Experimental study on repair characteristics of damaged rock salt of underground gas storage

来源期刊:中南大学学报(英文版)2019年第8期

论文作者:李浩然 尹洪武 马洪岭 施锡林 葛鑫博 高昂

文章页码:2185 - 2196

Key words:gas storage; rock salt; permeability; damage; uniaxial compression; self-healing

Abstract: Damage in rock salt has significant implication on permeability, which affects the tightness of underground salt cavern gas storage in further. During the leaching of a salt cavern, the brine with formation temperature and pressure can promote the self-healing of rock salt in the excavation damage zone (EDZ). Laboratory tests were conducted to study the promoting effect. The permeability of two intact rock salt specimens was tested. Then they were damaged into two kinds of the state respectively through uniaxial compression. After that, they were put in saturated brine (with a temperature of 50 °C and pressure of 12 MPa, which we called the repair environment in this paper) for 7 d. Finally, the permeability and mechanical properties were obtained after the damaged specimens being repaired. The results show that the permeability of intact rock salt is below 10-19 m2; the permeability increases by more than two orders because of damage; the permeability decreases significantly after being repaired, which can be comparable to its intact state. Discussions of the repair mechanisms are presented (especially the mechanism of recrystallization), which may help to provide significant guidance for the study of the tightness and stability of gas storage facilities in China.

Cite this article as: YIN Hong-wu, MA Hong-ling, SHI Xi-lin, LI Hao-ran, GE Xin-bo, GAO Ang. Experimental study on repair characteristics of damaged rock salt of underground gas storage [J]. Journal of Central South University, 2019, 26(8): 2185-2196. DOI: https://doi.org/10.1007/s11771-019-4165-9.

ARTICLE

J. Cent. South Univ. (2019) 26: 2185-2196

DOI: https://doi.org/10.1007/s11771-019-4165-9

YIN Hong-wu(尹洪武)1, 2, MA Hong-ling(马洪岭)1, 2, SHI Xi-lin(施锡林)1, 2,LI Hao-ran(李浩然)3, GE Xin-bo(葛鑫博)1, 4, GAO Ang(高昂)5

1. State Key Laboratory of Geomechanics and Geotechnical Engineering, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, Wuhan 430071, China;

2. University of Chinese Academy of Sciences, Beijing 100049, China;

3. Structural Health Monitoring and Control Institute, Shijiazhuang Tiedao University,Shijiazhuang 050043, China;

4. School of Mining and Safety Engineering, Shandong University of Science and Technology,Qingdao 266590, China;

5. Daqing International Exploration and Development Company, Daqing 163000, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract: Damage in rock salt has significant implication on permeability, which affects the tightness of underground salt cavern gas storage in further. During the leaching of a salt cavern, the brine with formation temperature and pressure can promote the self-healing of rock salt in the excavation damage zone (EDZ). Laboratory tests were conducted to study the promoting effect. The permeability of two intact rock salt specimens was tested. Then they were damaged into two kinds of the state respectively through uniaxial compression. After that, they were put in saturated brine (with a temperature of 50 °C and pressure of 12 MPa, which we called the repair environment in this paper) for 7 d. Finally, the permeability and mechanical properties were obtained after the damaged specimens being repaired. The results show that the permeability of intact rock salt is below 10-19 m2; the permeability increases by more than two orders because of damage; the permeability decreases significantly after being repaired, which can be comparable to its intact state. Discussions of the repair mechanisms are presented (especially the mechanism of recrystallization), which may help to provide significant guidance for the study of the tightness and stability of gas storage facilities in China.

Key words: gas storage; rock salt; permeability; damage; uniaxial compression; self-healing

Cite this article as: YIN Hong-wu, MA Hong-ling, SHI Xi-lin, LI Hao-ran, GE Xin-bo, GAO Ang. Experimental study on repair characteristics of damaged rock salt of underground gas storage [J]. Journal of Central South University, 2019, 26(8): 2185-2196. DOI: https://doi.org/10.1007/s11771-019-4165-9.

1 Introduction

Due to the characteristics of extremely low permeability and low porosity, rock salt is a well-known ideal medium for energy storage and high radioactive waste disposal [1-9]. Rock salt possesses a propensity to creep stably under deviatoric stresses, which leads to the ability of self-healing. Rock salt is soluble in water (~0.36:1 mass ratio for salt and water), allowing salt caverns easy and facilitative to be constructed. Salt caverns have been used for gas storage for several decades in Europe and America [10-13]. There is no doubt that the excavation damage zone (EDZ) with increased permeability will affect the functionality and the effectiveness of underground facilities. During the leaching of a salt cavern, the damage in rock salt results in an increase of permeability, which is not conducive for tightness of the salt cavern [14]. This situation may lead to storage accidents and cause incalculable losses.

Self-healing of damaged rock salt has been extensively studied, and it is a special characteristic that many of other rocks do not have. CHAN et al [15] presented MDCF model by considering the mechanisms of dislocation creep, damage and self-healing of rock salt, and he found that creep damage in rock salt can be healed by high pressures and temperatures [16]. SCHULZE et al [2] found that minimal principal stress and loading geometry affected damage porosity and permeability seriously. PFEIFLE and HURTADO [17] estimated recovery time by using laboratory data of WIPP salt. RATIGAN et al [18] studied whether complete healing of the EDZ would occur when the salt cavern was at maximum gas pressure by analyzing the healing behavior of rock salt. BRODSKY [19] found that under the conditions of pressures and temperatures, the damaged WIPP salt could be partially healed, the volume and a compressional wave of salt could be comparable to its undamaged state.

From the microscopic point of view, the self-healing process of damaged rock salt is the recrystallization of rock salt crystals. Microstructural evidence for fluid-assisted dynamic recrystallization (FADRX) exists widely in underground native rock salt, which acts as a healing mechanism of dilatation and work hardening [20]. HIRTH and TULLIS [21] determined three regimes of dislocation creep by using optical and transmission electron microscopy. The recrystallization mechanism is related to grain boundary migration and new grain boundary formation, which is a common microstructural transformation of rocks [22]. HEEGE and BRESSER [23] studied the effects of strain, temperature, stress, and water content on rock salt recrystallization.

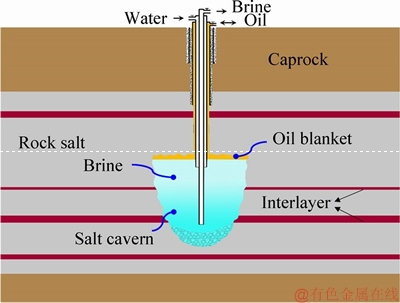

These research achievements have important guiding significance for the construction and operation of salt cavern gas storage facilities, but the damage and self-healing characteristics (especially permeability property) of rock salt during the leaching are rarely mentioned and need to be further studied. During the leaching of a salt cavern, the temperature and pressure of saturated brine in the cavity (at the depth of about 1000 m) are about 50 °C and 12 MPa. A diagrammatic sketch of leaching of a salt cavern is shown in Figure 1 [24] (modified from Figure 6 in their paper). To study the damage and self-healing characteristics (especially permeability property) of rock salt in the saturated brine with temperature and pressure corresponding to the field conditions, laboratory tests were conducted.

Figure 1 Leaching diagrammatic sketch of a salt cavern (after SHI et al [24])

2 Experimental work

The specimens were damaged by uniaxial compression test and the uniaxial mechanical properties were obtained. The pulse-decay technique was employed to estimate the permeability of rock salt. The advantage of this method is that permeability can be calculated directly from the linear portion of the solution [25] and it is the best option for ultra-low permeability rocks [26]. In consideration of gas storage/ compressibility and non-Darcy components, this method will be suitable to estimate tightness of salt cavern gas storage [27].

2.1 Experimental scheme

During the leaching of a salt cavern, the surrounding rock is in the environment of formation temperature, pressure and brine, which can promote the self-healing of rock salt. In order to study this promoting effect, the damaged rock salt specimens were put into an environment similar to that in situ (brine with a temperature of 50 °C and pressure of 12 MPa) for repair. The repair time of the damaged specimens was set to 7 d [28]. The initial state of rock salt was defined as a state without damage. The intact specimens numbered D1-D4 were used for uniaxial compressive strength (UCS) tests. Then the damage and self-healing experiments were carried out based on the UCS tests results. In order to determine the influence of damage and self-healing on permeability, the permeability test was carried out on specimens A1 and A2.

The permeability of specimens was tested under the same conditions: the pore pressure was 6.90 MPa; the confining pressure was 13.80 MPa; the temperature was 20 °C, and the pressure difference was 0.24 MPa.

2.2 Test devices

The mechanical instrument (used for uniaxial compression tests) and the warm press device (used for providing repair environment) are all developed by the Institute of Rock and Soil Mechanics (Chinese Academy of Sciences, Wuhan, China). The details and figures can be seen in previous research [28]. The present work focus on the permeability instrument.

2.2.1 Direct shear test calculation model

The permeability instrument PDP-200 adopts the pulse-decay technique to test the permeability of rocks. Its working medium is nitrogen (N2). The major technical parameters for PDP-200 are depicted as follows: Core specimen diameters are 25 mm and 38 mm. Maximum length is 150 mm. Maximum confining pressure is 68.95 MPa. The measuring range is 0.00001~10 mD (1 mD=10-15 m2). Temperature is room temperature. And sensor accuracy is 0.1%.

2.2.2 Test methods and principles

The pulse-decay technique was employed to estimate the permeability of rock salt. The principles and methods of the pulse-decay technique were introduced in detail by BRACE et al [29] and WALDER et al [30]. The pressure transient equation is shown in Eq. (1)

(1)

(1)

where α0 is given in Eq. (2):

(2)

(2)

Therefore, the permeability of pulse-decay method can be obtained by Eq. (3) [27, 31]:

(3)

(3)

where Kg is the permeability of core specimen; P1(t) and P2(t) are the upstream and downstream pressures at time t; P1(t0) and P2(t0) are the initial upstream and downstream pressures respectively; △P(t) is pressure-decay function; A is the cross-sectional area of core specimen; L is the length of the specimen; μ is the viscosity coefficient of N2 gas; β0 is the compressibility of N2 gas; V1 and V2 are the upstream and downstream reservoir volumes respectively; α0 is absolute value of the slope curve (the logarithm of pressure-decay function versus the time); t is the time during the test.

3 Test results

3.1 Mechanical properties of damage and repair of rock salt

3.1.1 Uniaxial properties

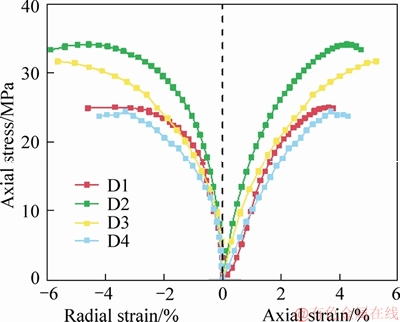

In order to obtain uniaxial compressive strength and other parameters of rock salt, uniaxial compressive strength tests had been carried out on the intact specimens numbered D1-D4. The stress- strain curves (Figure 2) indicate that rock salt has good deformation capacity and the average UCS of the specimens is about 30 MPa. The analysis of uniaxial mechanical properties of rock salt have been studied in many research, and will not be discussed deeply here.

Figure 2 Stress-strain curves of rock salt under uniaxial compression

3.1.2 Properties of damage and repair

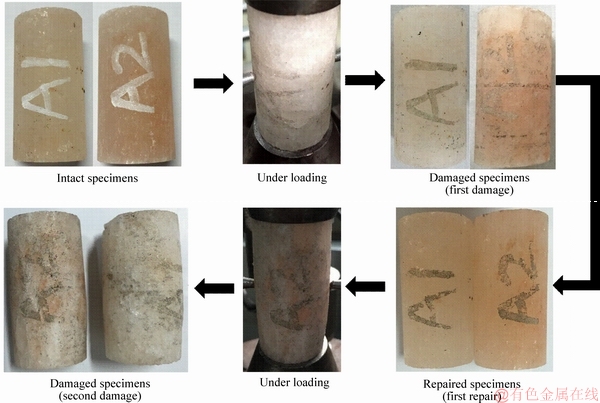

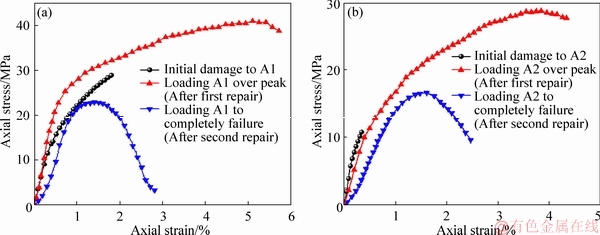

The specimens numbered A1 and A2 were loaded initially to 29 MPa and 11 MPa at the first stage. Then the damaged specimens were placed into the repair environment (brine with a temperature of 50 °C and pressure of 12 MPa) for 7 d. After being repaired, they were loaded beyond peak stress. After that, the damaged specimens (second time) were put into the repair environment for 7 d. Finally, the repaired specimens were loaded into complete failure. Pictures of specimens are shown in Figure 3, and the stress-strain curves after each loading are shown in Figure 4.

It can be seen from Figure 4, compared with the specimen without damage, that the repaired specimen (especially after the second time) has an obvious compaction stage. The elastic stage, as well as the yield stress of the repaired specimen (first repair) are 2 times higher than that of the intact specimen. Even if the specimen was loaded over peak stress, it still has a certain strength and deformation capacity before complete failure.

Figure 3 Pictures of specimens at various damage and healing steps

Figure 4 Stress-strain curves after each loading

3.2 Permeability of damaged and repaired specimens

3.2.1 Results of intact specimens

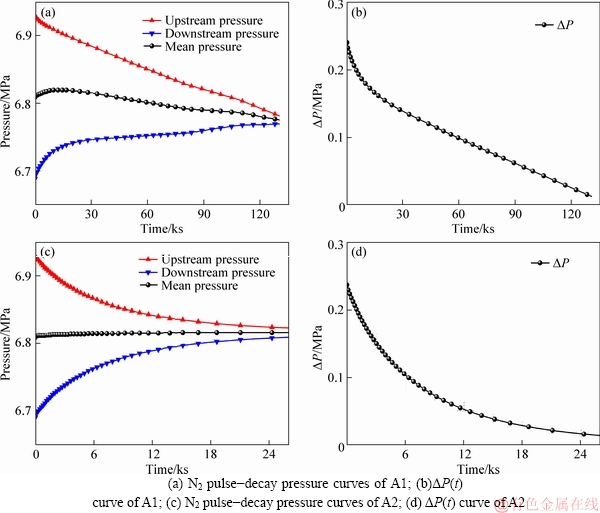

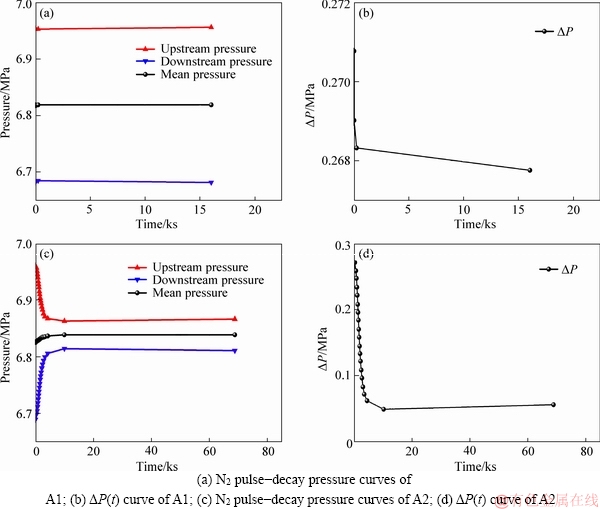

The porosities of intact specimens (A1, A2) are 2.24% and 1.34% respectively. The permeability of intact specimens (A1, A2) are 3.48×10-20 m2 and 1.72×10-19 m2. Figure 5 shows the experimental pressure-time curves.

It can be seen from Figure 5 that, although there are individual differences between the two specimens, the permeability test takes a very long time for the intact specimens (about 36.2 h for A1, about 7.7 h for A2). This indicates that the intact rock salt has a low porosity and a lack of porosity inter-connection.

3.2.2 Results of damaged specimens (first damage)

The specimens numbered A1 and A2 were loaded to 29 MPa and 11 MPa for the first damage test, and then the permeability test was carried out. The porosities of damaged specimens (A1, A2) are 3.76% and 2.82% respectively. The permeabilities of damaged specimens (A1, A2) are 1.94×10-17 m2 and 2.93×10-17 m2. Figure 6 shows the experimental pressure-time curves.

It can be seen from Figure 6 that the permeability test takes a very short time for the damaged specimens (about 313 s for A1, and about 216 s for A2). The permeability of the damaged specimens is much higher than that of intact specimens (three orders of magnitude higher for A1, two orders of magnitude higher for A2), which means the porosity inter-connection of the damaged specimens is enhanced.

3.2.3 Results of repaired specimens (first repair)

The damaged specimens were placed into the repair environment for 7 d, then the porosity and permeability tests were carried out. The results show that the permeability of A1 is less than 6.88×10-20 m2, which cannot be obtained accurately, and its porosity is 2.74%. The permeability of A2 is about 3.04×10-20 m2, with a porosity of 1.53%. Figure 7 shows the experimental pressure-time curves.

It can be seen from Figure 7 that, the permeability test lasted 16025 s (about 4.45 h) for A1 (after being repaired). There is no drop in the pore pressure in the specimen, and the upstream pressure and the downstream pressure are basically parallel, which means that the permeability cannot be obtained. The permeability of A1 (after being repaired) is less than 6.88×10-20 m2 (maybe below 10-21 m2). The permeability test lasted 68782 s (about 19.11 h) for A2 (after being repaired), and the pore pressure in the specimen reached a steady state at 15000 s (about 4.17 h). The permeability of A2 (after being repaired) is about 3.04×10-20 m2. The permeability of the repaired specimens is much lower than that of damaged specimens (three orders of magnitude lower for A1, three orders of magnitude lower for A2), which can be comparable to their intact state.

Figure 5 Experimental pressure-time curves of intact specimens:

Figure 6 Experimental pressure-time curves of damaged specimens (first damage):

Figure 7 Experimental pressure-time curves of repaired specimens (first repair):

3.3 Analysis of permeability test results

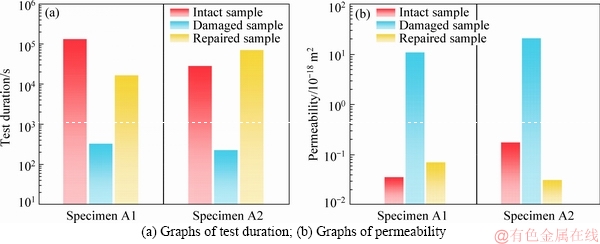

Graphs of the permeability and test duration of each stage for the rock salt specimens are shown in Figure 8. It can be seen from Figure 8 that:

1) The permeability of intact specimens is extremely low, and can reach 10-19 m2 or even 10-20 m2, and the test duration is very long. This is because the main constituent of rock salt is NaCl (ionic crystal), and the adhesion strength is strong and the structure is stable. The particles in the rock salt are periodically repeated in three-dimensional space with a lattice structure, which means that the pores in the rock salt are poorly connective and extremely undeveloped, resulting in extremely low permeability.

2) The permeability of damaged specimens is much higher than that of intact specimens (three orders of magnitude higher for A1, two orders of magnitude higher for A2), and the test duration is about one hundred times shorter than for intact specimens. This is because, under axial compression, the inner atoms are in an unstable state and swell in the radial direction. The damage of rock salt is caused by the dislocation and slippage between grains, during the loading, white spots and intergranular crack appear on the sidewall of the specimens. Therefore, the pore connectivity of the damaged specimens is enhanced, which results in higher permeability.

3) The permeability of the repaired specimens is much lower than that of damaged specimens (three orders of magnitude lower for A1, three orders of magnitude higher for A2), which can be comparable to their initial state. The test duration is about one hundred times longer than for the damaged specimens, which means that the repair environment has a remarkable effect on the recovery of the permeability of rock salt. The reasons for the healing effect will be discussed in the next section.

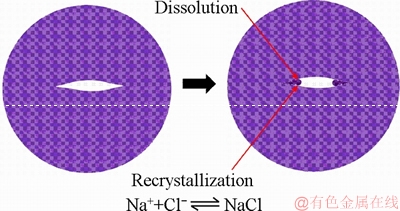

4 Recovery mechanisms of damaged rock salt

During the leaching of the salt cavern gas storage, the weakening of mechanic capability and the increase of permeability in excavation damaged zone (EDZ) will affect the functionality and the effectiveness of underground facilities. Meanwhile, the saturated brine (with a formation temperature of 50 °C and a pressure of 12 MPa) can promote the self-healing of rock salt. There are three physical recovery mechanisms of damaged rock salt [32]: the cracks inside damaged rock salt may be closed by increasing mean normal stress [33-35]; diffusive or ‘‘chemical’’ driven by surface energy reduction may heal the damage in rock salt [36-38]. The process restores strength, as illustrated in the recent work by SALZER et al [39] on cohesion developed by mass transfer at interfaces between polycrystalline salt blocks; the recrystallization, which is a gradual process of filling cracks by crystal particles [40, 41].

Figure 8 Graphs of each stage for rock salt specimens:

In this paper, the mechanism of recrystallization is the keystone, and the sketch of this mechanism is shown in Figure 9.

Figure 9 Sketch of salt repair caused by recrystallization

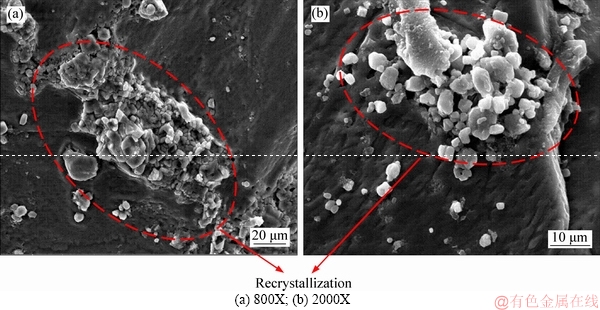

Rock salt is a crystalline structure (NaCl), which means the recrystallization of rock salt is bound to occur in the repair environment. The crack surface is uneven which can act as the nucleus of a crystal, and the crystal continues to grow along the crystal nucleus. The pore throat in the specimen will be filled by the recrystallization, which leads to poor pore connectivity and lower permeability. A scanning-electron microscope assessment of the repaired rock salt, which is shown in Figure 10.

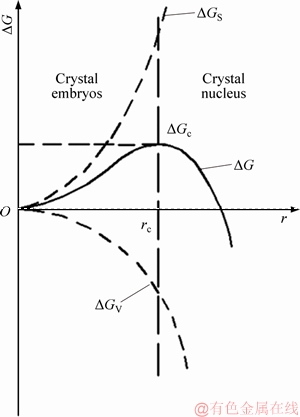

The internal energy of the crystal is minimum under the same thermodynamic conditions, and the internal energy is the superposition of kinetic energy and potential energy. As is well known, kinetic energy is the energy of molecules that are irregularly vibrating around the equilibrium point,while the potential energy is the energy produced by molecules at a relative position. According to the theory of crystal growth, the growth of crystals is a change from the old to the new, and the new phase represents the growing crystal, while the old phase is the source of the transport of atoms (molecules) to the new [42]. In the repair environment, the brines will produce heterogeneous nucleation in the rock salt, which is the formation of new phase nucleus equal to or over a critical size in the old phase. The nucleation process can be expressed as: brine (Na+ and Cl-)→crystal embryos (short range ordered atomic groups)→critical nucleus (larger than a certain size of crystal embryos)→grow (crystal growth). According to the classical nucleation theory, during the process of forming a crystalline nucleus with a radius of  , the free energy change of the system can be regarded as the two parts of the contribution: chemical change of ionic state to crystal, and interfacial tension changes between solution and crystal surface. The contribution of these two parts is opposite and is related to the size of nucleation, which means there is a critical size rc that makes the sum of the contribution of the two parts to an extreme point. If the size of the nucleation in the solution has a radius larger than rc, it tends to crystallize. Conversely, if the radius is less than rc, it tends to dissolve. Based on a large number of experimental results, ARRHENIUS [43] proposed the following empirical formula (Eq. (4)), which can estimate the time required for crystallization.

, the free energy change of the system can be regarded as the two parts of the contribution: chemical change of ionic state to crystal, and interfacial tension changes between solution and crystal surface. The contribution of these two parts is opposite and is related to the size of nucleation, which means there is a critical size rc that makes the sum of the contribution of the two parts to an extreme point. If the size of the nucleation in the solution has a radius larger than rc, it tends to crystallize. Conversely, if the radius is less than rc, it tends to dissolve. Based on a large number of experimental results, ARRHENIUS [43] proposed the following empirical formula (Eq. (4)), which can estimate the time required for crystallization.

(4)

(4)

where k is the reaction rate constant at the temperature T; A0 refers to the pre-exponential factor, also known as the Arrhenius constant; Ea is experimental activation energy, which can generally be considered a temperature independent constant; T is the thermodynamic temperature; R is the molar gas constant.

Figure 10 SEM pictures of recrystallization:

In the repair environment, the crystals grow along the asperity boundaries of specimens, and the nucleation process is mainly heterogeneous nucleation. During the process of nucleation, the volume of free energy decreases (the driving force of crystallization) when the old phase changes toward the new phase, which can be written as △GV. The surface free energy rises (crystallization resistance) when the interface forms between the old phase and the crystal embryo, which can be written as △GS. Set △GV=△GV/V as the free energy change per unit volume and is the surface free energy per unit area (specific surface energy). Assuming that the crystal embryo is a sphere with a radius of r, the sketch map of heterogeneous nucleation can be shown as Figure 11.

is the surface free energy per unit area (specific surface energy). Assuming that the crystal embryo is a sphere with a radius of r, the sketch map of heterogeneous nucleation can be shown as Figure 11.

Figure 11 Sketch map of heterogeneous nucleation

The change in the free energy of the system caused by nucleation can be written as Eq.(5):

(5)

(5)

where,

(6)

(6)

(7)

(7)

(8)

(8)

where r is the radius of curvature of the new phase (β phase); θ is the contact angle (wetting angle) between the crystal nucleation and the solid phase (S phase) in the solution;  are the specific surface energy of phase interface.

are the specific surface energy of phase interface.

Putting Eq. (6) and Eq. (7) into Eq. (5), Eq. (5) can be written as:

(9)

(9)

In order to obtain the critical radius, derive Eq. (9) and then get the following equation:

(10)

(10)

At the extreme point △Gc,  .

.

Then the critical radius can be obtained:  and the change in the free energy of the corresponding system is

and the change in the free energy of the corresponding system is

The relationship between the radius of the nucleus and the change of free energy of the system can be shown as Figure 12.

Figure 12 Relationship between r and △G

In this paper, the solid phase is rock salt specimen (NaCl), the old phase is the dissolved NaCl in brine (Na+, Cl-), and the new phase is NaCl (crystal), same as the solid phase. Thus θ=0, which means f(θ)=0 (according to Eq. (8)), and the particles of the solid phase can be used as the crystal nucleus.

The growth of the crystal nucleus is the formation and enlargement of the interface between the old and new phases, which requires the increase of total surface energy of the interface. The repair environment can provide enough energy to increase the surface energy and promote crystallization growth.

5 Conclusions

In order to study the promoting effect of the leaching environment (brine with a temperature 50 °C and a pressure 12 MPa) of the storage on the self-healing of damaged rock salt, a study was carried out through uniaxial compression test and permeability test. Based on the test results, the following conclusions are drawn:

1) The rock salt has almost no compaction phase during uniaxial compression. The damaged rock salt shows an apparent compaction stage after being repaired. As a result of the second repair, the plasticity of the rock salt is more obvious.

2) The permeability of intact rock salt is below 10-19 m2, and the permeability increases by more than two orders because of damage. The permeability decreases significantly as a result of repair, which can be comparable to that of its initial state.

3) About the repair mechanisms, recrystallization is an important factor in crack healing of rock salt.

Nomenclature

Kg

Permeability of core specimen, m2

P1(t)

Upstream pressure at time t, MPa

P2(t)

Downstream pressure at time t, MPa

P1(t0)

Initial upstream pressure, MPa

P2(t0)

Initial downstream pressure, MPa

△P(t)

Pressure-decay function, MPa

μ

Viscosity coefficient of N2 gas, Pa·s

β0

Compressibility of N2 gas, Pa-1

V1, V2

Upstream and downstream reservoir volume, m3

α0

Absolute value of slope curve (the logarithm of pressure-decay function versus the time), s-1

k

Reaction rate constant at temperature T

A0

Arrhenius constant

Eα

Experimental activation energy, J/mol

T

Thermodynamic temperature, K

R

Molar gas constant, 8.314 J/(mol·K)

△GV

Decrement of volume free energy

△GS

Increment of surface free energy

△gV

Free energy change per unit volume

Surface free energy per unit area

r

Radius of curvature of the new phase

α

Symbol of old phase (salt)

β

Symbol of new phase (salt)

S

Symbol of solid phase

θ

Contact angle (wetting angle) between the crystal nucleation and the solid phase

Specific surface energy of phase interface

References

[1] YANG Chun-he, DAEMEN J J K, YIN Jian-hua. Experimental investigation of creep behavior of salt rock [J]. International Journal of Rock Mechanics and Mining Sciences, 1999, 36(2): 233-242. DOI: 10.1016/S0148- 9062(98) 00187-9.

[2] SCHULZE O, POPP T, KERN H. Development of damage and permeability in deforming rock salt [J]. Engineering Geology, 2001, 61(2, 3): 163-180. DOI: 10.1016/S0013- 7952(01)00051-5.

[3] TSANG C F, BERNIER F, DAVIES C. Geohydromechanical processes in the excavation damaged zone in crystalline rock, rock salt, and indurated and plastic clays—In the context of radioactive waste disposal [J]. International Journal of Rock Mechanics and Mining Sciences, 2005, 42(1): 109-125. DOI: 10.1016/j.ijrmms.2004.08.003.

[4] MA Hong-ling, YANG Chun-he, LI Yin-ping, SHI Xi-lin, LIU Jian-feng, WANG Tong-tao. Stability evaluation of the underground gas storage in rock salts based on new partitions of the surrounding rock [J]. Environmental Earth Sciences, 2015, 73(11): 6911-6925. DOI: 10.1007/s12665-015- 4019-1.

[5] SHI Xi-lin, LI Yin-ping, YANG Chun-he, XU Yu-long, MA Hong-ling, LIU Wei, JI Guo-dong. Influences of filling abandoned salt caverns with alkali wastes on surface subsidence [J]. Environmental Earth Sciences, 2015, 73(11): 6939-6950. DOI: 10.1007/s12665-015-4135-y.

[6] LIU Wei, CHEN Jie, JIANG De-yi, SHI Xi-lin, LI Yin-ping, DAEMEN J J K, YANG Chun-he. Tightness and suitability evaluation of abandoned salt caverns served as hydrocarbon energies storage under adverse geological conditions (AGC) [J]. Applied Energy, 2016, 178: 703-720. DOI: 10.1016/ j.apenergy.2016.06.086.

[7] ZHANG Nan, SHI Xi-lin, WANG Tong-tao, YANG Chun-he, LIU Wei, MA Hong-ling, DAEMEN J J K. Stability and availability evaluation of underground strategic petroleum reserve (SPR) caverns in bedded rock salt of Jintan, China [J]. Energy, 2017, 134: 504-514. DOI: 10.1016/j.energy. 2017.06.073.

[8] YIN Hong-wu, MA Hong-ling, SHI Xi-lin, YANG Chun-he. A new method for permeability test on mudstone interlayer in a salt cavern gas storage [J]. Rock and Soil Mechanics, 2017, 38(8): 2241-2248. (in Chinese)

[9] ZHANG Nan, YANG Chun-he, SHI Xi-lin, WANG Tong-tao, YIN Hong-wu, DAEMEN J J K. Analysis of mechanical and permeability properties of mudstone interlayers around a strategic petroleum reserve cavern in bedded rock salt [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 112: 1-10. DOI: 10.1016/j.ijrmms.2018. 10.014.

[10] BAUER S, BEYER C, DETHLEFSEN F, DIETRICH P, DUTTMANN R, EBERT M, FEESER V, G RKE U, K

RKE U, K BER R, KOLDITZ O, RABBEL W, SCHANZ T, SCH

BER R, KOLDITZ O, RABBEL W, SCHANZ T, SCH FER D, WURDEMANN H, DAHMKE A. Impacts of the use of the geological subsurface for energy storage: an investigation concept [J]. Environmental Earth Sciences, 2013, 70(8): 3935-3943. DOI: 10.1007/s12665-013-2883-0.

FER D, WURDEMANN H, DAHMKE A. Impacts of the use of the geological subsurface for energy storage: an investigation concept [J]. Environmental Earth Sciences, 2013, 70(8): 3935-3943. DOI: 10.1007/s12665-013-2883-0.

[11] BROWN C J, POIENCOT B K, HUDYMA N, ALBRIGHT B, ESPOSITO R A. An assessment of geologic sequestration potential in the panhandle of Florida, USA [J]. Environmental Earth Sciences, 2014, 71(2): 793-806. DOI: https://doi.org/ 10.1007/s12665-013-2481-1.

[12] DETHLEFSEN F, EBERT M, DAHMKE A. A geological database for parameterization in numerical modeling of subsurface storage in northern Germany [J]. Environmental Earth Sciences, 2014, 71(5): 2227-2244. DOI: 10.1007/ s12665-013-2627-1.

[13] YIN Hong-wu, MA Hong-ling, CHEN Xiang-sheng, SHI Xi-lin, YANG Chun-he, DUSSEAULT M B, ZHANG Yu-hao. Synthetic rock analogue for permeability studies of rock salt with mudstone [J]. Applied Sciences, 2017, 7(9): 946. DOI: 10.3390/app7090946.

[14] CHEN Jie, REN Song, YANG Chun-he, JIANG De-yi, LI Lin. Self-healing characteristics of damaged rock salt under different healing conditions [J]. Materials, 2013, 6(8): 3438-3450. DOI: 10.3390/ma6083438.

[15] CHAN K S, BODNER S R, MUNSON D E, FOSSUM A F. A constitutive model for representing coupled creep, fracture, and healing in rock salt [R]. Albuquerque, United States: Sandia National Labs, 1996.

[16] CHAN K S, BODNER S R, MUNSON D E. Recovery and healing of damage in WIPP salt [J]. International Journal of Damage Mechanics, 1998, 7(2): 143-166. DOI: 10.1177/105678959800700204.

[17] PFEIFLE T W, HURTADO L D. Permeability of natural rock salt from the waste isolation pilot plant (WIPP) during damage evolution and healing [J]. International Journal of Rock Mechanics and Mining Sciences, 1998, 35(4, 5): 637-638. DOI: 10.1016/S0148-9062(98)00044-8.

[18] RATIGAN J L, NIELAND J D, DEVRIES K L. Feasibility study for lowering the minimum gas pressure in solution-mined caverns based on geomechanical analyses of creep-induced damage and healing [R]. Morgantown, United States: Federal Energy Technology Center; Pittsburgh, Unitede States: Federal Energy Technology Center, 1998.

[19] BRODSKY N S. Thermomechanical damage recovery parameters for rocksalt from the Waste Isolation Pilot Plant [R]. Albuquerque, United States: Sandia National Labs, 1995.

[20] PEACH C J, SPIERS C J, TRIMBY P W. Effect of confining pressure on dilatation, recrystallization, and flow of rock salt at 150 °C [J]. Journal of Geophysical Research: Solid Earth, 2001, 106(B7): 13315-13328. DOI: 10.1029/2000JB900300.

[21] HIRTH G, TULLIS J. Dislocation creep regimes in quartz aggregates [J]. Journal of Structural Geology, 1992, 14(2): 145-159. DOI: 10.1016/0191-8141(92)90053-Y.

[22] DRURY M R, URAI J L. Deformation-related recrystallization processes [J]. Tectonophysics, 1990, 172(3, 4): 235-253. DOI: 10.1016/0040-1951(90)90033-5.

[23] ter HEEGE J H, de BRESSER J H P, SPIERS C J. Dynamic recrystallization of wet synthetic polycrystalline halite: Dependence of grain size distribution on flow stress, temperature and strain [J]. Tectonophysics, 2005, 396(1, 2): 35-57. DOI: 10.1016/j.tecto.2004.10.002.

[24] SHI Xi-lin, LIU Wei, CHEN Jie, YANG Chun-he, LI Yin-ping, MA Hong-ling, PENG Hui-hua, WANG Tong-tao, MA Xu-qiang. Geological feasibility of underground oil storage in Jintan salt mine of China [J]. Advances in Materials Sicence and Engineering, 2017: 3159152. DOI: 10.1155/2017/3159152.

[25] KAMATH J, BOYER R E, NAKAGAWA F M. Characterization of core scale heterogeneities using laboratory pressure transients [J]. SPE Formation Evaluation, 1992, 7(3): 219-227. DOI: 10.2118/20575-PA.

[26] LIU Wei, MUHAMMAD N, LI Yin-ping, SPIERS C J, YANG Chun-he, MA Hong-ling. Experimental study of permeability of salt rock and its application to deep underground gas storage [J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(10): 1953-1961. (in Chinese)

[27] WANG Yi, LIU Shi-min, ELSWORTH D. Laboratory investigations of gas flow behaviors in tight anthracite and evaluation of different pulse-decay methods on permeability estimation [J]. International Journal of Coal Geology, 2015, 149: 118-128. DOI: 10.1016/j.coal.2015.07.009.

[28] YIN Hong-wu, YANG Chun-he, MA Hong-ling, SHI Xi-lin, CHEN Xiang-sheng, ZHANG Nan, GE Xin-bo, LIU Wei. Study on damage and repair mechanical characteristics of rock salt under uniaxial compression [J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 659-671. 10.1007/ s00603-018-1604-0.

[29] BRACE W F, WALSH J B, FRANGOS W T. Permeability of granite under high pressure [J]. Journal of Geophysical research, 1968, 73(6): 2225-2236. DOI: 10.1029/ JB073i006p02225.

[30] WALDER J, NUR A. Permeability measurement by the pulse-decay method: Effects of poroelastic phenomena and non-linear pore pressure diffusion [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1986, 23(3): 225-232. DOI: 10.1016/ 0148-9062(86)90968-X.

[31] LIU Wei, LI Yin-ping, YANG Chun-he, MA Hong-ling, SHI Xi-lin, HUANG Xiao-lan. Methods for testing permeability of deep mudstone and analysis of data reliability of each method [J]. Rock and Soil Mechanics, 2014, 35(1): 85-90. (in Chinese)

[32] HOUBEN M E, TEN HOVE A, PEACH C J, SPIERS C J. Crack healing in rocksalt via diffusion in adsorbed aqueous films: Microphysical modelling versus experiments [J]. Physics and Chemistry Earth, Parts A/B/C, 2013, 64: 95-104. DOI: 10.1016/j.pce.2012.10.001.

[33] CHAN K S, BODNER S R, MUNSON D E. Permeability of WIPP salt during damage evolution and healing [J]. International Journal of Damage Mechanics, 2001, 10(4): 347-375. DOI: 10.1106/H3UV-1URA-AFUY-FX49.

[34] CHEN D L, WEISS B, STICKLER R. A model for crack closure [J]. Engineering Fracture Mechanics, 1996, 53(4): 493-509. DOI: 10.1016/0013-7944(95)00169-7.

[35] KIM J H, LEE S B. Behavior of plasticity-induced crack closure and roughness-induced crack closure in aluminum alloy [J]. International Journal of Fatigue, 2001, 23(sup1): 247-251. DOI: 10.1016/S0142-1123(01)00155-4.

[36] BRANTLEY S L, EVANS B, HICKMAN S H, CRERAR D A. Healing of microcracks in quartz: Implications for fluid flow [J]. Geology, 1990, 18(2): 136-139. DOI: 10.1130/0091-7613(1990)018<0136:HOMIQI>2.3.CO;2.

[37] CINAR Y, PUSCH G, REITENBACH V. Petrophysical and capillary properties of compacted salt [J]. Transport in Porous Media, 2006, 64(2): 199-228. DOI: 10.1007/s11242- 005-2848-1.

[38] LUX K H, EBERTH S. Fundamentals and first application of a new healing model for rock salt [C]// MANFRED W, KARL-HEINZ L, WOLFGANG M, HARDY H R J. The Mechanical Behavior of Salt–Understanding of THMC Processes in Salt. London: CRC Press, 2017: 129-138.

[39] SALZER K, POPP T, B HNEL H. Mechanical and permeability properties of highly pre-compacted granular salt bricks [C]// MANFRED W, KARL-HEINZ L, WOLFGANG M, HARDY H R J. The Mechanical Behavior of Sact-Understanding of THMC Processes in Salt. London: CRC Press, 2017: 239-248.

HNEL H. Mechanical and permeability properties of highly pre-compacted granular salt bricks [C]// MANFRED W, KARL-HEINZ L, WOLFGANG M, HARDY H R J. The Mechanical Behavior of Sact-Understanding of THMC Processes in Salt. London: CRC Press, 2017: 239-248.

[40] URAI J L, SPIERS C J, ZWART H J, LISTER G S. Weakening of rock salt by water during long-term creep [J]. Nature, 1986, 324(6097): 554. DOI: 10.1038/324554a0.

[41] ter HEEGE J H, de BRESSER J H P, SPIERS C J. Rheological behaviour of synthetic rocksalt: The interplay between water, dynamic recrystallization and deformation mechanisms [J]. Journal of Structural Geology, 2005, 27(6): 948-963. DOI: 10.1016/j.jsg.2005.04.008.

[42] ter HEEGE J H, de BRESSER J H P, SPIERS C J. Dynamic recrystallization of wet synthetic polycrystalline halite: dependence of grain size distribution on flow stress, temperature and strain [J]. Tectonophysics, 2005, 396(1, 2): 35-57. DOI: 10.1016/j.tecto.2004.10.002.

[43] VESSELINOV M I. Crystal growth for beginners: fundamentals of nucleation, crystal growth and epitaxy [M]. Singapore: World Scientific, 2017. DOI: https://doi.org/ 10.1142/10127.

(Edited by ZHENG Yu-tong)

中文导读

储气库损伤盐岩修复特征的试验研究

摘要:盐岩的损伤会严重影响其渗透特性,进一步影响储气库的密闭性。在盐穴溶腔过程中,处于地层温压状态下的卤水可以促进开挖扰动区内损伤盐岩的自愈合。为了研究这种促进效果,进行了室内试验:首先测试了两个无损试样的渗透率,然后利用单轴压缩对试样分别进行不同程度的损伤,接着将损伤试样置于处于温压状态下(温度50 °C,压力12 MPa)的饱和卤水(文中将其定义为修复环境)中进行修复(为期7 d),最后对修复后的试样进行了渗透率及单轴压缩试验。结果表明:无损盐岩渗透率小于10-19 m2;损伤后的盐岩渗透率增大了两个量级;修复后的盐岩渗透率明显降低,与无损试样渗透率相当。文中对盐岩的修复机理进行了探讨,尤其分析了盐岩结晶机理,研究结果对我国储气库的稳定性和密闭性研究有一定指导意义。

关键词:储气库;盐岩;渗透率;损伤;单轴压缩;自愈合

Foundation item: Project(201704910741) supported by the China Scholarship Council; Projects(51874274, 51774266, 51874273, 51621006) supported by the National Natural Science Foundation of China; Project(2018YFC0808401) supported by the National Key Research and Development Program of China

Received date: 2019-05-05; Accepted date: 2019-07-19

Corresponding author: LI Hao-ran, PhD, Lecturer; Tel: +86-311-87935307; E-mail: lihaoran@stdu.edu.cn; ORCID: 0000-0002-2326- 8670