文章编号:1004-0609(2011)09-2126-06

纯钼板坯高温塑性变形行为及本构方程

杨松涛1, 李继文1, 魏世忠1, 2, 徐流杰1, 2, 张国赏1, 张二召3

(1. 河南科技大学 材料科学与工程学院,洛阳 471003;

2. 河南科技大学 河南省耐磨材料工程技术研究中心,洛阳471003;

3. 洛阳高科钼钨材料有限公司,洛阳471000)

摘 要:采用Gleeble-1500热模拟机,在变形温度为1 100~1 350 ℃、变形速率为0.01~5 s-1、变形量为60%的实验条件下,对纯钼板坯的高温塑性变形行为进行研究。结果表明:流变应力随变形温度的升高而减小,随应变速率的增大而增大;不同变形温度下流变应力之间的差值随着应变速率的增加逐渐减小;同一应变速率下,峰值应力随变形温度的升高向应变小的方向推移。采用包含Zene-Hollomon参数的双曲正弦模型,建立了纯钼板高温塑性流变应力与变形温度和应变速率之间的本构方程。依据本构方程计算出的纯钼板坯流变应力理论值与实际值的平均相对误差仅为3.68%,表明该本构方程可为纯钼热成形加工工艺的制定提供理论依据。

关键词:纯钼板坯;热模拟;流变应力;本构方程

中图分类号:TG146.4 文献标志码:A

Pyroplastic deformation behavior of

pure molybdenum plate slab and constitutive equation

YANG Song-tao1, LI Ji-wen1, WEI Shi-zhong1, 2, XU Liu-jie1, 2, ZHANG Guo-shang1, ZHANG Er-zhao3

(1. College of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471003, China;

2. Henan Engineering Research Center for Wear of Material,

Henan University of Science and Technology, Luoyang 471003, China;

3. Luoyang Hi-tech Molybdenum and Tungsten Material Company, Luoyang 471000, China)

Abstract: The pyroplastic deformation behavior of pure molybdenum slabs was studied on the Gleeble-1500 thermal-mechanical simulator at 1 100-1 350 ℃ with the rate of deformation 0.01-5 s-1 and the deformation of 60%. The results indicate that the rheological stress is decreased with increasing the temperature, and increased with increasing the rate of deformation. The difference between rheological stresses at different deformation temperatures is decreased with increasing the strain rate. At the same strain rate, the peak stress is moved from high strain to low strain with increasing temperature. The constitutive equation including rheological stress, strain rate and temperature was established by hyperbolic sine model with Zene-Hollomon parameter. Using this equation, the average relative error between the theoretical value and actual value is only 3.68%. The constitutive equation can provide theoretical basis for formulating hot-forming processing of molybdenum sheet.

Key words: pure molybdenum slab; thermal simulation; rheological stress; constitutive equation

我国是钼资源大国,但不是钼产业强国,作为高端产品的钼板、钼棒、钼丝、钼异型件等在钼制品结构中比例偏低。钼及钼合金变形抗力大,变形温度高且高温下氧化严重、低温脆性、温降快等一系列加工特性,使钼的深加工技术落后,产品发展缓慢[1-3]。随着等离子液晶显示器、加热炉等行业的迅速发展,国内外对大单重、超宽、超长的钼合金板材需求越来越紧迫,对钼板材制品的要求向超重、超宽、超长、超薄的方向发展。目前,国内能够加工制作的钼及钼合金板材宽度限制在600 mm以下,单件质量仅为几十千克;国外则只有奥地利普兰西金属加工公司等少数几家钼深加工企业能生产大单重的钼合金宽板[4-5]。要获得高品质的加工板材,需要高品质的坯料作为保障。虽然我国钼板坯的生产与研究取得了一定的成果,但与世界先进水平相比差距仍然很大,急需技术的进步与提升。研究钼的高温塑性变形行为,不仅可以较准确地描述变形温度、变形程度以及变形速率等工艺参数对其流变应力的影响规律,而且可以为制定合理的产品加工工艺提供可靠的理论依据。

目前,国内外关于镁合金、铝合金以及钛合金在高温下塑性变形行为的研究很多,而对于钼及其钼合金的高温塑变行为研究则相对较少。对粉末冶金纯钼板坯流变应力行为和应力应变本构方程的研究则更少。本文作者在Gleeble-1500热模拟机上,采用矩形试样研究高温压缩下粉末冶金纯钼板坯的热加工流变应力行为,并建立流变应力本构方程,以期为粉末冶金纯钼板坯热加工工艺的制定提供理论依据。

1 实验

本实验所用试样来源于洛阳高科钼钨材料有限公司,通过混料→冷等静压成形→高温烧结得到粉末冶金纯钼板坯,其尺寸为450 mm×320 mm×72 mm,单件质量达100 kg,钼含量(质量分数)99.95%。板坯的原始显微组织如图1(a)所示。由图1(a)可以看出,晶粒呈等轴状,且晶界平直,但晶粒大小不均匀。为了保证板材平面变形的条件,根据热模拟机对矩形试样的要求,在板坯上取10 mm×15 mm×25 mm的矩形试样,采用Gleeble-1500热模拟机,在真空状态下进行高温压缩实验。主要实验参数如下:变形温度为1 100、1 150、1 200、1 250和1 350 ℃;变形速率为0.01、0.1、1和5 s-1;变形程度为60%;加热速度为20 ℃/s,达到温度点后保温3 min。压头采用纯钨合金,试样和压头之间用石墨做润滑剂。实验装置示意图如图1(b)所示。

2 结果与分析

2.1 真应力—真应变曲线及机理分析

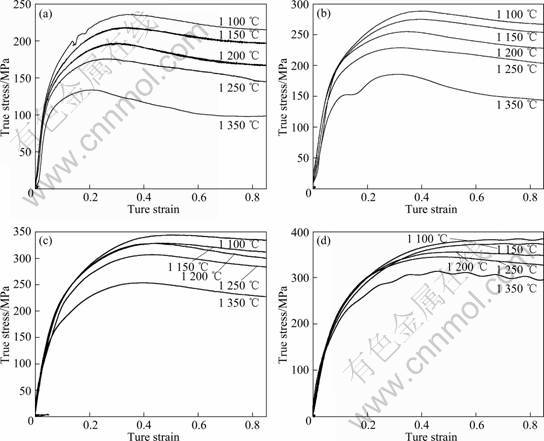

图2所示为纯钼板坯在不同变形温度和不同变形速率下的真应力—应变曲线。由图2可以看出,在给定的实验工艺参数下,粉末冶金烧结态纯钼板坯的真应力—真应变的总体变化规律如下:在应变不大的情况下(ε<0.2),流变应力随应变的增大而迅速上升,在某一对应应变处达到峰值,继而随着应变的增大趋于稳定状态。分析认为流变应力的这种变化规律主要取决于两方面的作用:一方面,变形过程中位错增值及位错间的相互作用导致加工硬化的产生;另一方面,位错通过攀移或交滑移发生了合并重组,使材料产生动态软化,两方面的作用在热变形过程中同时存在并彼此竞争[6-7]。在变形的初始阶段,位错密度随应变的进行不断增大,出现大量的位错缠结,使位错运动的阻力增大,导致加工硬化的产生。当变形进行到一定程度时,由于在加工硬化过程中,材料的能量升高而处于不稳定状态,这为位错的运动提供驱动力,发生动态回复和动态再结晶,使材料软化,抵消热压时的加工硬化,表现为流变应力的降低。

图1 纯钼板坯的显微组织及热模拟试验示意图

Fig.1 Microstructure of pure molybdenum slab (a) and sketch of thermal simulation experiment (b)

图2 纯钼板在不同变形条件下的真应力—应变曲线

Fig.2 True stress—strain curves for pure molybdenum sheet under different deformation conditions: (a)  =0.01 s-1; (b)

=0.01 s-1; (b)  =0.1 s-1; (c)

=0.1 s-1; (c)  =1 s-1; (d)

=1 s-1; (d)  =5 s-1

=5 s-1

流变应力随变形温度的变化规律如下:在变形速率一定的条件下,同一应变时纯钼板坯的流变应力随温度的升高而降低。主要原因是随着温度的升高,原子的动能增大,原子间临界切应力减弱,热激活能降低,有利于塑性变形的进行[8-9]。此外,动态回复和再结晶引起的软化程度也随温度的升高而增大,导致合金应力水平降低。应变速率的增加有利于增加单位时间内的变形量和位错数目,使位错攀移和位错反应等引起的软化速率相对降低。因此,当变形温度相同时,流变应力随应变速率的增加而增加。另外,从图2中还可以看出,在变形温度一定的条件下,流变应力随应变速率的增大而增大,应变速率越高,流变应力之间的差值逐渐减小;同一应变速率下,峰值应力随变形温度的升高向应变小的方向推移。

2.2 本构方程的建立

从纯钼板坯的真应力—应变曲线中可以看出,高温塑性变形条件下,流变应力与变形温度和变形速率之间有着紧密的关系。其关系式可由包括变形激活能、应变速率和变形温度的双曲正弦模型公式(1)来表 达[10]。

(1)

(1)

式中:F(σ)为应力函数。应力函数F(σ)在不同的应力水平时有相应的表达形式如下:

在低应力条件下,

(ασ<0.8) (2)

(ασ<0.8) (2)

在高应力条件下,

(ασ>1.2) (3)

(ασ>1.2) (3)

对于所有应力,

(4)

(4)

式中: 为真应变速率;Q为变形激活能;R为摩尔气体常数,其值为8.314 J/(mol·K);T为热力学温度;σ为峰值应力或稳定流变应力;

为真应变速率;Q为变形激活能;R为摩尔气体常数,其值为8.314 J/(mol·K);T为热力学温度;σ为峰值应力或稳定流变应力; ;n为应力指数,A为常数。

;n为应力指数,A为常数。

对于一定温度的塑性变形,在低、高应力条件下,将式(2)和(3)分别代入式(1),可得到:

(5)

(5)

(6)

(6)

式中:A1和A2为常数。

对式(5)和(6)分别取对数得:

(7)

(7)

(8)

(8)

式中: n1和β分别为ln σ—ln 和σ—ln

和σ—ln 曲线的斜率。

曲线的斜率。

利用式(7)和(8),结合图2所得到的真应力-真应变曲线数据,通过线性回归处理,可得到如图3所示不同温度下的lnσ—ln 和σ—ln

和σ—ln 的关系曲线。 取图3(a)中5条直线斜率的倒数求平均值,得n1= 10.288 8,同时取图3(b)中直线斜率的倒数并求平均值,得β=0.038 7。此时对应α1=β/n1=0.003 8。对所有应力状态下,将式(4)代入式(1)可得:

的关系曲线。 取图3(a)中5条直线斜率的倒数求平均值,得n1= 10.288 8,同时取图3(b)中直线斜率的倒数并求平均值,得β=0.038 7。此时对应α1=β/n1=0.003 8。对所有应力状态下,将式(4)代入式(1)可得:

(9)

(9)

材料在高温塑性变形时应变速率受热激活过程控制,应变速率与温度之间的关系可用Zene-Hollomon参数Z来表示[11]:

(10)

(10)

将式(10)代入式(1)可得:

(11)

(11)

根据式(9)可将σ表达为Z的函数:

(12)

(12)

分别对式(9)、(10)和(11)两边取对数得:

(13)

(13)

(14)

(14)

(15)

(15)

在一定的应变速率下,通过式(13)对1/T求偏导数可得:

(16)

(16)

图3 不同温度下峰值应力σ与应变速率 的关系

的关系

Fig.3 Relationships between peak stress (σ) and strain rate ( ) at different temperatures: (a) ln σ—ln

) at different temperatures: (a) ln σ—ln ; (b) σ—ln

; (b) σ—ln

由式(13)可知,在一定的温度下,对于所有应力条件下的应力指数,n为曲线ln[sinh(ασ)]—ln 的斜率。由式(16)知,当Q与T无关时,

的斜率。由式(16)知,当Q与T无关时, 与1/T呈线性关系,其斜率用B表示。取峰值应力和对应温度值,采用最小二乘法线性回归处理,绘制出当α1=0.003 8 MPa-1时的

与1/T呈线性关系,其斜率用B表示。取峰值应力和对应温度值,采用最小二乘法线性回归处理,绘制出当α1=0.003 8 MPa-1时的 —

— 和

和 —

— 的曲线图,分别如图4和5所示。对图4中各直线斜率的倒数求平均值得应力指数n=7.717 5,对图5各直线的斜率求平均值得 B=4.402 5×103。将所计算得数值代入式(16),求得应变激活能Q=282.478 9 kJ/mol。

的曲线图,分别如图4和5所示。对图4中各直线斜率的倒数求平均值得应力指数n=7.717 5,对图5各直线的斜率求平均值得 B=4.402 5×103。将所计算得数值代入式(16),求得应变激活能Q=282.478 9 kJ/mol。

由式(15)可知,ln A为直线 —

— 的截距,取相应的参数值代入式(14)中可得到ln Z的值,然后再取相应的ln Z和

的截距,取相应的参数值代入式(14)中可得到ln Z的值,然后再取相应的ln Z和 ,通过最小二乘法线性拟合,可得

,通过最小二乘法线性拟合,可得 —

— 的关系曲线,如图6所示。

的关系曲线,如图6所示。

由图6可知,ln A=20.243 91,所以 A=6.191 82×108。将所得的参数代入式(9)中可得粉末冶金纯钼析在高温塑性变形的流变应力本构方程为

图4 不同变形温度下 与ln

与ln 的关系

的关系

Fig.4 Relationship between ln[sinh(ασ)] and ln at different deformation temperatures

at different deformation temperatures

图5 不同变形速率下 与温度的关系

与温度的关系

Fig.5 Relationship between ln[sinh(ασ)] and temperature at different strain rates

图6 ln Z和 之间的关系

之间的关系

Fig.6 Relationship between flow stress and Zene-Hollomon parameter

(17)

(17)

由式(12)可知,本构方程还可以用带有Zene-Hollomon参数Z来表示:

(18)

(18)

2.3 理论值与实际值的误差分析

为了验证粉末冶金钼板坯的流变应力方程的正确性,将试验得到的真实应力、应变速率和应变温度值代入式(10)和(18)中,可得到应力峰值的理论值以及试验值和理论值的相对误差,如表1 所列。

表1 理论峰值应力与试验值的比较

Table 1 Comparisons of theoretical and experimental results of peak stress

通过表1可以看出,由流变应力本构方程式(18)得出的理论值与实验值相差不大,除了变形温度为 1 350 ℃、应变速率为0.01 s-1时的相对误差为12.53%外,其他试验参数下的相对误差均在8%以下。对相对误差的绝对值求平均值,得到平均相对误差为3.68%。由此可知,用含有Zene-Hollomon参数的双曲正弦函数计算得到的本构方程可以用来描述粉末冶金纯钼板坯的高温塑性变形行为,可以作为该材料在热加工成形中的理论依据。

3 结论

1) 粉末冶金纯钼高温压缩变形时流变应力随变形温度的升高而减小,随应变速率的增大而增大;随着应变速率的增加,流变应力之间的差值逐渐减小;同一应变速率下,峰值应力随变形温度的升高向应变小的方向推移。

2) 得到了纯钼高温塑性变形流变应力与变形温度及应变速率之间的本构关系方程;算得平均热激活能Q=282.478 9 kJ/mol。

3) 运用推导出的流变应力本构方程得到峰值应力的预测值与实验值较吻合,最大相对误差为12.53%,平均相对误差仅为3.68%。故此本构方程可为纯钼热成形加工工艺的制定提供理论依据。

REFERENCES

[1] 许洁瑜, 杨晓明. 2008年中国钼工业发展报告[J]. 中国钼业, 2009, 33(2): 11-18.

XU Jie-yu, YANG Xiao-ming. Report of China molybdenum industry development in 2008[J]. China Molybdenum Industry, 2009, 33(2): 11-18.

[2] 程景峰, 余 莉, 许洁瑜. 中国钼金属制品发展现状分析[J]. 中国钼业, 2009, 33(4): 16-20.

CHENG Jing-feng, YU Li, XU Jie-yu. Analysis on the present situation of China molybdenum metal products [J]. China Molybdenum Industry, 2009, 33(4): 16-20.

[3] 付静波, 赵宝华. 国内外钼工业发展现状[J]. 稀有金属, 2007, 31(S1): 151-154.

FU Jing-bo, ZHAO Bao-hua. Present states of development of molybdenum industry at home and abroad[J]. Chinese Journal of Rare Metal, 2007, 31(S1): 151-154.

[4] 许洁瑜, 程景峰. 2008年上半年我国钼产品进出口分析[J]. 稀有金属快报, 2008, 27(9): 20-23.

XU Jie-yu, CHENG Jing-feng. Import and export of molybdenum products in China in first half of 2008[J]. Rare Metals Letter, 2008, 27(9): 20-23.

[5] 李大成, 杨刘晓, 孙院军, 朱 琦. 钼金属深加工产品现状及技术应用分析[J]. 中国钼业, 2008, 32(1): 8-13.

LI Da-cheng, YANG Liu-xiao, SUN Yuan-jun, ZHU Qi. The present condition and technical application analysis of downstream processing for molybdenum products[J]. China Molybdenum Industry, 2008, 32(1): 8-13.

[6] 王宏伟, 易丹青, 王 斌, 蔡金伶, 钱 峰, 陈缇萦. Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd 镁合金的高温塑性变形行为的热压缩模拟[J]. 中国有色金属学报, 2010, 20(3): 378-384.

WANG Hong-wei, YI Dan-qing, WANG Bin, CAI Jin-ling, QIAN Feng, CHEN Ti-ying. Hot compressive deformation simulation of Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd magnesium alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 378-384.

[7] 王 斌, 易丹青, 顾 威, 方西亚, 刘会群, 吴春萍, 王宏伟. Mg-5.3Zn-0.8Zr 镁合金高温变形行为的热模拟研究[J]. 中南大学学报: 自然科学版, 2009, 40(1): 123-128.

WANG Bin, YI Dan-qing, GU Wei, FANG Xi-ya, LIU Hui-qun, WU Chun-ping, WANG Hong-wei. Thermal simulation of hot deformation behavior for Mg-5.3Zn-0.8Zr magnesium alloy[J]. Journal of Central South University: Science and Technology, 2009, 40(1): 123-128.

[8] 李庆波, 叶 凡, 周海涛, 钟建伟, 赵伸恺, 王孟君. Mg-9Y-3Zn-0.5Zr合金的热变形行为[J]. 中国有色金属学报, 2008, 18(6): 1012-1019.

LI Qing-bo, YE Fan, ZHOU Hai-tao, ZHONG Jian-wei, ZHAO Zhong-kai, WANG Meng-Jun. Hot deformation behavior of Mg-9Y-3Zn-0.5Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 1012-1019.

[9] 李慧中, 李 洲, 刘 咏, 张 伟, 王海军. TiAl基合金的高温塑性变形行为[J]. 中国有色金属学报, 2010, 20(1): 79-85.

LI Hui-zhong, LI Zhou, LIU Yong, ZHANG Wei, WANG Hai-jun. Plastic deformation behavior of TiAl based alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 79-85.

[10] SELLARS C M, McTEGRT W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[11] SOHEIL S. Analysis of flow stress up to the peak at hot deformation[J]. Materials and Design, 2009, 30(8): 3036–3040.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50972039)

收稿日期:2010-12-30;修订日期:2011-03-10

通信作者:李继文,副教授,博士;电话:0379-64276880;E-mail: ljwzq@163.com