文章编号:1004-0609(2008)09-1645-06

微量Cr对93W-Ni-Fe合金组织及力学性能的影响

刘文胜,唐 芳,马运柱,黄伯云

(中南大学 粉末冶金国家重点实验室,长沙 410083)

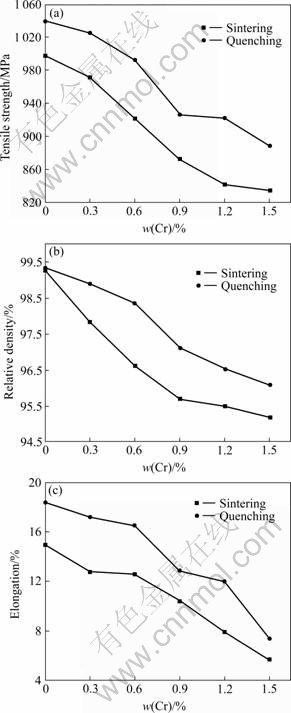

摘 要:研究了Cr元素对93W-4.9Ni-2.1Fe高密度合金性能和微观结构的影响,并探讨固溶淬火工艺对添加微量Cr的93W-Ni-Fe合金微观结构及力学性能的影响。实验采用光学金相、扫描电镜和能谱等对烧结态、固溶淬火态样品的组织形貌进行表征,采用准静态拉伸实验对合金的拉伸强度和伸长率进行测试,采用阿基米德排水法对合金的相对密度进行测试。结果表明:随着Cr含量(质量分数)由0增加到1.5%,烧结态93W-Ni-Fe合金的拉伸强度、相对密度、伸长率分别由997.2 MPa、99.27%和14.94%降至834.7 MPa、95.21%和5.69%。随着Cr含量由0增加到1.5%,固溶淬火态93W合金的拉伸强度、相对密度、伸长率分别由1 039 MPa、99.33%和18.37%降至888.5 MPa、96.10%和7.39%;Cr元素与W、Ni、Fe、O等元素在93W-Ni-Fe合金中生成富Cr固溶体,并在合金界面上形成偏聚,降低93W-Ni-Fe合金界面的结合强度,导致合金的力学性能降低。

关键词:93W-Ni-Fe合金;固溶淬火;力学性能

中图分类号:TF 125.2; TG 146.4 文献标识码:A

Effect of minor Cr additions on microstructure and

mechanical properties of 93W-Ni-Fe alloys

LIU Wen-sheng, TANG Fang, MA Yun-zhu, HUANG Bai-yun

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The effects of solid solution quenching and element chromium additions on the properties and microstructure of 93W-4.9Ni-2.1Fe alloy were investigated deeply. Optics microsccopy(OM), scanning electricity microsccopy(SEM) and EDAX energy spectrum were used to study the microstructure and compositions of the alloys, respectively. The strength and elongation of alloys were tested with quasi-static tensile testing machine, and the relative densities of the alloys were measured by Archimedes method. The results indicate that when the Cr content (mass fraction) increases from 0 to 1.5%, the tensile strength, relative density and elongation of 93W-Ni-Fe alloy reduce from 997.2 MPa, 99.27% and 14.94% to 834.7 MPa, 95.21% and 5.69%, respectively. Meanwhile, with the Cr content increases from 0 to 1.5%, the tensile strength, relative density and elongation of solid solution quenching 93W-Ni-Fe alloy reduce from 1 039 MPa, 99.33% and 18.37% to 888.5 MPa, 96.10% and 7.39%, respectively. Elements Cr, W, Ni, Fe and O form Cr-rich solid solutions and gather along the interfaces of the alloys, which result in reducing the mechanical properties of 93W-Ni-Fe alloys.

Key words: 93W-Ni-Fe alloy; solid solution quenching; mechanical properties

钨基高密度合金是以W为基体(W含量为85%~98%),加入少量的Ni、Cu、Fe、Cr、Co、Mo等元素组成的合金体系,这类合金具有一系列优异的物理力学性能:如高强度、延性好、韧性好、热膨胀系数小、抗腐蚀和抗氧化性强,因而在国防军工领域得到应用[1?2]。随着主战坦克装甲防护材料的不断发展,动能穿甲弹的长径比、初速度必须增加才能满足新型穿甲的要求[3?4]。长径比和初速度的增加,使得穿甲弹弹体承受的应力相应提高,对制造新型穿甲弹的钨合金材料的综合性能提出更高的要求。因此,如何改善穿甲弹弹芯用钨合金材料的强韧性能仍然是研究的热门课题[5?12]。目前关于在钨合金中添加Cr元素的研究报道较少。本文作者探讨Cr元素和固溶淬火工艺对93W-4.9Ni-2.1Fe合金微观结构和性能的影响。

1 实验

将还原W粉、还原Ni粉、羰基Fe粉按照质量比93?4.9?2.1进行混合,加入酒精作球磨介质,然后放入QM-1SP4型行星式球磨机中进行球磨,球磨筒为不锈钢,研磨球采用钨球(TB),球磨的工艺参数选择球料比为10?1,转速为200 r/min,固液比为1?1,球磨时间为50 h。为了研究Cr元素对93W-Ni-Fe合金微观结构和性能的影响,在球磨工艺中,往93W-Ni-Fe混合粉末中再添加粒度为5~8 ?m、纯度为99.5%的Cr元素进行球磨,Cr含量(质量分数)分别为0、0.3%、0.6%、0.9%和1.2%、1.5%。所制备的预合金粉末分散均匀,其BET粒度为0.30 μm。

本实验采用优化后的氢气气氛烧结条件:温度 1 490 ℃、时间90 min;烧结样的密度采用阿基米德排水法测定;烧结样在LJ-3000A型机械式拉力实验机上测量其拉伸强度(σ)和伸长率(δ),测量时应变速率为2 mm/min。采用JSM?6360LV型扫描电镜观察拉伸断口的形貌特征,电镜加速电压为20 kV,分辨率为3.0 nm,并采用EDAX能谱分析系统对合金成分进行分析;试样在自动抛光机上研磨抛光后,在MeF3A型金相显微镜上进行显微组织观察。

为了改善烧结样品的力学性能,将样品在真空条件下于1 280 ℃时保温2 h,然后水淬使样品快速冷却。

2 结果与讨论

2.1 微量Cr对93W-4.9Ni-2.1Fe合金力学性能的 影响

图1所示为烧结样品拉伸强度、相对密度和伸长率随Cr含量的变化曲线。

图1 93W-4.9Ni-2.1Fe合金力学性能随Cr含量的变化曲线

Fig.1 Changing curves of mechanical properties with Cr content for 93W-4.9Ni-2.1Fe alloys: (a) Tensile strength; (b) Relative density; (c) Elongation

从图1(a)可以看出,样品的拉伸强度随Cr含量增加而逐渐减小,烧结态合金的拉伸强度从0%Cr时的997.2 MPa下降到1.5%Cr时的834.7 MPa;而经固溶淬火的合金拉伸强度具有相似的规律,从0%Cr的 1 039 MPa降到1.5%Cr时的888.5 MPa。由图1(b)可知,随着Cr含量的增加,样品的相对密度急剧下降,但是当Cr含量大于0.9%时样品的密度变化趋于平缓。图1(c)所示为样品伸长率随Cr含量的变化曲线,由图可知,随着Cr含量的增加,样品的伸长率总体是呈减小趋势的。这是因为添加Cr元素后,Cr元素在合金界面形成偏聚,改变了合金的微观组织。

从图1也可以看出,对于相同含量的Cr元素,经固溶淬火后,钨合金的拉伸强度、相对密度、伸长率均有所提高。这说明固溶淬火处理可有效改善合金的力学性能。

2.2 微量Cr对烧结态93W-4.9Ni-2.1Fe合金微观组织的影响

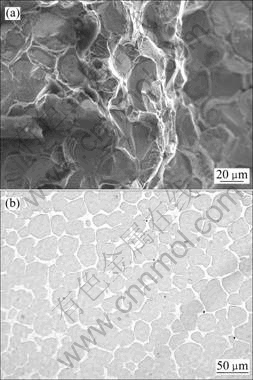

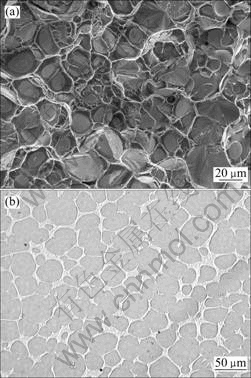

图2所示为未添加Cr元素烧结样品的拉伸断口扫描图和金相显微组织图。

图2 不含Cr元素烧结样品的断口形貌及微观组织

Fig.2 Factural morphology(a) and microstructure(b) of 93W- 4.9Ni-2.1Fe alloys sintered without Cr

图2(a)所示为不含Cr元素烧结样品的拉伸断口形貌。由图可知,试样呈钨颗粒的穿晶解理断裂和粘结相的延性撕裂,粘结相很好的包裹着钨晶粒,样品具有较好的强韧性。图2(b)所示为未添加Cr元素样品金相组织图。从图中可以看出,不含Cr元素的93W-Ni-Fe合金中钨晶粒分布均匀,且基本上呈球形或近球形。粘结相呈网状分布,W-W接触较少,且大小较均匀。

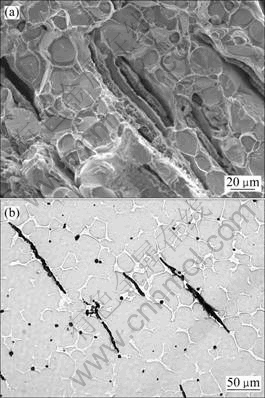

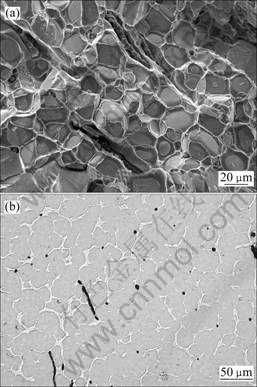

图3所示为 Cr含量为0.9%的烧结样品断口形貌及金相组织。由图3(a)可看出,当样品中Cr含量为0.9%时,样品呈W-W断裂和少量的穿晶解理断裂,合金中Cr元素出现明显的偏聚,并由此形成条状。这也是图1中样品的性能在Cr含量为0.9%时剧降的原因。由图3(b)可以看出,Cr元素的偏聚很严重,基本上将粘结相与钨颗粒的联结隔开,而且偏聚的分布也极不规则。钨颗粒球化的比例下降,且大小不均匀。这说明添加Cr元素后Cr原子形成偏聚会降低钨原子的扩散,减小了钨颗粒在粘结相中的溶解-析出进程,一定程度上抑制了钨颗粒的长大[13?14]。

图3 含 0.9% Cr烧结样品断口形貌及微观组织

Fig.3 Factural morphology(a) and microstructure(b) of 93W- 4.9Ni-2.1Fe alloys sintered with 0.9%Cr

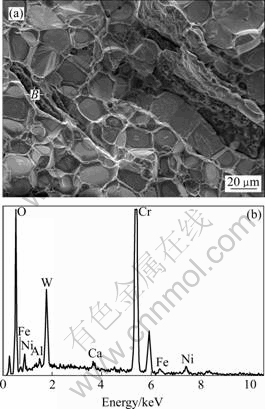

图4所示为Cr含量为0.9%烧结样品拉伸断口的中间相EDAX谱(A点),经测算中间相中Cr为57.03%,O为27.56%,因此,引起合金内部偏聚的主要元素是Cr与O,条状是由于Cr元素的偏聚造成的,且Cr、O元素与W等元素生成中间相,Cr元素的偏聚会使粘结相与钨颗粒之间出现明显的断裂,很大程度地降低了合金的力学性能。

图4 Cr含量为0.9%的烧结样品断口形貌及中间相的能谱图

Fig.4 Fractural morphology(a) and EDAX spectrum(b) of middle phase in fracture plane of 93W-4.9Ni-2.1Fe alloys sintered with 0.9%Cr

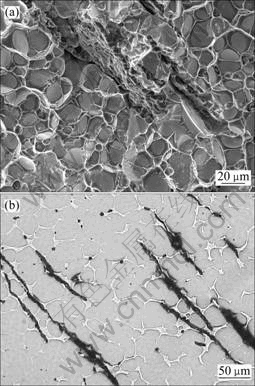

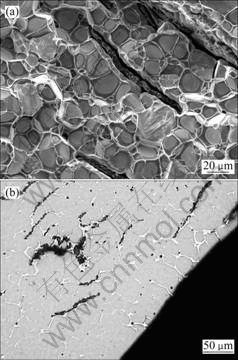

图5所示为Cr含量为1.5%的烧结样品拉伸断口形貌及金相组织图。由图可知,随Cr含量的增加,中间相的生成和聚集更明显,合金基本上为W-W和少量的W-M断裂。

图5 含1.5%Cr的烧结样品拉伸断口形貌及微观组织

Fig.5 Fractural morphology(a) and microstructure(b) of 93W- 4.9Ni-2.1Fe alloys sintered with 1.5%Cr

2.3 微量Cr对固溶淬火态93W-4.9Ni-2.1Fe合金微观组织的影响

图6(a)所示为不含Cr元素经固溶淬火样品拉伸断口扫描。由图可知,粘结相分布很均匀,合金断口的断裂是穿晶解理断裂和粘结相延性撕裂,样品具有较高强韧性。

图6 不含Cr元素经固溶淬火样品拉伸断口形貌及微观组织

Fig.6 Fractural morphology(a) and microstructure(b) of 93W- 4.9Ni-2.1Fe alloys quenched without Cr additions

图6(b)所示为不含Cr元素的合金固溶淬火样品的金相组织。与图2(b)比较可以看出,经固溶淬火处理的合金钨颗粒和粘结相分布更加均匀,钨晶粒多数呈球形或近球形,粘结相呈网状均匀分布。由此可见,固溶淬火能很明显地改善合金的组织结构,其力学性能也有所改善。

图7所示为含0.9%Cr经固溶淬火处理样品的拉伸断口形貌及金相组织。从图7(a)可以看出,合金断裂机理是W-W断裂和穿晶解理断裂,粘结相分布也较均匀,形成很多韧窝,不过有很明显的Cr元素偏聚形成的条状,图7(b)与图3(b)的明显区别就是Cr元素偏聚形成的深槽周围粘结相分布较均匀,且聚集相对较少。

图7 含0.9%Cr经固溶淬火处理样品拉伸断口形貌及微观组织

Fig.7 Factural morphology(a) and microstructure(b) of 93W- 4.9Ni-2.1Fe alloys quenched with 0.9%Cr

图8所示为含0.9%Cr经固溶淬火样品拉伸断口中间相的EDAX能谱图(B点),经测算中间相中Cr为46.21%,O为26.04%。与烧结态能谱(图4)对比可以看出,图4中的Cr含量与O含量都比图8中的要高,因为在真空热处理过程中,部分O以易挥发性氧化物的形式析出,Cr在淬火过程中固溶度增加,即粘结相中Cr含量增加,Cr偏聚量相对降低。

图8 含0.9%Cr经固溶淬火处理样品的拉伸断口形貌及中间相EDAX谱

Fig.8 Fractural morphology(a) and EDAX spectrum(b) of middle phase in fracture plane of 93W-4.9Ni-2.1Fe alloys quenched with 0.9%Cr

这说明固溶淬火能使Cr原子扩散均匀,更好的渗透到粘结相中,可一定程度上改善样品的力学性能。

图9所示为含1.5%Cr经固溶淬火处理样品拉伸断口形貌及金相组织图。从图9(a)可看出,随着Cr含量的增加,偏聚现象加剧,断裂深槽处虽有粘结相但是能看到很明显的间隙。对比图9与图5可看出,固溶淬火可以在一定程度上改善合金显微组织。这是因为固溶淬火能加大合金中W原子与Cr原子的扩散能力,相对减少Cr的聚集,粘结相中Cr含量的增加将阻止粘结相周围的W原子的相互扩散,降低了W晶粒在粘结相中的溶解?析出进程。当Cr含量过多时,Cr与W、Ni、Fe、O等元素形成中间相,一方面阻止了W晶粒的溶解与析出,导致W晶粒的形状呈多边形[15];另一方面致使粘结相与W晶粒分布不均匀,W-W联结度较高,导致合金出现脆性断裂的机会增加。

图9 1.5%Cr经固溶淬火处理样品的断口形貌及微观组织

Fig.9 Factural morphology(a) and microstructure(b) of 93W-4.9Ni-2.1Fe alloys quenched with 1.5%Cr

3 结论

1) 未添加Cr元素的烧结态93W-4.9Ni-2.1Fe合金的相对密度为99.27%,伸长率为14.94%,拉伸强度为997.2 MPa。未添加Cr元素的固溶淬火态93W-4.9Ni-2.1Fe合金的相对密度为99.33%,伸长率为18.37%,拉伸强度为1 039 MPa。固溶淬火能有效提高93W-4.9Ni-2.1Fe合金的伸长率、拉伸强度和相对密度。

2) 在Cr添加量为0~1.5%,随Cr含量从0增加到1.5%,烧结态93W-Ni-Fe合金的拉伸强度、相对密度、伸长率分别由997.2 MPa,99.27%,14.94%降至834.7 MPa,95.21%,5.69%。Cr含量由0增加到1.5%,固溶淬火态93W-Ni-Fe合金拉伸强度、相对密度、伸长率分别由1 039 MPa、99.33%、18.37%降至888.5 MPa、96.10%、7.39%。随着Cr含量的增加,93W-Ni-Fe合金的拉伸强度、相对密度、伸长率均减小。

3) 添加Cr元素后,Cr在样品中形成偏聚,降低了W合金界面的结合强度,导致合金力学性能下降。

REFERENCES

[1] UPADHYAYA A, TIWARI S K, MISHRA P. Microwave sintering of W-Ni-Fe alloy[J]. Scripta Materialia, 2007, 56(1): 5?8.

[2] 张朝晖, 王富耻, 李树奎. 静液挤压钨合金的显微组织与力学性能[J]. 中国有色金属学报, 2001, 11(S1): 88?91.

ZHANG Zhao-hui, WANG Fu-chi, LI Shu-kui. Microstructure and properties of tungsten alloy deformed by hydrostatic extrusion[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S1): 88?91.

[3] 齐志望, 攀存山, 侯福青, 史洪刚. 大变形锻造钨合金显微组织特征研究[J]. 兵器材料科学与工程, 1999, 22(4): 18-23.

QI Zhi-wang, PAN Cun-shan, HOU Fu-qing, SHI Hong-gang. Microstructure characteristic of tungsten heavy alloys by large swaged deformation[J]. Ordnance material science and engineering, 1999, 22(4): 18?23.

[4] SUNWOO A, GROVES S, GOTO D, HOPKINS H. Effect of matrix alloy and cold swaging on micro-tensile properties of tungsten heavy alloys[J]. Materials Letters, 2006, 60(3): 321?325.

[5] LEE K H, CHA S I, RYU H J, HONG S H. Effect of oxide dispersoids addition on mechanical properties of tungsten heavy alloy fabricated by mechanical alloying process[J]. Mater Sci Eng A, 2007, 452/453(1): 55?60.

[6] RYU H J, HONG S H. Fabrication and properties of mechanically alloyed oxide-dispersed tungsten heavy alloys[J]. Mater Sci Eng A, 2003, 363(1/2): 179?184.

[7] 马运柱, 黄伯云, 刘文胜, 汪登龙. 稀土Y对纳米粉90W-Ni-Fe合金性能和微观结构的影响[J]. 稀有金属材料与工程, 2005, 34(11): 1708?1712.

MA Yun-zhu, HUANG Bai-yun, LIU Wen-sheng, WANG Deng-long. Effect of rare earth Y on properties and microstructure of nano-powder 90W-7Ni-3Fe alloy[J]. Rare Metal Materials and Engineering, 2005, 34(11): 1708?1712.

[8] 马运柱, 黄伯云, 范景莲, 熊 翔, 汪登龙. 纳米级90W-7Ni-3Fe 复合粉末的低温烧结机制[J]. 稀有金属材料与工程, 2005, 34(10): 1661?1665.

MA Yun-zhu, HUANG Bai-yun, FAN Jing-lian, XIONG Xiang, WANG Deng-long. Low-temperature sintering mechanism of nanometer 90W-7Ni-3Fe composite powder[J]. Rare Metal Materials and Engineering, 2005, 34(10): 1661?1665.

[9] GERMAN R M, SHEN J W, CAMPBELL L G, SURI P. Liquid-phase-sintered tungsten heavy alloys: development of microstructure during densification[J]. Int J Powder Metall, 2005, 41(2): 37?45.

[10] GERMAN R M, OLEVSKY E. Strength predictions for bulk structures fabricated from nanoscale tungsten powders[J]. Int J of Refractory Metals and Hard Materials, 2005, 23(1): 77?84.

[11] RYU H J, HONG S H, BAEK W H. Microstructure and mechanical properties of mechanically alloyed and solid-state sintered tungsten heavy alloys[J]. Mater Sci Eng A, 2000, 291(1/2): 91?96

[12] BOLLINA R, GERMAN R M. Heating rate effects on microstructural properties of liquid phase sintered tungsten heavy alloys[J]. International Journal of Refractory Metals & Hard Materials, 2004, 22 (2): 117?127.

[13] FORTUNA E, SIKORSKI K, KURZYDLOWSKI K J. Experimental studies of oxygen and carbon segregation at the interfacial boundaries of a 90W-7Ni-3Fe tungsten heavy alloy[J]. Materials Characterization, 2004, 52(4/5): 323?329.

[14] 马运柱, 黄伯云, 范景莲, 熊 翔, 汪登龙. 镧和钇对氢气还原(W, Ni, Fe)复合氧化物粉末的影响[J]. 中国有色金属学报, 2004, 14(9): 1551?1556.

MA Yun-zhu, HUANG Bai-yun, FAN Jing-lian, XIONG Xiang, WANG Deng-long. Effect of La and Y on H2-reduction of (W, Ni, Fe) composite oxide powder[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1551?1556.

[15] SUN J. Strength for decohesion of spherical tungsten particle-matrix interface[J]. International Journal of Fracture, 1990, 44(1): 51?56.

基金项目:国家自然科学基金资助项目(50774098);国防基础科研资助项目(ZNDX2008194);中国博士后科学基金资助项目(20060390261)

收稿日期:2007-12-15;修订日期:2008-05-30

通讯作者:马运柱,博士,副教授;电话:0731-8877825;E-mail: zhuzipm@mail.csu.edu.cn

(编辑 龙怀中)