DOI: 10.11817/j.issn.1672-7207.2020.11.011

微米级三维多孔高纯铝材料的制备与特性研究

张茂贵1,王君1,汤水1,贾明1,刘芳洋1,蒋良兴1,艾亮2,艾燕3

(1. 中南大学 冶金与环境学院,湖南 长沙,410083;

2. 湖南艾华集团股份有限公司,湖南 益阳,413000;

3. 全固态储能材料与器件湖南省重点实验室,湖南城市学院,湖南 益阳,413000)

摘要:采用浆料涂敷-烧结法制备一种微米级三维多孔高纯铝材料,研究黏结剂用量对样品电化学活性表面积AECS以及机械性能的影响。研究结果表明:通过将微米级铝粉与溶剂N-甲基-2-吡咯烷酮(NMP)、黏结剂聚偏氟乙烯(PVDF)均匀混合,配制成黏度适中的浆料,将浆料双面涂敷在铝光箔上并加热固化,再经过烧结后,可获得AECS高于223.9 cm2、折弯次数为88次、抗拉强度为1.5 kN/m的微米级三维多孔高纯铝材料;PVDF质量分数与三维多孔高纯铝材料的电化学活性表面积呈负相关,对机械性能影响较小。

关键词:多孔铝;浆料;烧结;机械性能

中图分类号:TB31 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3093-08

Preparation and characterization of micron-sized 3D porous high-purity aluminum

ZHANG Maogui1, WANG Jun1, TANG Shui1, JIA Ming1, LIU Fangyang1, JIANG Liangxing1,

AI Liang2, AI Yan3

(1. School of Metallurgy and Environment, Centre South University, Changsha 410083, China;

2. Hunan Aihua Group Co. Ltd., Yiyang 413000, China;

3. Key Laboratory of All-Solid-State Energy Storage Materials and Devices of Hunan Province,

Hunan City University, Yiyang 413000, China)

Abstract: A micron-sized 3D porous high-purity aluminum was prepared by the paste coating-sintering method, and the influence of the content of the binder on the electrochemically active surface area(AECS) and mechanical properties of the sample were studied.The results show that by mixing micron-sized aluminum powder with N-methyl-2-pyrrolidone(NMP) and polyvinylidene fluoride(PVDF) uniformly to prepare a paste with moderate viscosity, the paste is coated on both sides of an aluminum foil. After heat curing and sintering, a micron-scale 3D porous high-purity aluminum material with AECS higher than 223.9 cm2, bending time of 88, and tensile strength of 1.5 kN/m is obtained. The mass fraction of PVDF is negatively correlated with AECS of the 3D porous high-purity aluminum and has less impact on mechanical properties.

Key words: porous aluminum; paste; sintering; mechanical property

多孔铝是一种以纯铝或铝合金为基体、内部分布大量孔穴的金属基复合功能材料,广义地说,含有孔隙的铝制品都可以称为多孔铝,也称泡沫铝[1]。因多孔铝具有金属基体和大量孔穴的双重特质,且铝及其合金具有密度小、比强度高、铸造性能好、环境友好和丰度高等特点,故其作为一种集结构和功能于一体的材料,具有轻质、比强度高、比表面积高、阻尼高、换热散热强及能吸声隔声、能量吸收、电磁屏蔽等优良特性,在冶金化工、航空航天、电子制造、建筑等方面具有广阔的应用前景[2-4]。传统多孔铝的制备方法主要有熔体发泡法、渗流铸造法、熔模铸造法、粉末冶金法、喷溅沉积法、电沉积法和阳极氧化法等[5-9]。但面对人们所提出的诸如成本低、精细化程度等更高要求,这些传统方法制备的多孔铝材料不能满足要求,急需采用更高性价比、更加工业化的方法来开发新型高性能多孔铝材料。浆料涂敷-烧结法作为一种新兴的制备手段,仅包含电池工业中常用的浆料制备、涂敷工艺和普通的热处理手段,工艺简单可控,成本低,对基体表面和设备要求低,能够适用于不同形状和尺寸的基体,具有广阔的工业应用前景[10-12]。李荐等[13]将导电碳粉和有机树脂混合,制备成浆料涂敷在铝箔表面,再经过热处理制备了界面冶金结合良好、表面电阻率低至9.75×10-8 Ω·m的铝/碳复合箔。马洪春等[14]在铜导电浆料中添加质量分数为4.5%的银粉,提高了浆料中铜粉的烧结活性,在烧结温度为600 ℃时获得了结合力强和导电性良好的导电铜膜。STUCKNER等[15]将直径为20~30 nm的球形银颗粒与溶剂、分散剂混合制备纳米银浆料并通过烧结成型,研究了烧结温度、气氛和时间对其显微结构的影响,发现氧气能促进有机溶剂和分散剂的去除,形成联通孔更大、孤立孔更少的粗糙的网络结构。LI等[16]将预处理后的银粉加入α-松油醇、聚乙二醇、无水乙醇的混合溶剂中超声搅拌,制备出导电性能良好、在室温下放置6月以上也不会出现氧化和团聚现象的纳米银浆料,并在300 ℃下烧结40 min获得了电阻率低至3.83×10-5  ·m的薄膜。本文作者基于浆料涂敷-烧结法制备一种微米级三维多孔高纯铝材料,通过在微米级铝粉末中加入溶剂、黏结剂等成分,进行长时间均匀混合,配制成分散均匀、黏度适中的糊状浆料,将浆料均匀涂敷后加热固化,再通过烧结固定成型,以构成三维联通的金属导电网络结构,增大比表面积;然后,通过研究黏结剂质量分数对材料电化学活性表面积(AECS)以及机械性能的影响,优化浆料中黏结剂的质量分数,从而制备出比表面积高、机械性能优异的三维多孔高纯铝材料。

·m的薄膜。本文作者基于浆料涂敷-烧结法制备一种微米级三维多孔高纯铝材料,通过在微米级铝粉末中加入溶剂、黏结剂等成分,进行长时间均匀混合,配制成分散均匀、黏度适中的糊状浆料,将浆料均匀涂敷后加热固化,再通过烧结固定成型,以构成三维联通的金属导电网络结构,增大比表面积;然后,通过研究黏结剂质量分数对材料电化学活性表面积(AECS)以及机械性能的影响,优化浆料中黏结剂的质量分数,从而制备出比表面积高、机械性能优异的三维多孔高纯铝材料。

1 实验

1.1 实验原料

本实验原料为粒度为5 μm雾化球型铝粉(湖南宁乡唯信金属粉体有限公司生产)和粒度为30 μm的铝清洗放电光箔(吴江飞乐天和电子材料有限公司生产)。其他试剂包括聚偏氟乙烯(PVDF,武汉飞腾亚化工生产)和分析纯级N-甲基-2-吡咯烷酮(NMP,天津市科密欧化学试剂有限公司生产)。

1.2 实验方法

分别称取1,2,3和4 g黏结剂PVDF与35 g溶剂NMP加入至50 mL搅拌釜中,使用搅拌机于转速为600 r/min时搅拌2 h,分别称取64,63,62和61 g铝粉加入搅拌釜,再次搅拌1 h后得到固质量分数为65%,PVDF质量分数分别为1,2,3和4%的浆料(当PVDF质量分数小于1%时,浆料不易黏附于铝箔上;当其质量分数大于4%时,浆料过黏,导致涂敷不稳定)。将长×宽为20 cm×30 cm的铝光箔放置于红外烘干平板涂敷机的平台上,并用平台上的真空孔吸附平整后,利用刮刀将配好的浆料涂敷在铝箔上,涂敷厚度控制在60 μm,在120 ℃下红外烘干30 min,将铝箔从附有一层膜的一面翻转至另一光滑面。重复涂敷烘干过程,得到厚度约为120 μm的预制膜。将预制膜放入管式高温烧结炉,在200 ℃下预烧结120 min,按10 ℃/min的速率升温至618 ℃,烧结160 min。烧结结束后炉冷至室温,得到微米级三维多孔高纯铝样品。

1.3 样品表征

采用X射线衍射仪(X-ray diffractometer,XRD)分析所制备的三维多孔高纯铝样品晶体结构;采用扫描电镜(scanning electron microscope,SEM)和能谱分析(EDS)对三维多孔高纯铝样品的微观结构进行表征;采用MIT式耐折强度试验机(GT-6014-A GOTECH),按照GB/T 457—2008“纸和纸板耐折度的测定方法”对所制备的三维多孔高纯铝样品的折弯性能进行测试;采用YT-L型薄膜拉力仪,按照GB/T 12914—2008“纸和纸板抗张强度的测定方法”对所制备的三维多孔高纯铝样品的抗拉性能进行测试。

采用电化学工作站(PARSTAT2273)测试三维多孔高纯铝样品的AECS[17]:通过循环伏安法(CV)在电压为0.2~0.3 V的非法拉第电位区间,扫描速率分别为20,40,60,80和100 mV/s条件下测量样品(长×宽为2 cm×2 cm)的双电层电容(Cdl)。Cdl计算式如下:

(1)

(1)

式中:ic为双电层充电电流;v为扫描速率。

以扫描速率为变量绘制关于电位窗中间阳极充电电流(Ia)和阴极充电电流(Ic)之间的充电电流差(ΔI)的斜线,斜线的斜率即为Cdl的2倍。AECS计算式为:

(2)

(2)

式中:Cs为样品的比电容(即在相同电解液条件下,光滑材料单位面积上的电容)。

常用的Cs是各种金属电极在酸性和碱性溶液中的测量值[18-19],本实验中使用的电解液是1 mol/L的Na2SO4水溶液,其尚未作为电解液用于Cs的测量。考虑到该系统的测试条件,测量了铝光箔基底在1 mol/L的Na2SO4水溶液中的Cs,以计算AECS。

2 结果及讨论

2.1 三维多孔高纯铝材料的结构分析

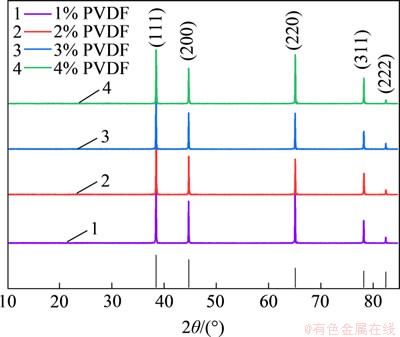

图1所示为不同PVDF质量分数的三维多孔高纯铝样品的XRD图谱。由图1可见:样品衍射峰与金属Al的标准PDF卡片(JCPDS #89-2769)一一对应,没有明显杂峰,证明样品为铝且在制备过程中没有引入杂相;2θ为38.47°,44.72°,65.09°,78.22°和82.43°时的衍射峰分别对应Al的(111),(200),(220),(311)和(222)晶面。计算每个衍射面上的晶格常数,均约为0.405 0 nm。不同PVDF质量分数的样品晶格常数无明显差异,说明晶体内部的成分、受力状态相似。

图1 不同PVDF质量分数的多孔高纯铝样品的XRD谱

Fig. 1 XRD pattern of porous high purity aluminum with different PVDF mass fractions

2.2 三维多孔高纯铝材料的微观形貌分析

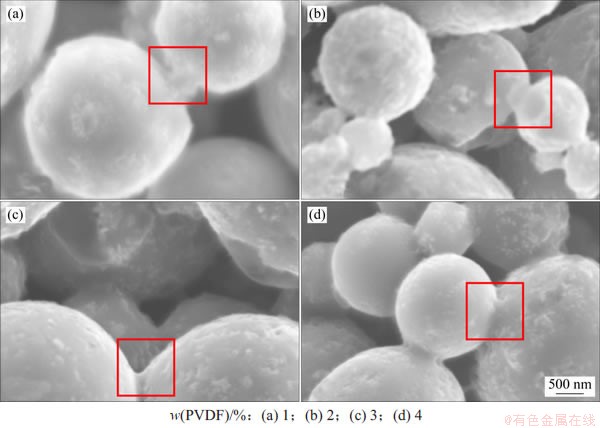

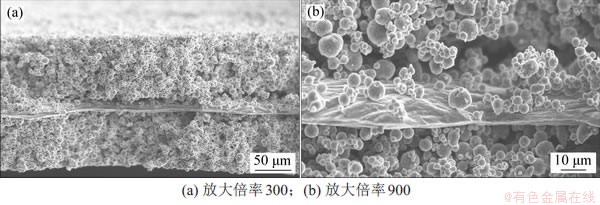

图2所示为不同PVDF质量分数的多孔高纯铝样品的表面形貌。由图2可见:不同质量分数的PVDF多孔高纯铝材料表面形貌相似;铝颗粒与周围1个或者多个铝颗粒之间发生冶金结合,形成烧结颈(如图2中方框所示),烧结颈作为铝颗粒之间的纽带使彼此互相联结,颗粒间距离缩小,形成连续的孔隙网络。细小的烧结颈和互相连通的孔隙都说明烧结过程只进行到烧结中期即烧结颈长大阶段。材料处于该阶段能够保证微粒间互相导通,有效表面积较高。烧结程度相似也说明PVDF质量分数对多孔高纯铝材料的烧结过程无明显影响。图3所示为不同放大倍率下多孔高纯铝材料的截面形貌。由图3可见:铝颗粒通过烧结颈彼此联结,并且与中间的铝光箔烧结在一起,形成三维联通的致密金属导电网络。

图2 不同PVDF质量分数(w(PVDF))的多孔高纯铝样品的表面SEM图像

Fig. 2 Surface SEM images of porous high purity aluminum with different PVDF mass fractions

图3 不同放大倍率下多孔高纯铝材料的截面SEM图像

Fig. 3 Cross-sectional SEM images of porous high purity aluminum in different magnifications

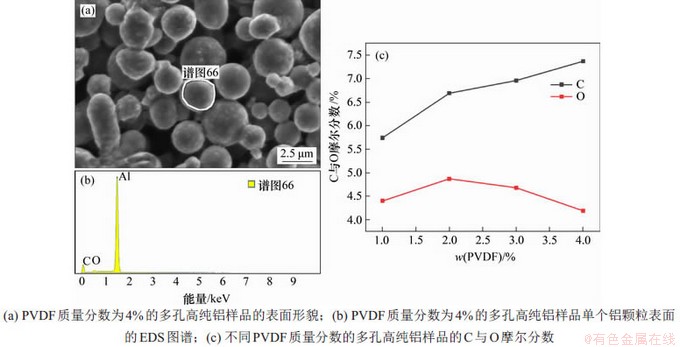

图4所示为PVDF质量分数为4%时多孔高纯铝样品的表面形貌、EDS图谱以及PVDF质量分数不同时多孔高纯铝样品的C与O摩尔分数。图4(a)中颗粒间互相结合,采用EDS对单个铝颗粒表面(图4(a)中白色框内区域)元素种类与质量分数进行分析,结果如图4(b)所示,此时,颗粒表面主要是Al,还含有少量的C和O。PVDF由C,H和F元素组成,其分解温度为390 ℃,EDS图像中没有F,说明材料中的PVDF已经在烧结过程中分解;颗粒表面存在少量C,说明PVDF并没有分解完全,还有少量碳残留物;颗粒表面存在少量O,说明颗粒被轻微氧化。由图4(c)可见:随着PVDF质量分数从4%降低到1%,O摩尔分数无固定变化趋势,为4.5%左右,说明PVDF质量分数对颗粒被氧化程度无明显影响;C摩尔分数从7.37%降到5.74%;PVDF作为浆料的成分之一,当其质量分数从4%降到1%时,预制膜中的C物质的量比也降低,但在烧结过程结束后,C始终存在,且当PVDF质量分数为1%时,C摩尔分数为5.72%,减小了22%,这说明烧结过程中高温会使PVDF分解,但对铝颗粒表面碳残留物的去除能力有限;当PVDF质量分数为1%时,C仍然不能完全除去。

2.3 三维多孔高纯铝材料的电化学活性表面积

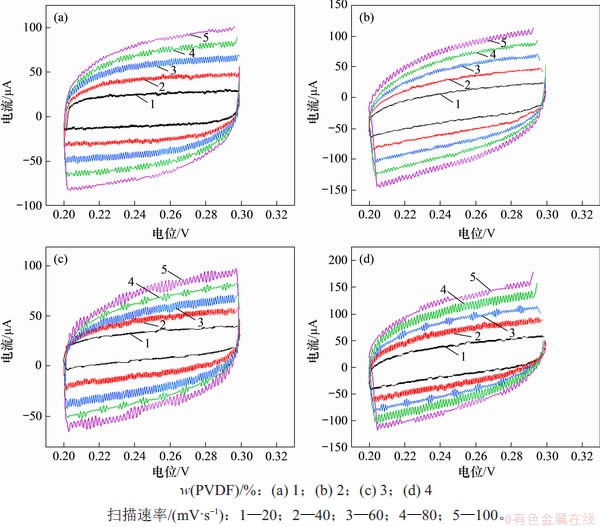

当三维多孔高纯铝材料应用于催化、分离及电极材料等时,其全部内表面往往并不能等同地发挥作用,而用电化学方法测出的表面积即AECS能够有效地反映参与反应的那部分表面积。图5所示为不同扫描速率下不同质量分数的PVDF多孔高纯铝样品的CV曲线。通过测试,三维多孔高纯铝材料的电位非法拉第电位区间为0.2~0.3 V,电位窗口中值为0.25 V,设定扫描速率分别为20,40,60,80和100 mV/s。为了计算样品的AECS,通过CV测量得到铝光箔基底在1 mol/L的Na2SO4水溶液中的Cs为3.82×10-3 μF/cm2。

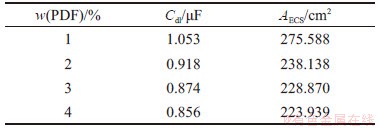

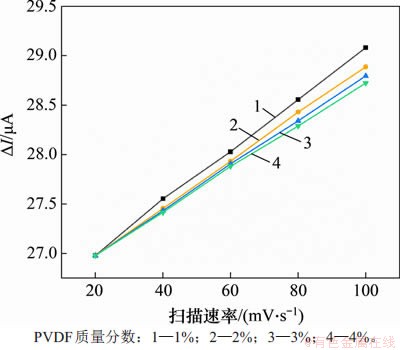

当电压为0.25 V时,在不同扫描速率下,不同PVDF质量分数的多孔高纯铝样品充电电流差见图6,不同质量分数的PVDF多孔高纯铝样品的AECS见表1。从图6可见:PVDF质量分数为1%的多孔高纯铝样品的充电电流差曲斜斜率最大,为Cdl曲线斜率的2倍,故此时Cdl也最大(从表1可知为1.053 μF)。由式(2)可知此时样品的AECS最大,并且随着PVDF质量分数增大,AECS曲线斜率逐渐减小,多孔高纯铝样品的Cdl和AECS也逐渐减小,AECS从275.588 cm2降到223.939 cm2。从前面分析可知,当PVDF质量分数在1%~4%范围内时,PVDF质量分数对多孔高纯铝样品的表面形貌无明显影响,不同PVDF质量分数的多孔高纯铝样品烧结程度相似,这说明此时AECS减小不是因为铝颗粒间结合程度增加使颗粒间重叠面积增加、总面积减小,而是因为在固质量分数固定条件下,PVDF质量分数增加意味着铝颗粒质量分数减少,而组成金属导电网络的铝颗粒数量减少,导致金属导电网络致密程度降低,从而导致多孔高纯铝样品的AECS减小。同时,由表1可见:样品的AECS都很高(大于220 cm2),这归因于细微铝粉末本身的表面积较高,以及将烧结阶段控制在烧结中期使烧结颈尺寸较小、孔隙互相连通,导致金属导电网络的有效表面积较高。

表1 不同PVDF质量分数(w(PVDF))的多孔高纯铝样品的Cdl和AECS

Table 1 Cdl and AECS of porous high purity aluminum with different PVDF mass fraction

图4 PVDF质量分数为4%时多孔高纯铝样品的表面形貌、EDS图谱以及PVDF质量分数不同时多孔高纯铝样品的C与O摩尔分数

Fig. 4 Surface SEM image, EDS spectrum of porous high purity aluminum, molar fraction of C and O in porous high purity aluminum samples with different PVDF mass fractions

图5 在0.2~0.3 V的非法拉第电位区间,不同扫描速率下不同PVDF质量分数(w(PVDF))的多孔高纯铝样品CV曲线

Fig. 5 CV curves measured in a non-Faradaic region of 0.2-0.3 V at various scan rates for porous high purity aluminum with different PVDF mass fractions

图6 在电压为0.25 V,不同扫描速率下,不同PVDF质量分数(w(PVDF))的多孔高纯铝样品充电电流差

Fig. 6 Charging current differences measured at 0.25 V plotted against scan rate for porous high purity aluminum with different PVDF mass fractions

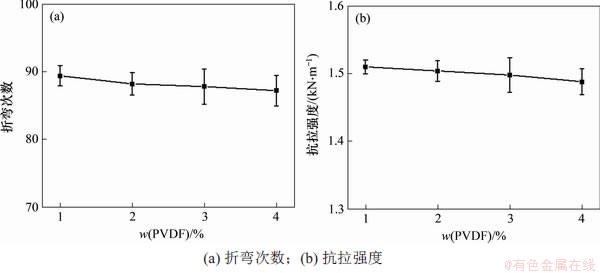

图7 不同PVDF质量分数(w(PVDF))的多孔高纯铝样品的机械性能

Fig. 7 Mechanical properties of porous high purity aluminum with different PVDF mass fractions

2.4 三维多孔高纯铝材料的机械性能

折弯次数和抗拉强度是表征三维多孔高纯铝材料机械性质的基本参数;折弯次数用于表征材料抵抗往复折叠的能力,取决于材料的强度、柔韧性和组分间的结合力;抗拉强度为材料在拉断前承受的最大应力,对于三维多孔高纯铝材料,其抗拉强度也代表断裂抗力。图7所示为不同质量分数的PVDF三维多孔高纯铝样品的机械性能。从图7可见:样品的折弯次数和抗拉强度都较高,表明样品具有优异的机械性能;当PVDF质量分数为1%时,样品折弯次数较高(89次),抗拉强度较大(1.51 kN/m),其原因是铝颗粒质量分数增大,三维网络的比表面积更大,结构更致密。但随着PVDF质量分数从1%增加到4%,样品的折弯次数为88次左右,抗拉强度为1.5 kN/m左右,这也说明当PVDF质量分数为1%~4%时,PVDF质量分数对多孔高纯铝材料的折弯、抗拉性能影响较小。

3 结论

1) 采用浆料涂敷-烧结法,将粒径为5 μm的铝粉与溶剂NMP、黏结剂PVDF均匀混合,控制浆料固质量分数为65%,将获得的浆料均匀涂敷,控制加热固化温度为120 ℃,预烧结温度为200 ℃、烧结时间为120 min或烧结温度为618 ℃、烧结时间为160 min,制备出比表面积高、机械性能优异的微米级三维多孔高纯铝材料。

2) PVDF质量分数与三维多孔高纯铝材料的电化学活性比表面积呈负相关,对机械性能影响较小。当PVDF质量分数为1%时,样品的电化学活性表面积AECS、折弯次数和抗拉强度最高,分别达275.588 cm2,89次和1.51 kN/m。

参考文献:

[1] GERAMIPOUR T, OVEISI H.Effects of foaming parameters on microstructure and compressive properties of aluminum foams produced by powder metallurgy method[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(7): 1569-1579.

[2] 徐戎, 李落星, 姚再起. 交通用铝型材挤压在线淬火过程的数值模拟和实验验证[J]. 中南大学学报(自然科学版), 2017, 48(12): 3263-3270.

XU Rong, LI Luoxing, YAO Zaiqi. Numerical simulation and experimental verification of extrusion online quenching process of aluminum profile used for traffic[J]. Journal of Central South University(Science and Technology), 2017, 48(12): 3263-3270.

[3] 罗乐, 郑旭, 郝志勇, 等. 基于结构-声耦合法研究高铁铝型材的隔声性能[J]. 中南大学学报(自然科学版), 2015, 46(9): 3513-3519.

LUO Le, ZHENG Xu, HAO Zhiyong, et al. Sound insulation performance analysis of high-speed train aluminum extrusions based on structure-sound coupling method[J]. Journal of Central South University(Science and Technology), 2015, 46(9): 3513-3519.

[4] TAUSEEF-UR-REHMAN, ALI H M, JANJUA M M, et al. A critical review on heat transfer augmentation of phase change materials embedded with porous materials/foams[J]. International Journal of Heat and Mass Transfer, 2019, 135: 649-673.

[5] ZHOU Xu, LI Yanxiang, CHEN Xiang. Development of AlMg35-TiH2 composite foaming agent and fabrication of small pore size aluminium foams[J]. Journal of Materials Processing Technology, 2020, 283: 116698.

[6] XUE Yingying, HAN Fusheng. Compressive mechanical property of a new three-dimensional aluminum based double-V lattice structure[J]. Materials Letters, 2019, 254: 99-102.

[7] ZHANG Xin, LI Shufeng, PAN Bo, et al. Regulation of interface between carbon nanotubes-aluminum and its strengthening effect in CNTs reinforced aluminum matrix nanocomposites[J]. Carbon, 2019, 155: 686-696.

[8] SHAHIEN M, YAMADA M, FUKUMOTO M. Splat morphology and influence of feeding rate during reactive plasma spray of aluminum powder[J]. Journal of Thermal Spray Technology, 2016, 25(8): 1490-1501.

[9] ZHANG Aiqin, ZHOU Jiajing, DAS P, et al. Revisiting metal electrodeposition in porous anodic alumina: toward tailored preparation of metal nanotube arrays[J]. Journal of the Electrochemical Society, 2018, 165(3): D129-D134.

[10] JANG Jiajie, TONG Kuing, PEI Qibing. A water-based silver-nanowire screen-print ink for the fabrication of stretchable conductors and wearable thin-fil[J]. Advanced Materials, 2016, 28(28): 5986-5996.

[11] 马小强,朱晓云,龙晋明,等.电子浆料烧结工艺的研究现状与发展趋势[J]. 热加工工艺, 2017, 46(18): 14-19.

MA Xiaoqiang, ZHU Xiaoyun, LONG Jinming, et al. Research status and development tendency of sintering process for electronic paste[J]. Hot Working Technology, 2017, 46(18): 14-19.

[12] 张宝鹏, 刘伟, 王鹏, 等.浆料-烧结法制备ZrB2-SiC-B4C涂层及性能研究[J]. 宇航材料工艺, 2020, 50(3): 43-48.

ZHANG Baopeng, LIU Wei, WANG Peng, et al.Preparation and property of ZrB2-SiC-B4C coatings by slurry painting-sintering method[J]. Aerospace Materials & Technology, 2020, 50(3): 43-48.

[13] 李荐, 黄祖琼, 姚建军, 等. 浆料涂敷法制备的低电阻铝/碳复合箔界面结构及其性能[J]. 中南大学学报(自然科学版), 2013, 44(12): 4793-4798.

LI Jian, HUANG Zuqiong, YAO Jianjun, et al. Micro-structure and performance of low resistance aluminum/carbon composite foil prepared by resin pyrolysis[J]. Journal of Central South University(Science and Technology), 2013, 44(12): 4793-4798.

[14] 马洪春, 朱晓云, 龙晋明, 等. 银对氧化锌压敏电阻器用铜导电浆料的影响[J]. 化工新型材料, 2020, 48(7): 85-88.

MA Hongchun, ZHU Xiaoyun, LONG Jinming, et al. Influence of adding Ag on copper electrode paste for ZnO varistor[J]. New Chemical Materials, 2020, 48(7): 85-88.

[15] STUCKNER J A, LU GUO-QUAN, MITSUHARA M, et al. The influence of processing conditions on the 3D interconnected structure of nanosilver paste[J]. IEEE Transactions on Electron Devices, 2017, 64(2): 494-499.

[16] LI Hongke, ZHU Xiaoyang, LI Zhenghao, et al. Preparation of nano silver paste and applications in transparent electrodes via electric-field driven micro-scale 3D printing[J]. Nanomaterials, 2020, 10(1): 107.

[17] NING Fanfu, SHAO Mingfei, XU Simin, et al. TiO2/graphene/NiFe-layered double hydroxide nanorod arrays photoanode for efficient photoelectrochemical water splitting[J]. Energy & Environmental Science, 2016, 9(8): 2633-2643.

[18] MCCRORY C C L, JUNG S, PETERS J C, et al. Benchmarking Heterogeneous Electrocatalysts for the Oxygen Evolution Reaction[J]. Journal of the American Chemical Society, 2013, 135(45): 16977-16987.

[19] WASZCZUK P, ZELENAY P, SOBKOWSKI J. Surface interaction of benzoic acid with a copper electrode[J]. Electrochimica Acta, 1995, 40(11): 1717-1721.

(编辑 陈灿华)

收稿日期: 2020 -08 -28; 修回日期: 2020 -10 -10

基金项目(Foundation item):国家自然科学基金资助项目(51774343);国家重点研究发展计划项目(2018YFB104200) (Project(51774343) supported by the National Natural Science Foundation of China; Project(2018YFB0104200) supported by the National Key Research and Development Program of China)

通信作者:贾明,博士,副教授,从事固态储电器件制造及应用技术研究;E-mail: jiamingsunmoon@aliyun.com