所受瞬时截割力(N)。

由式(3)~(5)可知:当采煤机结构参数一定时,其截割负载与牵引速度vq、滚筒转速n、滚筒工作时间t以及截割阻抗A有关;而滚筒的工作时间t仅与某一时刻截入煤层的截齿位置和数量有关,影响滚筒截割载荷的周期性波动,对平均载荷的影响可以忽略。

综上所述,当采煤机牵引速度和滚筒转速一定时,其截割负载仅与煤层的截割阻抗A有关。采煤机的截割负载可用截割电机定子电流及其持续时间表征。因此,可通过采煤机截割电机定子电流及其持续时间反映所截煤层的截割阻抗。

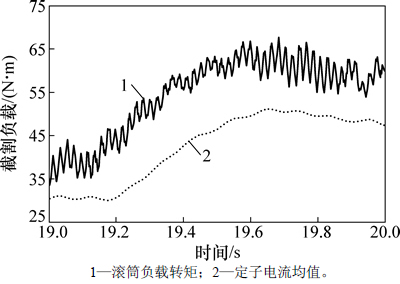

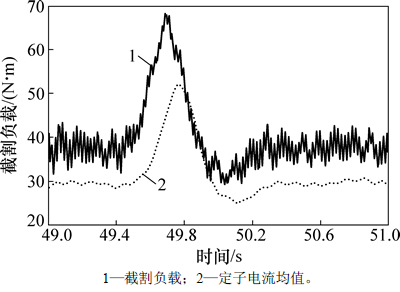

为了验证采煤机截割电机定子电流与截割负载之间的关系,搭建采煤机变速截割传动系统试验台架,获得截割负载与采煤机截割电机定子电流间的关系,如图2和图3所示。

由图2及图3可知:截割负载发生变化时,截割电机定子电流与截割负载变化趋势一致,时间上约有0.1 s延迟。由理论分析及试验结果可知,截割电机定子电流均值能够反映截割负载,进而为间接识别煤层的截割阻抗提供依据。

2.2 煤层按截割阻抗范围划分

不考虑夹矸等情况,煤层按其截割阻抗可分为三大类:A≤180 N/mm的煤层称为软煤层;A为180~240 N/mm的煤层称为中硬煤层;A为240~360 N/mm的煤层称为硬煤层[19]。

图2 阶跃载荷下截割电机定子电流

Fig. 2 Cutting motor stator current in step load

图3 脉冲载荷下截割电机定子电流

Fig. 3 Cutting motor stator current in pulse load

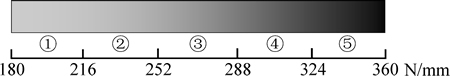

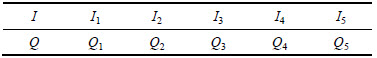

由于煤层是非均匀的,呈各向异性,且煤层的物理性质不稳定,硬度变化很大,即截割阻抗为变量。采煤机在截割煤层过程中不可能针对每一确切的截割阻抗的煤调节牵引速度vq和滚筒转速n,因此,针对适合使用滚筒采煤机开采的截割阻抗范围为180~360 N/mm的中硬煤层及硬煤层,采用分级区域划分的方法将煤层截割阻抗划分为5个等级范围,见图4;对应于所划分的每个截割阻抗等级范围,对滚筒采煤机截煤时的牵引速度vq和滚筒转速n进行优化调节,使采煤机自适应变速截割更具有可行性。

图4 煤层按截割阻抗范围划分

Fig. 4 Coal seam divided by cutting impedance ranges

2.3 截割参数分级优化

采煤机在截割煤层过程中的截割性能与采煤机的截割参数及结构参数有关。对于某一种类型的采煤机,只能改变其截割参数即牵引速度vq和滚筒转速n。因此,块煤率W、截割比能耗Hw等截割性能参数便主要与采煤机的牵引速度vq、滚筒转速n和截割阻抗A有关。

块煤率W以切削总面积S表征:

(7)

(7)

截割比能耗Hw为

(8)

(8)

式中:n为滚筒转速(r/min);vq为采煤机牵引速度(m/min);D为滚筒直径(mm);α为滚筒螺旋叶片的升角(rad);m为滚筒每条截线上的截齿数(个);φ为煤体破碎时的崩落角(rad);K为综合考虑煤的压张情况、脆塑性、截割条件等参数的修正系数;b为截齿的齿刃宽度(mm);A为截割阻抗(N/mm)。

以块煤率W和截割比能耗HW综合最优为目标,以牵引速度vq和滚筒转速n为设计变量,有

(9)

(9)

以截割电机功率和截割力、牵引电机功率和牵引力等为约束条件,利用模拟退火的粒子群算法对采煤机截煤时的截割参数进行优化,获取该截割阻抗范围内较优的牵引速度vq和滚筒转速n。优化目标函数为

(10)

(10)

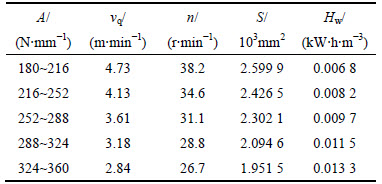

式中:K1和K2分别为块煤率、截割比能耗权重系数,具体数值可根据煤矿企业的具体生产要求和经济指标来确定。经过优化后,各截割阻抗范围所对应的采煤机截煤时的牵引速度vq和滚筒转速n及其截割性能参数见表2。

表2 运动参数及截割性能参数分级优化

Table 2 Optimization for movement parameters and cutting performance parameters correspond to ranges

3 采煤机自适应变速截割

3.1 煤层截割阻抗识别数据库建立

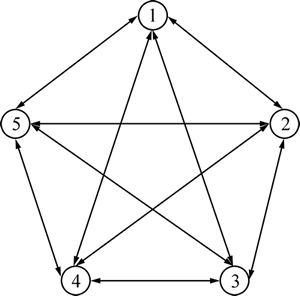

采煤机截割电机的定子电流均值和持续时间可以作为识别所截煤的截割阻抗的参数。而采煤机截割同一介质的时间一般大于3 s,由介质性质波动引起的异常截割电流持续时间一般小于3 s[20]。由于煤的不均匀性和滚筒参数的影响,截割电机定子电流均值也会有波动,同时为了便于识别,这里采用截割电机定子电流均值对时间的积分I作为识别煤的截割阻抗的参数,积分时间选取3 s。

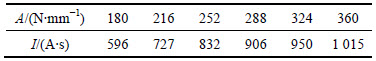

在采煤机结构参数和截割参数给定情况下,影响截割电机定子电流均值对时间的积分I的参数便是截割阻抗A。以截割阻抗范围⑤(见图4)时采煤机的截割参数为例,牵引速度vq=2.84 m/min,滚筒转速n=26.7 r/min。设采煤机以上述的牵引速度和滚筒转速开始截煤,煤质均匀,即煤的截割阻抗为一定值,取A=360N/mm,则可得到一确定的截割电机定子电流均值对时间的积分值,I=1 015 A·s。同理,可得到各个截割阻抗区间节点(180,216,252,288,324和360 N/mm)所对应的积分值,并以此建立该运动参数下的数据库D5,作为识别截割阻抗范围的标准,见表3。

表3 截割电机定子电流积分值数据库D5

Table 3 Integral value database D5 of cutting motor stator current

同理,可以得到采煤机在另外4组牵引速度和滚筒转速下截煤时,各个截割阻抗范围节点所对应的截割电机定子电流对时间的积分值数据库。

3.2 截割阻抗范围的模糊识别

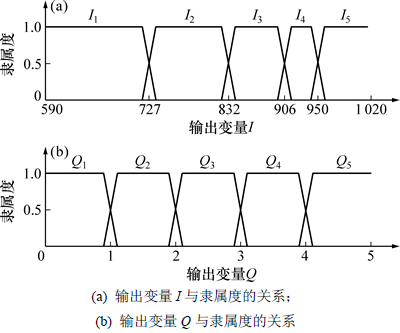

以表3中参数为例,设计自适应模糊识别控制器。以截割电机定子电流均值对时间的积分I为输入,值域为[590 , 1020] A·s;以截割阻抗范围Q为输出,值域为[1 , 5];建立该条件下的单输入单输出模糊识别控制器F5。

由式(4)~(6)可知滚筒负载与截割阻抗之间呈线性关系, 并由图2和图3得到截割电机定子电流与负载变化趋势一致,呈近似线性关系,且输出为用数值表示的截割阻抗范围,故选择trapmf型隶属度函数曲线,该制器的隶属度函数见图5。

图5 模糊控制器F5的隶属度函数

Fig. 5 Membership function of fuzzy controller F5

所设计的单输入单输出模糊控制器F5的模糊控制规则见表4。

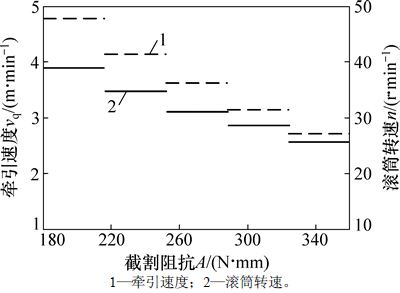

模糊控制器的输出变量截割阻抗Q,利用开关选择器选择并输出相应截割阻抗范围对应的牵引速度和滚筒转速。在所定义的整个煤层的截割阻抗范围(180~360 N/mm),牵引速度vq和滚筒转速n的输出见图6。

表4 模糊控制器F5的控制规则

Table 4 Control rules of fuzzy controller F5

图6 采煤机截割参数分级优化输出

Fig. 6 Outputs of movement parameters correspond to ranges

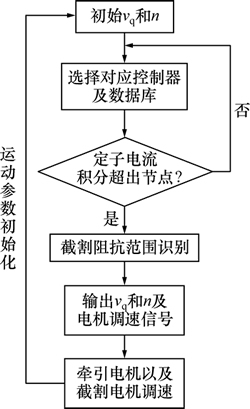

3.3 采煤机自适应变速截割控制策略

在煤层截割阻抗范围内分级划分和识别以及牵引速度和滚筒转速分级优化的基础上,制定相应的控制策略,实现滚筒采煤机按煤层截割阻抗的自适应变速截割。

对煤层截割阻抗范围内分级划分的目的在于更好地实现采煤机的自适应变速截割控制。采煤机实际截煤过程中不可能针对某一确定截割阻抗确定牵引速度和滚筒转速。由于煤的不稳定性,煤层截割阻抗变化较大,其截割阻抗范围的变化如图7所示。

对于给定的煤层,其截割阻抗范围为180~360 N/mm。由于滚筒采煤机在开始截煤作业时不知所截煤层的截割阻抗范围,为保护采煤机工作安全,选取初始截割参数为截割阻抗范围⑤时的优化参数。具体自适应变速控制策略如下:

1) 采煤机初始滚筒转速n=26.7 r/min,牵引速度vq=2.84 m/min,此时,选用模糊控制器F5。

2) 采煤机开始检测截割电机定子电流,采样时间为3 s,并求得积分值I,作为模糊控制器F5的输入。

图7 煤层截割阻抗范围变化示意图

Fig. 7 Change of coal seam cutting impedance ranges

3) 采用所选择的模糊控制器识别煤层截割阻抗所属范围,若判断为范围⑤,则不改变牵引速度vq和滚筒转速n以及模糊控制器。

4) 若模糊控制器F5判断煤层截割阻抗不为范围⑤,假设为范围③,则调节牵引速度vq=3.61 m/min,滚筒转速n=31.1 r/min,同时关闭范围⑤所对应的模糊控制器F5,而选择模糊控制器F3,并继续检测在该牵引速度和滚筒转速下截割电机定子电流积分值I。

5) 若煤层截割阻抗范围不变,则式(3)不改变牵引速度vq、滚筒转速n以及模糊控制器。

6) 若煤层截割阻抗范围发生变化,则按步骤(4)调节采煤机的牵引速度vq和滚筒转速n,同时调用相应的模糊控制器,并继续检测截割电机定子电流积分值I。

采煤机按截割阻抗范围自适应变速截割控制的控制策略示意图见图8。

采煤机根据煤层截割阻抗范围变化实现自适应变速截割控制的关键在于:建立采煤机在不同牵引速度和滚筒转速下截煤时各截割阻抗节点所对应的截割电机定子电流均值积分I的数据库和相应的模糊控制器,并根据所识别的煤层截割阻抗范围选择相应模糊识别控制器,输出相应牵引速度和滚筒转速。

3.4 采煤机电机调速控制方法

采煤机截煤时,若煤层截割阻抗发生变化,如由范围①变化至范围③,则相应的采煤机的牵引速度vq由4.73 m/min降至3.61 m/min,滚筒转速n由38.2 r/min降至31.1 r/min。牵引电机和截割电机均采用矢量控制变频调速,在进行调速时会对电机本身及采煤机传动系统产生影响,应采用合适的电机调速控制方法。

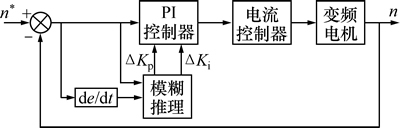

为提高电机调速性能,调速系统的速度控制器采用参数自整定模糊PI控制器。系统以电机目标转速与实际转速的差值及其变化率为输入,经模糊推理后,调整PI控制器参数。交流变频电机具有非线性、强耦合等特点,能够提高电机调速的控制效果,其结构见图9。

图8 采煤机自适应变速截割控制策略

Fig. 8 Adaptive control strategy of shearer with variable speed cutting

图9 参数自整定模糊PI控制器结构图

Fig. 9 Structure diagram of parameter tuning fuzzy PI controller

要实现电机的调速控制,需对调速系统给定转速控制信号,而不同形式的转速信号也会影响调速效果。 给定电机不同形式的转速信号和调速控制方法见图10。

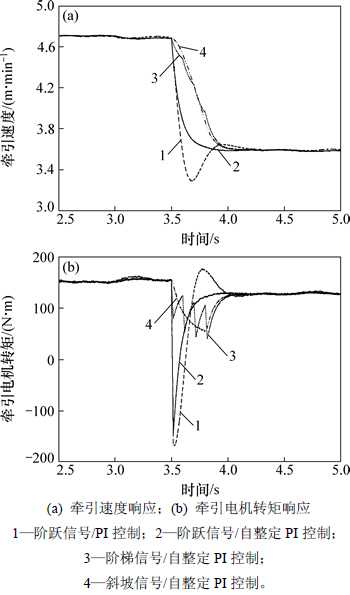

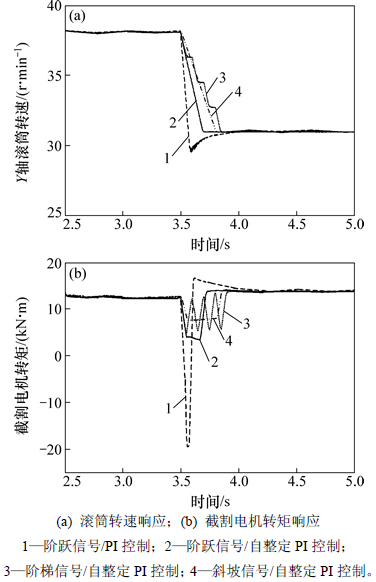

对采煤机截煤时的牵引调速过程进行仿真,给定煤层的截割阻抗为252 N/mm,滚筒转速为38 r/min,牵引速度vq由4.73 m/min降至3.61 m/min,此时,牵引速度及电机的转矩响应见图11。同理可得截割电机滚筒转速n由38.2 r/min降至31.1 r/min时不同调速方法的滚筒转速和电机转矩响应,见图12。

由图11及图12可知:牵引电机和截割电机采用参数自整定的PI控制时,电机的响应速度和超调比仅有PI控制的电机响应均为优;而对于同为参数自整定的PI控制的电机调速,给定斜坡形式的调速信号其电机转矩响应波动最小。由于牵引部、截割部电机功率、系统惯量等不同,两者的响应曲线变化幅度有所不同。综上可知:选择斜坡形式的转速信号给定方式并结合参数自整定PI控制的电机调速控制方法,其调速效果较优。

图10 不同转速信号给定方式及不同电机调速控制方法对比

Fig. 10 Comparison of different rotation speed signals settings ways and different motor speed control methods

图11 牵引速度及牵引电机转矩响应

Fig. 11 Response of hauling speed and hauling motor torque

图12 滚筒转速及截割电机转矩响应

Fig. 12 Response of drum rotation speed and cutting motor torque

4 采煤机自适应变速截割试验研究

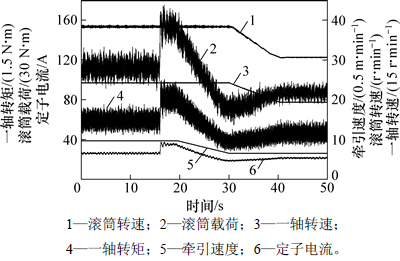

利用已搭建的采煤机变速截割传动系统试验台架对采煤机自适应变速截割控制方法进行验证。由于受目前条件限制,试验台架仅有截割电机,其功率为15 kW,采用变频控制,牵引电机的调速则通过程序实现。在试验过程中所采用的采煤机自适应变速截割控制策略示意图如图13所示,变速截割控制试验结果如图14所示。

由图13和图14可知:17 s时煤层截割阻抗发生变化(这里以阶跃载荷的形式给定),3 s后控制器判定煤层截割阻抗由范围①变化至范围③,并输出相应的牵引速度和滚筒转速;先对牵引速度vq进行调节,由4.73 m/min降至3.61 m/min,此时截割负载下降;然后,调节滚筒转速n由38.2 r/min降至31.1 r/min,截割负载有所上升,截割电机定子电流变化趋势与截割负载一致。

结果表明:截割电机定子电流可以反映煤层截割阻抗变化;验证了采煤机截割电机调速控制方法的有效性;本文所提出的采煤机无人自适应变速截割控制方法可自动适应不同硬度煤层的截割要求,为最终实现采煤机无人开采提供参考。

图13 采煤机自适应变速截割控制策略

Fig. 13 Adaptive control strategy of shearer with variable speed cutting

图14 采煤机自适应变速截割控制试验结果

Fig. 14 Adaptive control result of shearer with variable speed cutting

5 结论

1) 针对煤层截割阻抗变化的问题,对煤层截割阻抗进行区域划分,并进行了牵引速度和滚筒转速的分级优化。

2) 采用截割电机定子电流均值对时间积分的方法识别煤层截割阻抗范围,并利用仿真模型获得了截割电机定子电流积分值数据库,建立了煤层阻抗识别的模糊控制器。

3) 基于煤层截割阻抗划分,提出按截割阻抗范围进行自适应变速截割的控制策略和采煤机电机调速控制方法。

4) 搭建了采煤机变速截割传动系统试验台架,并对所提出的控制方法和策略进行了验证,为实现采煤机自适应变速截割控制以及无人化采煤提供了研究思路和参考。

参考文献:

[1] 葛世荣. 智能化采煤装备的关键技术[J]. 煤炭科学技术, 2014, 42(9): 7-11.

GE Shirong. Key technology of intelligent coal mining equipment[J]. Coal Science and Technology, 2014, 42(9): 7-11.

[2] 方新秋, 何杰, 郭敏江, 等. 煤矿无人工作面开采技术研究[J]. 科技导报, 2008, 26(9): 56-61.

FANG Xinqiu, HE Jie, GUO Minjiang, et al. Study on unmanned workface mining technology[J]. Science & Technology Review, 2008, 26(9): 56-61.

[3] 刘丹丹, 赵灿, 汤春瑞. 基于磁流变阀的采煤机恒功率控制应用[J]. 煤炭学报, 2009, 34(7): 988-992.

LIU Dandan, ZHAO Can, TANG Chunrui. Application of constant power control of shearer based on magnetorheological valve[J]. Journal of China Coal Society, 2009, 34(7): 988-992.

[4] 赵奕辉, 高晓光, 刘志明. 基于模糊控制的电牵引采煤机恒功率自动控制系统[J]. 煤矿机电, 2012(4): 41-43.

ZHAO Yihui, GAO Xiaoguang, LIU Zhiming. Constant power automatic control system of electric haulage shearer based on fuzzy control[J]. Colliery Mechnical & Electrical Technology, 2012(4): 41-43.

[5] 谷勇. 基于模糊控制的采煤机截割自动调速系统[J]. 煤矿机械, 2013, 34(12): 151-153.

GU Yong. Constant power automatic control system of electric haulage shearer based on fuzzy control[J]. Coal Mining Machinery, 2013, 34(12): 151-153.

[6] 黄华. 基于模糊控制理论的采煤机自适应截割控制研究[J]. 煤矿机械, 2014, 35(6): 110-112.

HUANG Hua. Research of adaptive cutting control of shearer based on fuzzy theory[J]. Coal Mining Machinery, 2014, 35(6): 110-112.

[7] ZHOU Xin, WANG Zhongbin, TAN Chao, et al. A novel approach for shearer memory cutting based on fuzzy optimization method[J]. Advances in Mechanical Engineering, 2013, 5(5): 319272.

[8] 王刚, 方新秋, 谢小平, 等. 薄层无人工作面自动化开采技术应用[J]. 工矿自动化, 2013, 39(8): 9-13.

WANG Gang, FANG Xinqiu, XIE Xiaoping, et al. Application of automatic mining technology of unmanned coal face of thin seam[J]. Industry and Mine Automation, 2013, 39(8): 9-13.

[9] 桓希传, 曹广海, 王涛. 采煤机截割电机变频调速控制的探讨[J]. 山东煤炭科技, 2009(1): 99-100.

HUAN Xichuan, CAO Guanghai, WANG Tao. Discusses on variable frequency speed control for cutting motor of shearer[J]. Shandong Coal Science and Technology, 2009(1): 99-100.

[10] 刘送永, 杜长龙, 崔新霞, 等. 采煤机滚筒运动参数的研究[J]. 煤炭科学技术, 2008, 36(8): 62-64.

LIU Songyong, DU Changlong, CUI Xinxia, et al. Analysis and research on cutting drum movement parameters of coal drum shearer[J]. Coal Science and Technology, 2008, 36(8): 62-64.

[11] 刘春生, 侯清泉. 采煤机滚筒转速与牵引速度范围匹配[J]. 煤矿机械, 2002(6): 11-12.

LIU Chunsheng, HOU Qingquan. The match of shearer drum rotational speed and traction speed[J]. Coal Mining Machinery, 2002(6): 11-12.

[12] 马正兰, 杜长龙, 刘送永. 高煤块率采煤机变速截割的理论研究[J]. 煤炭工程, 2009(12): 91-92.

MA Zhenglan, DU Changlong, LIU Songyong. Study on high lump coal rate shearer with variable speed[J]. Coal Engineering, 2009(12): 91-92.

[13] 赵丽娟, 刘旭南, 马联伟. 基于经济截割的采煤机运动学参数优化研究[J]. 煤炭学报, 2013, 38(8): 1490-1495.

ZHAO Lijuan, LIU Xunan, MA Lianwei. Optimization research on shearer’s kinematic parameters based on economical cutting[J]. Journal of China Coal Society, 2013, 38(8): 1490-1495.

[14] ORDIN A A, METEL’KOV A A. Optimization of the fully-mechanized stoping face length and efficiency in a coal mine[J]. Journal of Mining Science, 2013, 49(2): 254-264.

[15] VENKATARAMAN M. Effect of rate of sumping on fragmentation process in laboratory rotary cutting simulator[D]. USA: West Virginia University. College of Mineral and Energy Resources, 2003: 67-68.

[16] EINICKE G A, RALSTON J C, HARGRAVE C O, et al. Longwall mining automation: an application of minimum-variance Smoothing[J]. IEEE Control System Magazine, 2008, 28(6): 28-37.

[17] KELLY M S, HAINSWORTH D W. Outcomes of the landmark longwall automation project with reference to ground control issues[C]//24th Interantional Conference on Ground Control in Mining. Morgantown, 2005: 66-73.

[18] OSBORNE D. The coal handbook: towards clean production[M]. Philadelphia: Woodhead Publishing Limited, 2013: 193-225.

[19] 刘春生. 滚筒式采煤机工作机构[M]. 哈尔滨: 哈尔滨工业大学出版社, 2013: 19-20.

LIU Chunsheng. Working mechanism of drum shearer[M]. Harbin: Harbin Institute of Technology Press, 2013: 19-20.

[20] 苏秀平. 采煤机自动调高控制及其关键技术研究[D]. 徐州: 中国矿业大学机电工程学院, 2013: 16-19.

SU Xiuping. Study on key technologies of auto-height adjustment for shearer[D]. Xuzhou: China University of Mining & Technology. School of Mechanical and Electrical Engineering, 2013: 16-19.

(编辑 陈灿华)

收稿日期:2016-07-10;修回日期:2016-09-22

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2014CB046304)(Project(2014CB046304) supported by the National Basic Research Program(973 Program) of China)

通信作者:刘永刚,博士,副教授,从事动力传动系统及其综合控制研究;E-mail:andyliuyg@cqu.edu.cn