文章编号:1004-0609(2008)10-1802-05

晶面指数对高纯铝表面腐蚀发孔的影响

李 东1,毛卫民1, 2

(1. 北京科技大学 材料科学与工程学院,北京 100083;

(2. 北京科技大学 新金属材料国家重点实验室,北京 100083)

摘 要:采用含有盐酸、硝酸、氢氟酸的混合溶液腐蚀了从高纯铝锭上切割出的单晶{100}和{124}表面。定量统计两表面腐蚀孔密度随腐蚀时间的变化,并对变化规律进行了非线性拟合。研究表明,试样表面发生点蚀的位置为表面位错露头,其腐蚀发孔的难易程度与相应的位错应变能有关。研究表明,{100}面潜在发孔位置密度高于{124}面,而初始发孔率低于{124}面。{124}面较高的表面能使腐蚀孔生长较快,造成腐蚀后期其孔密度明显低于{100}面。

关键词:高纯铝;晶面指数;位错;腐蚀发孔;表面

中图分类号:TG 146.2; O 77 文献标识码: A

Influence of surface indices of high purity aluminum crystals on initiation process of pit etching

LI Dong1, MAO Wei-min1, 2

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. State Key Laboratory of Advanced Metals and Materials, University of Science and Technology Beijing,

Beijing 100083, China)

Abstract: The solution containing hydrochloric acid, nitric acid and hydrofluoric acid was used to etch the {100} and {124} surfaces of single crystal which were cut from ingot of high purity aluminum. The densities evolvement of pitting holes on the surfaces of the samples was quantitatively and statistically analyzed during the etching process, of which the regularity was obtained by the nonlinear fitting regression. It was observed that the pit etching initiates at the locations of dislocation ends on the samples surface. The difficulty of the pit etching was related to the strain energy of corresponding dislocations. The results show that density of potential pit nucleation on {100} surface is higher than that on {124} surface, and the primary nucleation rate of pit etching on {100} surface is lower than that on {124} surface. Pitting holes on {124} surface grow faster than those on {100} surface because the surface energy on {124} surface is higher than that on {100}, which leads to obviously lower pitting hole density on {124} after long etching treatment.

Key words: high purity aluminum; miller indices; dislocation; pit etching, surface

含铝99.99%以上的高纯铝箔是制作优质电解电容器的重要原料[1]。借助特定的电化学腐蚀技术可使高纯铝箔表面萌生腐蚀孔坑,并使孔坑不断向铝箔内部深化扩展,以急剧扩大铝箔的有效表面积,从而实现获得高比电容的目的[2-3]。铝箔的腐蚀起源于表面的位错、晶界、机械划痕等结构不均匀处的点蚀行为[4-6],因此铝箔表面的位错组态对其腐蚀性能具有重要的影响。铝箔成品的织构主要有立方织构{100}晶面以及R织构{124}晶面[7],其中高压电解电容器阳极铝箔的{100}面织构占有率可达到95%以上[8]。不同指数的铝晶体表面的位错会因映像力的不同会呈现不同的位错组态[9],因而相应的腐蚀发孔过程也会不一样。目前文献中关于织构和腐蚀发孔的研究大多为定性分 析[10-11],定量分析有关铝表面晶体学指数与位错腐蚀发孔过程之间关系还未见报道,所以本文作者在此有必要开展相应的研究。

1 实验

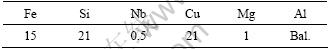

实验中使用的材料是高纯多晶铝块(>99.994% Al),铝块的成分如下表1所列。

表1 多晶铝块的化学成分

Table 1 Chemical composition of polycrystal aluminum ingots(10-6)

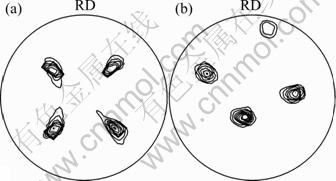

为排除晶界对腐蚀的影响,从多晶高纯铝锭中切割出了铝单晶,并获得了高纯铝箔中常见到的,表面分别为{100}面和{124}面的单晶样品,标识为样品100和样品124。图1所示为从这两个单晶表面测得的{111}极图。在图1所示的样品坐标系内,样品100的取向近似为(100)[001],样品124的取向近似为(214) 。

。

图1 样品100和样品124的{111}极图

Fig.1 {111} pole figures of sample 100 and sample 124: (Density levels: 1, 2, 4, 8, 16, 32, 64)

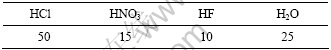

单晶样品表面经机械抛光、均匀化退火和电解抛光等预处理过程,以消除表面应力、机械滑痕以及其他外界因素对实验的影响。预处理后,采用纯化学腐蚀的方法对样品进行发孔实验。选用盐酸、硝酸、氢氟酸的混合腐蚀溶液,所用试剂都为分析纯级,腐蚀溶液的配方如表2所列。

表2 100 mL溶液中各成分的配比

Table 2 mixture ratio of 100 mL solution compositions (volume fraction, %)

用镊子夹持经清洗的电解抛光样品浸入腐蚀液中,分别停留5、10、20或40 s后取出;用蒸馏水清洗干净,用冷风吹干试样。腐蚀后的试样采用Leo-1450型扫描电子显微镜观察,并统计腐蚀孔的数量和腐蚀孔平均面积。

2 结果与分析

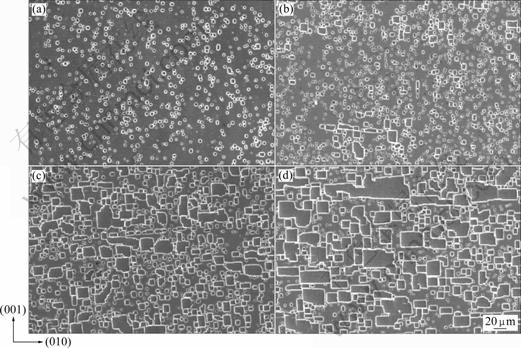

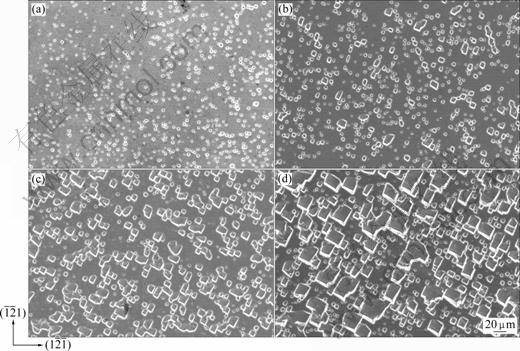

图2和图3所示分别为样品100和样品124的扫描电镜照片。由图可以观察到腐蚀孔的均匀分布,样品100的腐蚀孔大多呈正方形或长方形,样品124的腐蚀孔大多呈三角形或斜四边形,符合已有的观察[10]。在腐蚀过程中存在着腐蚀的“发孔”和腐蚀孔长大后互相合并形成“并孔”。随着腐蚀时间的延长,样品100腐蚀孔的数量先增大再减少;样品124腐蚀孔的数量则一直在减少。长时间腐蚀后,随并孔的大量出现,两样品中不规则的大孔数量越来越多。

图2 样品100腐蚀后的扫描电镜观察

Fig.2 SEM images of sample 100 after eching: (a) 5 s; (b) 10 s; (c) 20 s; (d) 40 s

图3 样品124腐蚀后的扫描电镜观察

Fig.3 SEM images of sample 124 after eching: (a) 5 s; (b) 10 s; (c) 20 s; (d) 40 s

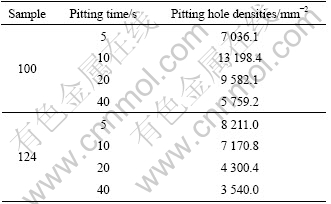

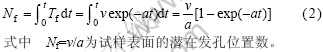

图2和3中每个观察视场的面积为123 250 ?m2,对每个腐蚀实验条件取6组扫描电镜照片,采用IMAGETOOL和DESIGER等图像处理工具软件统计蚀孔个数,并换算成单位面积腐蚀孔的密度,统计结果如表3所列。

表3 样品腐蚀孔的统计数据

Table 3 Statistical data of samples’ pitting holes

3 腐蚀孔密度变化规律的回归拟合

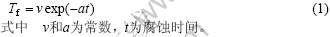

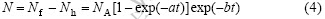

纯化学腐蚀实验过程中存在发孔和并孔两个过程;随腐蚀液的消耗,腐蚀发孔的发孔率会随着腐蚀时间的延长而逐渐下降。借鉴材料组织转变的形核率公式[12],可假定腐蚀孔的发孔率Tf为

对上式积分可求得t时发孔密度Nf为

在表面腐蚀发孔的情况下会发生并孔,从而减少腐蚀孔的数量。单位面积因并孔造成的腐蚀孔减少值称为并孔密度Nh,应与腐蚀发孔密度成比例关系,因此有:

因此,腐蚀样品表面实际观察到的孔密度N为

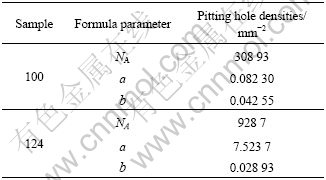

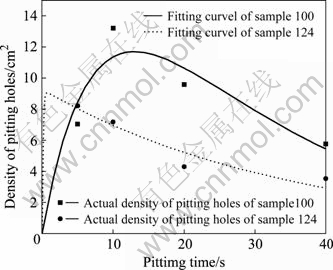

对样品100和样品124实际观察孔数进行非线性拟合,可获得式(1)~(3)中的常数v、a、b如表4所列。拟合后的图形如图4所示。拟合计算表明,{100}表面的最大发孔位置数NA高于{124}表面,而{124}表面的初始发孔速率高于{100}表面。由于{124}表面的并孔速率高于{100}表面,使得腐蚀后期在{124}表面观察到并拟合出了较低的腐蚀孔密度。

表4 腐蚀孔密度拟合参数值

Table 4 Fitting parameters of pitting hole densities

图4 实际孔数密度实测值及其回归曲线拟合

Fig.4 Observed densities of pitting holes and fitting curves

4 讨论

在铝晶体表面的位错露头附近的位错应力场会造成晶体畸变区,在腐蚀环境下位错附近容易产生应力腐蚀,先于表面其他地方开始腐蚀。把图2和3所示高纯铝单晶腐蚀孔坑的分布密度与退火铝晶体的位错密度比较可以判断出,试样表面的点蚀坑起源于一部分表面位错的露头处。因此NA可取为位错密度,或位错在晶体表面的露头密度。

实验表明,不是所有的位错露头都能同时发生应力腐蚀而转变为腐蚀孔。同一晶面上不同位错的露头会造成畸变能高低不同的应变区。畸变能较高位错露头附近会优先发生应力腐蚀,而这种微观应力腐蚀和我们平时讨论的宏观应力作用下的拉应力腐蚀在机制上差别不大。两个样品的潜在发孔位置数NA约为104(表4),靠近或落入了退火状态高纯铝的位错密度或位错露头密度范围(104~108 /mm2)[13]。

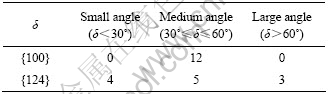

晶体表面位错映像力的作用会使部分位错逸出表面,使表面位错密度有所降低[12]。位错映像力也会使不能逸出表面的位错线向自由表面弯曲,转向稳定组态[9]。分析计算得出的[9]纯铝{100}和{124}晶面表层十二种稳定组态的位错线与自由表面法线夹角δ如表5所列。位错线与自由表面法线夹角δ越大,映像效应所释放的位错能量越少,因而位错因自身能量得到较多保留而容易发孔;反之则不容易发孔。表5显 示,{124}面表层存在4个小δ角的位错(δ<30?)和8个中、高δ角的位错(δ>30?),而{100}面表层没有小δ角的位错。因此,拟合样品100的潜在发孔位置数NA高于样品124(表4)。图4的拟合结果还显示,样品124应有更高的初始腐蚀孔密度,这可能源于少量更高δ角和更高能量位错区(表5,δ>60?)的率先发孔。

表5 12种不同的位错线与{100}和{124}面法线的夹角δ

Table 5 δ angles between twelve different dislocation lines and normal direction of {100} and {124} surface

铝晶体的表面能也会影响腐蚀发孔的过程。一般的实验和理论分析认为[14-15],{100}面的表面能会低于{124}面。图2和3显示,腐蚀孔内壁结构均由{100}晶面构成,表明本实验的腐蚀条件下{100}面具有较低的表面能。{124}面较高的表面能会促使腐蚀孔生成后以较快的速度长大并形成并孔,因此腐蚀后期{124}表面的腐蚀孔密度明显低于{100}表面(图4)。有关腐蚀孔生长速度及其影响因素的问题还有待进一步地深入研究。

5 结论

1) 表面位错露头是腐蚀孔发生的潜在位置,但只有造成较高应变区的位错露头才可以转变成腐蚀孔。

2) {100}表面高应变区位错露头的密度高于{124}表面,因而其潜在的腐蚀孔位置较多。{124}表面更高能量位错区的率先发孔使其腐蚀早期的孔密度较高。

3) {124}表面的表面能高于{100}表面,从而导致{124}表面在腐蚀后期的高速并孔,使腐蚀孔密度明显下降。

REFERENCES

[1] 毛卫民, 杨 宏, 余永宁, 冯惠平, 徐 进. 微量Mg对高压电子铝箔腐蚀结构的影响[J]. 中国有色金属学报, 2003, 13(5): 1057-1060.

MAO Wei-min, YANG Hong, YU Yong-ning, FENG Hui-ping, XU Jin. Influence of trace Mg on corrosion structure of high voltage aluminum foil[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1057-1060.

[2] OSAWA N, FUKUOKA K. Pit nucleation behavior of aluminum foil for electrolytic capacitors during early stage of DC etching[J]. Corrosion Science, 2000, 42: 585-597.

[3] THOMPSON G E, WOOD G C. Effect of alternating voltage on aluminum electrodes in hydrochloric acid[J]. Corrosion Science, 1978, 18: 721-746.

[4] NABI T M, SAMB? H, RAMAKER D E. AFM study of topographical changes on aluminum surfaces in sulfuric acid under low current anodic dissolution[J]. J Electroanalytical Chemistry, 2001, 501: 33-40.

[5] WU X, KUMAR P A, LYNN K G, et al. Detection of corrosion-related defects in aluminum using positron annihilation spectroscopy[J]. J Electrochemical Society, 1994, 141: 3361-3368.

[6] 毛卫民, 蒋 恒, 杨 平, 冯惠平, 余永宁. 微观结构和微量元素对铝箔腐蚀结构的影响[J]. 中国有色金属学报, 2004, 14(10): 1627-1631.

MAO Wei-min, JIANG Heng, YANG Ping, FENG Hui-ping, YU Yong-ning. Influence of microstructure and microelements on corrosion structure of aluminum foil[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(10): 1627-1631.

[7] MAO Wei-min. Formation of recrystallization cube texture in high purity FCC metal sheets[J]. Materials Engineering & Performance, 1999(8): 556-560.

[8] 徐 进, 毛卫民, 冯惠平, 舒龙卫. 退火加热过程对高压电解电容器阳极铝箔立方织构的影响[J]. 中国有色金属学报, 2001, 11(S2): 42-46.

XU Jin, MAO Wei-min, FENG Hui-ping, SHU Long-wei. Influence of annealing process on cube texture formation in aluminum foil of high voltage anode electrolytic capacitor[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S2): 42-46.

[9] 李 东, 毛卫民, 余永宁. 金属表层稳定位错组态[J]. 科学通报, 2007, 52(4): 487-488.

LI dong, MAO Wei-min, YU Yong-ning. Stable dislocation configuration in the surface layer of metals[J]. Chinese Science Bulletin, 2007, 52(4): 487-488.

[10] 张新明, 孟 亚, 周卓平, 周鸿章. Fe 杂质对高纯铝箔再结晶织构及比电容的影响[J]. 中国有色金属学报, 1999, 9(1): 19-24.

ZHANG Xin-ming, MENG Ya, ZHOU Zhuo-ping, ZHOU Hong-zhang. Effects of Fe impurity on recrystallization textures and specific capacitances of high pure aluminium foils[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 19-24.

[11] 刘 瑛, 张新明, 邓运来, 王宝峰. 微变形对强立方织构铝箔腐蚀发孔的影响[J]. 理化检验(物理分册), 2007, 43(7): 346-348.

LIU Ying, HANG Xin-ming, DENG Yun-lai, WANG Bao-feng. Effect of light deformation on the pitting of aluminum foils with strong cube textures[J]. Physical Testing and Chemical Analysis(Part A: Physical Testing), 2007, 43(7): 346-348.

[12] 余永宁. 金属学原理[M]. 北京: 冶金工业出版社, 2004.

YU Yong-ning. Physical metallurgy[M] . Beijing: Metallurgy Industry Press, 2004.

[13] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. London: Butter Worth, 1988: 38-41.

[14] 李云峰.低压电解电容器铝箔中织构与缺陷对腐蚀性能的影响[D]. 北京: 北京科技大学, 2003.

LI Yun-feng. Influence of texture and defects on corrosion performance of aluminum foil for low voltage electrolytic capacito[D]. Beijing: University of Science and Technology Beijing, 2003.

[15] WEN Yan-Ni, ZHANG Jian-Min. Surface energy calculation of the fcc metals by using the MAEAM[J]. Solid State Communications, 2007, 144(3): 163-167.

基金项目:国家自然科学基金资助项目(50571020);高等学校博士学科点专项科研基金资助项目(20040008010)

收稿日期:2008-03-13;修订日期:2008-06-18

通讯作者:李 东,博士研究生;电话:010-62332989;E-mail: donglee1980@126.com

(编辑 何学锋)