文章编号:1004-0609(2010)02-0329-10

镍基高温合金熔模铸件凝固过程宏/微观多尺度模拟

潘 冬,许庆彦,柳百成

(清华大学 机械工程系 先进成形制造教育部重点实验室,北京 100084)

摘 要:建立镍基高温合金熔模铸件凝固过程的宏/微观多尺度数理模型,基于射线追踪法处理热辐射,模拟铸件的温度分布,采用三维宏/微观网格嵌套和改进的CA方法模拟微观组织,并依据微观组织模拟结果处理结晶潜热,实现微观与宏观模拟的耦合。依据等效液面下降法、Niyama判据和Darcy定律预测铸件的宏观缩孔、宏观缩松和微观缩松缺陷分布位置,并浇注实际的高温合金叶轮铸件。结果表明:模拟获得的冷却曲线、微观组织及缺陷位置与实验结果吻合良好,模拟结果能够准确预测铸件中多种缺陷的分布。

关键词:高温合金;熔模铸造;多尺度模拟;宏观缩孔缩松;微观缩松;微观组织

中图分类号:TG292 文献标识码:A

Multi-scale modeling of solidification process of

Ni-based superalloy investment castings

PAN Dong, XU Qing-yan, LIU Bai-cheng

(Key Laboratory for Advanced Materials Processing Technology, Ministry of Education,

Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China)

Abstract: Three dimensional macro and micro multi-scale models were proposed for Ni-based superalloy investment castings. Temperature distribution in the casting was simulated using the ray tracing method to deal with the heat radiation. Microstructure was simulated with the modified CA method and three dimensional nested macro and micro grids. Latent heat releasing was calculated during microstructure simulation, which was coupled with the macro temperature calculation. Based on multi-scale modeling results, the shrinkage cavity, macroporosity and microporosity defects in the casting were predicted with the equivalent liquid surface descending method, Niyama Criterion and Darcy Law, respectively. Experiments for superalloy turbine wheel casting were carried out. The results show that the simulated cooling curves, microstructure and defects’ positions correspond well with the experimental. Various defects in the casting can be predicted precisely with the proposed model.

Key words: superalloy; investment casting; multi-scale modeling; shrinkage cavity and macroporosity; microporosity; microstructure

高温合金熔模铸件高温力学性能和化学稳定性出众,在航空、电力和船舶等工业应用广泛[1?2]。由于高温合金成分及凝固过程析出相组成复杂[3],且熔模铸造过程型壳透气性差、散热较快,铸件易产生宏/微观缩孔缩松和粗大晶粒等缺陷影响质量。采用数值模拟技术对高温合金熔模铸件凝固过程进行建模仿真和缺陷预测,可节省贵重的合金原材料,减少高昂的资金投入,缩短研发时间[4]。

国内外研究人员针对高温合金熔模铸件开展了多方面的数值模拟研究。YU等[5]模拟了镍合金熔模铸件凝固过程的温度和晶粒度分布,并预测了宏观缩孔、热裂纹等缺陷。SCHNEIDER等[6]模拟了单晶镍基高温合金定向凝固过程中的宏/微观偏析和雀斑缺陷。RAFIQUE等[7]模拟了常规熔模铸造过程中边界换热条件随时间的变化情况。NASTAC等[8]建立宏观温度场和微观组织的耦合计算模型,模拟了高温合金熔模铸造过程的温度和固相分数变化,并预测了Laves相的含量。TIAN等[9]基于Xue和Niyama判据模拟了镍基高温合金涡轮叶片凝固过程的缩孔缺陷分布。薛祥等[10]对镍基合金熔模铸造叶片的缩孔缩松进行了数值模拟。张喜娥等[11]对某Ni3Al基高温合金熔模铸件的凝固过程温度场进行了模拟,并根据模拟结果对浇注系统设计进行了改进。薛明等[12]模拟了高温合金空心涡轮叶片定向凝固过程中叶片、陶瓷芯和型壳内的温度场分布。于靖等[13]模拟了镍基高温合金单晶涡轮叶片凝固过程中的温度场分布并与实验结果进行对比,并分析了抽拉速度和定向凝固炉尺寸对叶片内部温度分布的影响。

但是目前针对高温合金熔模铸件的宏/微观多尺度耦合三维数值模拟的研究仍然较少,缺乏针对凝固过程多种缺陷形成及分布的综合分析研究。本文作者针对镍基高温合金熔模铸造过程的特点,建立了一个宏/微观多尺度数理模型,模拟了铸件凝固过程的温度分布和微观组织生长过程,并基于宏/微观模拟结果预测了铸件内部的宏观缩孔缩松、微观缩松缺陷的分布位置。

1 物理数学模型

1.1 宏观传热模型

熔模铸件一般随型壳在保护气体或者真空环境中冷却,其表面辐射换热对凝固过程的影响显著。根据能量守恒定律,熔模铸造过程的热量传输依据下式计算:

式中:T为温度;t为时间;ρ为密度;c为比热容;L为结晶潜热;λ为导热系数;x、y、z为直角坐标;fS为固相分数;QR为铸件和型壳的表面单元与周围环境的辐射换热量。

使用常规方法处理辐射换热往往需要消耗大量的内存和计算时间。本研究使用一种基于蒙特卡罗方法的射线追踪法[14]处理熔模铸造过程的辐射换热问题,大大减小了内存消耗并缩短了计算时间。具体处理过程参看文献[14]。

1.2 微观组织模型

微观组织的演变过程模拟基于改进的CA方 法[15]。其形核过程采用基于高斯分布的连续形核模 型[16],在过冷的金属液中新形成的晶粒数量依据下式计算:

式中:DT为过冷度;n(DT)为新生成的晶核的密度;fs(DT′)为固相分数;Nmax为最大形核密度;DTs为形核过冷度高斯分布标准差;DTN为平均形核过冷度。

晶粒前端固液界面的法向生长速度vn根据KGT模型[17]简化计算如下:

式中:α1、α2为计算系数。

对于任意一个微观网格单元,在某个微观时间步长δt内,其固相分数的增量δfS为

式中:vn,x、vn,y、vn,z为晶粒前端界面法向生长速度在x、y、z方向上的分量;δt为微观时间步长;lmic为微观网格单元长度。

1.3 宏/微观耦合技术

受理论模型的限制,与宏观温度场模拟相比,微观组织模拟所需的有限差分网格尺寸要小得多。要实现针对工业实际铸件的三维宏/微观耦合模拟,如果采用一套统一的网格,其整体网格规模过大且计算时间过长。

为了在可接受的计算规模、计算时间和模拟精度的条件下实现宏/微观多尺度模拟,本研究采取了宏观网格和微观网格嵌套、宏观计算时间步长和微观计算时间步长嵌套的方式处理。如图1(a)所示,在模拟过程中分别采用宏/微观两套不同尺寸的有限差分网格,并计算得到宏观和微观计算时间步长。模拟中首先依据宏观网格和宏观时间步长计算所有宏观单元的温度场,接下来将宏观网格的温度通过线性插值获得微观网格的温度。

实际合金在凝固过程枝晶前沿的局部结晶潜热释放会导致微观区域的温度分布不均匀,同时微观单元的整体温度梯度分布应与宏观单元的温度梯度保持一致,基于上述两点本研究设计如下的微观单元温度插值方法。

如图1(b)所示,针对宏观单元(i,j,k)内的某个微观单元(l,m,n),微观单元的温度依据下式计算:

式中: 为微观单元的温度;Ti,j,k为宏观单元的温度;Gi、Gj、Gk为x、y、z方向上的宏观温度梯度;a、b、c为宏观单元x、y、z方向上的长度;l、m、n为微观单元x、y、z三方向上的长度。

为微观单元的温度;Ti,j,k为宏观单元的温度;Gi、Gj、Gk为x、y、z方向上的宏观温度梯度;a、b、c为宏观单元x、y、z方向上的长度;l、m、n为微观单元x、y、z三方向上的长度。

其中,Gi、Gj、Gk可表示如下:

获得微观单元的温度之后,即可计算微观组织的形核、生长过程,然后根据式(5)计算微观单元的固相分数增量,即可得到某个宏观单元内所有微观单元所释放的结晶潜热量,具体如下式:

式中:Vmic为微观单元的体积。

图1 宏/微观耦合模拟示意图

Fig.1 Schematic diagrams of macro and micro integrated modeling: (a) Flowchart; (b) Micro cell temperature interpolation

获得宏观网格的结晶潜热释放量之后,再采用温度回升法修正宏观网格的温度。这样就实现了一个宏观时间步长内的微观模拟与宏观模拟的双向耦合。随后循环计算宏观温度场和微观组织,直到铸件全部凝固。

1.4 缺陷预测模型

凝固过程中的宏观缩孔模拟基于等效液面下降方法[18]。在模拟高温合金铸件宏观缩孔形成过程中,在每一个循环步长首先判断可补缩区域温度最高的液态单元位置,并设为补缩初始位置,然后以此为中心从内向外逐层进行补缩直至凝固结束。

宏观缩松的模拟采用Niyama判据[19],即在凝固过程中如果某一个单元满足如下条件则认为该单元会形成宏观缩松:

式中:G为温度梯度;R为冷却速率;C为临界常数。

微观缩松的模拟则依据Darcy枝晶间流动律[19]。在不考虑离心力的情况下,微观缩松的形成趋势采用梁作俭等[20]提出的模型,其计算方法如下:

式中:N表示微观缩松的形成趋势;ρl为金属液密度;g为重力加速度;β为线性收缩系数;μ为动力黏度;k为溶质分配系数;CN为常数。

2 实验

本研究针对高温合金叶轮铸件进行了验证实验,并将相关的实验与模拟结果进行对比分析。图2显示了该叶轮铸件的三维形状,包括浇口杯、直浇道等浇注系统和叶轮件,其总体外形尺寸为300 mm×160 mm×350 mm。型壳的平均厚度为5 mm。实验中在直浇道中部和中上部的叶轮表面放置了两个测温热电偶,其具体位置如图2所示。

图2 叶轮铸件的三维形状及热电偶排布位置

Fig.2 3D geometry of turbine wheel casting and thermo- couples allocation

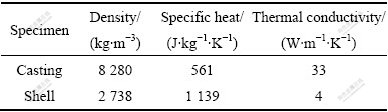

实验采用的铸件材料为Hastelloy-X镍基高温合金,其固液相线温度分别为1 295和1 381 ℃;型壳材料为刚玉砂,表1列出了铸件和型壳的主要热物性参数。实验中金属液的浇注温度为1 450 ℃,型壳的预热温度为1 100 ℃,合金在浇注后随模壳在空气中冷却,环境温度为25 ℃。实验中型壳的平均厚度约为4 mm。

表1 铸件和型壳的主要热物性参数

Table 1 Main thermo properties of casting and shell

3 结果及讨论

本文作者基于VC++ 6.0平台,针对上述镍基高温合金叶轮熔模铸件,模拟其凝固过程的温度场分布和微观组织演变过程,并预测了宏观缩孔缩松、微观缩松缺陷的分布。模拟中选取整个铸件为对象计算宏观温度场,同时选择位于中间直浇道上部的叶轮区域计算三维微观组织,并中根据中间叶轮的微观组织计算结果处理结晶潜热,修正该区域的宏观温度场,其他未进行微观组织模拟部分的结晶潜热处理依据宏观温度场的结果处理。表2列出了主要的模拟计算参数。

表2 主要的模拟计算参数

Table 2 Main simulation parameters

受铸件整体尺寸与微观网格总数的限制,上述模拟方案并未实现整个铸件的宏/微观耦合模拟。但是在本实验中,叶轮部分在铸件上只与直浇道连接,铸件其他部分对叶轮的影响主要是辐射换热因素。叶轮在凝固过程的结晶潜热释放对自身温度的影响受铸件其他部分影响较小,因而选择单个叶轮部分进行微观组织模拟并耦合修正宏观温度场计算仍然具有指导意义。

3.1 温度场分布及冷却曲线

图3所示是铸件不同位置冷却曲线的模拟和实验结果。由于实验中测温点位于型壳内部,所以温度曲线在金属液浇注之后会出现一个升温过程,温度升到一定值之后开始下降。点2的模拟结果与实验结果吻合良好,只是在峰值位置存在约40 ℃的误差;点1的模拟结果与实验结果总体趋势一致,但是中间降温段存在30~50 ℃的误差。模拟与实验结果存在误差的原因,主要是实验中的型壳因受到制壳工艺的限制存在厚薄不均的现象,而模拟中采用了均一厚度型壳的简化处理;与实验相比,模拟中点1和点2位置的型壳厚度较薄,因而模拟得到的温度比实验结果稍低。

图3 冷却曲线模拟与实验结果

Fig.3 Simulated and experimental cooling curves: (a) Point 1; (b) Point 2

图4所示是凝固过程不同时间铸件内部的温度场分布模拟结果(考虑到铸件的对称性,只显示了1/4体积)。模拟结果表明,凝固过程中直浇道与叶轮间的连接区域以及叶轮中心温度较高,冷却速度也较慢。当固相分数达到15% 时,叶轮心部的温度明显高于周围区域,形成了孤立的热节。当固相分数达到30% 的时候,叶轮心部未完全凝固的高温区域位于叶轮与直浇道的结合部位,而直浇道内靠近叶轮的结合部位也形成了两个孤立的热节。当固相分数达到60% 时,直浇道内上下热节周围的温度都已经低于合金固相线温度,完全切断了补缩通道。上述结果表明,直浇道与叶轮的结合部位可能会存在缩孔缩松缺陷。

图4 凝固过程不同时刻温度场分布的模拟结果

Fig.4 Simulated temperature distribution at different times during solidification process: (a) fS=15%, t= 49 s; (b) fS=30%, t=72 s; (c) fS=60%, t=108 s

3.2 微观组织

图5所示是模拟得到的叶轮三维微观组织,以及叶轮正面及中心截面微观组织的模拟与实验结果对比。模拟结果表明,叶轮从表面至心部存在细晶区、柱状晶区和等轴晶区的不同微观组织分布,这与实验结果吻合较好。模拟和实验结果均表明,该工艺下叶轮中间柱状晶晶粒较小,心部等轴晶的分布范围和尺寸都较小,整体微观组织较好,未出现粗大晶粒缺陷。

图5 叶轮微观组织的模拟及实验结果

Fig.5 Simulated and experimental microstructures of turbine wheel: (a), (b) and (d) Simulated; (c), (e) Experimental; (a) 3D view; (b), (c) Front view; (d), (e) Cross section in center

3.3 缺陷预测

3.3.1 宏观缩孔缩松预测

宏观缩孔缩松是熔模铸件的常见缺陷。图6所示是模拟预测的铸件宏观缩孔缩松分布情况,并标出了进行实验观察的两个截面位置(Section 1和Section 2,分别是铸件的中间和右侧直浇道的中央纵截面)。图7所示是直浇道区域模拟预测的缩孔缩松缺陷位置及形状与实验结果的对比,其中截面1的模拟和实验结果均未包括上部浇口杯部分。模拟结果显示,除了浇口杯顶部的缩孔之外,直浇道内多处存在长条形的缩孔,且在直浇道内部还存在分散的宏观缩松分布。实验观察到的直浇道内部缩孔的位置和形状与模拟结果吻合良好。此外,模拟结果表明,铸件的叶轮部分未出现宏观缩孔,这与图5(e)所示的实验观察结果一致;同时,模拟与实验获得的微观组织结果均表明叶轮中心区域在柱状晶前端存在一定数量的等轴晶,容易出现缩松缺陷,这与模拟结果预测的叶轮部分宏观缩松分布位置吻合。

图6 宏观缩孔缩松的模拟结果及实验观察截面位置

Fig.6 Simulated shrinkage cavity and macroporosity and positions for experimental observation: (a) Shrinkage cavity; (b) Macroporosity

图7 宏观缩孔缩松模拟与实验结果的比较

Fig.7 Comparison of simulated and experimental shrinkage cavity and macroporosity: (a), (c) Simulated; (b), (d) Experimental; (a), (b) Section 1; (c), (d) Section 2

3.3.2 微观缩松预测

微观缩松的存在严重影响铸件的性能。图8所示是模拟预测的铸件微观缩松分布情况(只显示了1/2体积)。模拟结果表明,直浇道与叶轮的结合部位存在微观缩松缺陷。图9所示是对应位置叶轮的截面宏观晶粒组织,并标出了进行金相观察的4个采样点的位置。

图8 微观缩松分布的模拟结果(中心截面)

Fig.8 Simulated microporosity distribution (cross section in center)

图9 微观缩松实验结果及微观组织取样点位置

Fig.9 Experimental result for microporosity and positions for microstructure observation

图10所示是图9中4个采样位置的微观组织和微观缩松观察结果。实验结果表明,叶轮中心及上下边缘没有出现明显的微观缩松,在叶轮与直浇道交界处则观察到了明显的微观缩松,这与图7所示的模拟预测结果一致。

上述针对叶轮铸件的宏观缩孔缩松、微观缩松缺陷分布的模拟和实验结果表明,当前工艺条件下铸件的叶轮部分未出现明显的宏观缩孔缩松和微观缩松缺陷,整体微观组织较好,只是在叶轮与直浇道结合部位存在明显的微观缩松缺陷。需要进一步改进工艺设计,消除直浇道与叶轮结合部位的微观缩松缺陷,保证铸件质量。

图10 图9所示的叶轮不同位置的微观组织

Fig.10 Microstructures at different points of turbine wheel as indicated in Fig.9: (a) Point 1; (b) Point 2; (c) Point 3; (d) Point 4

4 结论

1) 建立了镍基高温合金熔模铸件凝固过程的宏/

微观多尺度数理模型,基于射线追踪法处理辐射换热,根据改进的CA方法模拟微观组织并处理结晶潜热,采用三维宏/微观网格嵌套方法实现微/宏观耦合模拟。

2) 模拟了铸件凝固过程的宏观温度场分布和微观组织演变过程,并依据等效液面下降法、Niyama判据和Darcy定律预测了铸件的宏观缩孔、宏观缩松和微观缩松缺陷分布位置。

3) 针对Hastelloy-X镍基高温合金叶轮铸件进行了验证实验,实验获得的冷却曲线、微观组织形貌、宏观缩孔缩松位置及形状、微观缩松分布结果与模拟结果对比吻合良好。本研究提出的模型能够准确预测铸件内部多种缺陷的分布,数值模拟为工艺优化提供了依据。

REFERENCES

[1] 李成功, 傅恒志, 于 翘. 航空航天材料[M]. 北京: 国防工业出版社, 2002.

LI Cheng-gong, FU Heng-zhi, YU Qiao. Aerospace materials[M]. Beijing: National Defense Industry Press, 2002.

[2] 张卫国, 刘 林, 赵新宝, 屈 敏, 余竹焕, 傅恒志. 定向凝固高温合金的研究进展[J]. 铸造, 2009, 58(1): 1?6.

ZHANG Wei-guo, LIU Lin, ZHAO Xin-bao, QU Min, YU Zhu-huan, FU Heng-zhi. Progress in directionally solidified super alloys[J]. Foundry, 2009, 58(1): 1?6.

[3] REED C. The superalloys fundamentals and applications[M]. New York: Cambridge University Press, 2006: 34?72.

[4] 柳百成. 铸造技术与计算机模拟发展趋势[J]. 铸造技术, 2005, 26(7): 611?617.

LIU Bai-cheng. Development trend of casting technique and computer simulation[J]. Foundry Technology, 2005, 26(7): 611?617.

[5] YU K O, NICHOLS J J, Robinson M. Finite-element thermal modeling of casting microstructures and defects[J]. JOM, 1992, 44(6): 21?25.

[6] Schneider M C, Gu J P, Beckermann C, Boettinger W J, Kattner U R. Modeling of micro- and macrosegregation and freckle formation in single-crystal nickel-base superalloy directional solidification[J]. Metallurgical and Materials Transactions A, 1997, 28(7): 1517?1531.

[7] Rafique M M A, Iqbal J. Modeling and simulation of heat transfer phenomena during investment casting[J]. International Journal of Heat and Mass Transfer, 2009, 52(7/8): 2132?2139.

[8] Nastac L, Stefanescu D M. Macrotransport-solidification kinetics modeling of equiaxed dendritic growth: Part Ⅱ. Computation problems and validation on INCONEL 718 superalloy castings[J]. Metallurgical and Materials Transactions A, 1996, 27(12): 4075?4083.

[9] Tian J, Xue X A, Zhang Y B, Gao Y L, Liu L Z, Sun Q, Yuan S Y. Numerical simulation and shrinkage defects prediction of a turbine blade investment casting[J]. Journal of Materials Science & Technology, 2003, 19(s): 32?34.

[10] 薛 祥, 尹成明, 周彼德, 田 竞, 张跃冰, 高亚龙, 孙 勤, 袁世友. 精密铸造三级动叶片缩松和缩孔缺陷的预测[J]. 铸造, 2002, 51(4): 228?231.

XUE Xiang, YIN Cheng-ming, Zhou Bi-de, TIAN Jing, ZHANG Yue-bing, GAO Ya-long, SUN Qin, YUAN Shi-you. Prediction of shrinkage defects in a third class moving turbine blade by invested casting[J]. Foundry, 2002, 51(4): 228?231.

[11] 张喜娥, 骆合力, 曹 栩, 李尚平, 李世琼, 周业明. Ni3Al基合金复杂薄壁件精铸过程数值模拟[J]. 铸造. 2005, 54(10): 992?995.

ZHANG Xi-e, LUO He-li, CAO Xu, LI Shang-ping, LI Shi-qiong, ZHOU Ye-ming. Solidification simulation of complex Ni3Al thin wall castings[J]. Foundry, 2005, 54(10): 992?995.

[12] 薛 明, 曹腊梅, 刘世忠, 李嘉荣. 定向凝固过程中型芯型壳温度场数值模拟[J]. 铸造, 2007, 56(3): 287?289.

XUE Ming, CAO La-mei, LIU Shi-zhong, LI Jia-rong. Simulation of temperature fields on ceramic core and ceramic shell during directional solidification process[J]. Foundry, 2007, 56(3): 287?289.

[13] 于 靖, 许庆彦, 李嘉荣, 袁海龙, 刘世忠, 柳百成. 镍基高温合金多叶片定向凝固过程数值模拟[J]. 金属学报, 2007, 43(10): 1113?1120.

Yu Jing, Xu Qing-yan, Li Jia-rong, Yuan Hai-long, Liu Shi-zhong, Liu Bai-cheng.Numerical simulation of directional solidification process of multiple trubine blades of Ni-based superalloy[J]. Acta Metallurgica Sinica, 2007, 43(10): 1113?1120.

[14] 崔 锴, 许庆彦, 于 靖, 柳百成, 木间塚明彦, 黑木康德, 横山文彦. 高温合金叶片定向凝固过程中辐射换热的计算[J]. 金属学报, 2007, 43(5): 465?471.

CUI Kai, XU Qing-yan, YU Jing, LIU Bai-cheng, Kimatsuka A, Kuroki Y, Yokoyama F. Radiative heat transfer calculation for superalloy turbine blade in directional solidification process[J]. Acta Metallurgica Sinca, 2007, 43(5): 465?471.

[15] Rappaz M, Gandin C A. Probabilistic modelling of microstructure formation in solidification processes[J]. Acta Metallurgica et Materialia, 1993, 41: 345?360.

[16] Thevoz P, Desbiolles J L, Rappaz M. Modeling of equiaxed microstructure formation in casting[J]. Metallurgical Transactions A, 1989, 20A: 311?322.

[17] Kurz W, Giovanola B, Trivedi R. Theory of microstructure development during rapid solidification[J]. Acta Metallurgica, 1986, 34: 823?830.

[18] 李文珍, 柳百成. 铸钢件缩孔形成的三维定量模拟[J]. 铸造, 1995, 44(7): 1?5.

LI Wen-zhen, LIU Bai-cheng. 3-D quantitative simulation of shrinkage cavity formation in steel castings[J]. Foundry, 1995, 44(7): 1?5.

[19] 熊守美, 许庆彦, 康进武. 铸造过程模拟仿真技术[M]. 北京: 机械工业出版社, 2004: 180?187.

Xiong Shou-mei, Xu Qing-yan, Kang Jin-wu. Simulation technology of casting process[M]. Beijing: China Machine Press, 2004: 180?187.

[20] 梁作俭, 许庆彦, 李俊涛, 李世琼, 张 继, 柳百成, 仲增墉. Ti-Al合金精密铸件微观缩松预测[J]. 金属学报, 2003, 39(3): 278?282.

LIANG Zuo-jian, XU Qing-yan, LI Jun-tao, LI Shi-qiong, ZHANG Ji, LIU Bai-cheng, ZHONG Zeng-yong. Research on prediciton of microporosity in Ti-Al alloy investment casting[J]. Acta Metallurgica Sinca, 2003, 39(3): 278?282.

基金项目:国家重点基础研究发展计划资助项目(2005CB724105);国家自然科学基金资助项目(10477010);国家高技术研究发展计划资助项目(2007AA04Z141)

收稿日期:2009-06-18;修订日期:2009-09-30

通信作者:许庆彦,副教授,博士;电话:010-62795482;E-mail: scjxqy@tsinghua.edu.cn

(编辑 何学锋)